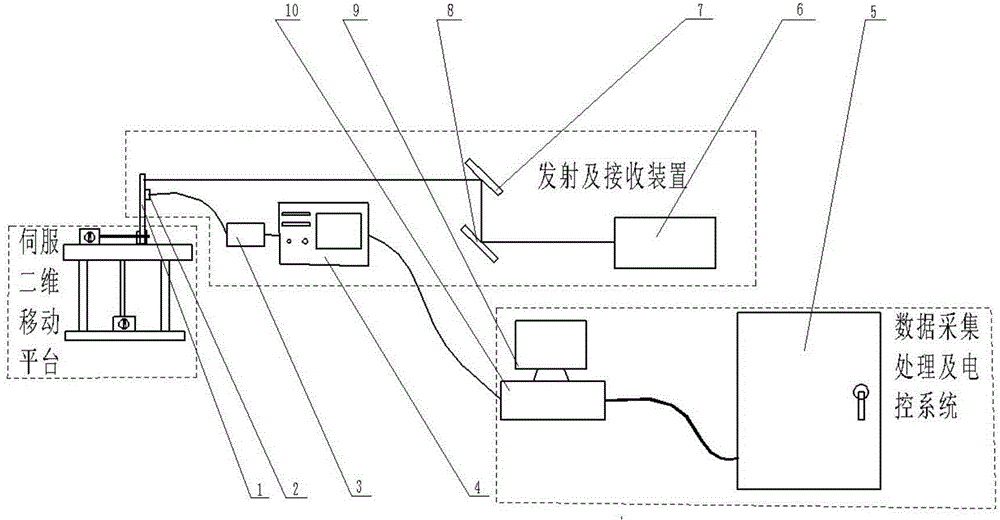

Device and method for measuring internal stress of plastic sheet products on basis of ultrasonic lamb waves

A plastic thin plate and internal stress technology, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of non-destructive and rapid quantitative measurement, and achieve the effects of avoiding errors, avoiding acoustic elastic coefficient, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] The Lamb wave amplitude attenuation of the sample was measured with the above-mentioned Lamb wave method polymer thin plate internal stress measuring device.

[0066] 1) Injection molding a number of plastic sheets to be tested and a number of standard tensile splines, and annealing the standard splines to remove stress as stress-free standard splines;

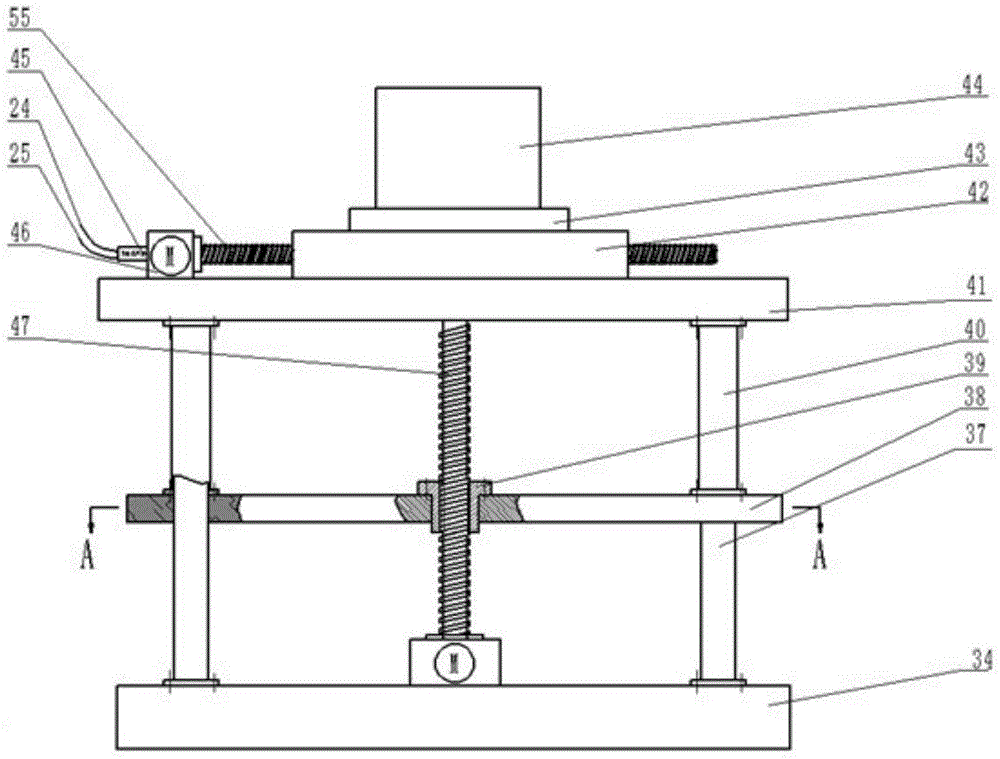

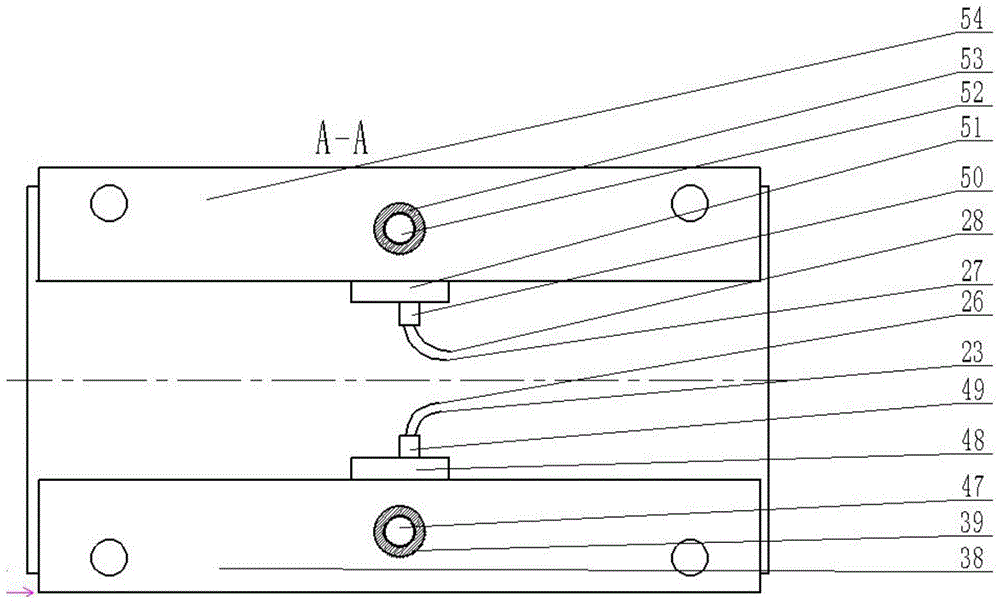

[0067] 2) Apply tensile stress and compressive stress to the unstressed standard spline through the tensile and compressive stress calibration device, and at the same time use the Lamb wave transmitting and receiving device to measure the Lamb wave voltage signal amplitude of the standard spline per unit length under different stress values, In this way, the functional relationship between the amplitude of the Lamb wave voltage signal and the stress of the test piece is found, and this functional relationship is used as a calibration benchmark.

[0068] 3) Carry out grid division to the tested piece, take the unit lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com