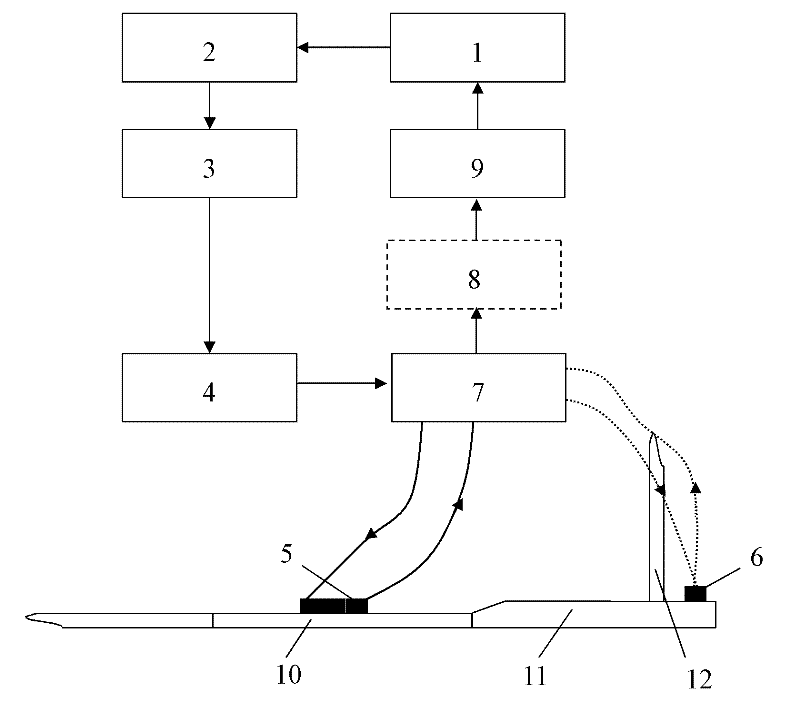

System and method for detecting corrosion of storage tank base plate based on ultrasonic Lamb wave

A technology for tank bottom and corrosion detection, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of low detection efficiency and insufficient detection practicability, and achieve the effect of low environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

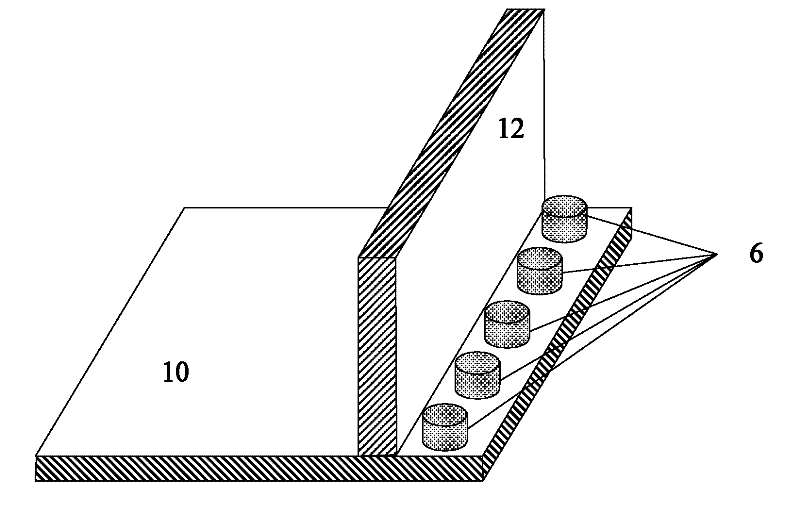

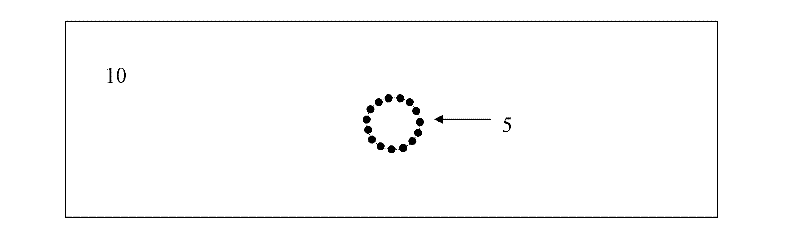

[0034] Take a 10*10 4 The detection of floating roof oil tank is taken as an example to illustrate.

[0035] The size of the edge plate of this kind of oil tank is: 21×2000×6350mm 3 , the plate is 12MnNiVR, and the size of the medium plate is: 11×2800×13800mm 3 , the plate is Q235-B.

[0036] Draw the dispersion curve of the edge plate and the frequency range of the middle amplitude less than 1MHz. The Lamb wave with low frequency (within 1MHz) and zero-order symmetrical mode (S0 mode) is selected for detection. Compared with Lamb waves in other modes and frequency ranges, its advantages are as follows: firstly, the S0 mode Lamb wave in this frequency range has a small dispersion degree, which makes the positioning accuracy higher; secondly, the S0 mode in this range The in-plane displacement of the state wave structure is almost evenly distributed along the thickness of the steel plate, so that the detection of corrosion defects on the entire plate thickness maintains a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com