Ultrasonic Lamb wave-based butt weld nondestructive testing method

A technology of butt weld and non-destructive testing, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and process detection response signals, etc. It can solve the problems of low detection energy, short detection distance, attenuation, etc. Distance detection problem, slow decay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

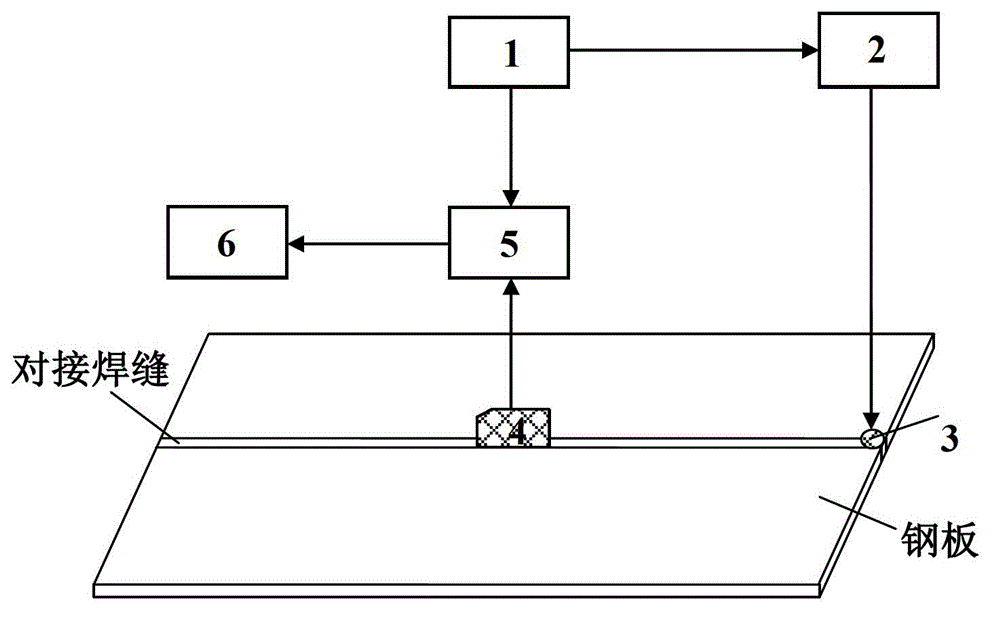

[0058] The system includes a function generator 1, a power amplifier 2, a piezoelectric sheet 3, an oblique-incidence piezoelectric ultrasonic sensor 4, an oscilloscope 5, and a computer 6. The two piezoelectric sheets 3 are symmetrically attached to the upper and lower surfaces of the welding plate and placed on the At the end of the weld seam, the oblique incidence piezoelectric ultrasonic sensor 4 is installed on the welding plate, the output end of the function generator 1 is connected to the input end of the power amplifier 2, and the output end of the power amplifier 2 is connected to the piezoelectric sheet 3, and the oblique incidence The piezoelectric ultrasonic sensor 4 is connected with the oscilloscope 5, and the computer 6 is connected with the oscilloscope 5.

[0059] Concrete implementation steps of the present invention include:

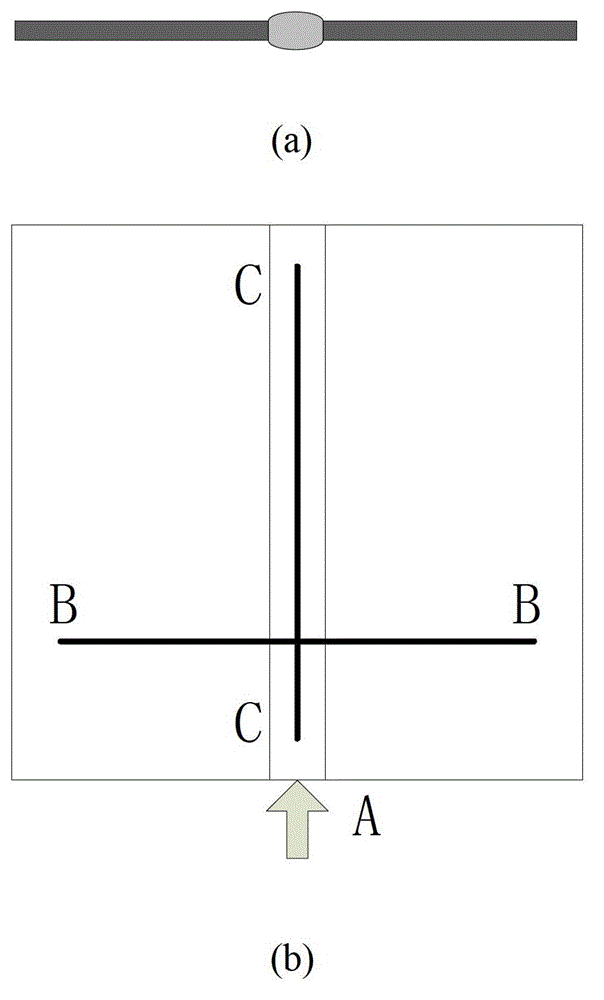

[0060] Step 1): The welding plate to be tested is welded together by two 500×1000×3mm steel plates by butt welding to form a 1000×10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com