Ray tracing type ultrasonic Lamb wave defect tomographic imaging method

A technology of ray tracing and imaging methods, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and analysis of materials, etc. It can solve the problem that the specific size and contour cannot be estimated very accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

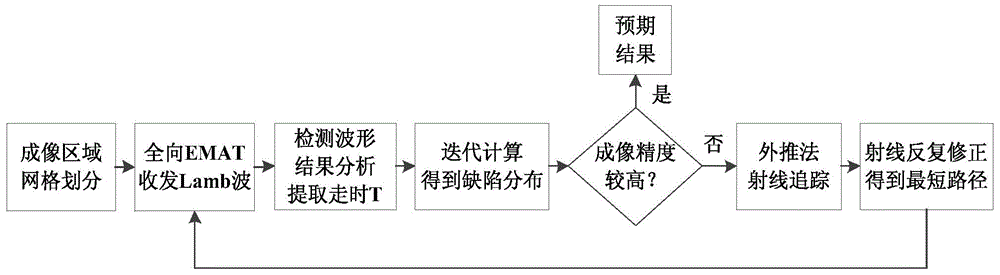

[0033] The essence of the method proposed by the present invention is to establish a brand-new ray tracing (Ray Tracing, RT) iterative algorithm model, and combine it with the TOF cross-hole tomography technology. Alternately, iteratively solves the problem, and corrects the ray paths in the positive problem to obtain a more realistic defect distribution. Below in conjunction with embodiment, the present invention is further described:

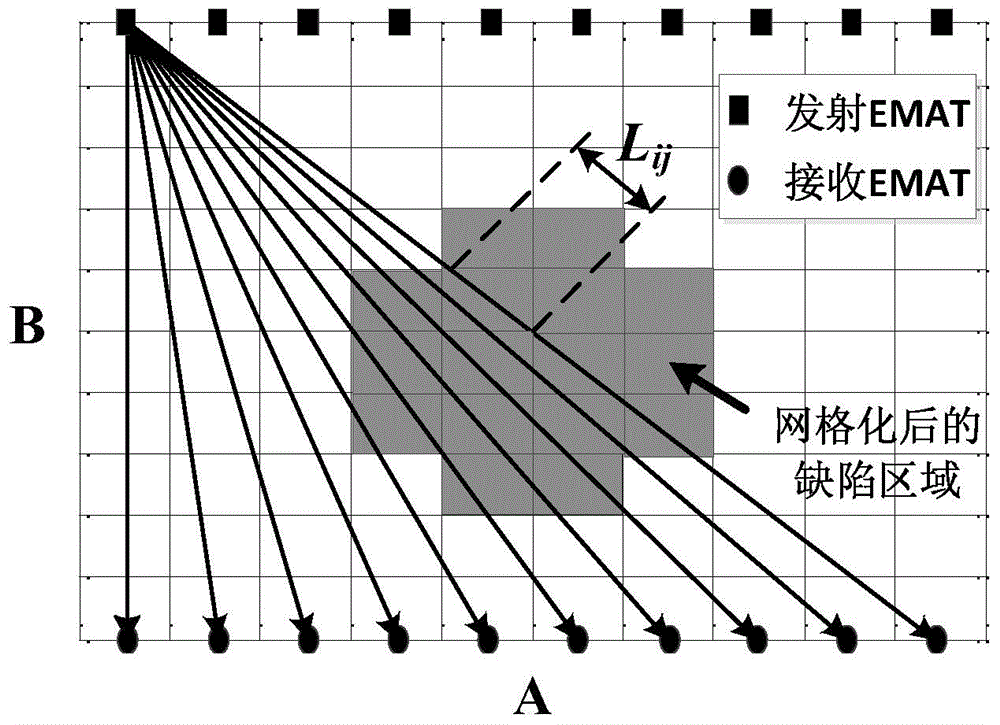

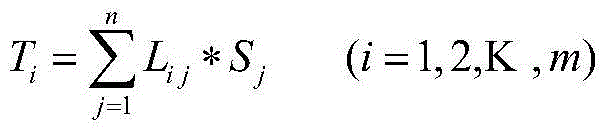

[0034] Step 1: Take the aluminum plate to be tested with a thickness of 1-5mm, and select a rectangular area with an area of A×B on the upper surface as the imaging area for the experiment, where A and B are positive real numbers, and both are greater than 30mm. A standard artificial corrosion pit defect with a diameter greater than or equal to 30 mm and a depth of 1-5 mm is processed in the area. The imaging area is then divided into N 1 ×N 2 small grids (i.e. N 1 ×N 2 pixels). M transmitting EMATs (electromagnetic acoustic transducer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com