Impeller machining cutter-axis vector control method based on five-axis interference-free cutter axis control line

A tool axis vector and control method technology, applied in metal processing, manufacturing tools, automatic control devices, etc., can solve the problems of poor impeller quality, achieve uniform and slow rotation, simple method, and avoid global interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

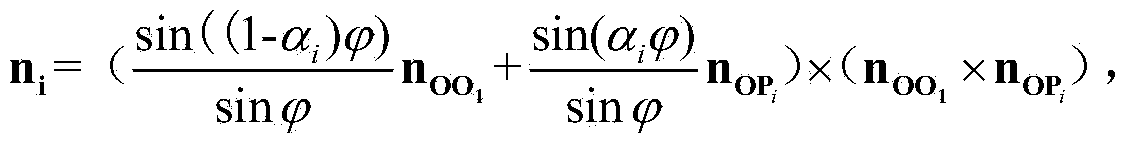

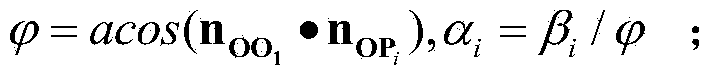

[0027] refer to Figure 1-6 . The specific steps of the impeller machining tool axis vector control method based on the five-axis non-interfering tool axis control line of the present invention are as follows:

[0028] Taking the semi-finishing of the blade back profile of an aeroengine impeller as an example, without loss of generality, the specific implementation steps of the present invention are described.

[0029] Generate tool axis selection boundaries. The blade back profile and the blade basin on the opposite side of the passage are offset by 4.8mm to the passage side, and the inner hub is offset by 4.4mm to the passage side. The semi-finishing is processed by a ball nose cutter with a radius of 4mm, the finishing allowance of the blade surface (blade pot surface, blade back) is 0.8mm, and the finishing allowance of the inner hub is 0.4mm.

[0030] Determine the projected surface where the tool axis control line is located. Offset the outer hub face outward by 52.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com