Three-dimensional ellipse vibration auxiliary cutting micro-texture morphology modeling method

A technology of elliptical vibration and modeling methods, applied in 3D modeling, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

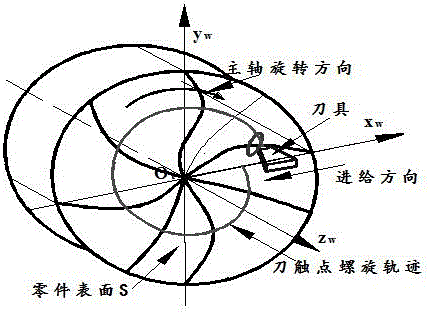

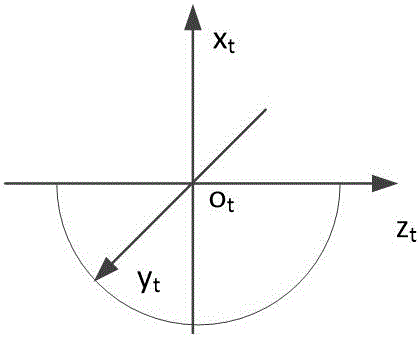

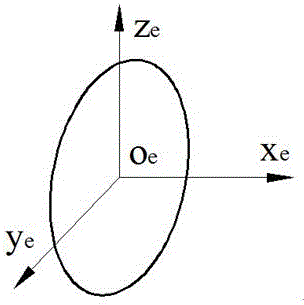

[0076] The following is attached Figures 1 to 5 , the technical solution of the present invention will be described in detail.

[0077] A three-dimensional elliptical vibration-assisted cutting micro-texture morphology modeling method, the method includes: establishing a workpiece coordinate system, a tool coordinate system and a local coordinate system for three-dimensional elliptical vibration-assisted cutting, In the local coordinate system of cutting, according to the processing parameters and elliptic vibration parameters, the arc curve equation of the tool tip and the three-dimensional elliptic vibration expression are established; in the workpiece coordinate system, the workpiece parameters and machine parameters are set, and the workpiece is processed In the process of surface S, first calculate the tool position point P of the surface S of the general turning part t trajectory, the general turning tool position P t On the basis of the trajectory, apply the tool pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com