Digital control system machining code general generation method and device

A technology for processing codes and numerical control systems, applied in digital control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

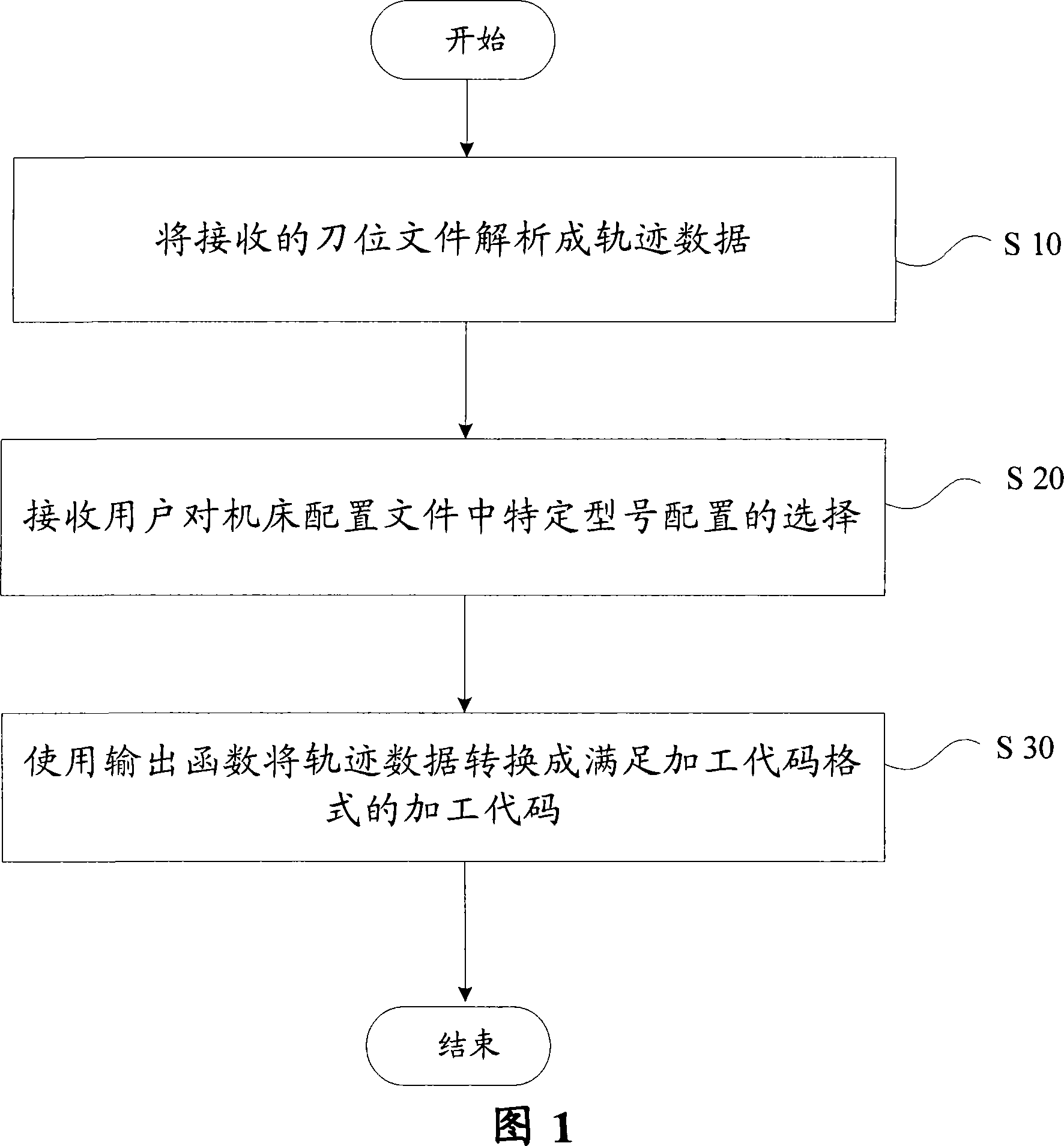

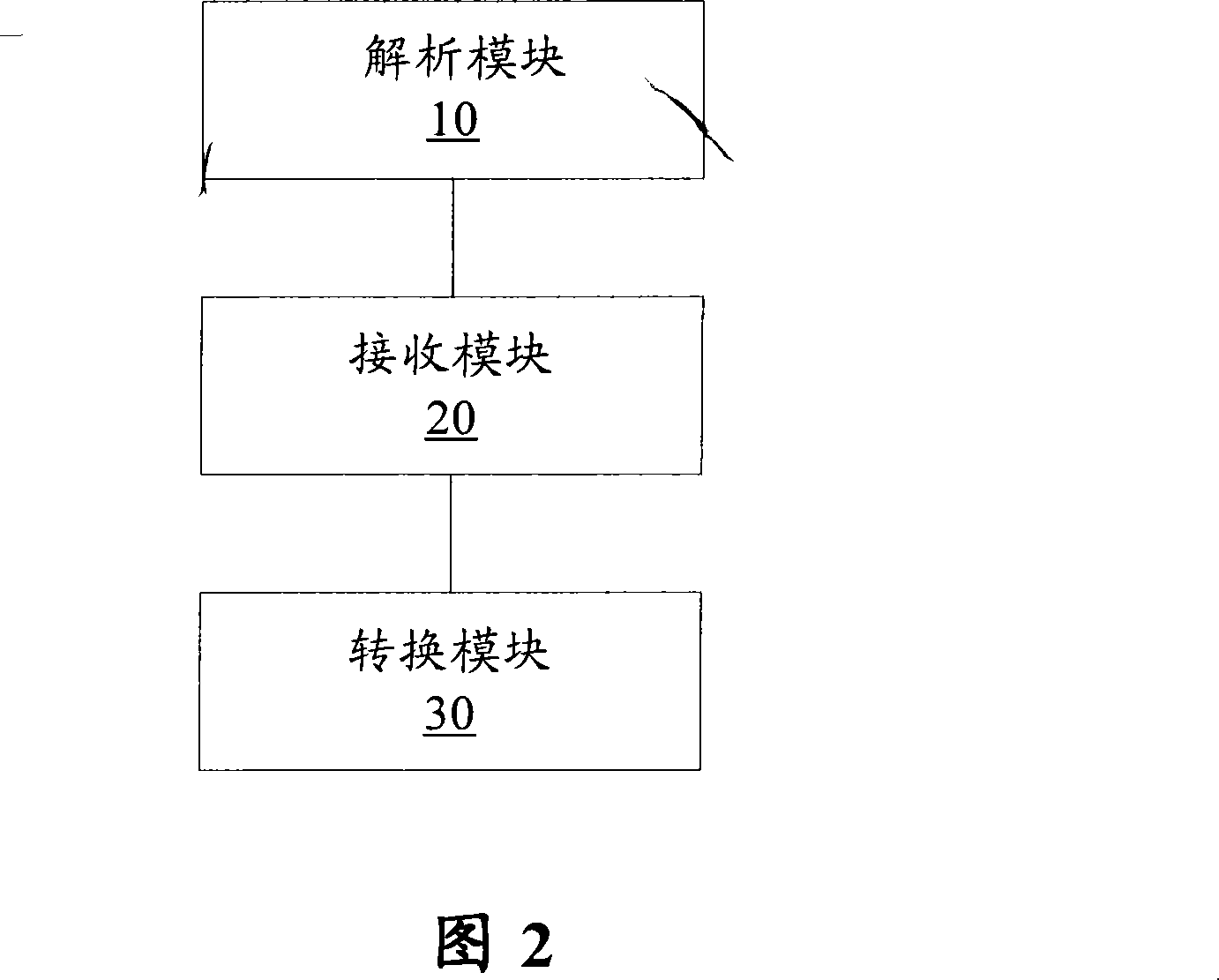

[0015] Fig. 1 shows the flowchart of the general generating method according to the embodiment of the present invention, comprises the following steps:

[0016] Step S10, parsing the received tool location file into trajectory data;

[0017] Step S20, receiving the user's selection of a specific model configuration in the machine tool configuration file, wherein the specific model configuration includes an output function related to the processing code format of a specific model of CNC machine tool; and

[0018] Step S30, using the output function to convert the trajectory data into a processing code that meets the processing code format.

[0019] Since the machine tool configuration file is established in this method, the user can choose to output the machining code of the corresponding model machine tool by selecting a specific mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com