Five-axis machine tool measuring method based on AxiSet

A measurement method and machine tool technology, applied in the field of numerical control, can solve the problems of high price and no error compensation, and achieve the effects of improving machining accuracy, improving measurement speed and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

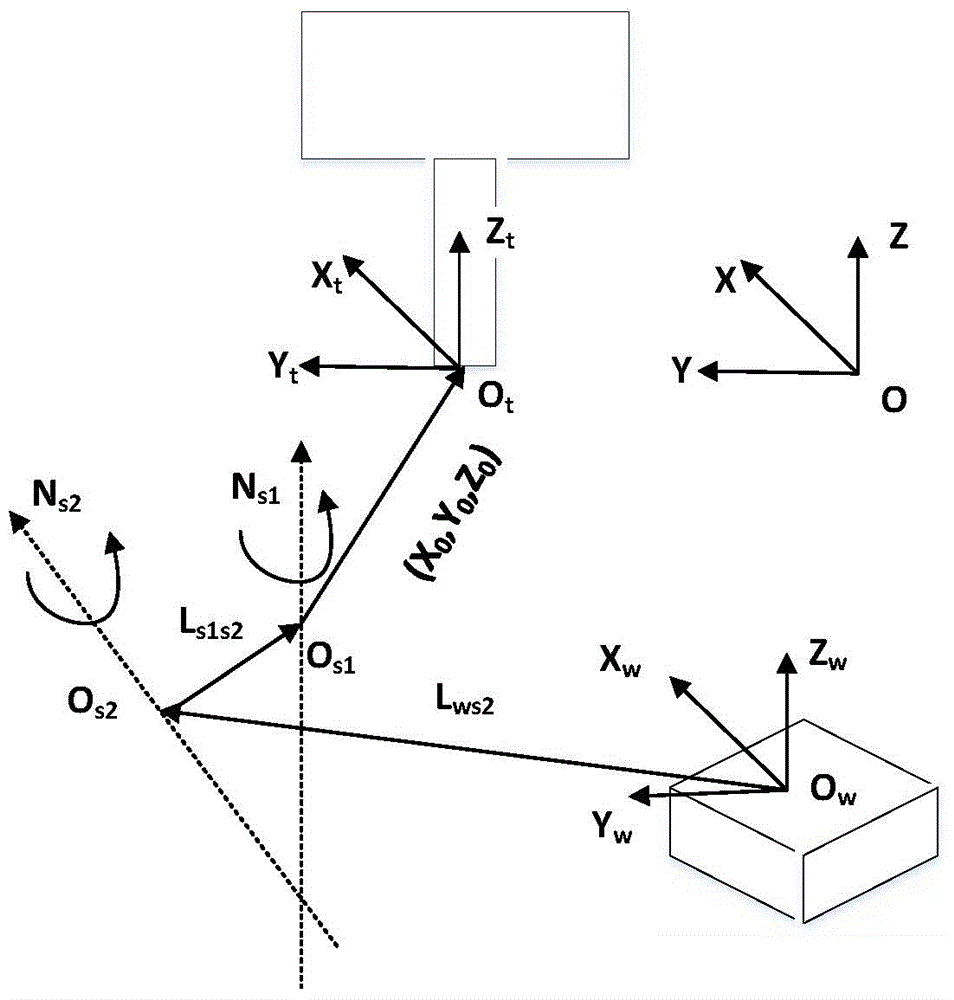

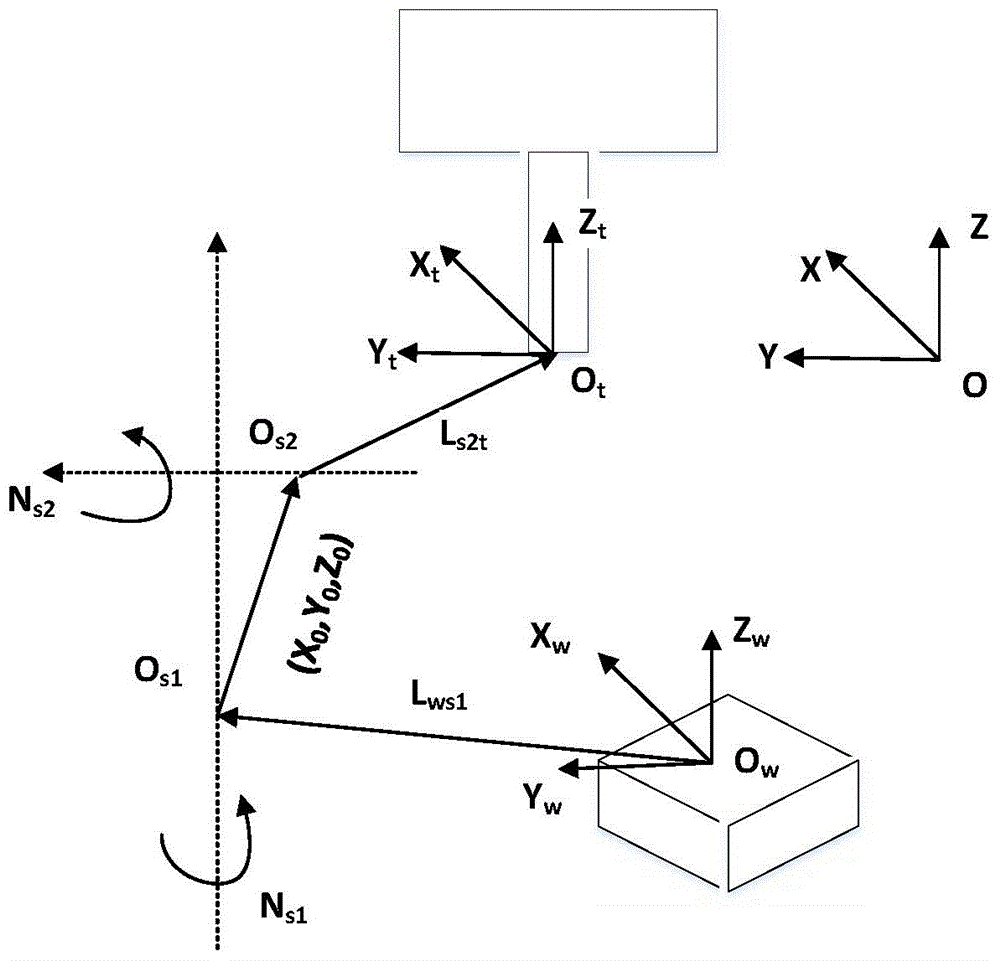

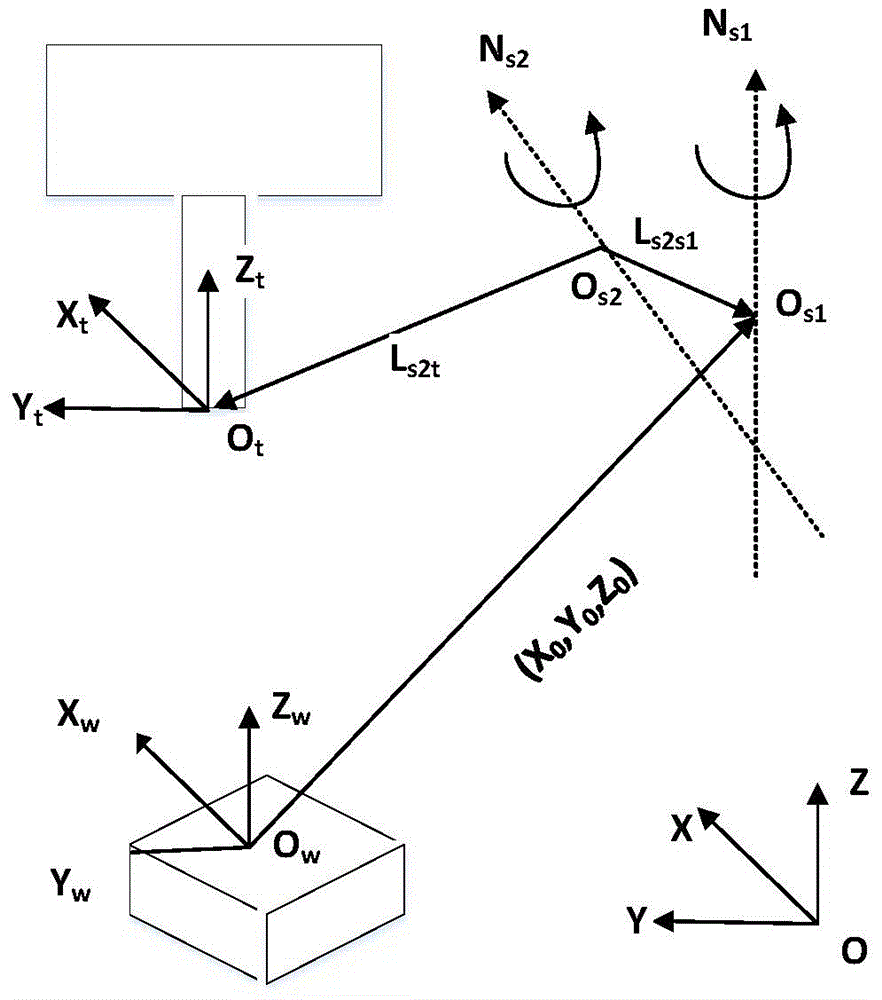

[0019] A measurement method for five-axis machine tools based on AxiSet. The main process includes: establishing the kinematics model and error model of the five-axis machine tool, and determining the four structural errors of the five-axis machine tool, that is, the axial error of the two rotating axes and the relationship between the two The position offset error from the tool coordinate system related to the rotary axis to the rotary axis; determine the measurement scheme: set AxiSet TM The Check-up component is installed on the CNC machine tool, and the center of the standard ball is calibrated by the trigger probe; according to the machine tool error model, the four structural errors of the five-axis machine tool are calculated; the calculated four structural errors are substituted into the kinematics model In the process, the kinematics model is corrected to realize the error compensation of the five-axis machine tool.

[0020] The present invention will be further descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com