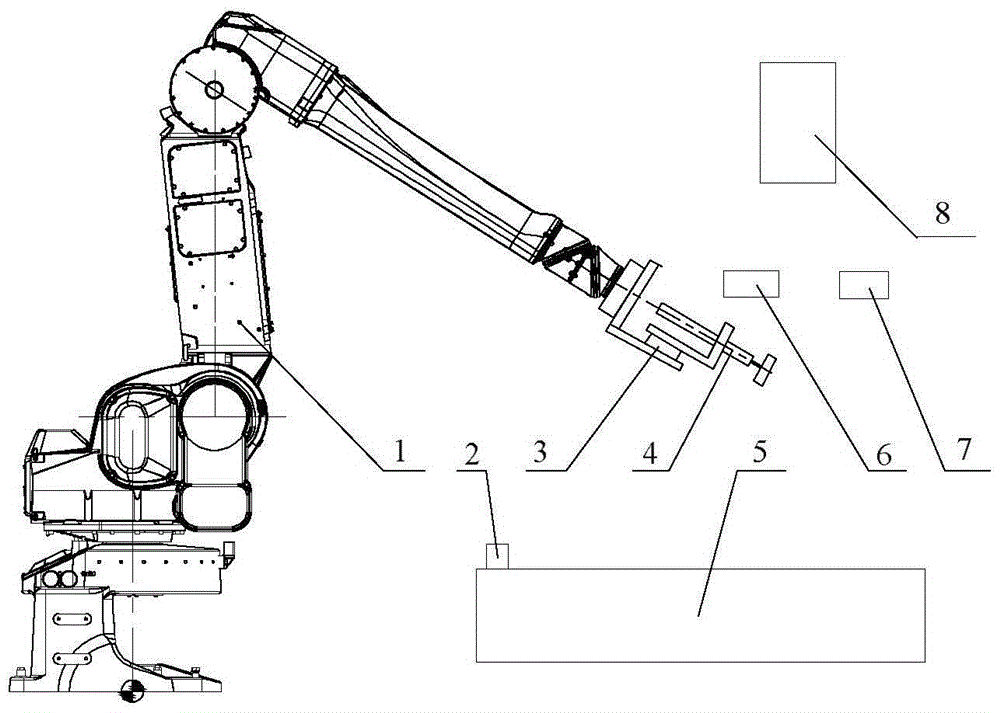

Automatic lapping and polishing system for complex surface of compliant control-based robot and machining method

A complex curved surface and compliant control technology, applied in the direction of digital control, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, difficulty in meeting low cost, unstable processing quality, etc., to facilitate heat dissipation and chip removal, reduce Processing cost, effect of achieving controllability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

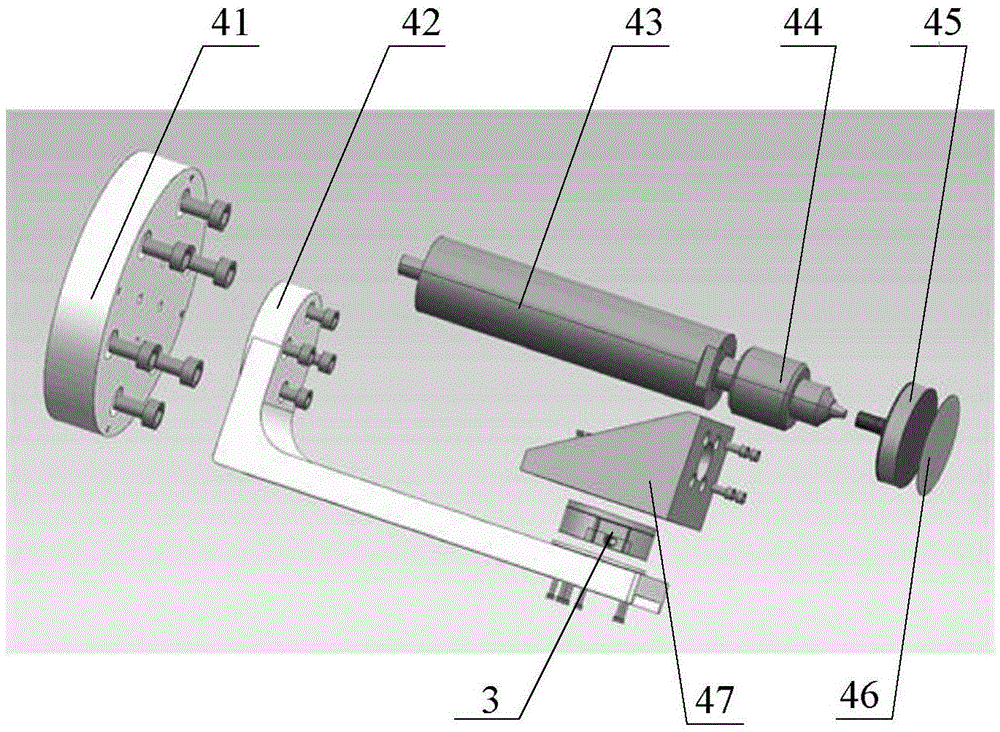

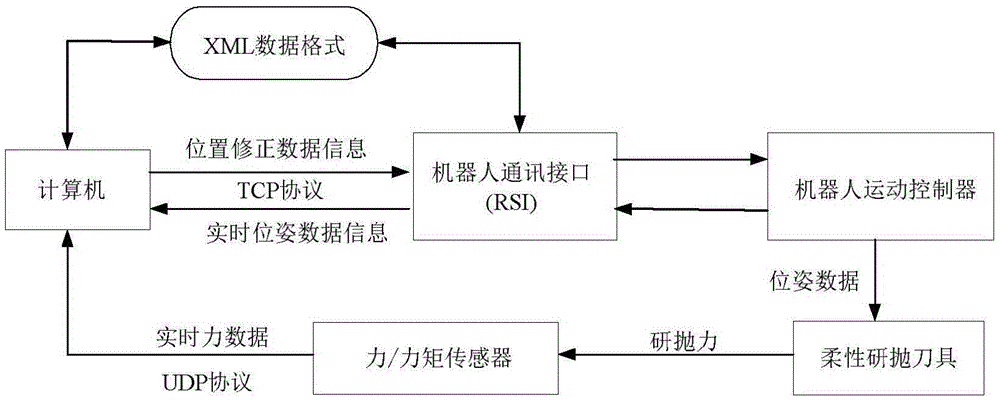

[0053] The invention is an automatic grinding and polishing system device and processing method of a complex curved surface of a robot based on compliance control, which is used to realize constant grinding and polishing force processing in the automatic grinding and polishing process of complex curved surfaces, and ensure the uniformity and stability of processing and removal. The invention mainly includes the composition of a complete set of system devices and active and passive control methods based on soft processing. The compensation calculation of the gravity of the polishing tool is carried out to eliminate the interference of the gravity of the polishing tool on the polishing force; the description of the contact form and state of the polishing tool and the workpiece during processing is carried out to ensure full contact and chip removal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com