Ball-end cutter multi-axis machining cutter axis vector optimization method

A tool axis vector, multi-axis machining technology, applied in electrical program control, digital control and other directions, can solve the problems of impact, reduce surface machining quality and machining efficiency, tool axis vector fluctuation and mutation, etc., to avoid severe fluctuations, improve Machining efficiency and machining quality, smooth and smooth movement of machine axes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Embodiment: The method for generating the tool path for processing the inlet and outlet edges of blades is taken as an example below to further describe the method in detail.

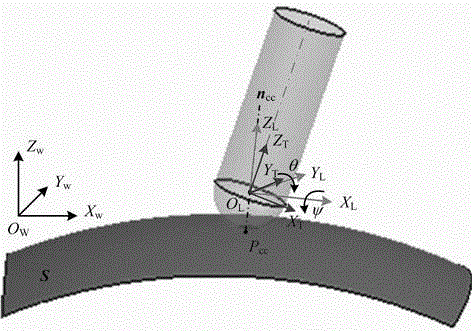

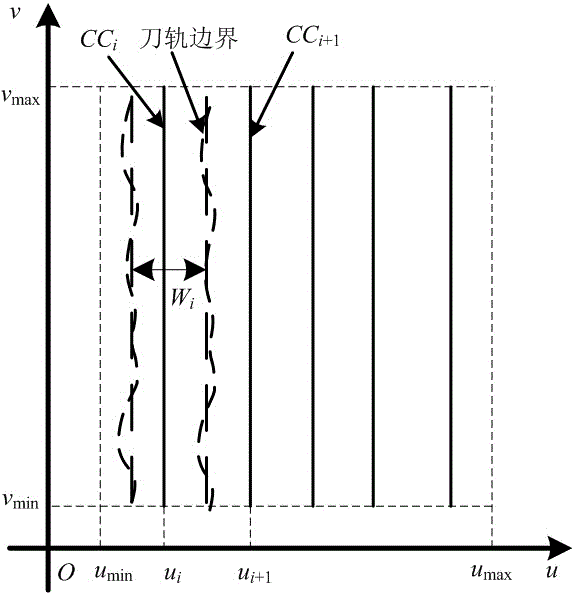

[0057] By analyzing a given workpiece surface S : r ( u , v )( , ) to determine the cutting direction of the tool, and describe the arrangement of the tool contact track on the surface of the workpiece in the parameter field, such as Figure 4 shown. set tool edge v The tool moves in the direction of the parameter, and the processing range of the surface in the parameter domain is , u min with u max respectively represent the left and right boundaries of surface processing, v min with v max respectively represent the front and rear boundaries of surface processing; CC i on the surface i strip knife contact track, W i for the first i Toolpath S i The average row width of . suppose h For a given programming tolerance, It is the processing line width coefficient. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com