Five-axis side milling machining cutter path smoothing method

A tool path and milling technology, which is applied in the field of computer graphics and five-axis CNC side milling, can solve the problems of no description or report, no data collected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

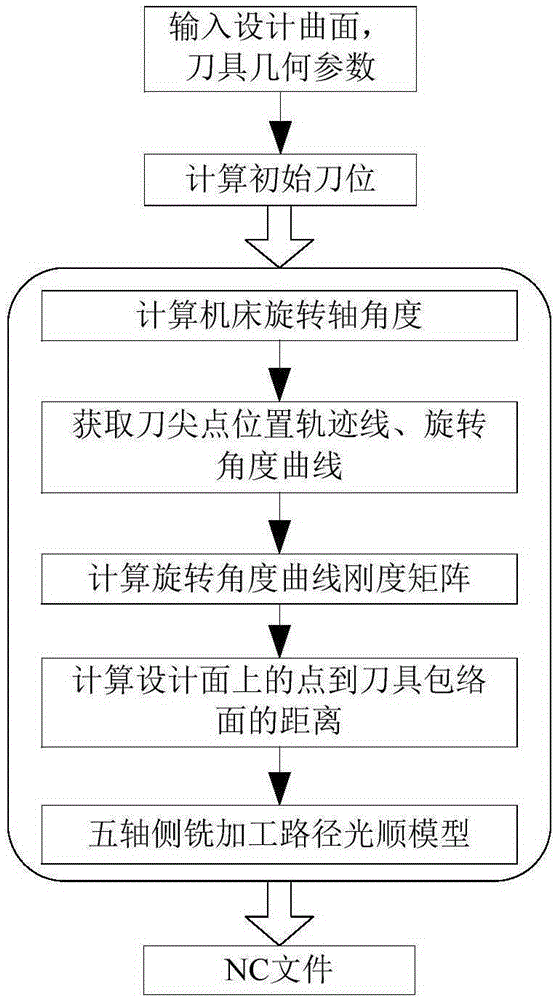

[0061] This embodiment provides a tool path smoothing method for five-axis side milling, which will be described in detail below with reference to the accompanying drawings.

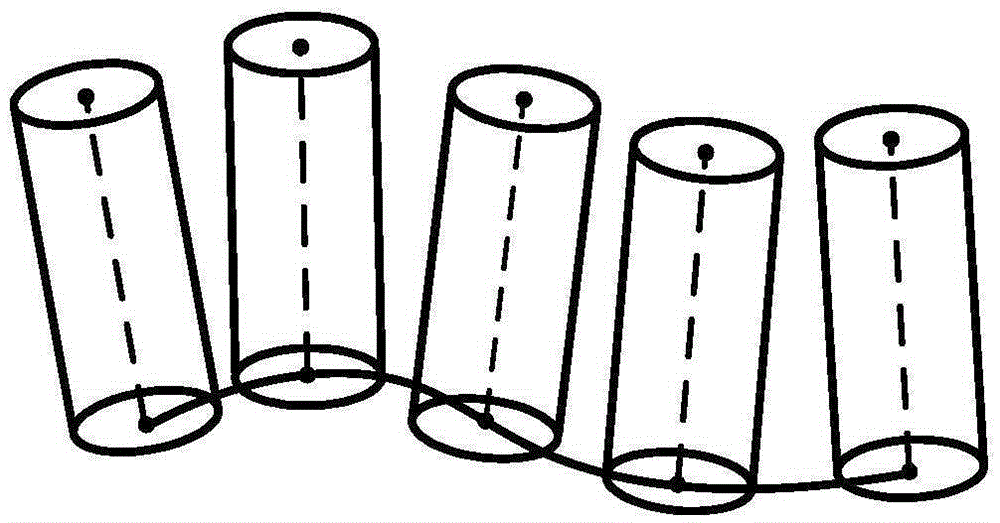

[0062] In this example, if figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, in this embodiment, the geometric deviation is calculated according to the two-parameter spherical envelope theory, and the smooth model of the five-axis side milling tool path is established by using the weighted least square method.

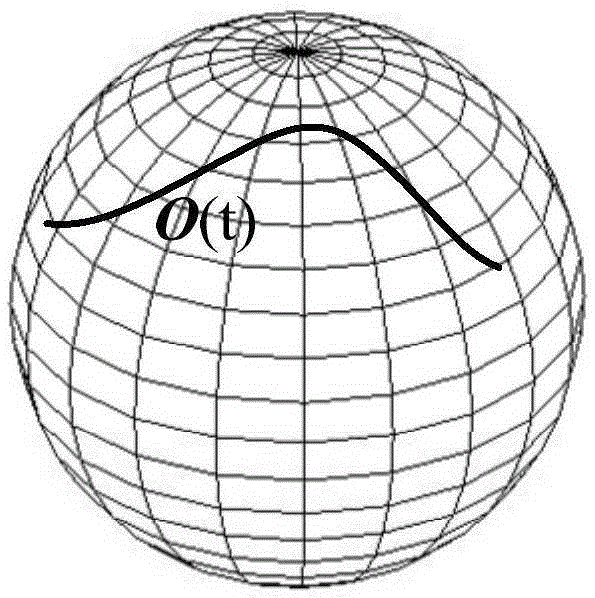

[0063] The five-axis side milling tool path can be represented by the tool nose point trajectory P(t) and the tool axis vector curve O(t) in the workpiece coordinate system

[0064] S(w; a, t) = P(t) + a·H·O(t)

[0065] in Indicates the set of control points of the tool path, including the control points of the tool nose point trajectory line and the control points of the machine tool rotation angle curve. H indicates the length of the tool edge. The formula for calculating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com