Post-processing method of five-axis linkage NC machining

A post-processing, five-axis linkage technology, applied in the direction of digital control, electrical program control, etc., can solve problems such as improper selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

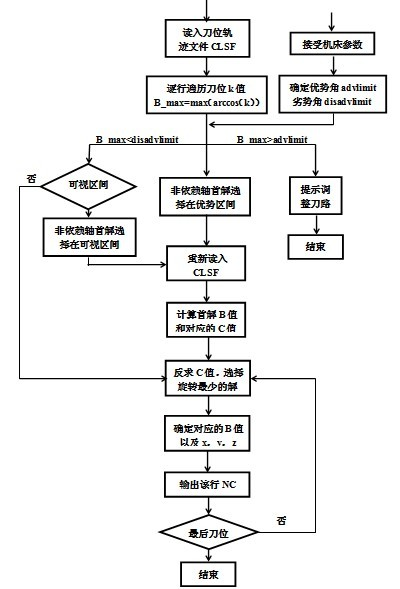

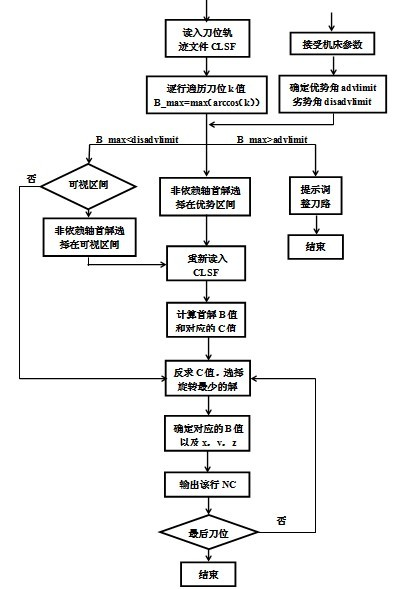

[0044] attached figure 1 Shown is a flow chart of the post-processing algorithm of the present invention. Taking MIKRONHSM600U machine tool to process a certain impeller blade as an example, to clarify the post-processing algorithm. The structure of the machine tool is a double-rotary table type, in which the B-axis is a non-dependent axis with a travel limit of -110° to 30°, and the C-axis is a dependent axis with a travel limit of 0° to 360°. The activity range of the independent axis in the negative angle interval is -110° to 0°, which is greater than the positive angle interval of 0° to 30°, so the negative angle interval is defined as the dominant interval, and -110° is the dominant angle. The positive angle interval is the inferior interval, and 30° is the inferior angle. When the non-dependent axis rotates at a positive angle, the parts processed on the machine tool are blocked by the rotating parts, making it difficult for the machine operator to observe the machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com