Burr removing machining method based on torque control and burr removing system

A processing method and torque control technology, applied in the field of machining, can solve the problems of automatically adjusting the feed of deburring tools, reducing the machining accuracy and machining quality of parts, and affecting the machining accuracy of parts, so as to ensure the machining quality and consistency, The effect of good processing quality and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

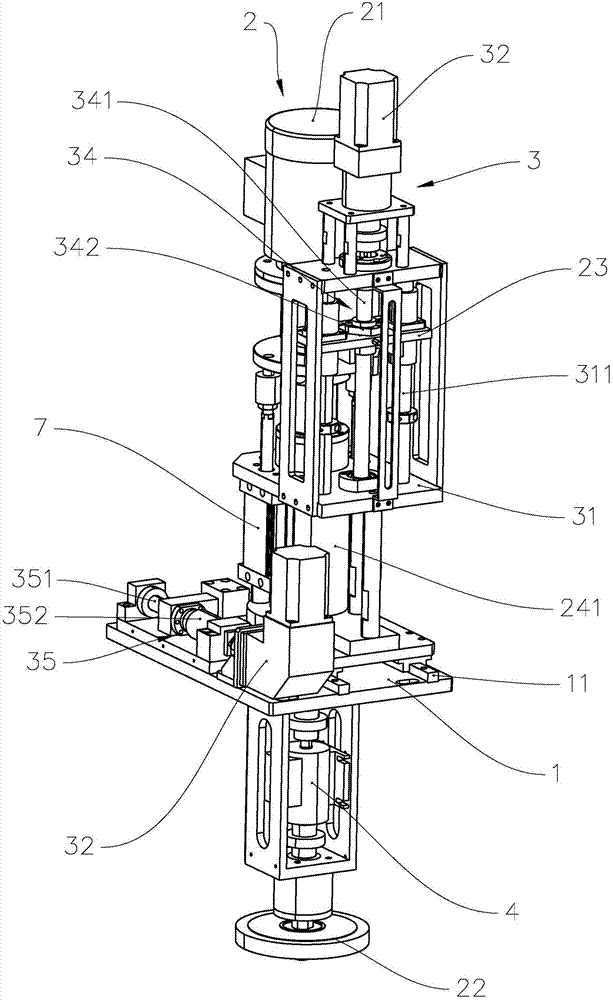

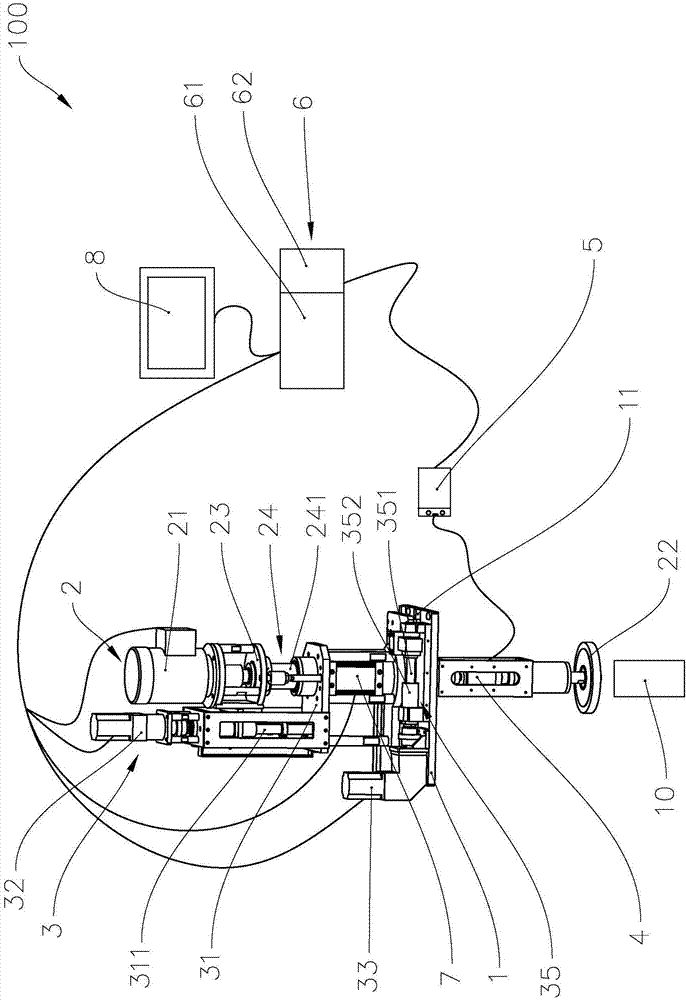

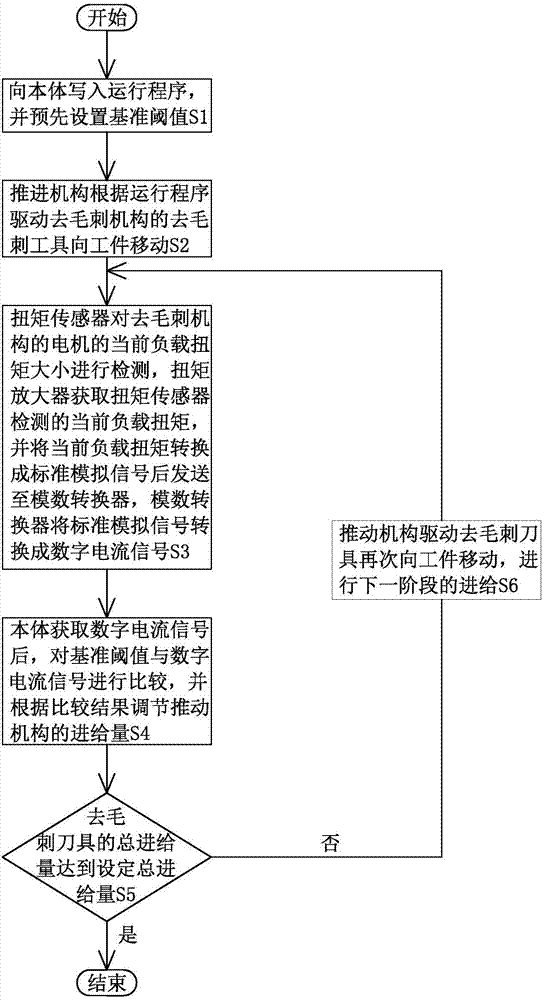

[0032] refer to figure 1 and figure 2 , the deburring system 100 includes a fixed seat 1 , a deburring mechanism 2 , a propulsion mechanism 3 , a torque sensor 4 , a torque amplifier 5 , a controller 6 , a counterweight cylinder 7 and a client 8 .

[0033] Wherein, the fixing base 1 is used to provide installation positions for the deburring mechanism 2 and the advancing mechanism 3, and the fixing base 1 can also be used to connect with the frame of the deburring equipment, so that the deburring system 100 can be installed on the deburring equipment on the rack.

[0034] The propulsion mechanism 3 is installed on the fixed seat 1, the deburring mechanism 2 is installed on the propulsion mechanism 3, and the propulsion mechanism 3 is used to drive the deburring mechanism 2 to move, so that the deburring tool 22 of the deburring mechanism 2 moves to the workpiece, and then realizes The workpiece 10 is deburred. Specifically, the propulsion mechanism 3 includes a mounting ba...

no. 2 example

[0066] Applying the inventive concept of the first embodiment of the deburring system, the difference between the second embodiment of the deburring system and the first embodiment is that the propulsion mechanism 3 of the second embodiment only includes a mounting base 31, a motor 32 and a ball screw assembly 34, the mounting base 31 is installed on the fixing base 1, the deburring mechanism 2 is slidably connected with the mounting base 31 along the axial direction of the driving end of the motor 21, the base body of the motor 32 is fixedly installed on the mounting base 31, the driving of the motor 32 The end is connected with the deburring mechanism 2, and the axis of the driving end of the motor 32 is parallel to the axis of the driving end of the motor 21. The ball screw assembly 34 includes a lead screw 341 and a lead screw nut 342 , the lead screw 341 is fixedly connected with the driving end of the motor 32 , the lead screw nut 342 is threaded with the lead screw 341 ,...

no. 3 example

[0069] Applying the inventive concept of the first embodiment of the deburring system, the third embodiment of the deburring system is different from the first embodiment in that the propulsion mechanism 3 of the third embodiment only includes a mounting base 31 and a motor 33, and the fixing base 1 A slide rail 11 is provided, and the mounting seat 31 is slidably connected with the slide rail 11 along the extending direction of the slide rail 11. The deburring mechanism 2 is installed on the mounting seat 31, and the seat body of the motor 33 is installed on the fixed seat 1. The motor 33 The driving end is connected with the mounting base 31.

[0070] The difference between the deburring processing method of this embodiment and the above-mentioned embodiment of the deburring processing method based on torque control is that the deburring processing method of this embodiment does not include the deburring mechanism 3 driving the deburring tool 22 of the burring mechanism 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com