Multi-axis laser processing system for error on-machine detection and correction

A laser processing and error technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the accuracy and efficiency cannot meet the actual processing requirements, cannot meet the precision manufacturing of complex curved surface textures, and the price is expensive. Guaranteed processing consistency, stable laser processing accuracy, and good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

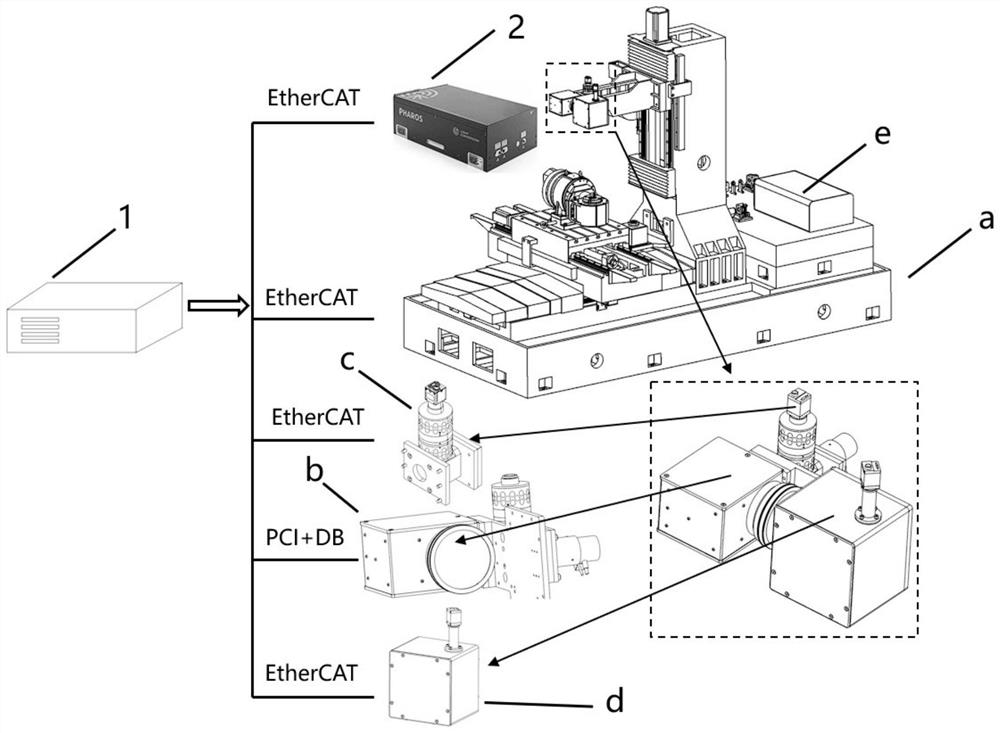

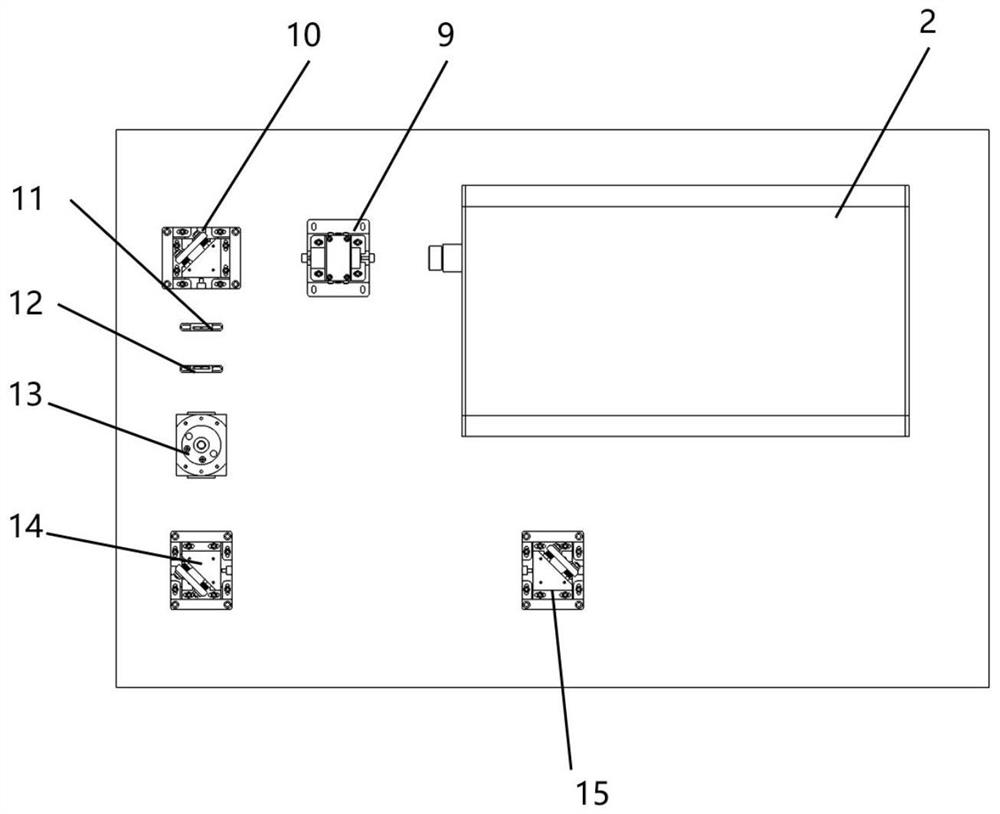

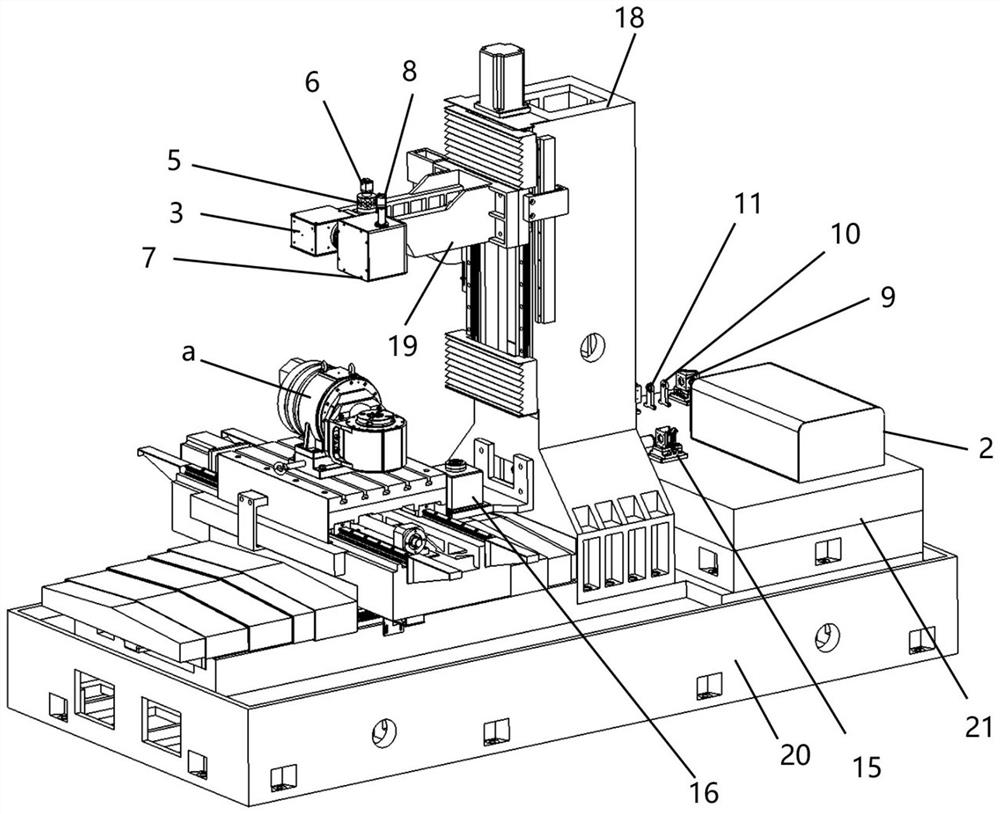

[0022] Such as figure 1 As shown, the present invention provides a multi-axis laser processing system with on-machine detection and correction of errors, including an industrial computer 1, a three-dimensional galvanometer scanning system b, a femtosecond laser system e, an in-situ visual measurement system c, and a beam stabilization system d and the five-axis CNC machine tool a; among them, the industrial computer 1 communicates with the three-dimensional galvanometer scanning system b through the PCI interface, communicates with the femtosecond laser system e, the in-situ visual measurement system c and the five-axis CNC machine tool a through the EtherCAT Ethernet, and communicates with the five-axis CNC machine tool a through The optical-mechanical-electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com