Automatic assembly production line for fan impellers

An automatic assembly, fan impeller technology, applied in the direction of assembly machine, feeding device, positioning device, etc., can solve the problems of low processing efficiency, high labor cost, poor product processing consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

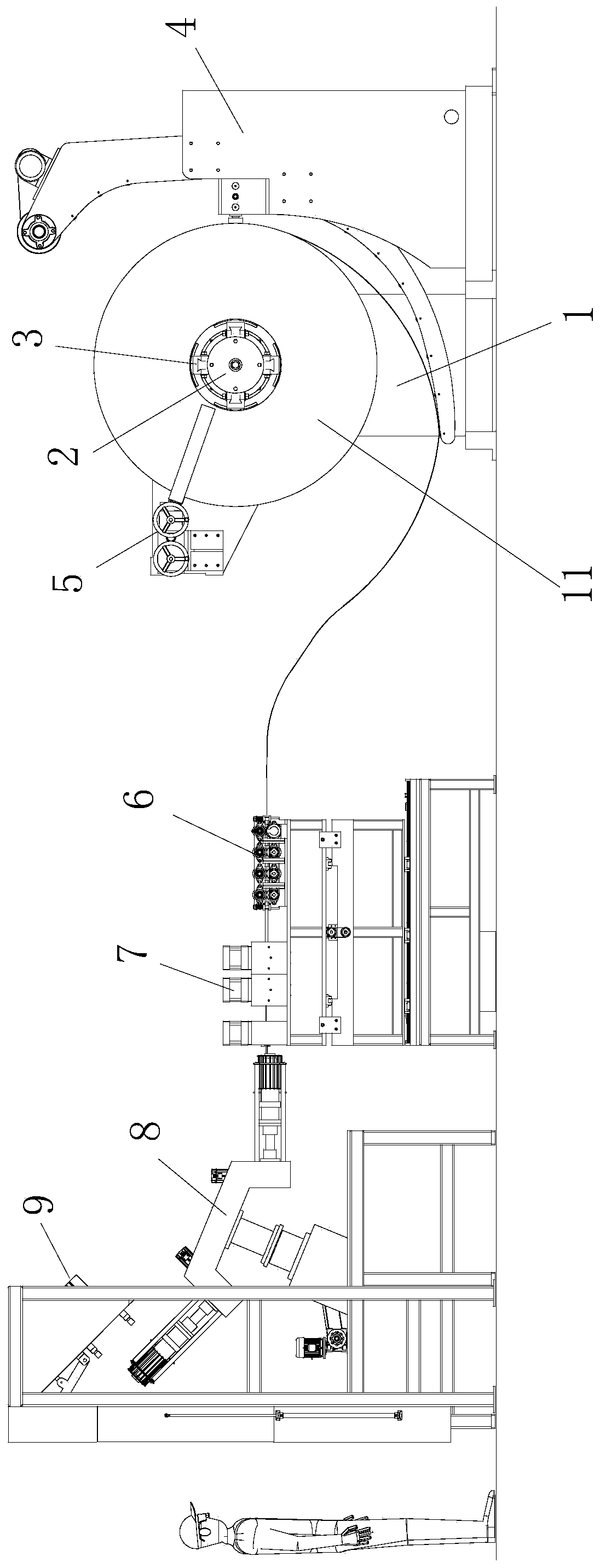

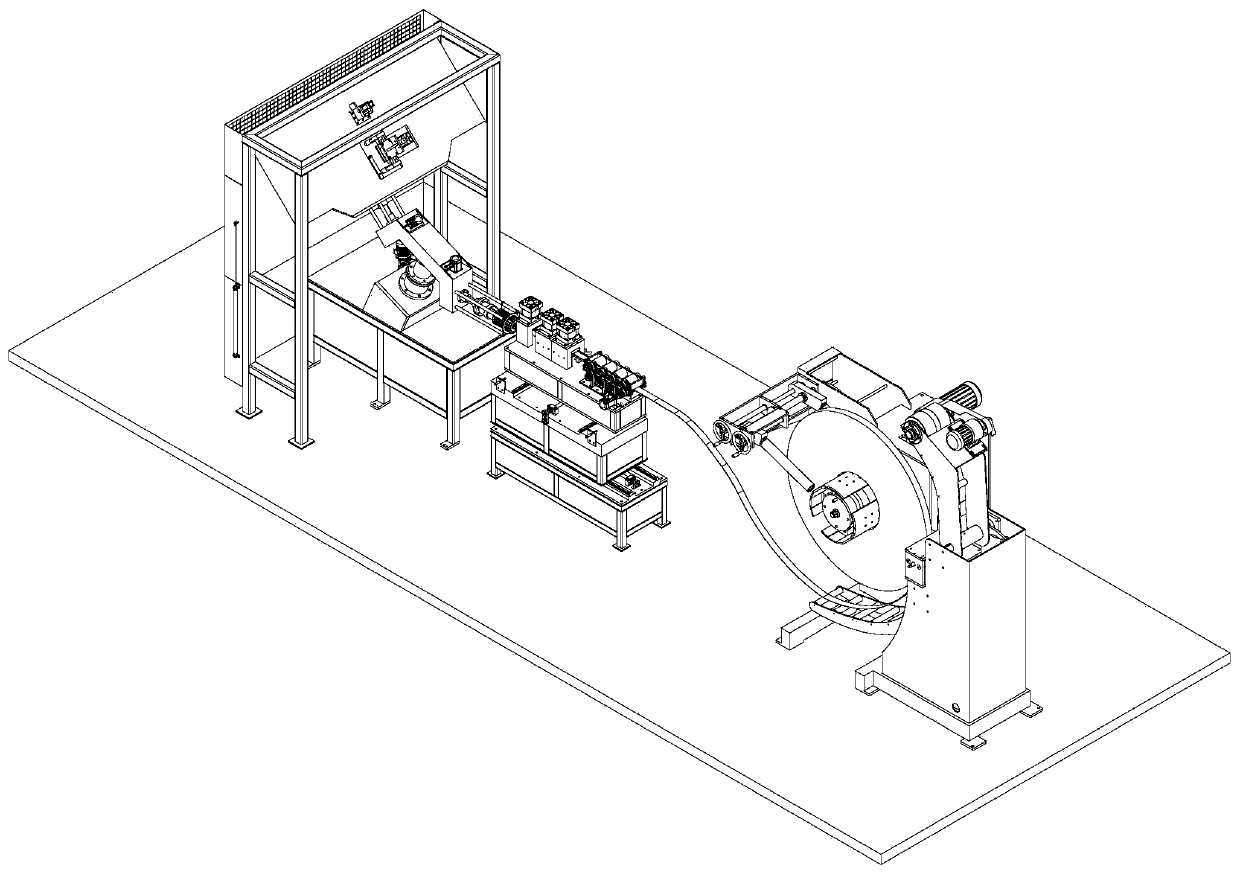

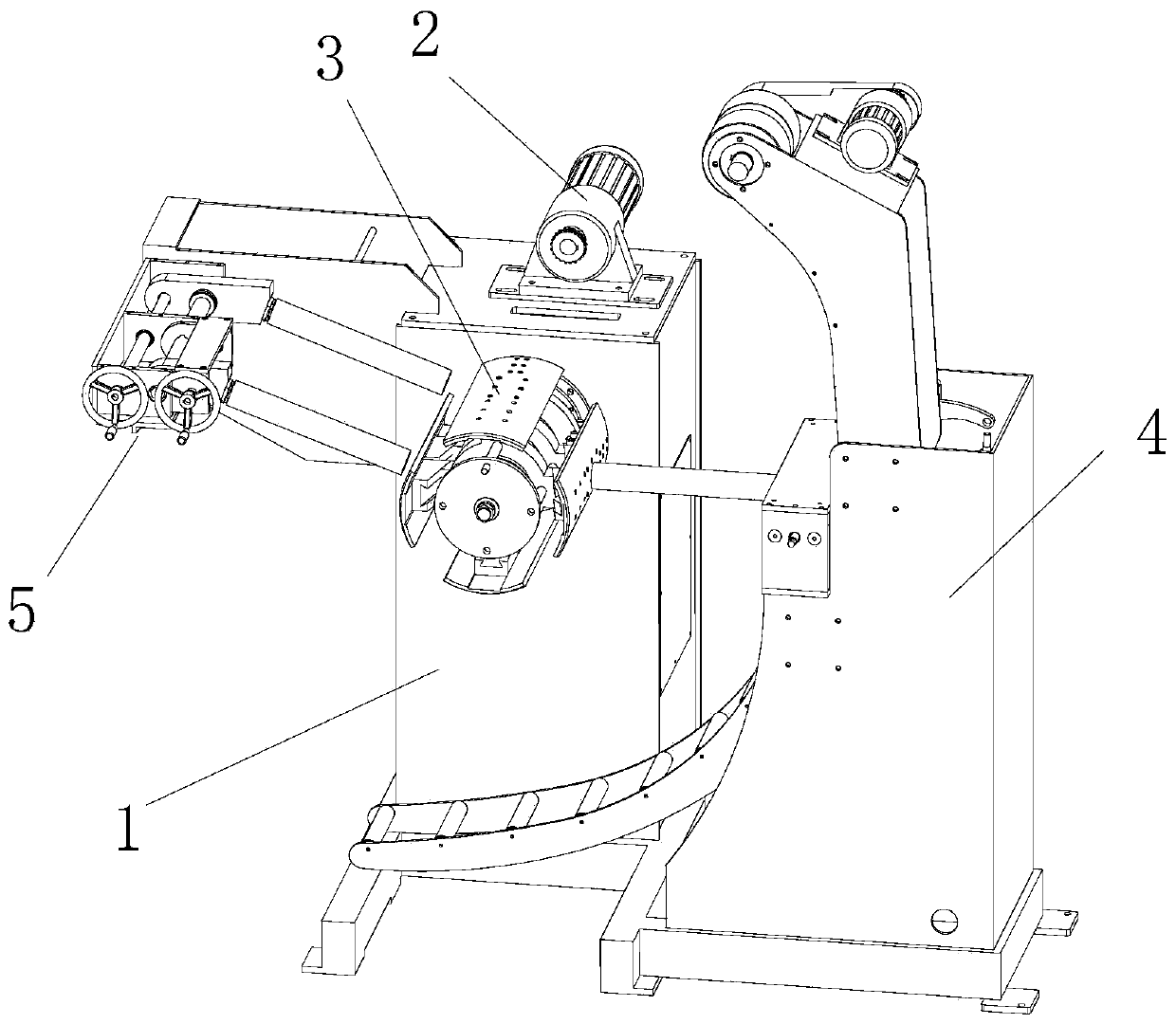

[0084] like figure 1 and figure 2 As shown in the figure, this embodiment discloses an automatic assembly production line for fan impellers. The assembly production line mainly includes a steel strip uncoiling mechanism, a blade roll forming feeding mechanism 6, a blade punching mechanism 7, and a double-station rotary assembly mechanism. 8, and the material pressing and unloading mechanism 9. The worker puts the steel strip coil material into the steel strip uncoiling mechanism, and the steel strip head extends into the blade roll forming feeding mechanism 6 . The rolled steel strip is sent into the blade blanking mechanism 7 for blanking and cutting. After being punched into a blade, it enters the double-station rotary assembly mechanism 8 for positioning and assembly together with the upper and lower end caps. The double-station rotary assembly mechanism 8 sends the blades and the upper and lower end caps to the material pressing and unloading mechanism 9 for positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com