Patents

Literature

36results about How to "Control contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

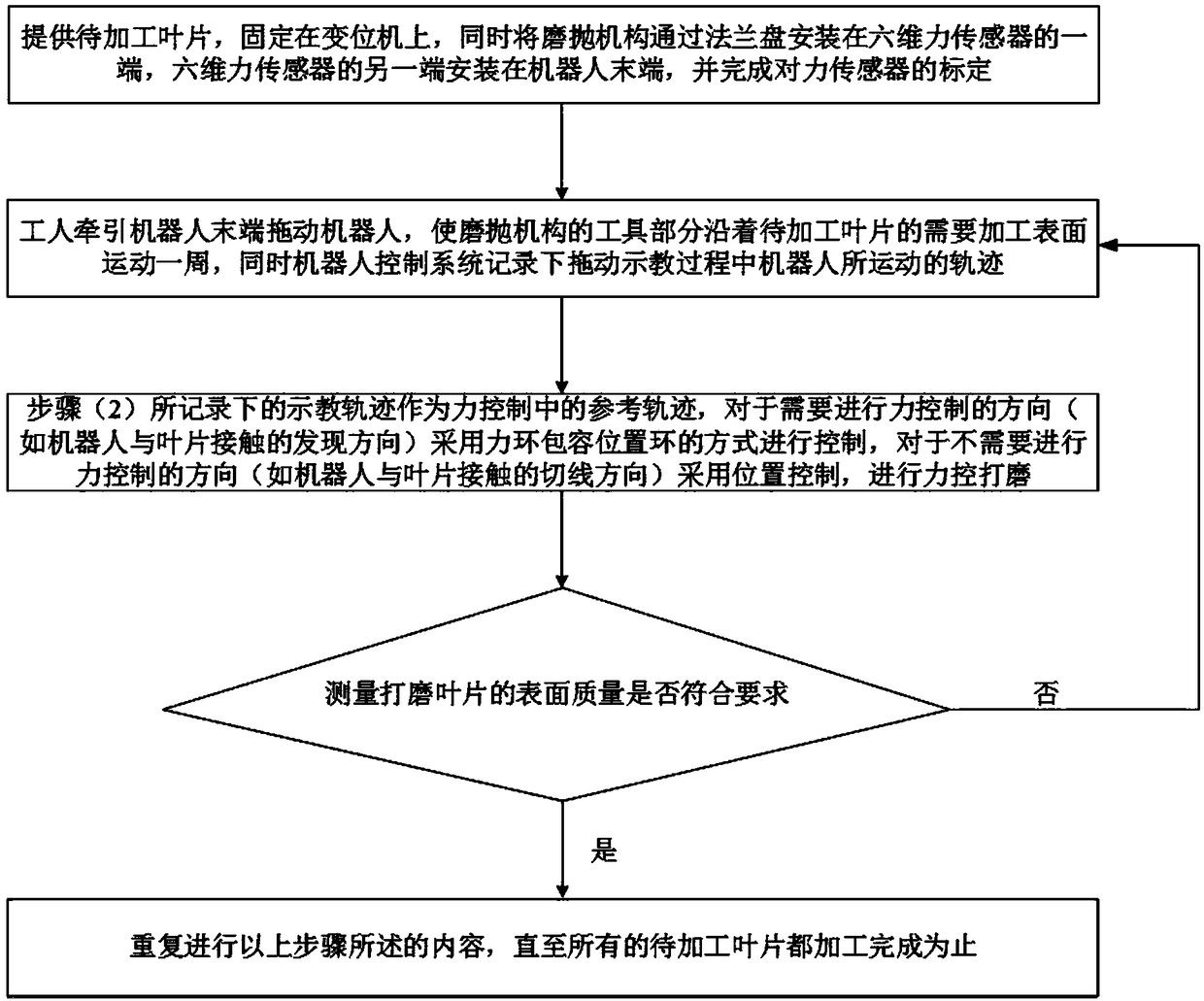

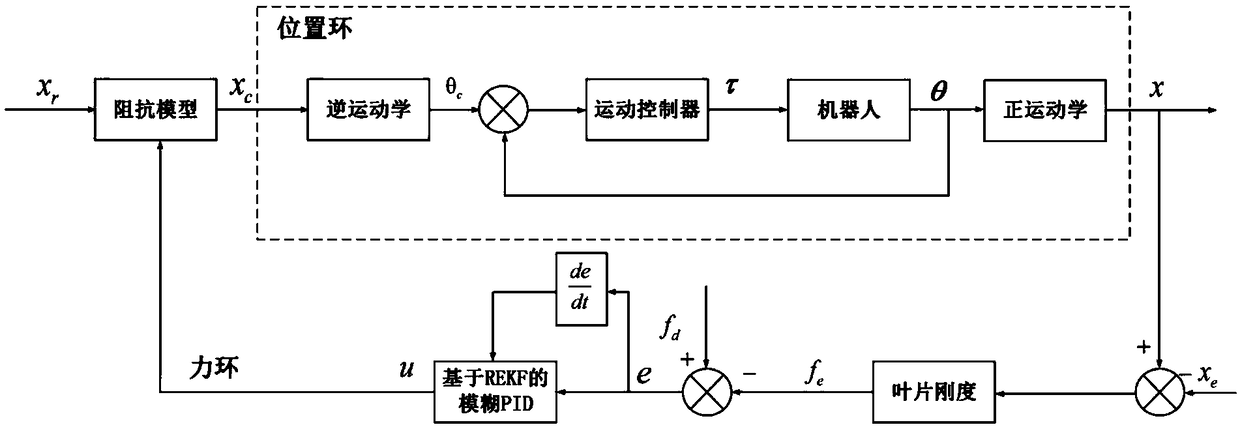

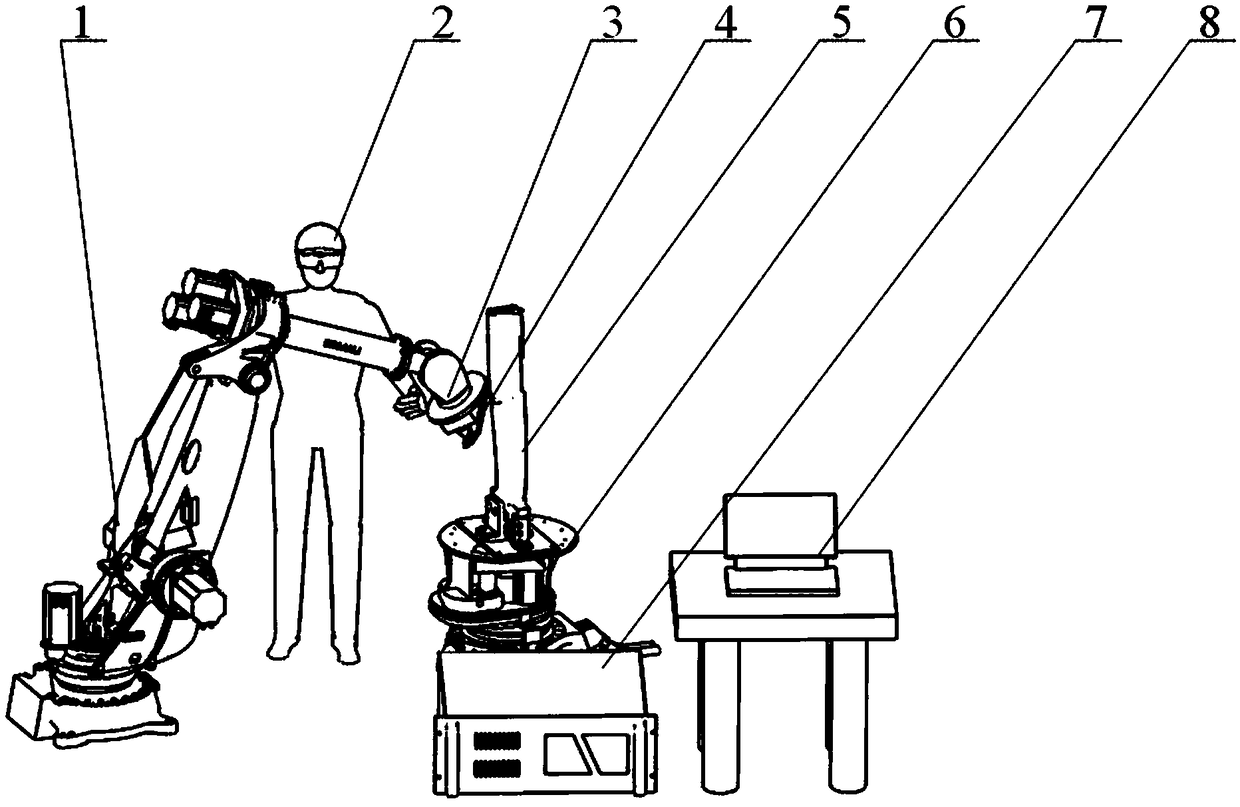

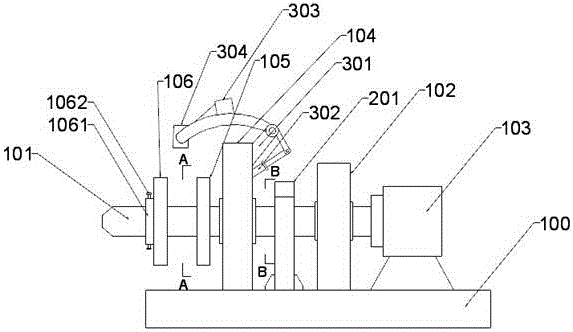

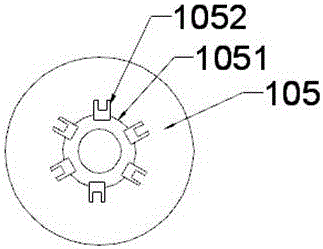

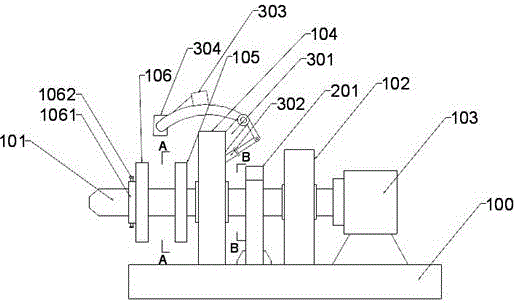

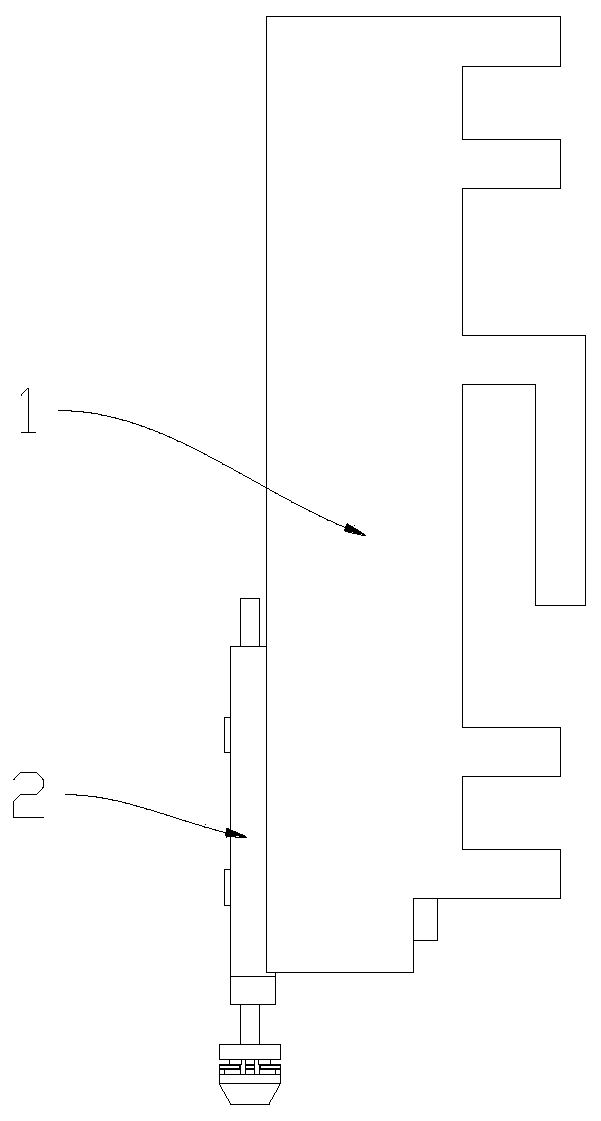

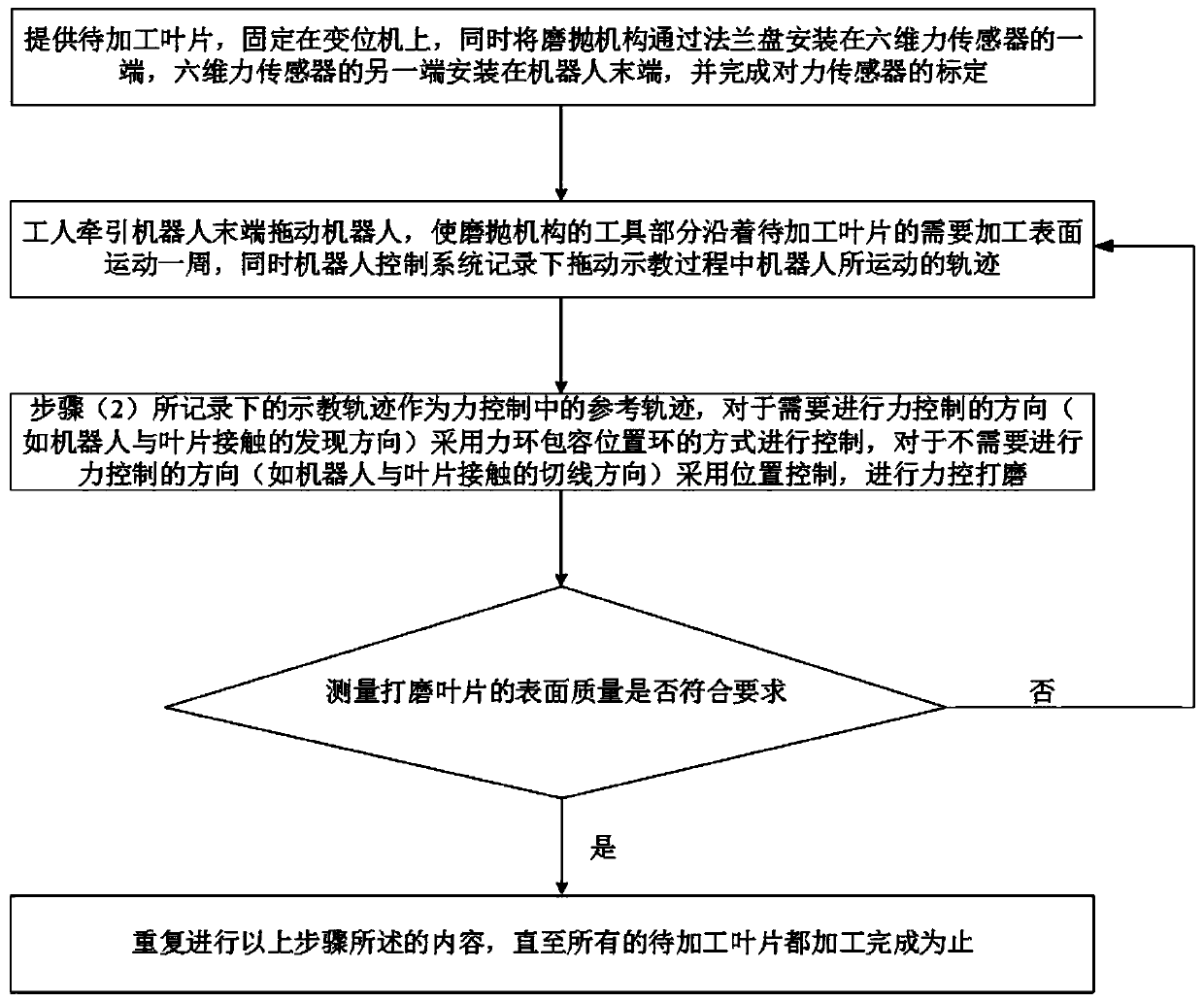

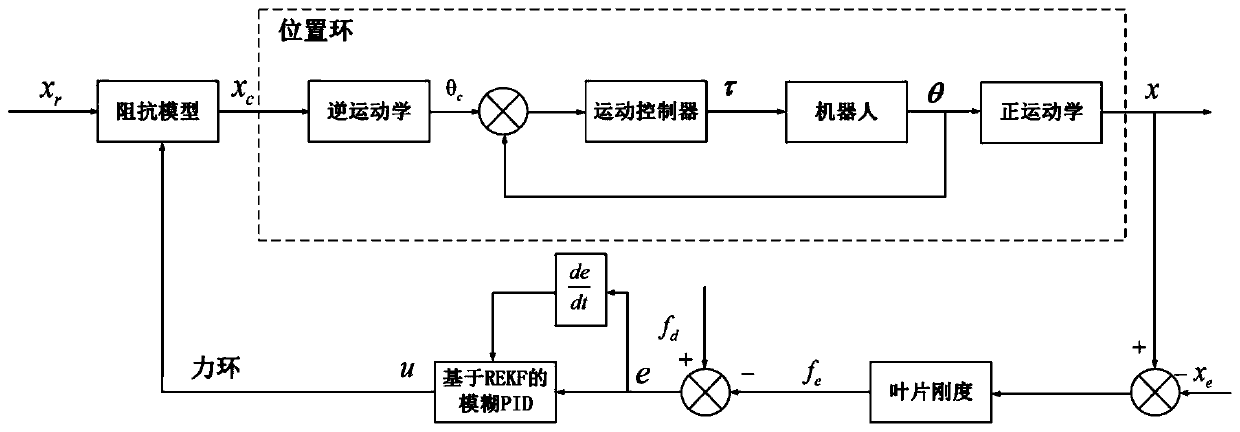

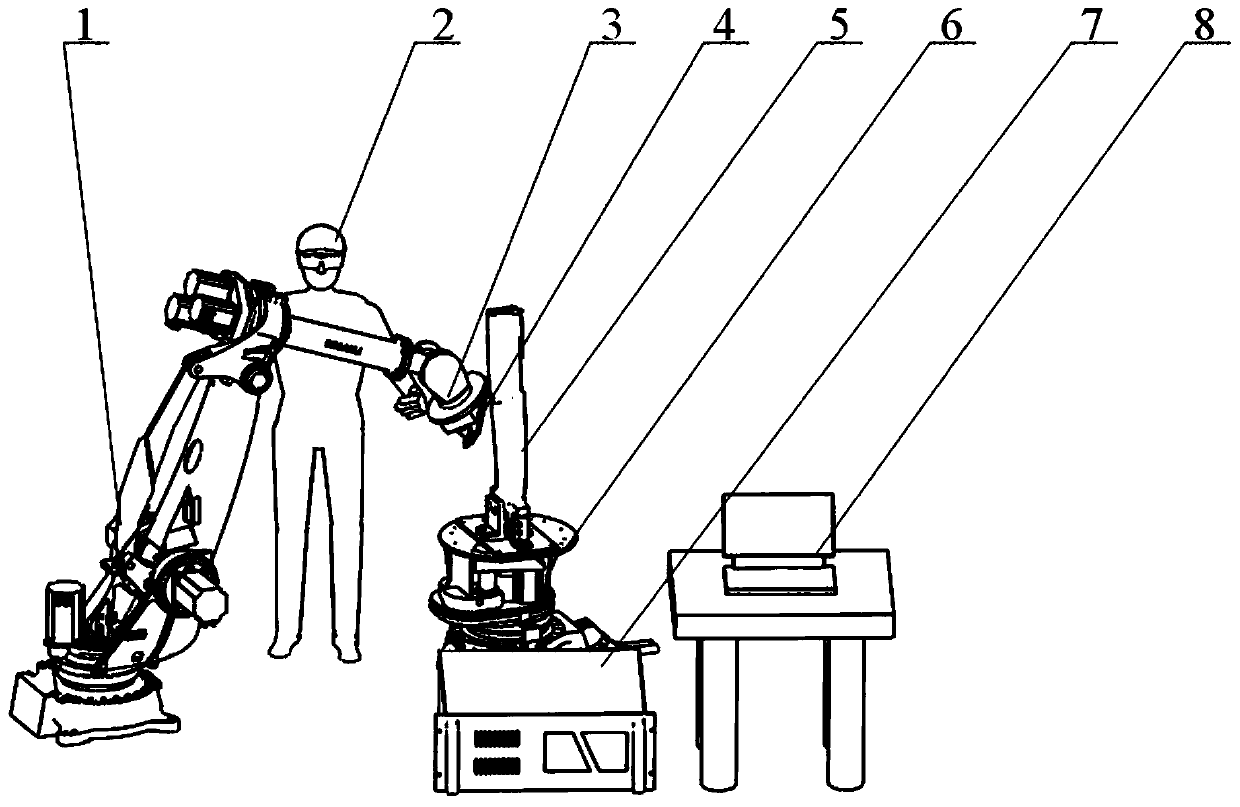

Device and method for force controlling polishing blade through dragging teaching robot

ActiveCN109434843AHigh degree of integrationImprove automationProgramme-controlled manipulatorControl systemContact force

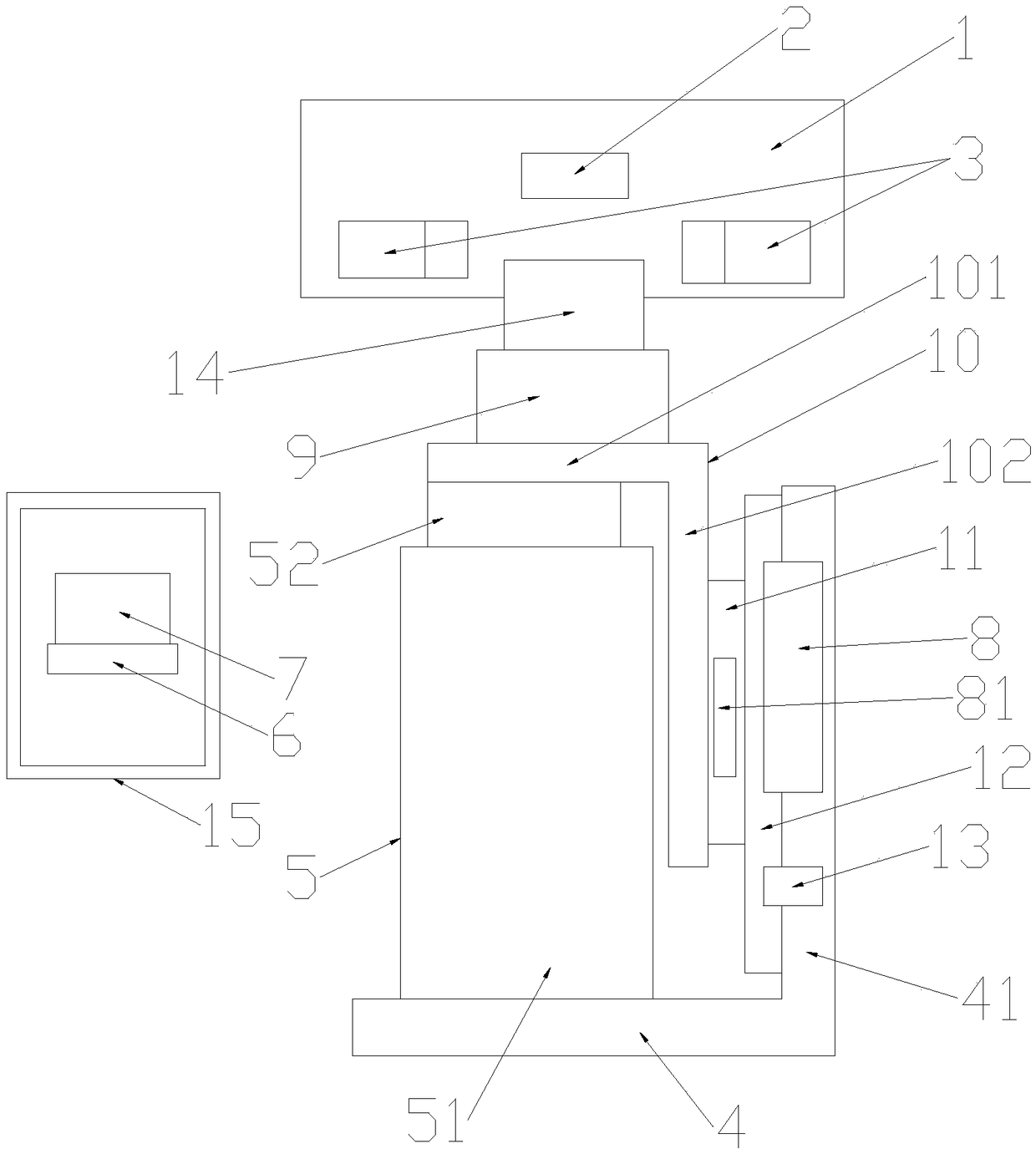

The invention belongs to the related technical field of intelligent machining, and discloses a device and a method for force controlling polishing a blade through dragging a teaching robot. The devicecomprises the robot, a six-dimensional force sensor, a polishing mechanism, a position changing machine, and a robot control system; the six-dimensional force sensor is connected with a tail end executor of the robot and the polishing mechanism; the position changing machine is used for bearing the to-be-machined blade; the robot, the six-dimensional force sensor and the polishing mechanism are connected to the robot control system; the six-dimensional force sensor is used for measuring the contact force between the blade and the polishing mechanism in the blade polishing process, and transmitting the detected data to the robot control system; the robot control system is further used for receiving the tail end position information data of the robot, processing the received data to obtainthe corresponding control quantity, and then controlling the robot to drive the polishing mechanism to carry out corresponding motion. According to the device and the method, the skill requirement foran operator is reduced, and the machining consistency and the machining precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

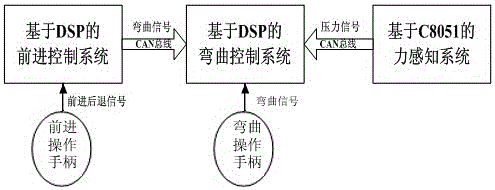

Endoscope robot control method and device based on pressure sensor information

ActiveCN105796043AControl contact forceSmall elastic deformationSurgeryEndoscopesControl systemSimulation

The invention discloses an endoscope robot control method and device based on pressure sensor information. An operator actively controls a robot to bend in the intestine according to intestinal interior information fed back by a camera at the front end of an S-shaped body of the colonoscope robot; a robot control system collects contact force information of the robot and the intestine in real time by means of a pressure sensor of the bent body part, and the relation between the robot motion distance r and contact force F is obtained by analyzing the colon tissue biomechanical characteristics, so that the joint posture of the robot is adjusted to ensure that the contact force is within the safety threshold value range; the control system corrects the whole posture of all joints of the robot by means of the motion coupling relation of all the joints, the contact force coming from all the joints of the robot can be effectively detected, and when the robot touches the intestine, the colonoscope robot control system can control the robot gently to enable the contact force between the robot and the intestine to be within the safety threshold value range, so that safety of the intestine of the human body during examination is ensured.

Owner:SUZHOU UNIV

Preparation method of edge-carboxylated graphene

ActiveCN110817853AStable manufacturingHigh degree of automationGrapheneBulk chemical productionGraphiteGraphene

The invention discloses a preparation method of carboxylated graphene. The method comprises the following steps of grinding graphite powder in the presence of supercritical carbon dioxide in a high-pressure millstone kettle. Through the preparation method, carboxyl-modified, especially edge-carboxyl-modified graphene can be directly obtained, the introduced carboxyl content can be controlled in arelatively wide range, and large-area edge-modified graphene can also be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

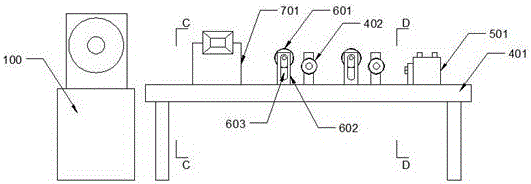

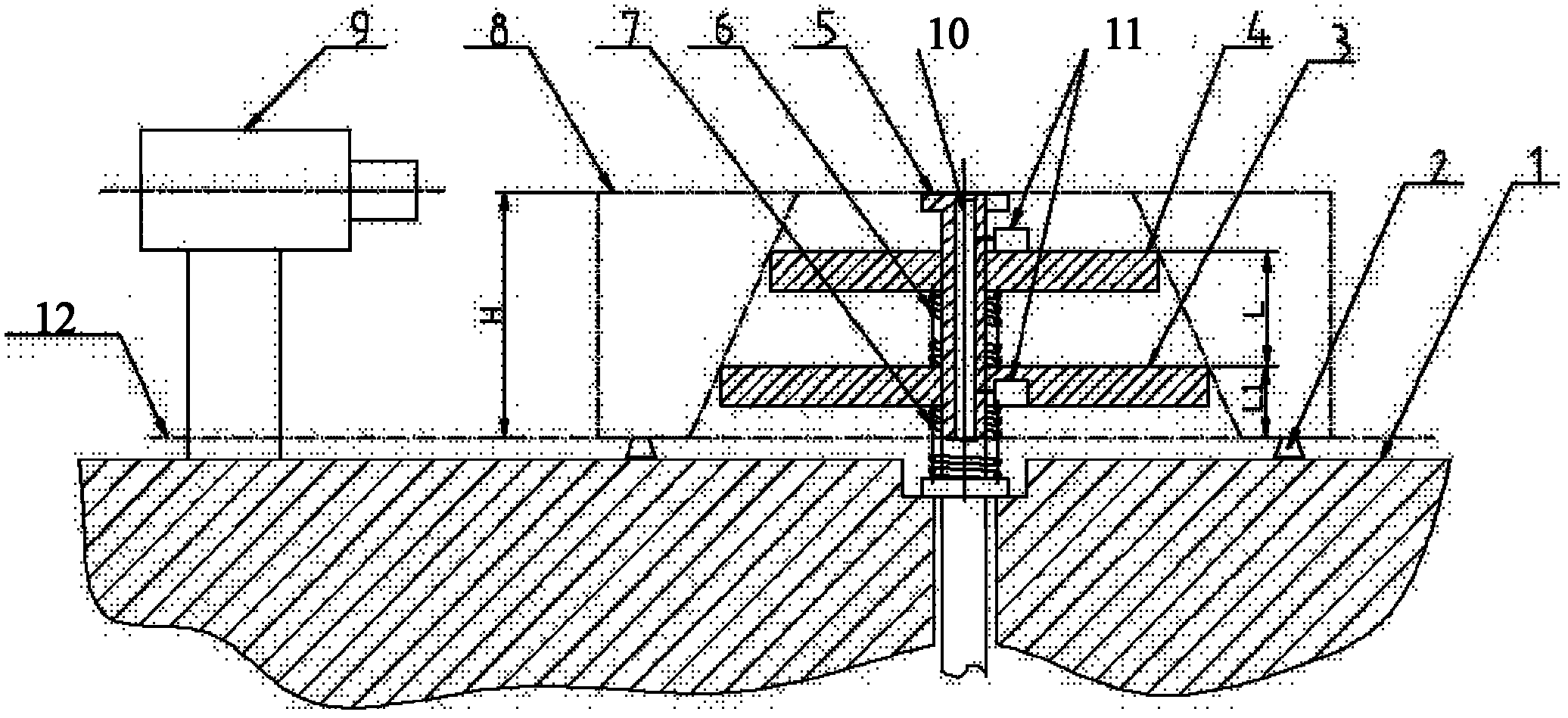

Efficient deburring system for stainless steel strip

InactiveCN106044313AControl the speed of dischargingControl contact forceWebs handlingEngineeringConductor Coil

The invention discloses an efficient deburring system for a stainless steel strip. The efficient deburring system comprises a discharging mechanism and a deburring mechanism. The discharging mechanism comprises a discharging base, a winding shaft, a motor bracket, a first motor, a fixed bracket, a supporting baffle and a spacing baffle. The motor bracket and the fixed bracket are fixedly arranged on two sides of the discharging base. The winding shaft is rotatably erected on the fixed bracket and the motor bracket, is driven by the first motor erected on the motor bracket to rotate, and penetrates through the supporting baffle and the spacing baffle. A steel strip sleeves a part between the supporting baffle and the spacing baffle. The deburring mechanism comprises a worktable, guide rollers, tension pulley components, a guiding component and deburring components. The tension pulley components are used for adjusting the tension forces of the steel strip and the guide rollers. The guiding component is used for spacing the steel strip during the conveying process. The deburring components are used for deburring the steel strip. The efficient deburring system is reasonable in structure, the steel strip can be stably and accurately discharged quickly and efficiently, and the efficient deburring system can be conveniently adjusted according to the size of the steel strip, and is high in deburring efficiency.

Owner:SUZHOU GUANXING METAL PROD MFG CO LTD

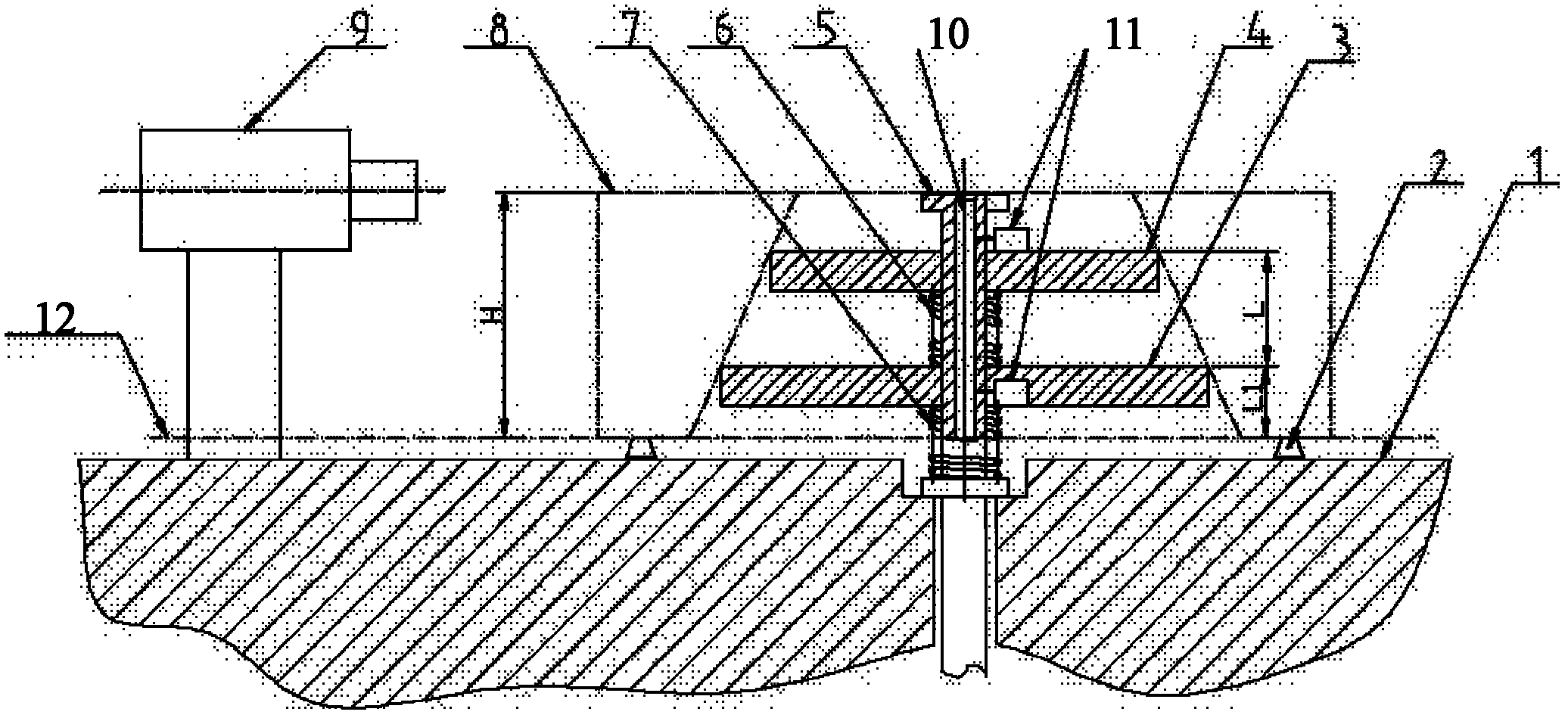

Comprehensive detection device for geometric parameters of conical ring

InactiveCN102607413AImprove efficiencyReduce mistakesUsing optical meansMeasurement deviceEngineering

The invention discloses a comprehensive detection device for geometric parameters of a conical ring. The device is applicable to comprehensively detecting various geometric parameters such as the conical degree, the conical height, the large-end (or small-end) diameter and the like of the conical ring (an inner cone), and mainly, functionally and structurally comprises a large movable measuring head, a small movable measuring head, a mandrel, a spring, a linear bearing, a positioning pin, a CCD ((charge coupled device), a displacement sensor and a contact detection sensor. The diameter difference of the two measuring heads is a fixed value, a detected part is movable while a measuring device is fixed in measurement so that measuring efficiency is greatly improved, and by the aid of the linear bearing and the spring, the detected part and the measuring heads can be placed in correct relative positions in measurement, so that measuring errors can be greatly decreased and the measuring efficiency is improved. The three geometric parameters including the conical degree, the conical height and the large-end (or small-end) diameter of the detected part can be detected by means of one-step operation, so that the measuring efficiency is equivalently improved by a few times. Besides, the device is simple in structure and convenient in operation, and the requirement on the technical level of operators is quite low.

Owner:XI AN JIAOTONG UNIV

Steel belt flattening device

InactiveCN106140887AControl the speed of dischargingControl contact forceMetal-working feeding devicesPositioning devicesFixed frameArchitectural engineering

The invention discloses a steel strip leveling device, which comprises: a discharging mechanism: the discharging mechanism comprises a discharging base, a reel, a motor bracket, a first motor, a fixing frame, a material bearing baffle and a limiter baffle, the motor bracket and the fixed bracket are fixed on both sides of the discharge base, the reel is rotatably erected on the fixed bracket and the motor bracket, and the reel is driven to rotate by the first motor erected on the motor bracket, The reel passes through the material-receiving baffle and the limit baffle, and the steel belt is sleeved between the material-receiving baffle and the limit baffle; a leveling mechanism: the leveling mechanism includes a worktable, a guide roller, Tensioner assembly for adjusting the tension between the steel belt and guide rollers, guide assembly for limiting the position of the steel belt in transit, and leveling assembly for leveling the steel belt. The invention has a reasonable structure design, can quickly and efficiently discharge the steel strip stably and accurately, can be conveniently adjusted according to the size and specification of the steel strip, and has high leveling efficiency.

Owner:SUZHOU GUANXING METAL PROD MFG CO LTD

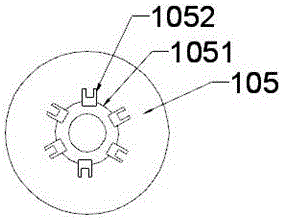

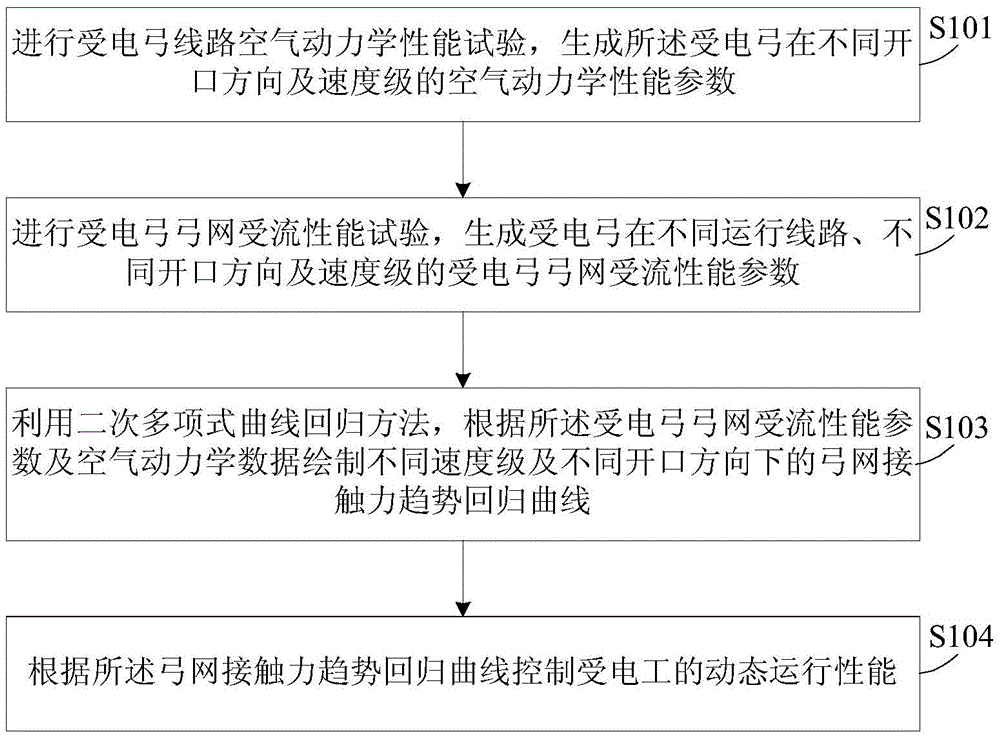

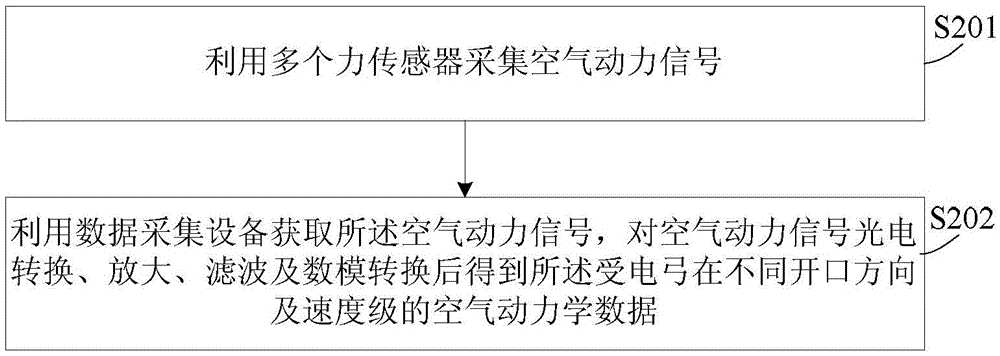

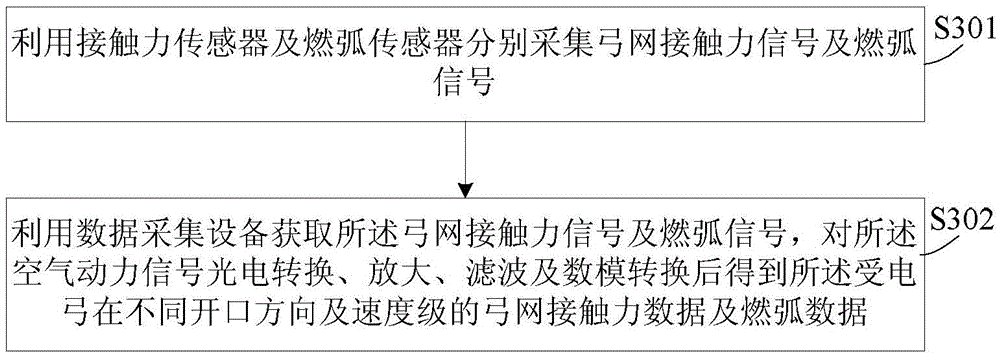

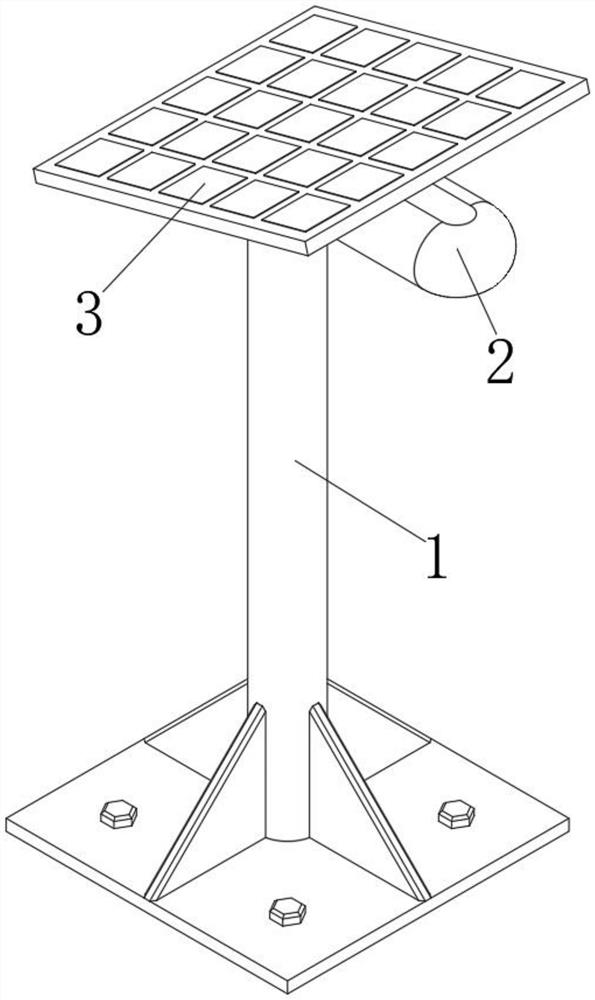

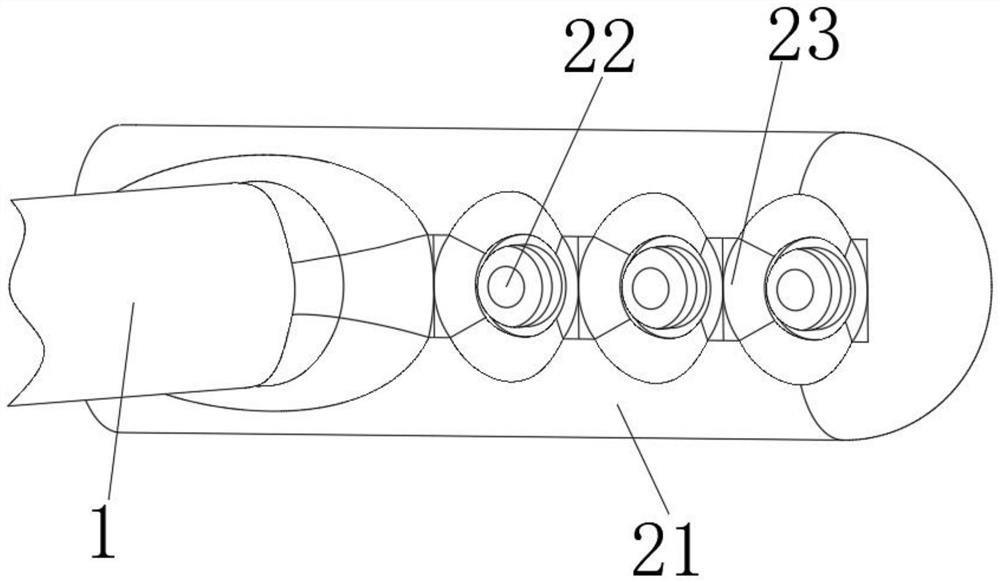

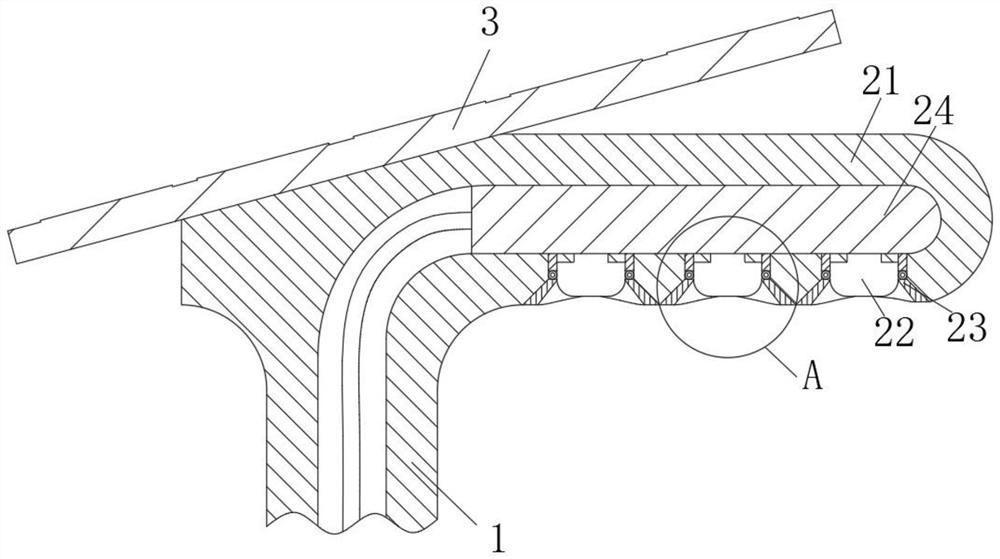

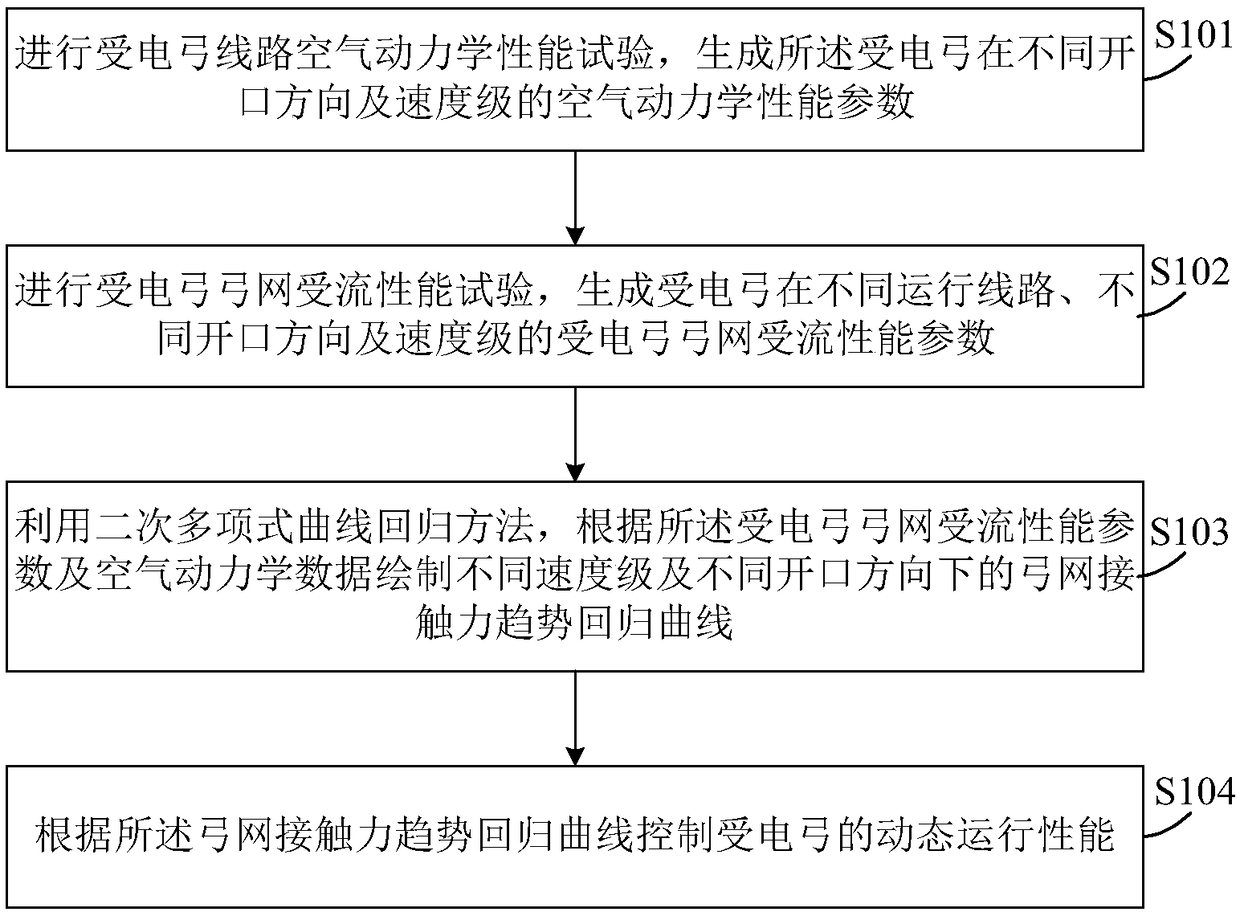

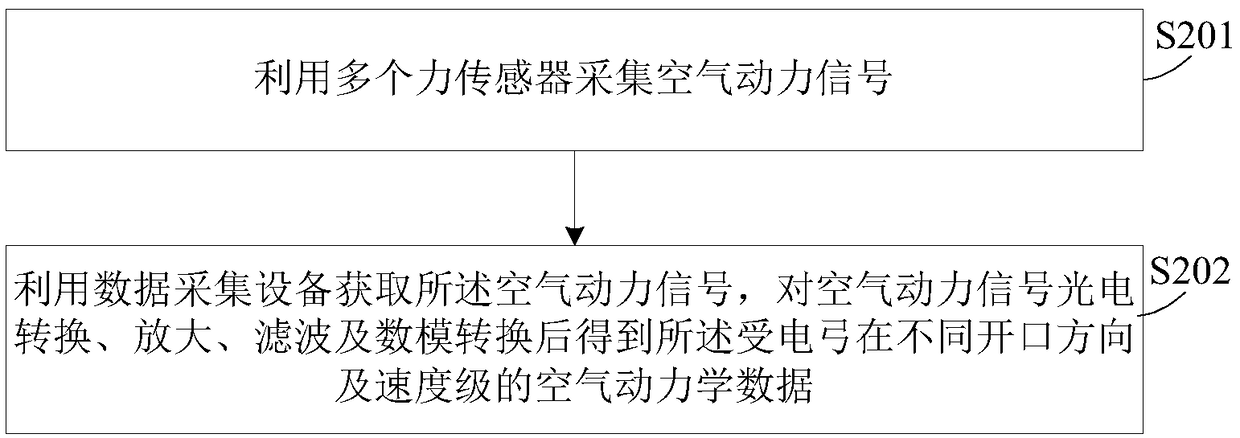

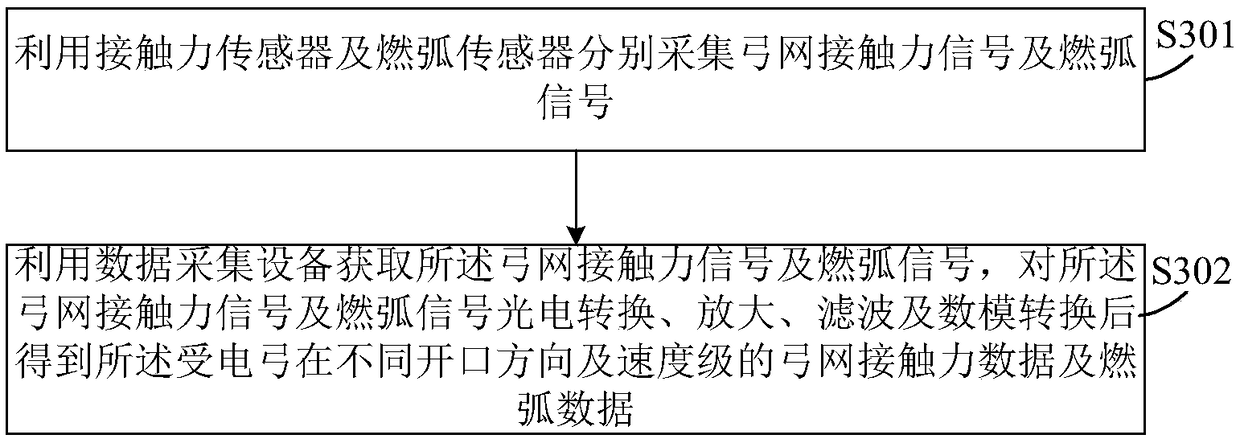

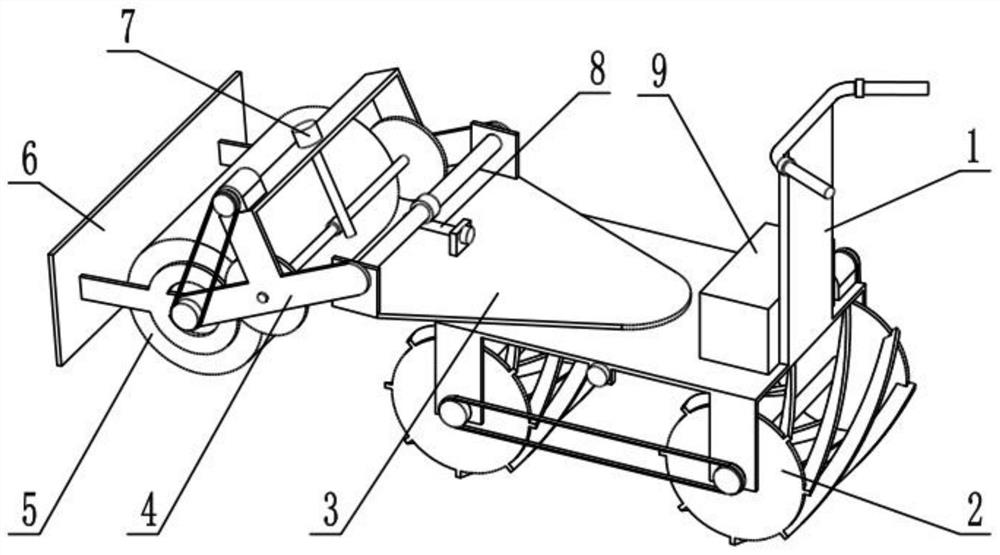

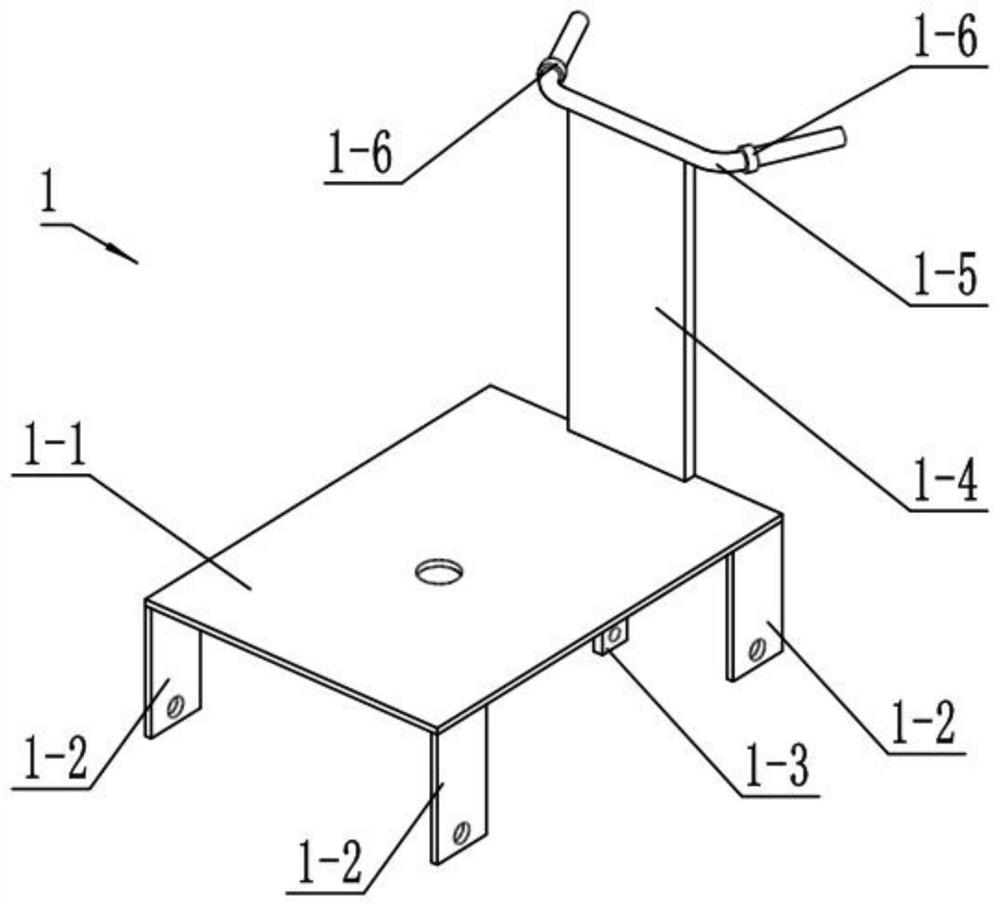

Pantograph dynamic operation performance control method and device

ActiveCN105652111AImprove flowPrecise control of contact forceTesting electric installations on transportPower current collectorsElectricityContact force

The invention provides a pantograph dynamic operation performance control method and device. The pantograph dynamic operation performance control method comprises the steps that a pantograph line aerodynamic performance test is performed so that aerodynamic performance parameters of a pantograph in different open directions and speed levels are generated; a pantograph and catenary current collection performance test is performed so that the pantograph and catenary current collection performance parameters of the pantograph in different operation lines and different open directions and speed levels are generated; a catenary contact force trend regression curve under different speed levels and different open directions is drawn by utilizing a quadratic polynomial curve regression method according to the pantograph and catenary current collection performance parameters and the aerodynamic data; and dynamic operation performance of the pantograph is controlled according to the catenary contact force trend regression curve. With application of the pantograph dynamic operation performance control method and device, the pantograph dynamic operation performance parameters of the pantograph can be accurately controlled so that indirect contact force of the pantograph and the catenary can be accurately controlled, and great current collection of the catenary and the pantograph can be guaranteed.

Owner:CHINA RAILWAYS CORPORATION +3

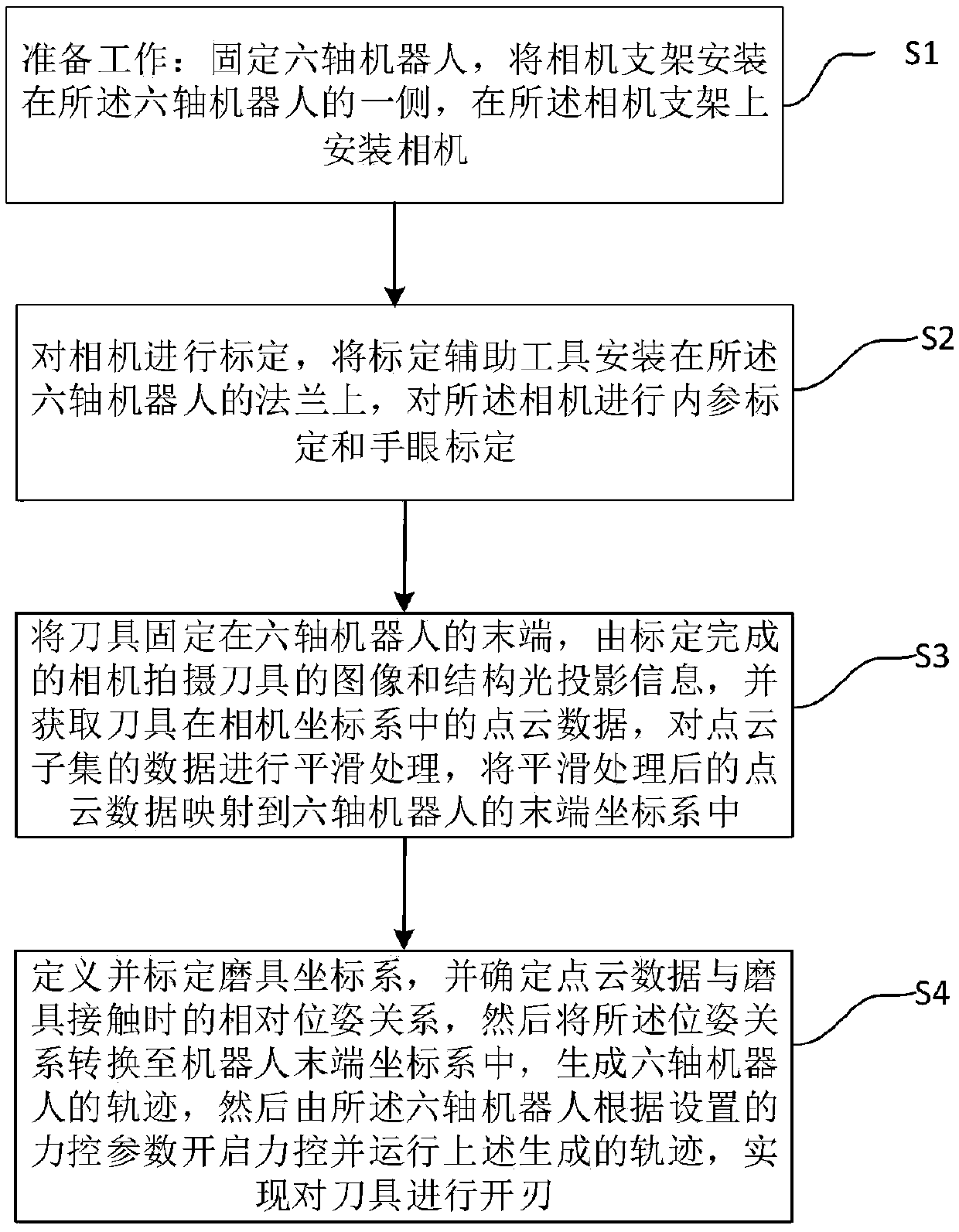

Tool edge sharpening method for six-axis mechanical arm with force control function based on machine vision

ActiveCN109605140ACutting edge to achieveCompensation errorOther manufacturing equipments/toolsAutomatic grinding controlMachine visionPoint cloud

The invention provides a tool edge sharpening method for a six-axis mechanical arm with a force control function based on machine vision. The tool edge sharpening method comprises the steps that preparing work is conducted; a camera is calibrated; a tool is fixed to the tail end of a six-axis robot, the calibrated camera is used for shooting a tool image and structure light projection information,point cloud data of the tool in a camera coordinate system are obtained, data of a point cloud subset is subjected to smoothing treatment, and the point cloud data obtained after smoothing treatmentare mapped into a tail end coordinate system of the six-axis robot; a grinding tool coordinate system is defined and calibrated, the relative posture relation when the point cloud data make contact with a grinding tool is determined, then, the posture relation is converted into the robot tail end coordinate system, the track of the six-axis robot is generated, the six-axis robot is used for starting force control and running the above generated track according to the set force control parameters, and tool edge sharpening is achieved. According to the tool edge sharpening method, the achievingcost is low, the error between the tool and a CAD file of the tool can be well offset, and a stable and good edge sharpening effect is achieved.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

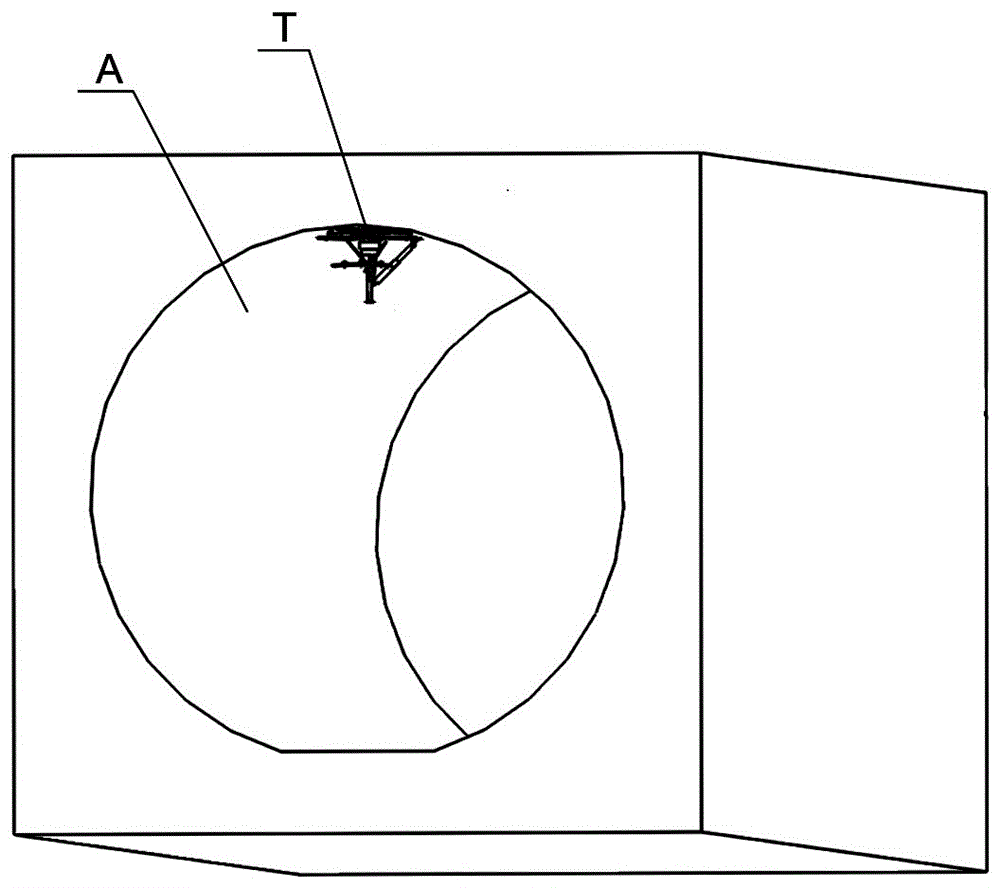

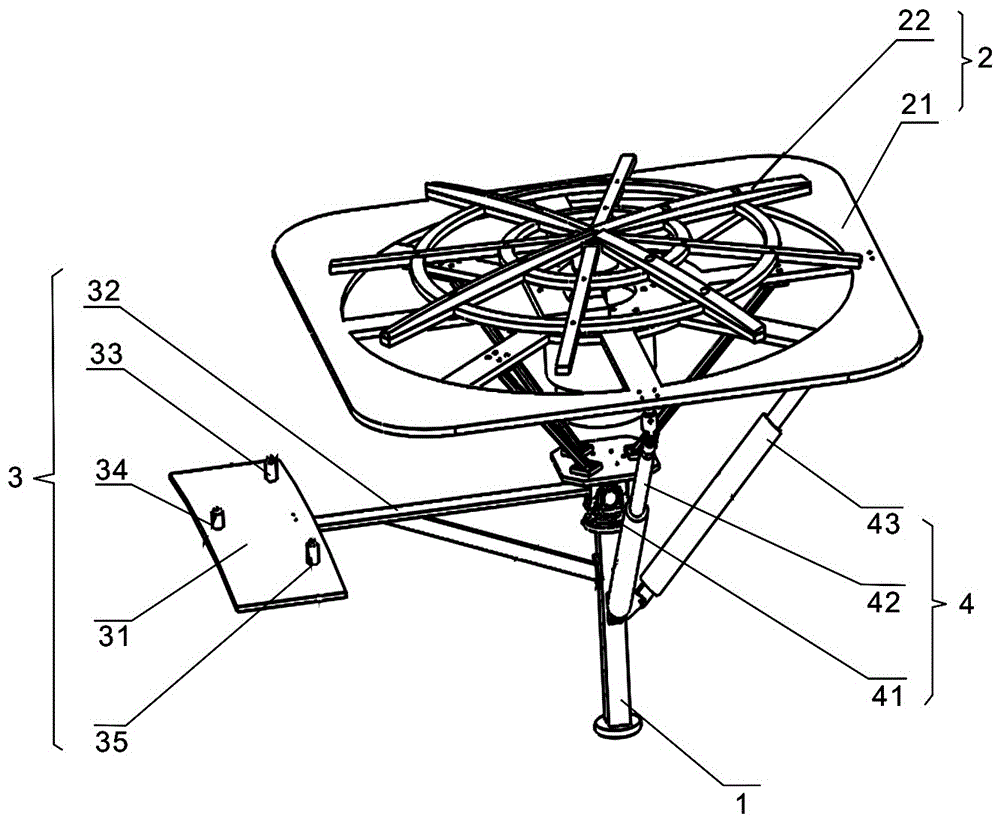

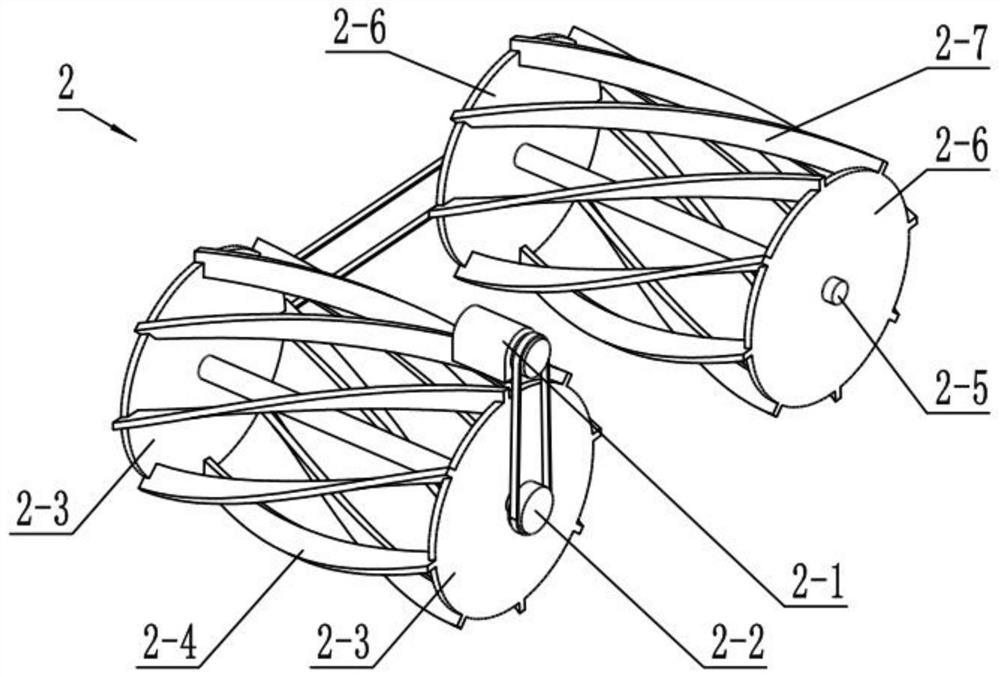

Tunnel adhered marine organism cleaning executing device

PendingCN106737725APrecise Cleaning PowerControl contact forceManipulatorLaser rangingThermodynamics

The invention discloses a tunnel adhered marine organism cleaning executing device which comprises a bracket, a sweeping disc, a laser ranging device and a self-adaptive adjustment device; and a contact state between the tunnel adhered marine organism cleaning executing device and the inner wall of a tunnel is judged according to measurement values, relative to the inner wall of the tunnel, measured by a first laser sensor, a second laser sensor and a third laser sensor, and the self-adaptive adjustment device adjusts a posture of the tunnel adhered marine organism cleaning executing device according to the contact state between the tunnel adhered marine organism cleaning executing device and the inner wall of the tunnel. With the implementation of the tunnel adhered marine organism cleaning executing device, the personal posture can be adjusted in a self-adaptive manner; the contact force between the tunnel adhered marine organism cleaning executing device and the inner wall of the tunnel is controlled precisely and an overload protection function is realized; and the structure is simplified, and safe, efficient and reliable cleaning can be realized.

Owner:TAISHAN NUCLEAR POWER JOINT VENTURE +4

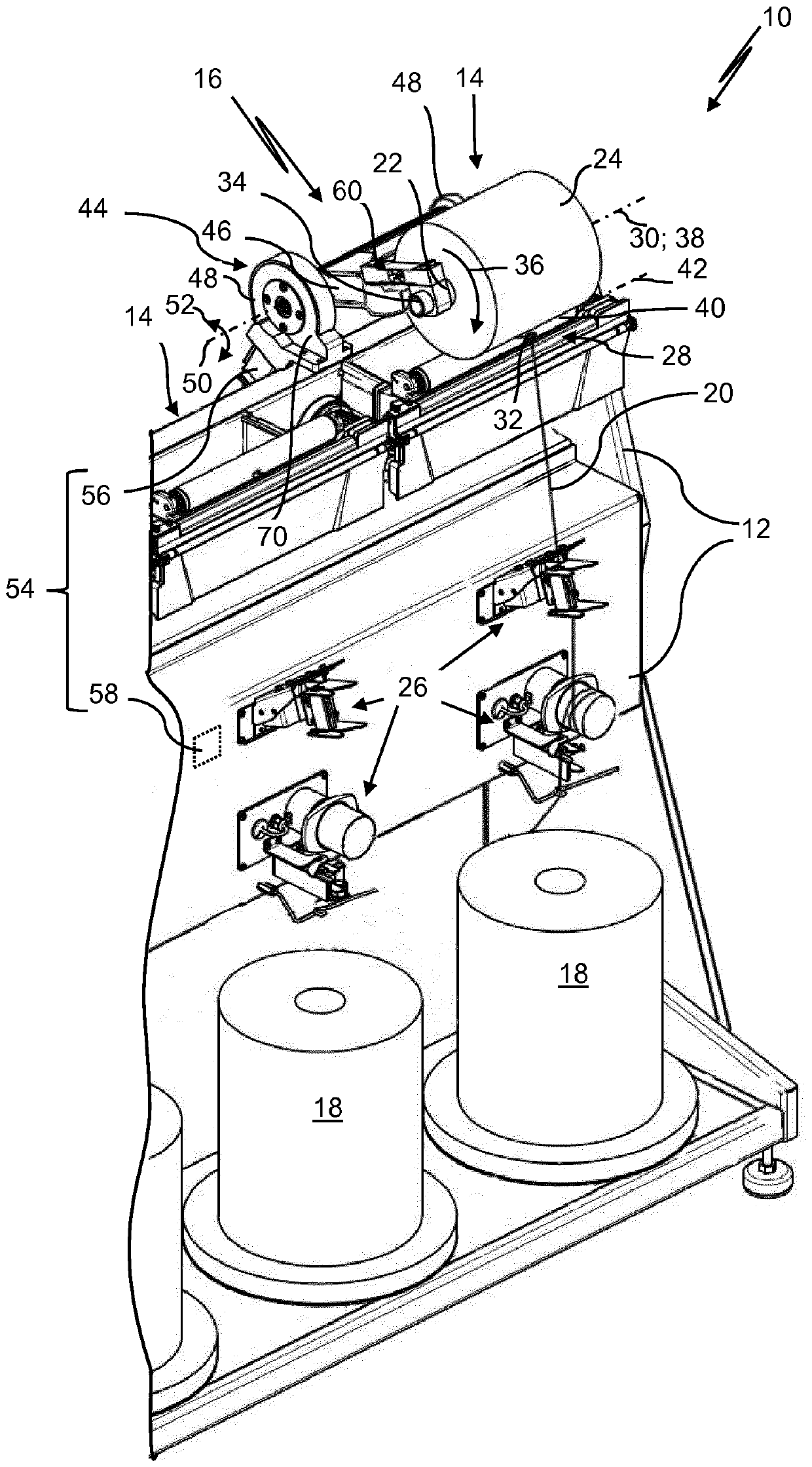

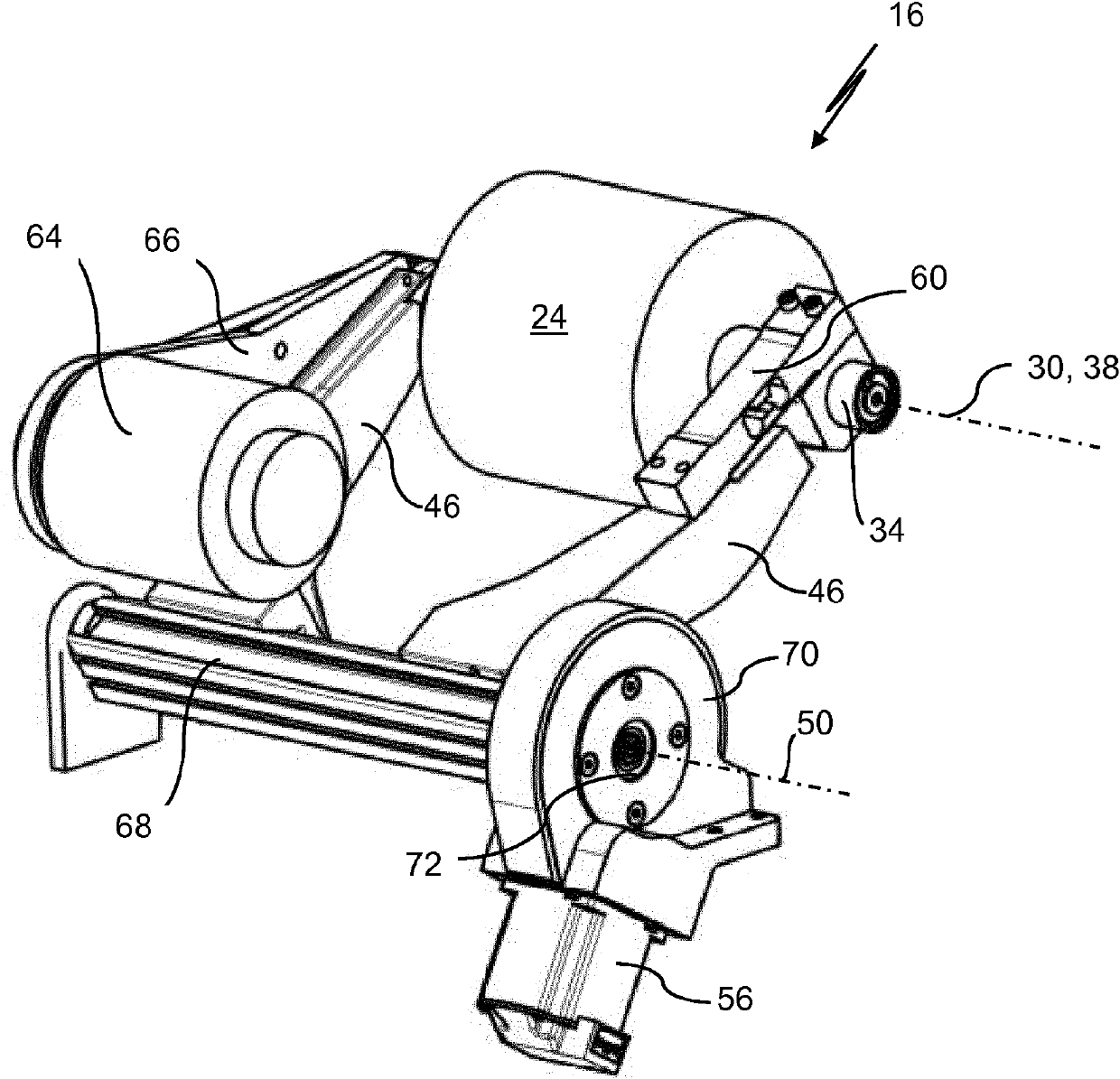

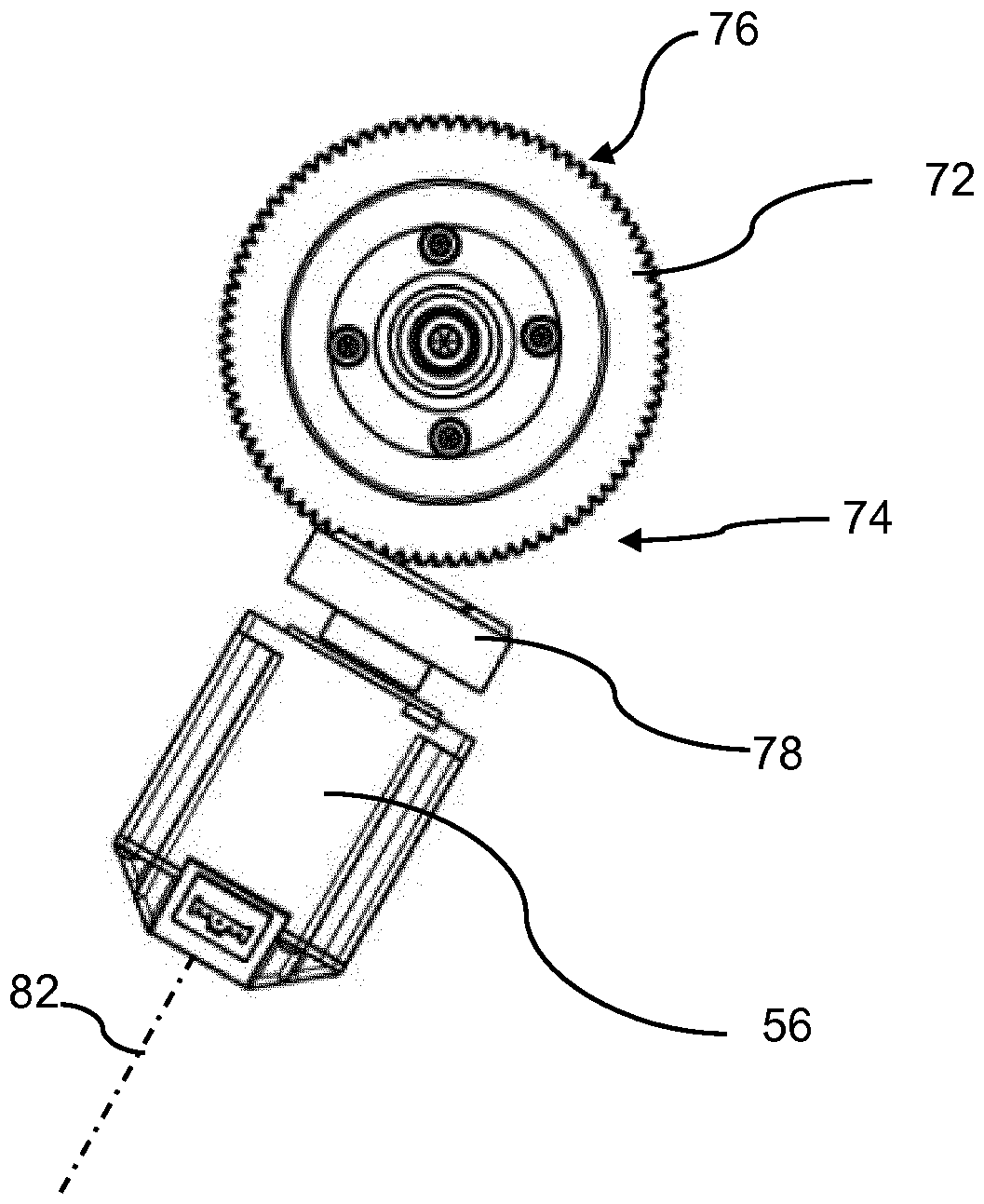

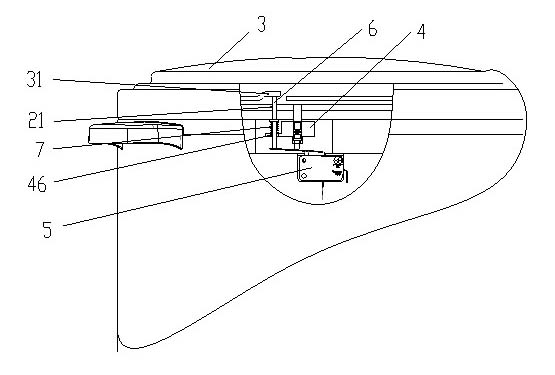

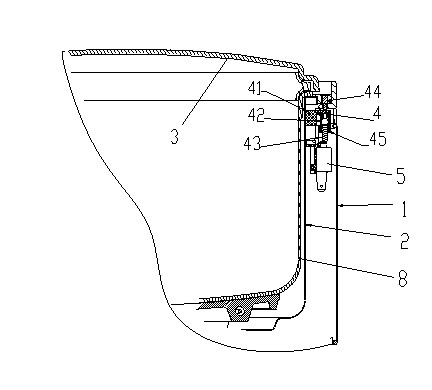

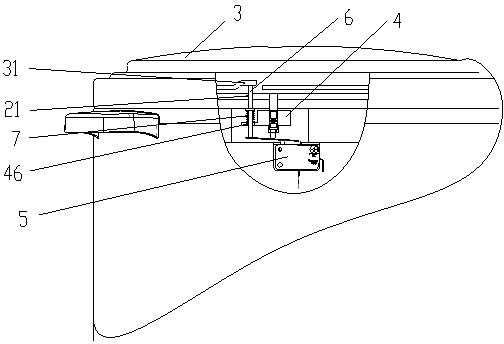

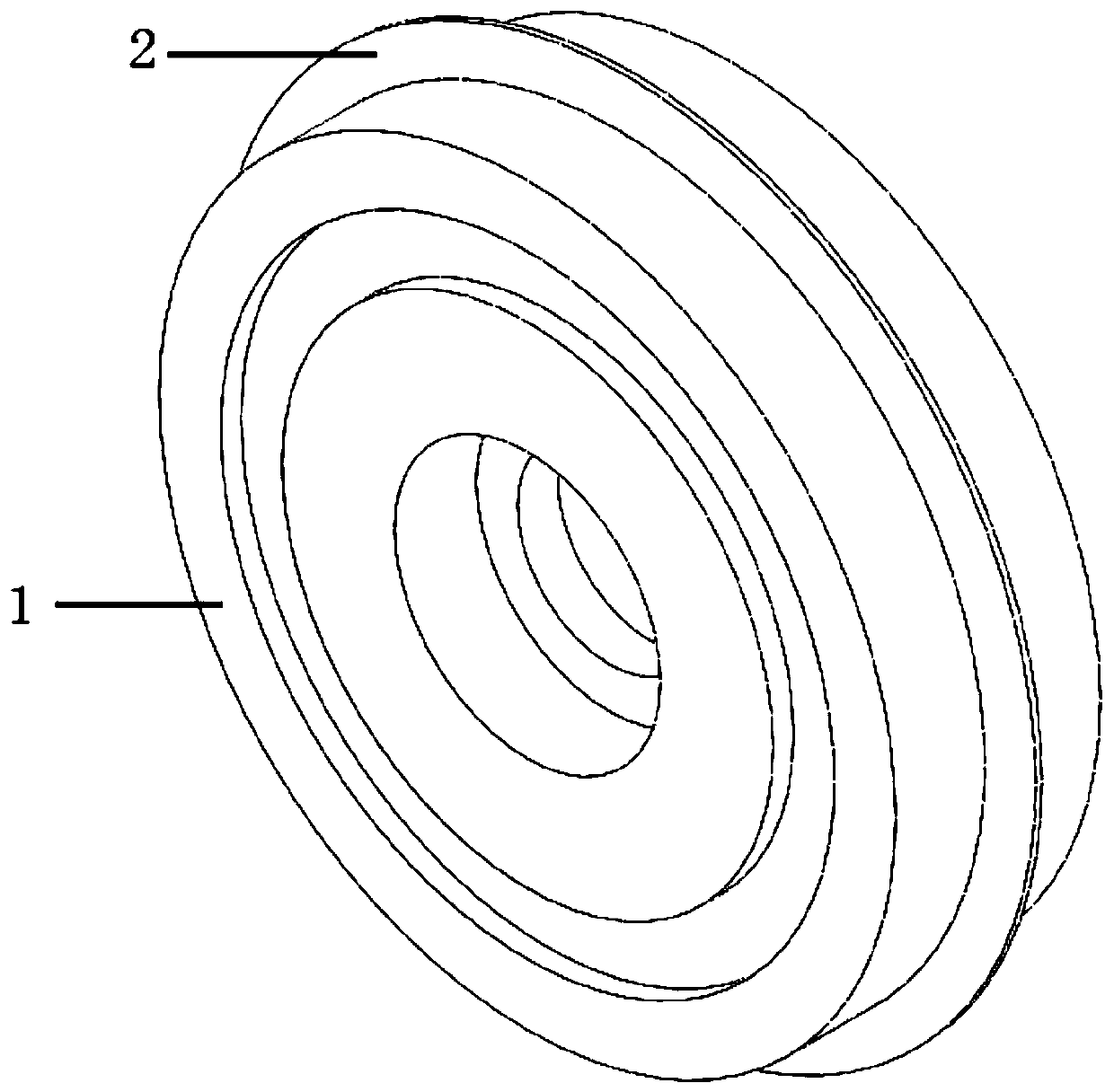

Winding device with support roller and pressing force-regulating device, and thread processing machine

The invention relates to a winding device (16) for winding a thread (20) onto a bobbin tube (22) in order to form a thread coil (24). The winding device comprises a spindle (34) for holding and rotating the bobbin tube (22) about its longitudinal axis (30) and a support roller (40) which rests against the circumferential surface of the thread coil (24) while the thread (20) is being wound. The spindle (34) together with the thread coil (24) can be pivoted relative to the support roller (40) by means of at least one pivotally mounted pivot arm (46). The winding device has a pressing force regulating device (54) comprising an actuator (56) for the pivot arm (46), a controller (58) for actuating the actuator (56), and a bending bar-type load cell (60) paired with the pivot arm (46). The loadcell is used to determine a respective actual value of the pressing force FA of the thread coil (24) against the support roller (40), said actual value being used to regulate the pressing force FA toa specified target value by means of the controller (58) by correspondingly actuating the actuator (56). The invention further relates to a thread processing machine (10) comprising the aforementionedwinding device (16).

Owner:SSM萨罗瑞士麦特雷有限公司

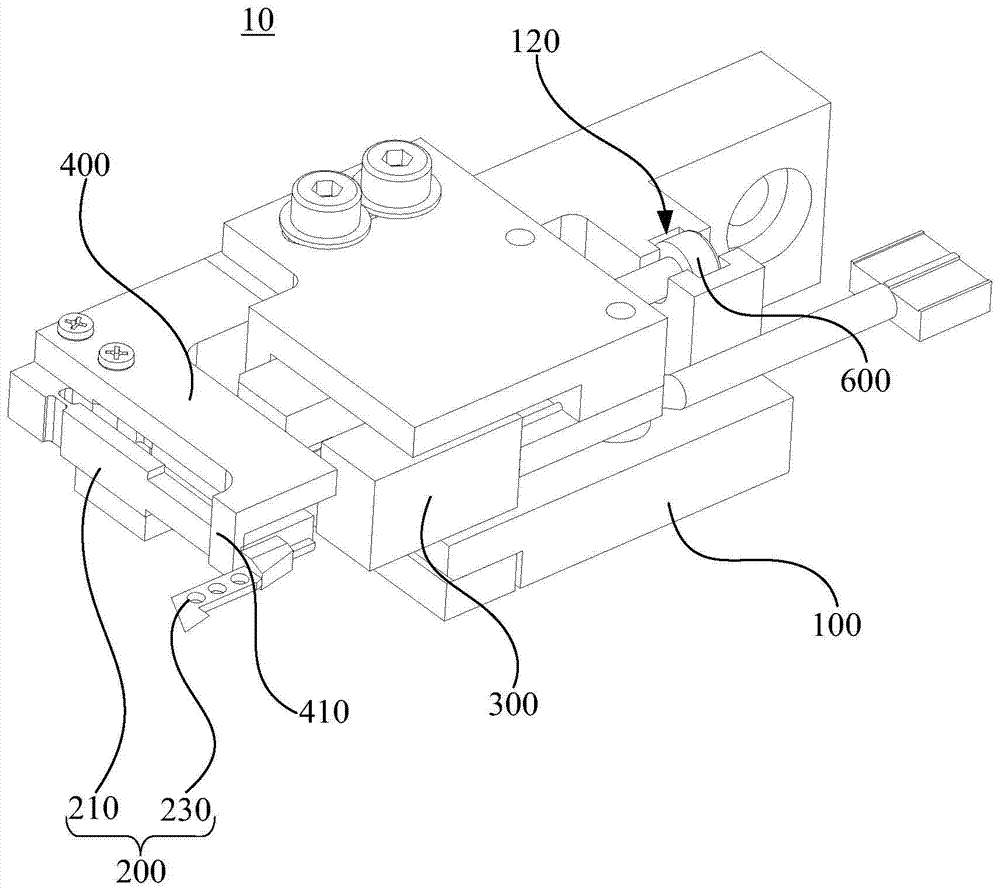

Force feedback closed-loop control composite bonding device

ActiveCN110034032ASmall stretchRelieve stressSolid-state devicesSemiconductor/solid-state device manufacturingLoop controlMagnetostrictive actuator

The invention discloses a force feedback closed-loop control composite bonding device. A micro-moving device is driven by a macro-moving device to perform transverse translation and vertical translation; the micro-moving device comprises a giant magnetostrictive actuator, and the length of the giant magnetostrictive actuator is changed to drive a mounting rod to move, and the telescopic amplitudeof the giant magnetostrictive actuator is very small, so that the giant magnetostrictive actuator is used for driving the mounting rod to accurately move in a small range; a strain gauge is used for detecting the contact force between the mounting rod and a substrate; the strain gauge is used for providing feedback for the micro-moving device, and the telescopic amount of the giant magnetostrictive actuator is controlled according to detection signals; when a chip is relatively far away from the substrate, the macro-moving device moves quickly, the macro-moving device is stopped when reachinga relatively close distance from the substrate, the micro-moving device drives the chip to move, and when the chip contacts the substrate, a contact force is generated, and feedback is formed throughthe contact force, so that larger pressure is avoided on the chip; and the macro-moving device or the micro-moving device is used for driving in different stages of mounting, so that the contact force is accurately controlled on the basis of guaranteeing the mounting efficiency, and the chips are prevented from being crushed.

Owner:GUANGDONG UNIV OF TECH

Detector for detecting pressure and whether cover is closed in place of electric pressure cooker

ActiveCN102113818AGuarantee the safety of useAchieve pressure controlPressure-cookersEngineeringPressure controlled ventilation

The invention discloses a detector for detecting the pressure and whether a cover is closed in place of an electric pressure cooker, which comprises an outer pot, a cover and a pressure regulator with an ejector rod. A switch is fixed on the outer pot, corresponding to a part below the pressure regulator. The ejector rod moves vertically to penetrate through a through hole of the pressure regulator and a through hole in the edge of the outer pot. One end of the ejector rod is contacted with the switch, and the other end of the ejector rod protrudes from the edge of the outer pot. The cover is closed in place. The guide slot of the cover is positioned right above the end of the ejector rod. The pressure regulator is composed of a casing, a spring, an ejector pin and a screw rod. The casing is provided with a through hole. The two ends of the through hole are provided with inwardly extending steps. The ejector pin is installed in the through hole. The step on the ejector pin is limited by the step on one end of the through hole, while one end of the ejector pin is contacted with the switch after passing through the through hole. One end of the spring is sheathed on the ejector pin, while the other end of the spring is sheathed on the step of the through hole on the casing. The detector is characterized by being low in cost and having multiple functions of safeguard, and can be suitable for the pressure control and the safeguard for opening and closing the cover of the electric pressure cooker.

Owner:MIDEA GRP CO LTD

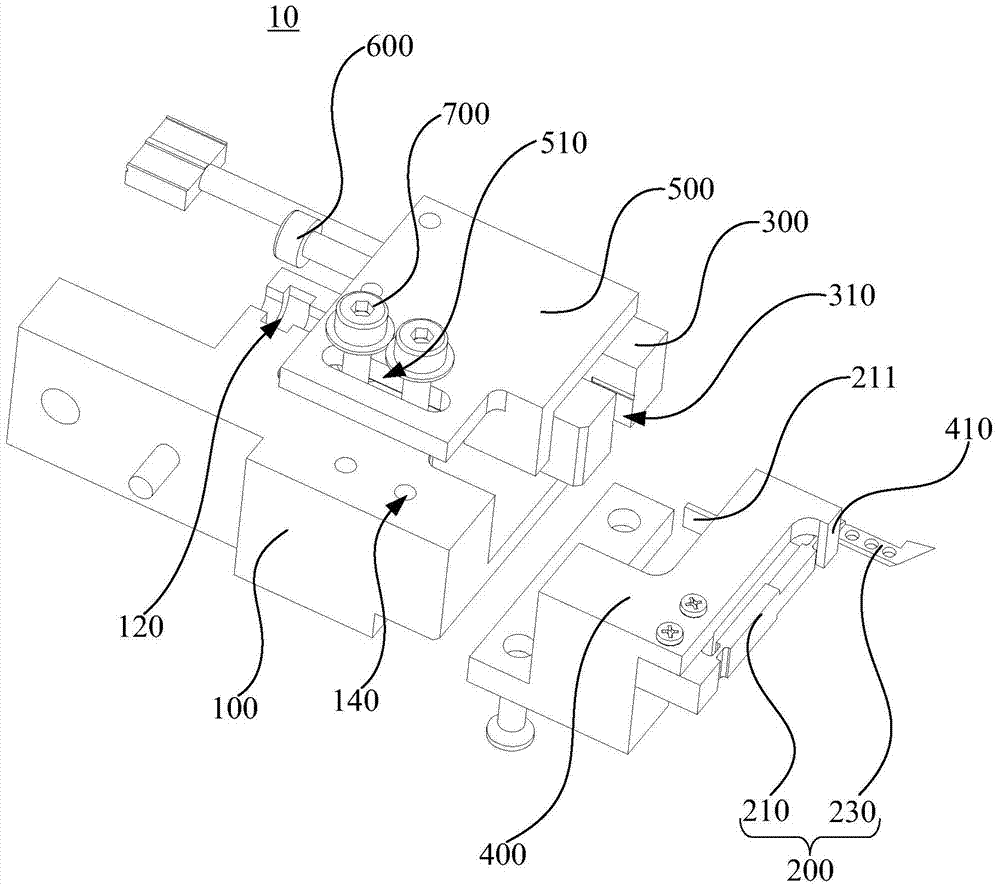

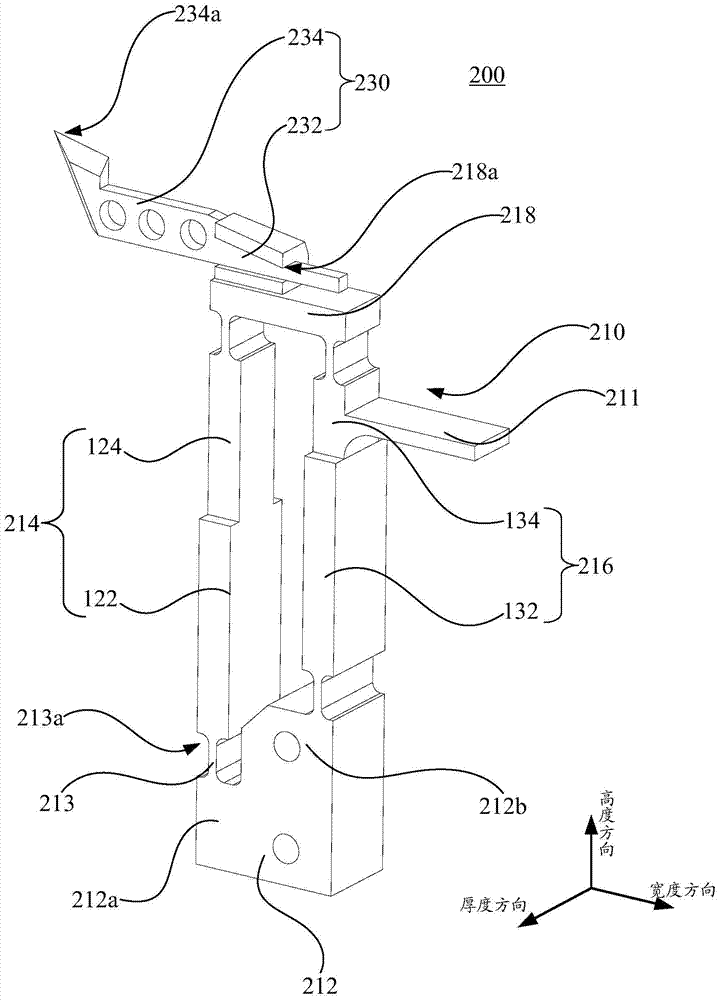

Four-line test probe device and application method thereof

ActiveCN104237579AControl contact forceAvoid tie flowersElectrical measurement instrument detailsElectrical testingShielding blockContact force

The invention relates to a four-line test probe device. The four-line test probe device comprises a traction mechanism, a body fixing base, two test probes and a photoelectric sensor. The two test probes are arranged on the two sides of the body fixing base respectively and respectively comprise an elastic support and a probe head arranged on the elastic support, and the elastic support of one test probe is provided with a protruding light-shielding block. The side, close to the test probe with the light-shielding block, of the photoelectric sensor is provided with a notch, and the photoelectric sensor has catadioptric light emitted from one side of the notch to the other side of the notch. The elastic supports deform in the testing process so that the amount of the catadioptric light shielded by the light-shielding block can be changed, and a changed output voltage is generated through the photoelectric sensor so as to control the pressure on a printed circuit board from the test probes. The four-line test probe device has the advantage that the contact force between the four-line test probe device and the printed circuit board can be effectively controlled. The invention further provides an application method of the four-line test probe device.

Owner:HANS CNC SCI & TECH

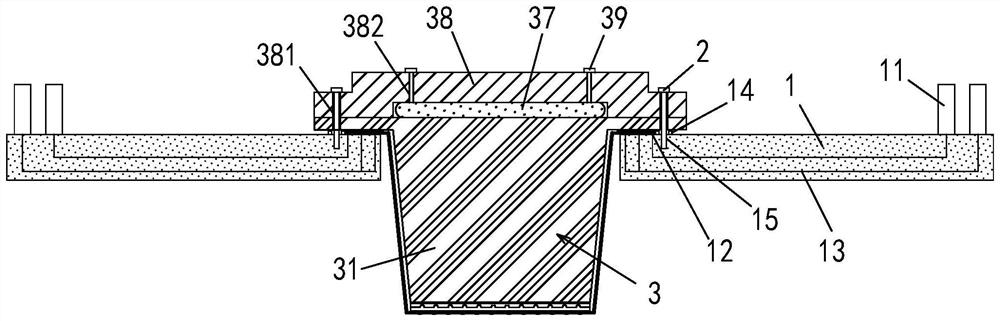

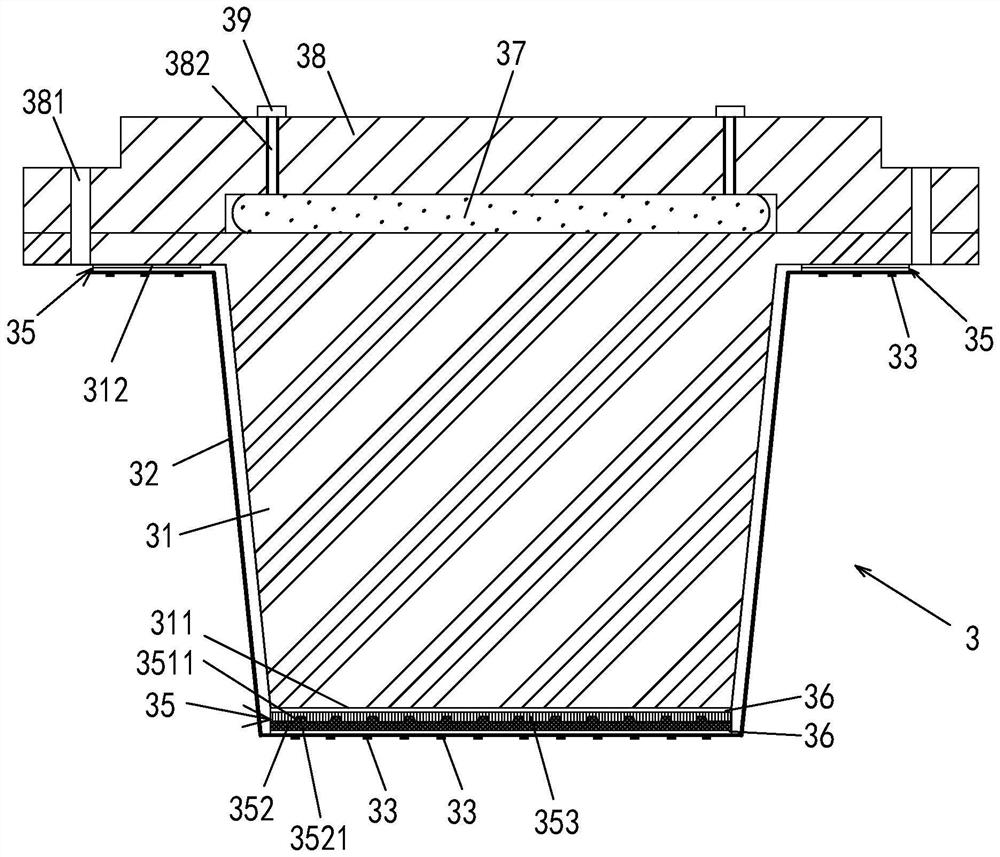

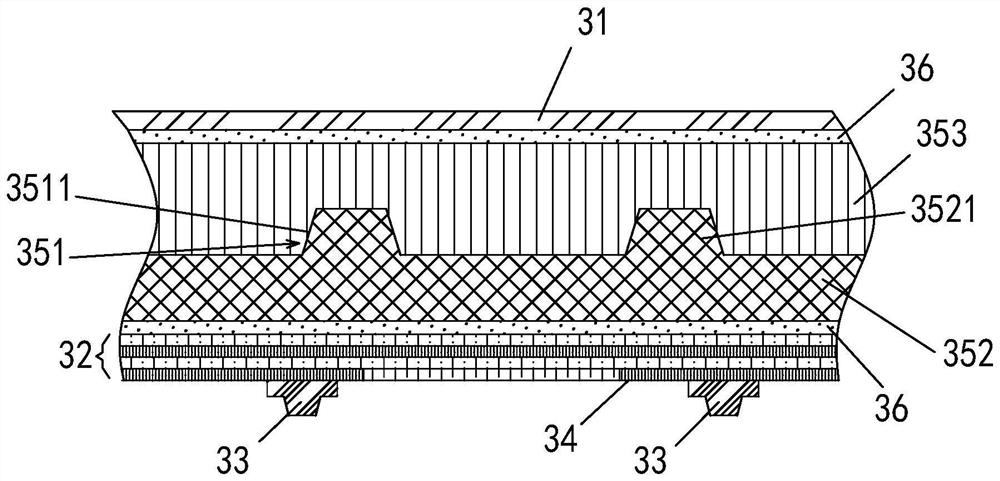

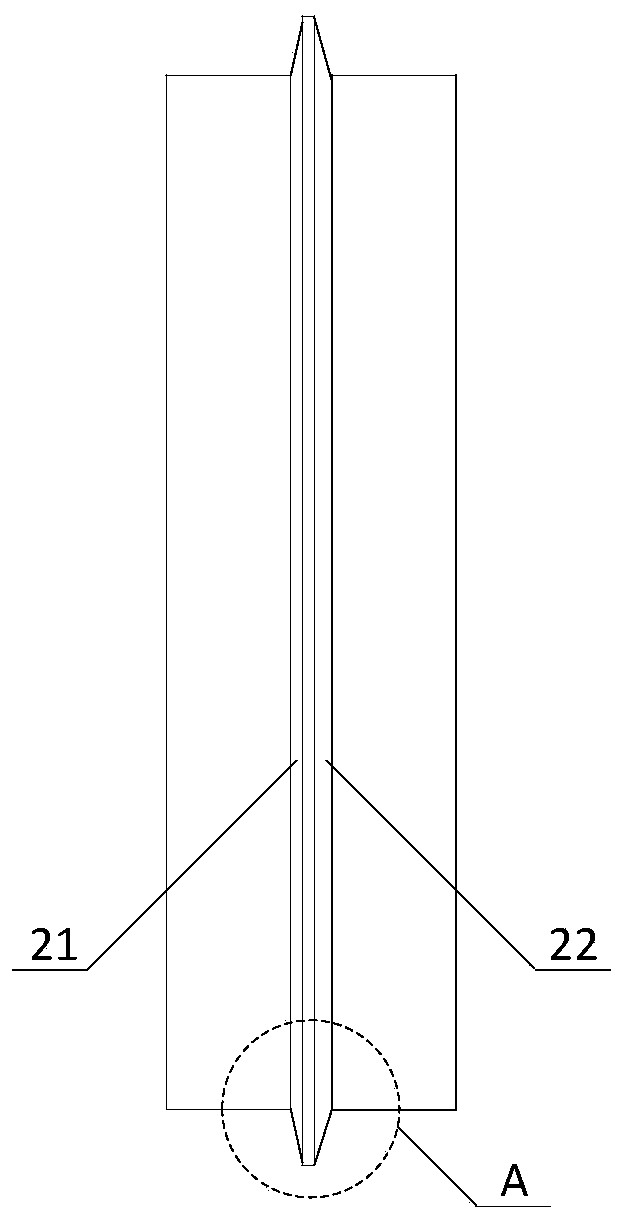

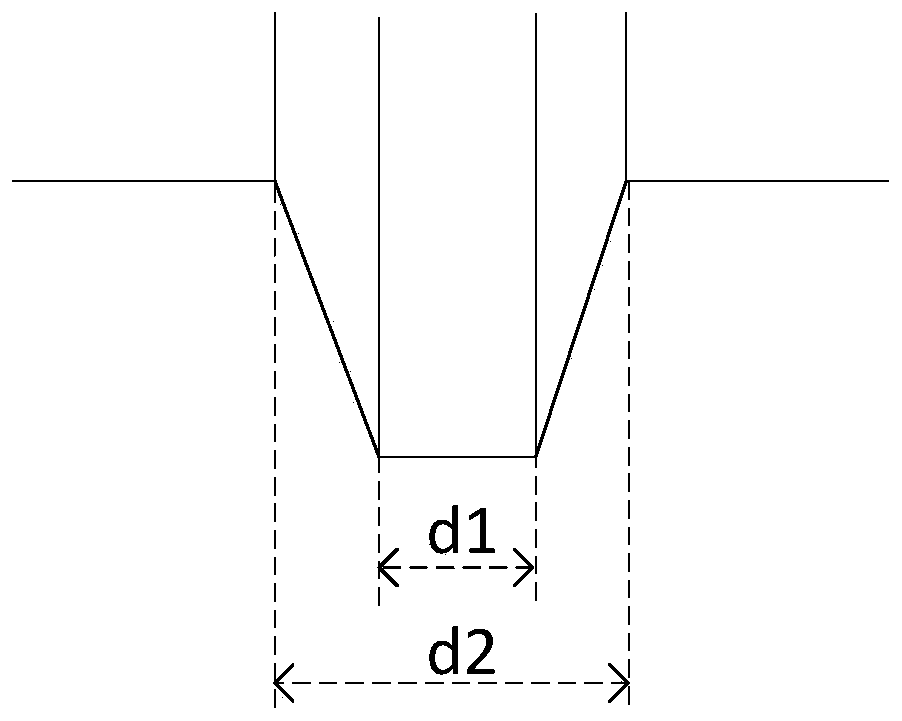

Film probe card and probe head thereof

ActiveCN114200280AReliable electrical contactControl Measure SlipElectrical measurement instrument detailsIndividual semiconductor device testingProbe cardThin membrane

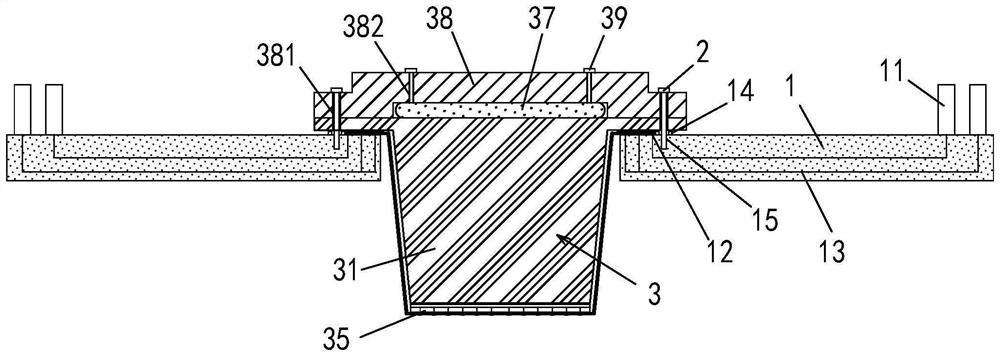

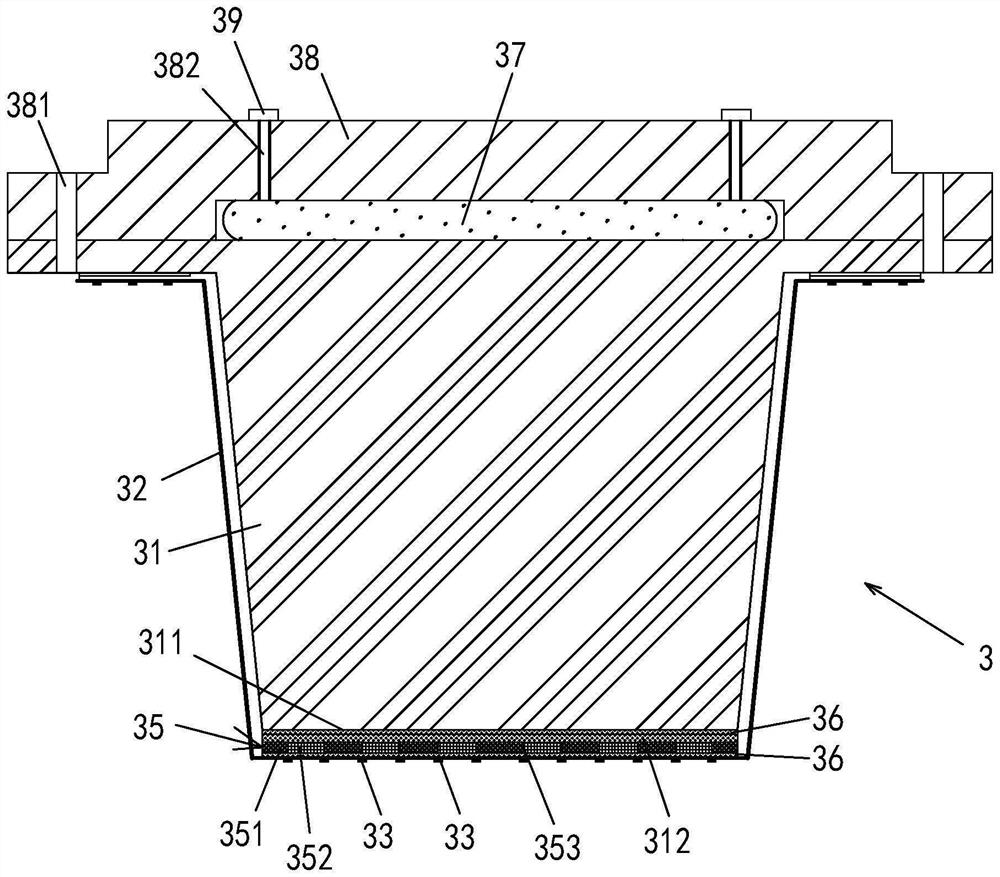

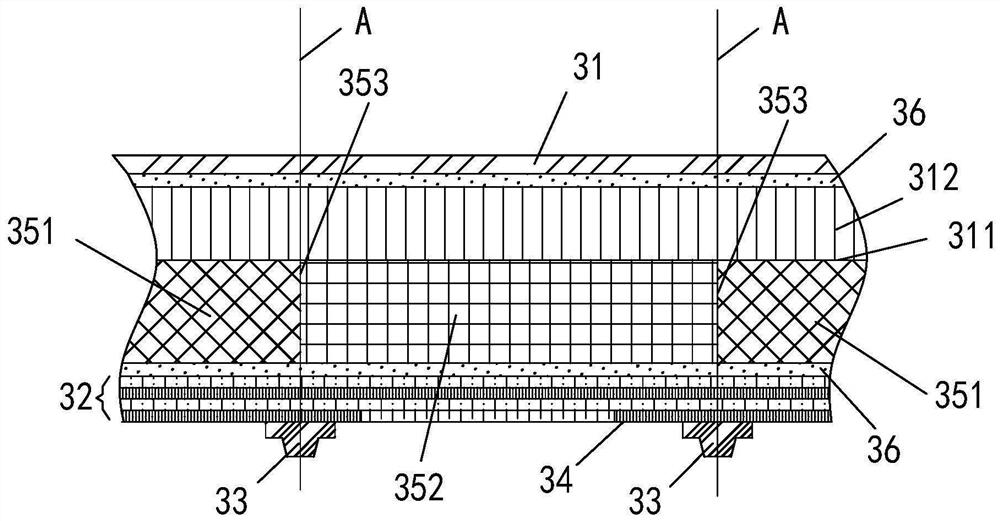

The invention relates to a film probe card and a probe head thereof, the film probe card comprises a film probe head (3), the film probe head (3) comprises a support body (31), a film (32), a probe (33) and an interconnection line (34); a concave supporting structure (35) is arranged between the acting surface (311) of the supporting body (31) and the thin film (32), the concave supporting structure (35) comprises a concave structure (351) and a supporting elastic layer (352), the concave structure (351) comprises one or more concave parts (3511), the positions of the concave parts (3511) correspond to those of the probes (33), and each concave part (3511) is eccentric to the corresponding probe (33); the protruding embedded blocks (3521) of the supporting elastic layer (352) are embedded into the corresponding recesses (3511), so that the portions, located on the two sides of each probe (33), of the supporting elastic layer (352) have a thickness difference.

Owner:MAXONE SEMICON CO LTD

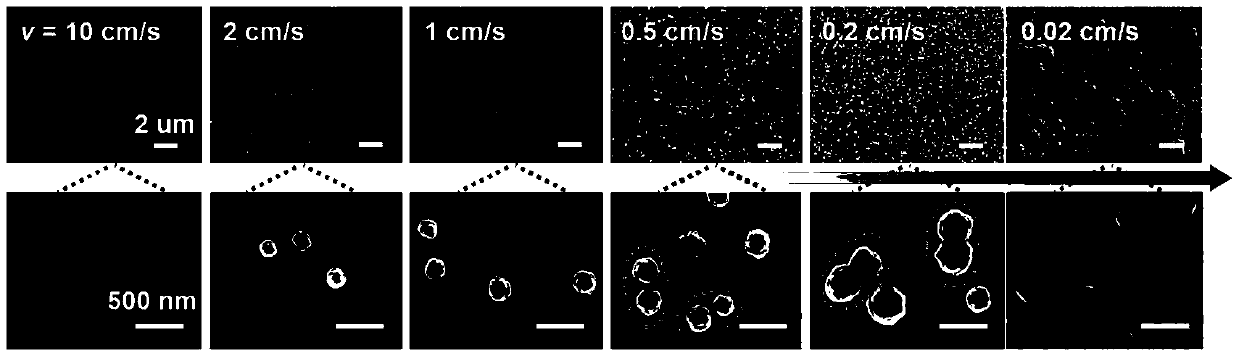

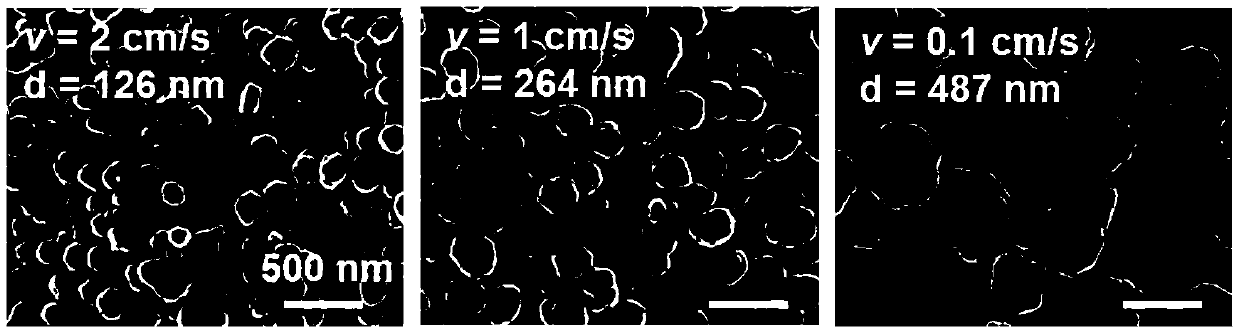

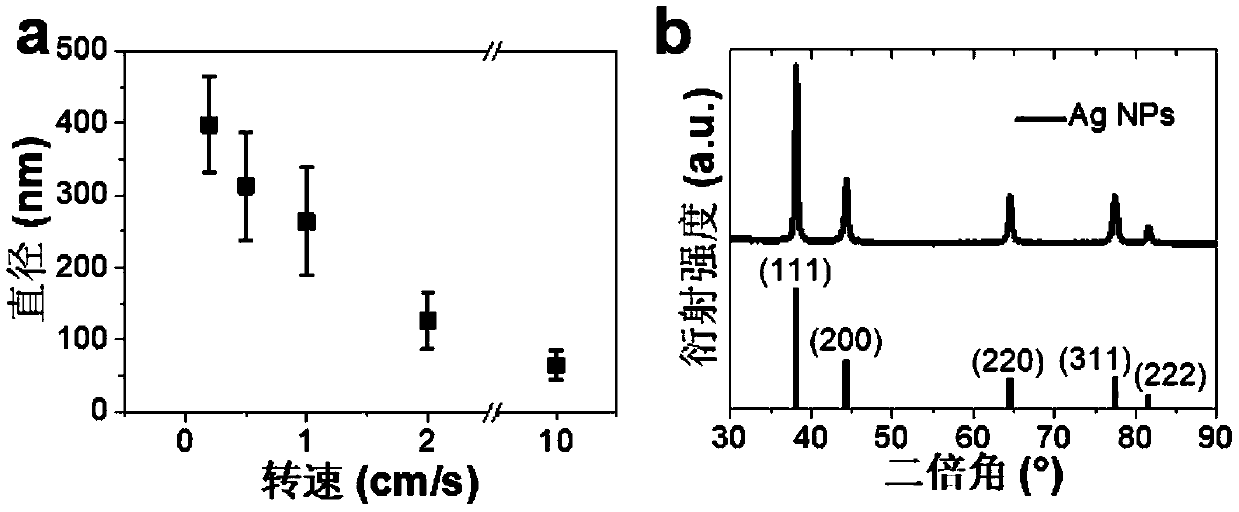

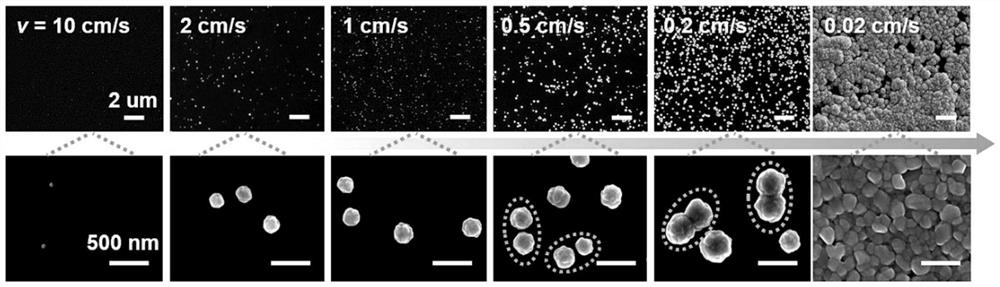

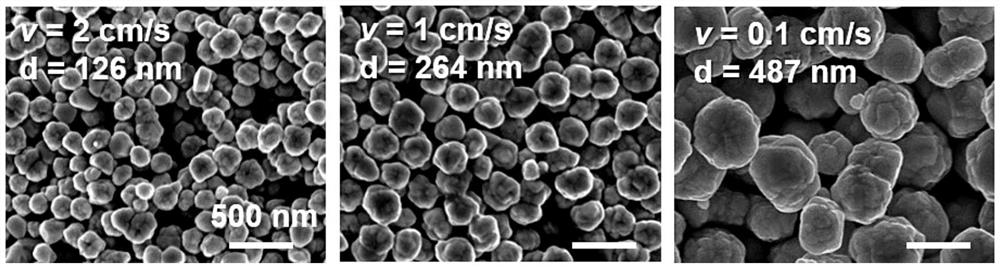

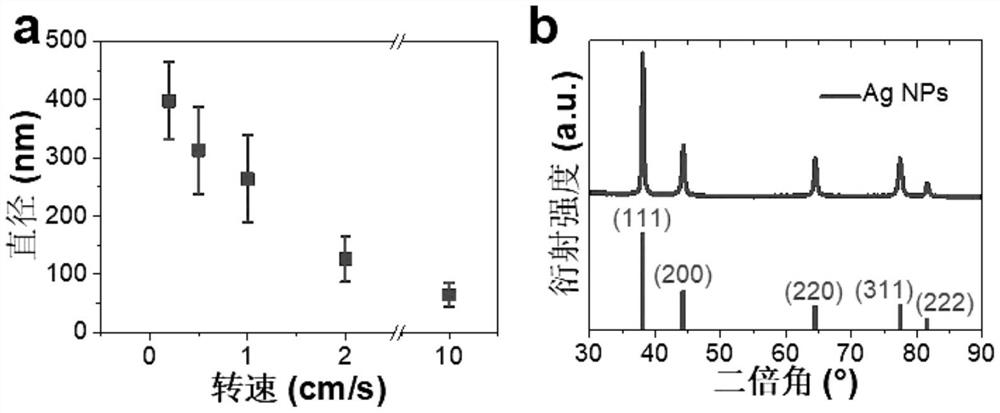

Method for preparing metal particles through continuous electrochemical deposition

ActiveCN110760892AEvenly distributedSmall particle sizeElectrolysis componentsNanotechnologyElectrolytic agentActive agent

The invention discloses a method for preparing metal particles through continuous electrochemical deposition. The method comprises the main steps: firstly, by controlling electrodeposition parameters,evenly-dispersed metal particles are electrodeposited on a movable substrate; then the movable substrate carry the electrodeposited metal particles, and the substrate and materials on the substrate are cleaned or subjected to surface treatment; and finally, the particles on the surface of the substrate are stripped through methods such as physical stripping, and the particles are dispersed in a solution to be collected. The method has the advantages that the metal particles are prepared through an electrodeposition electronic reduction method, wherein the particle diameter of the metal particles is even, the metal particles are evenly dispersed, and the surfaces of the metal particles are free of active agents; and contact force between the particles and the substrate is small so that theparticles can be collected through simple physical stripping, in the whole synthesis process, the particle size is controllable, an electrolyte can be reutilized, compared with a traditional method for synthesizing the metal particles, the cost is low, and the size is controllable.

Owner:TSINGHUA UNIV

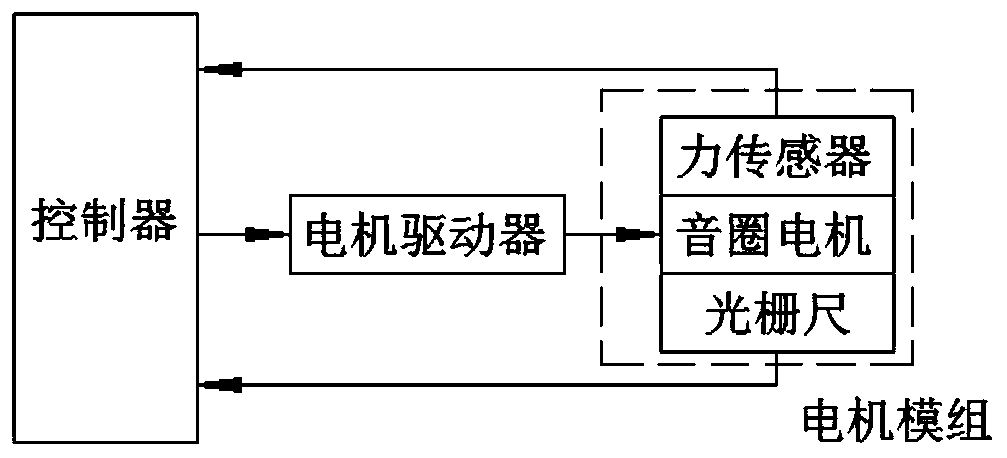

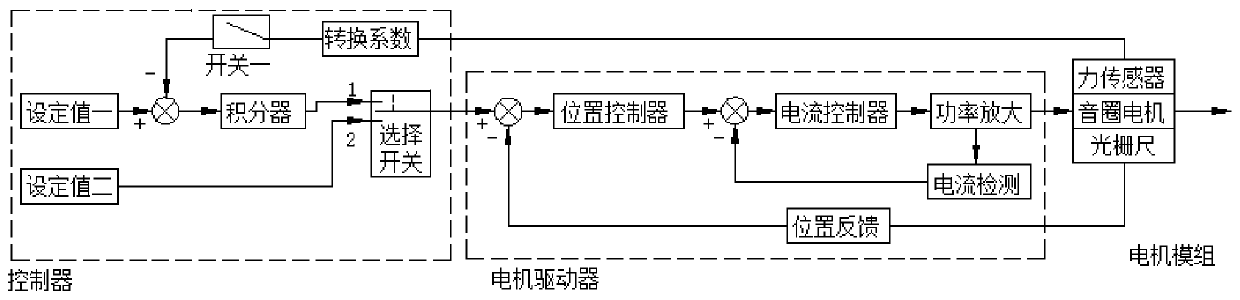

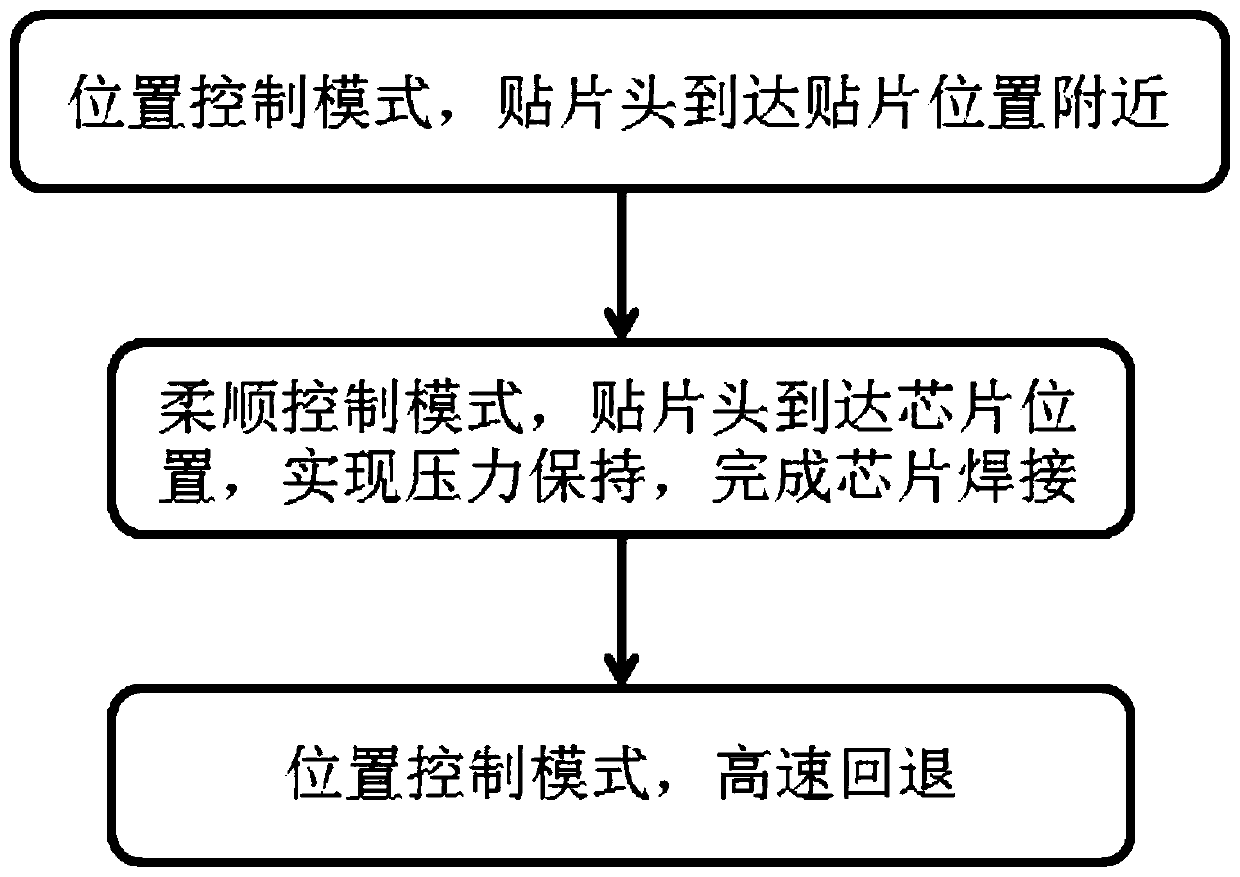

Voice coil motor control system and method for chip mounter

ActiveCN111478631AAchieve control speedAchieve compliant controlDC motor speed/torque controlAC motor controlAutomatic controlIntegrator

The invention discloses a voice coil motor control system for a chip mounter and a voice coil motor control method for a chip mounter, which are applied to the technical field of automatic control. The system comprises a controller, a motor driver and a motor module; the controller outputs a control signal to the motor driver, the motor driver outputs a driving current to the motor module, and themotor module feeds back a force signal and a position signal to the controller and the motor driver respectively and controls a chip mounting head on the chip mounter to reach and be far away from achip position; and a first switch and a selection switch are arranged in the controller and used for switching control modes. The controller is provided with an integrator, position control, speed control and compliance control of the voice coil motor are achieved by controlling a selection switch and a first switch in the controller, and the three control modes of the position control mode, the speed control mode and the compliance control mode can be switched in real time according to actual needs.

Owner:NANJING INST OF TECH

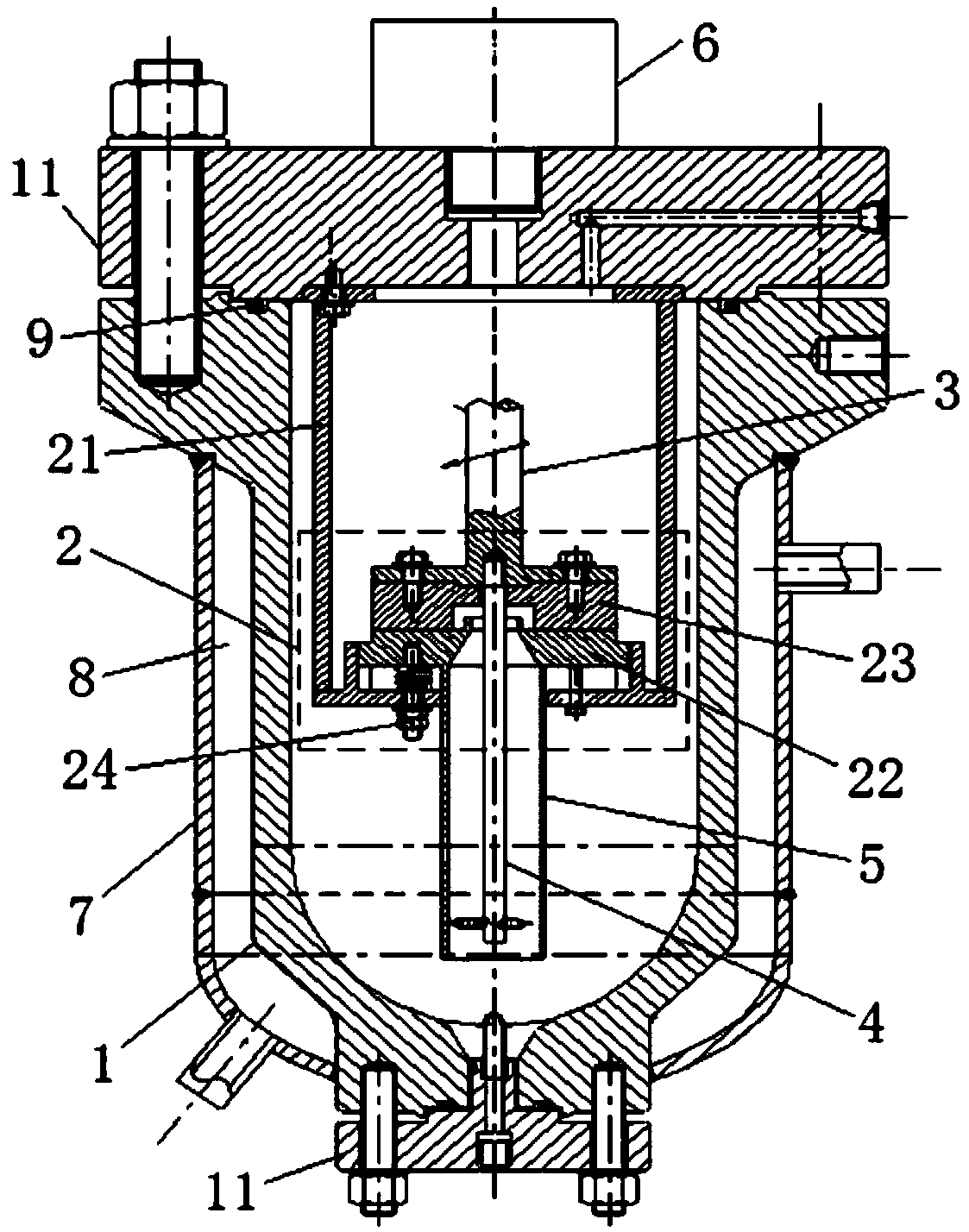

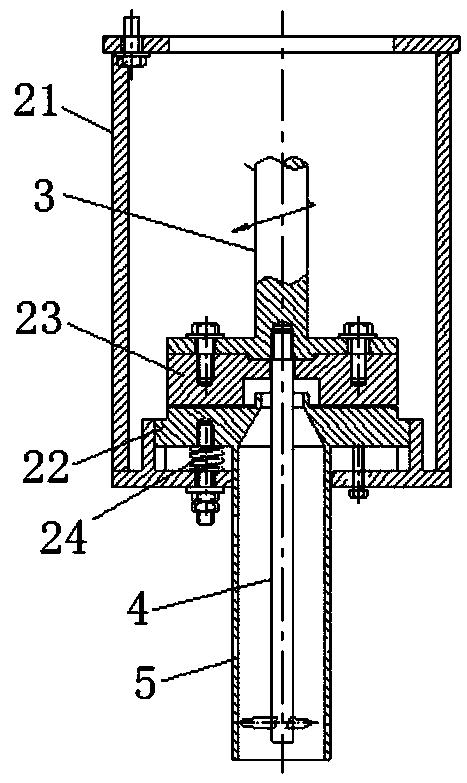

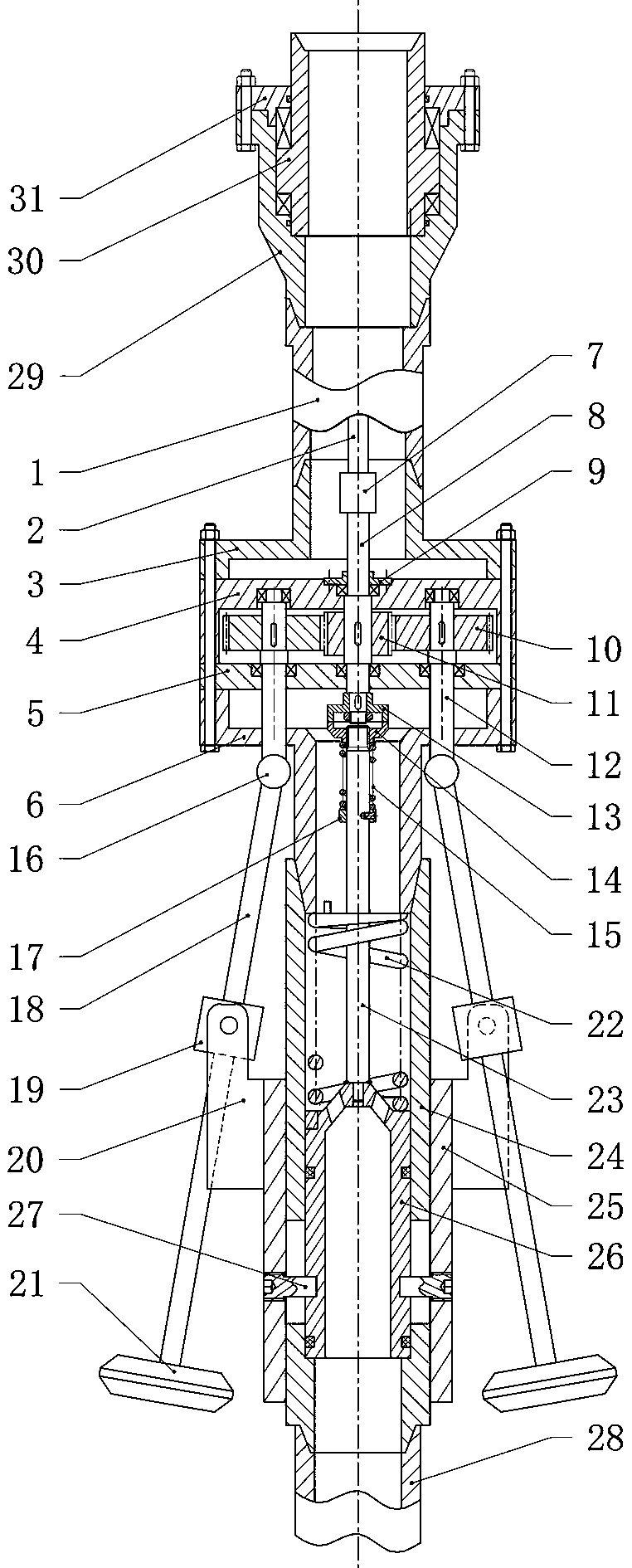

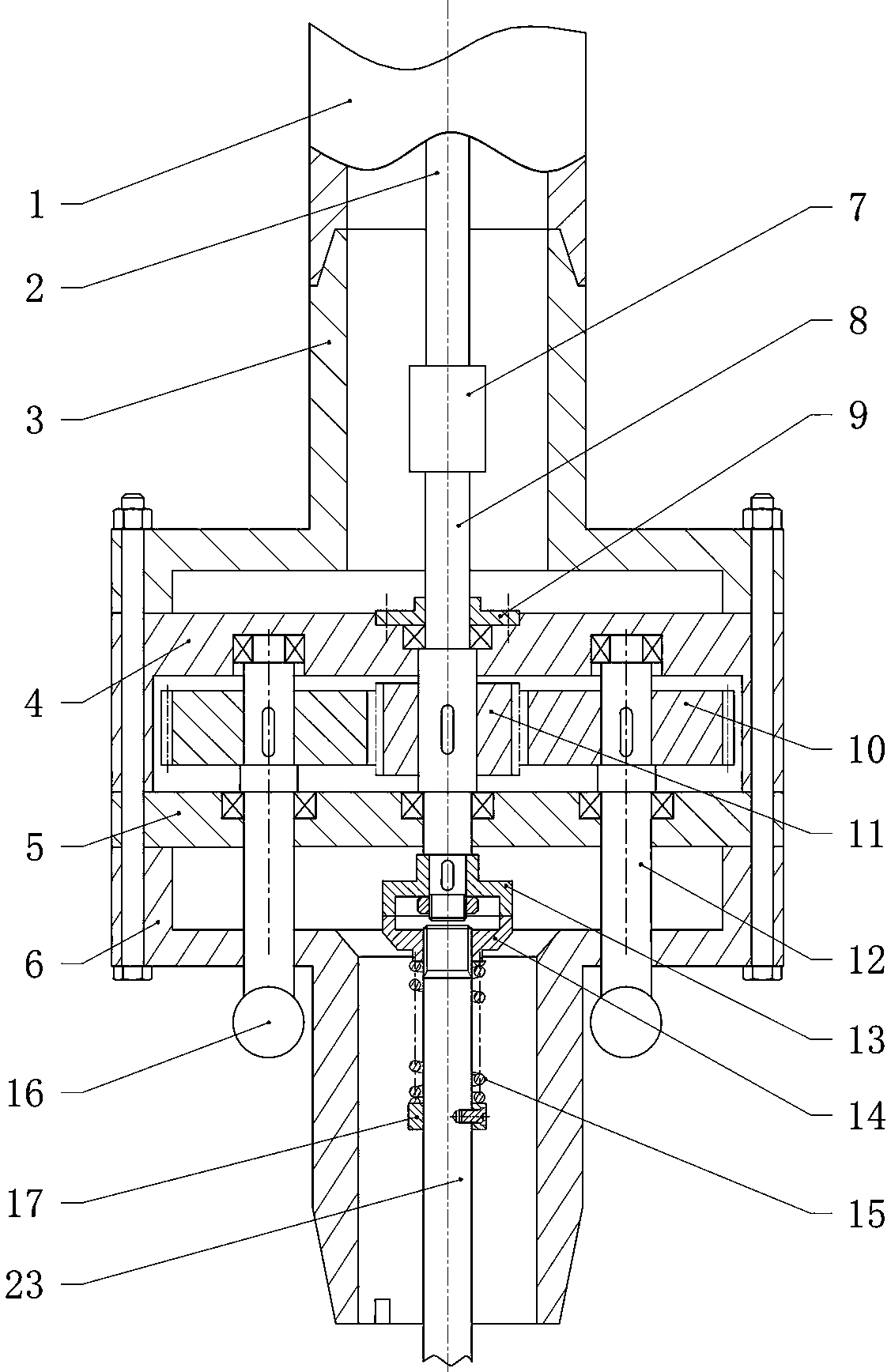

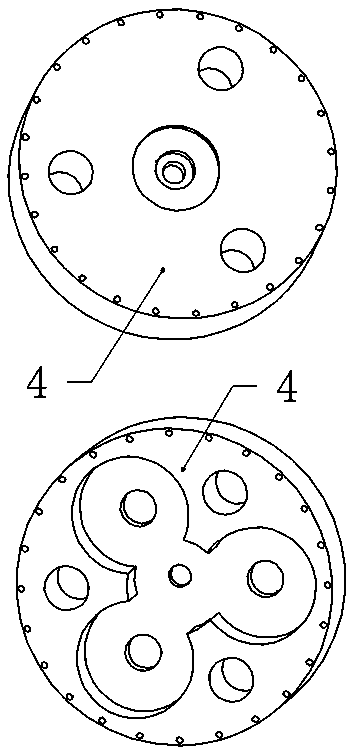

A coiled tubing turbocharged torque increasing tool

InactiveCN105888589BReduce the number of seriesShorten the lengthConstructionsBorehole/well accessoriesTransfer caseCoiled tubing

The invention relates to a turbine pressurizing and torque-increasing tool for continuous oil pipes. The tool can convert torque of a turbine drill into drilling pressure and torque of a front-end tool. The technical scheme includes that a rotary drum is arranged in a central sleeve and is driven to rotate by the turbine drill. The rotary drum is externally provided with spiral grooves and drives a slide sleeve to axially move, and the slide sleeve stretches axles through support arms, so that wheels are pressed on the well wall or the bushing. The turbine drill drives the three wheels to rotate through a transfer case. An input shaft of the transfer case drives the rotary drum to rotate through a friction ring. The opening angle of the axles of the wheels can be automatically and steplessly adjusted so as to adapt to changes of the hole diameter. The torque of the turbine drill can be increased through the transfer case, so that better conditions can be provided for the front-end drilling tool.

Owner:SOUTHWEST PETROLEUM UNIV

A method for preparing metal particles by continuous electrochemical deposition

ActiveCN110760892BControl contact forceAvoid the effects of reuseElectrolysis componentsNanotechnologyElectrolytic agentActive agent

A method for preparing metal particles by continuous electrochemical deposition. The main steps of the method include: firstly, electrodepositing uniformly dispersed metal particles on a movable substrate by controlling the electrodeposition parameters; and then carrying the electrodeposited metal particles on the movable substrate. The substrate and the above materials are cleaned or surface treated; finally, the particles on the surface of the substrate are peeled off by physical stripping and other methods, and the particles are dispersed in the solution for collection. The advantages of the present invention are that metal particles with uniform particle size, uniform dispersion and no surface active agent are prepared by means of electrodeposition electron reduction, and the contact force between the particles and the substrate is small, and the particles can be collected by simple physical peeling. The size of the diameter is controllable, and the electrolyte can be reused. Compared with the traditional method of synthesizing metal particles, the cost is low and the size is controllable.

Owner:TSINGHUA UNIV

Detector for detecting pressure and whether cover is closed in place of electric pressure cooker

ActiveCN102113818BGuarantee the safety of useAchieve pressure controlPressure-cookersEngineeringPressure controlled ventilation

Owner:MIDEA GRP CO LTD

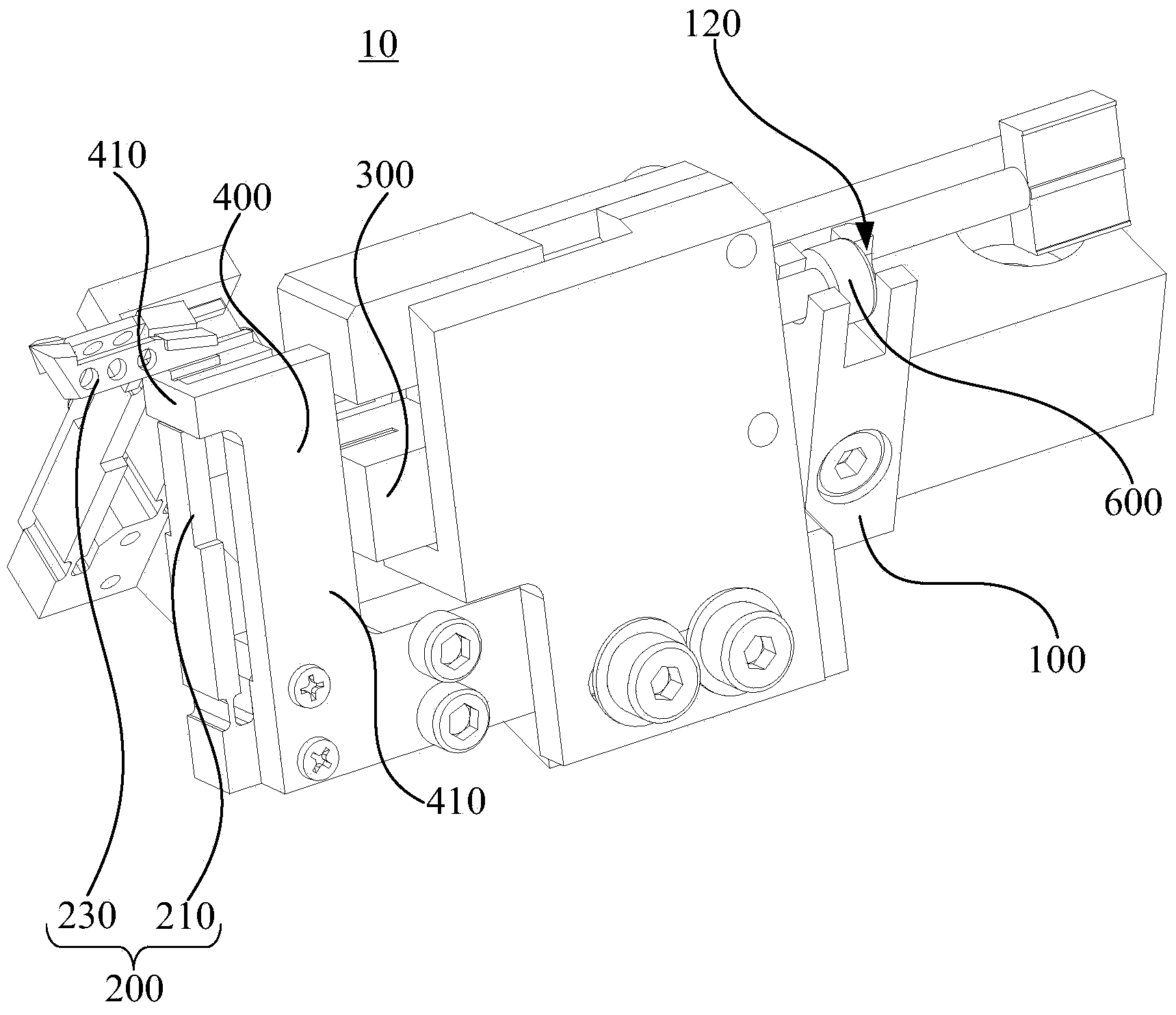

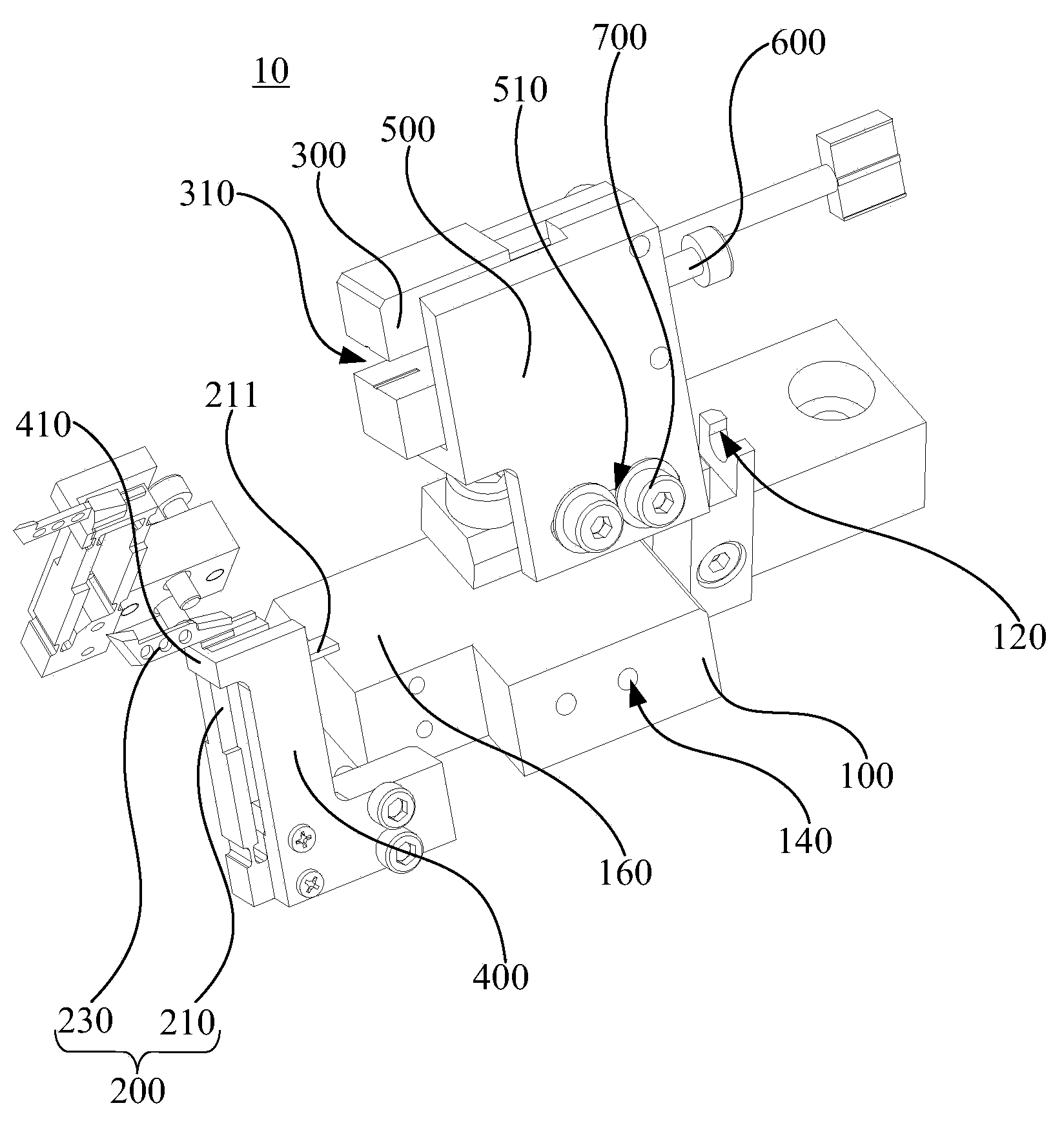

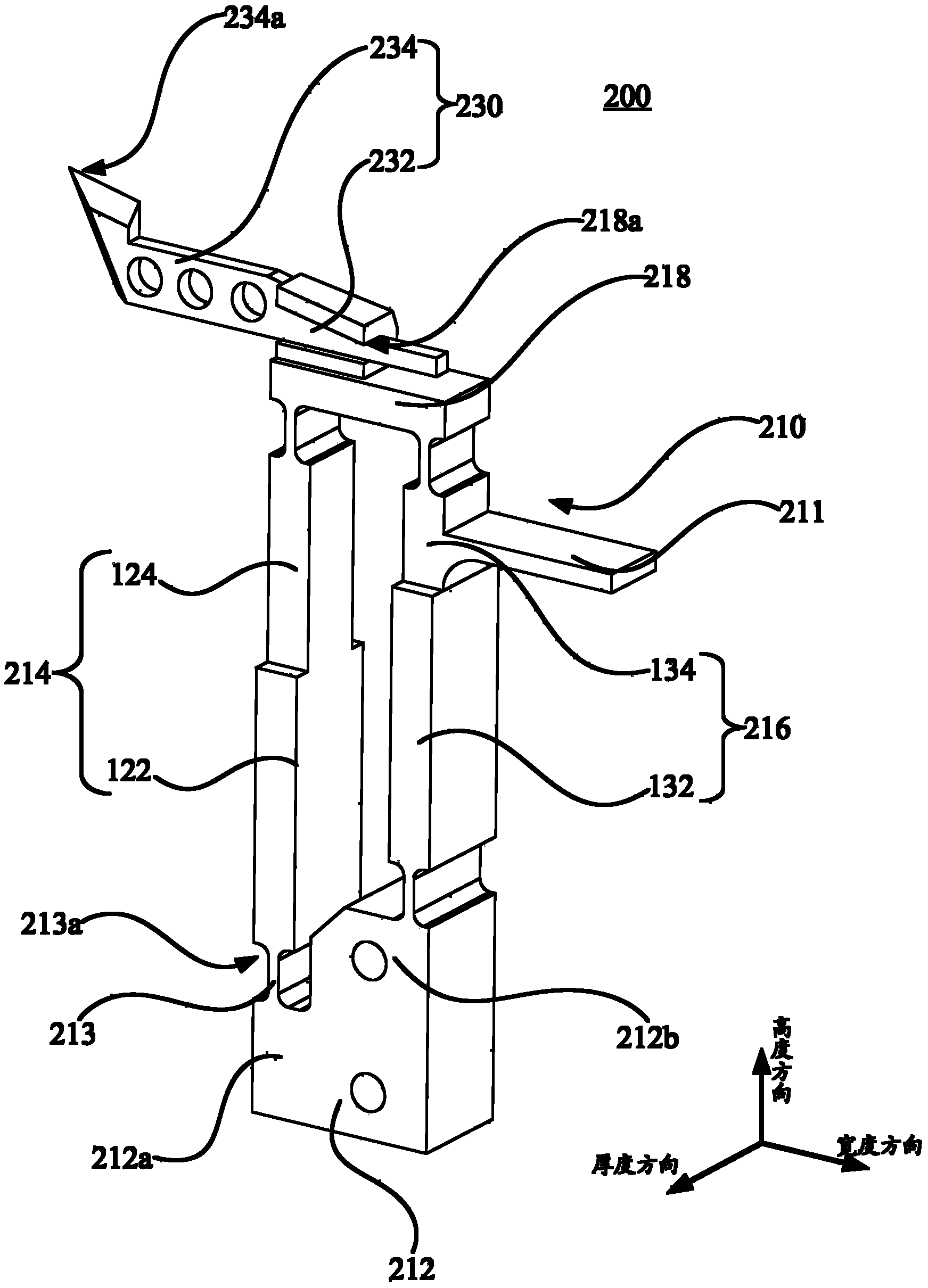

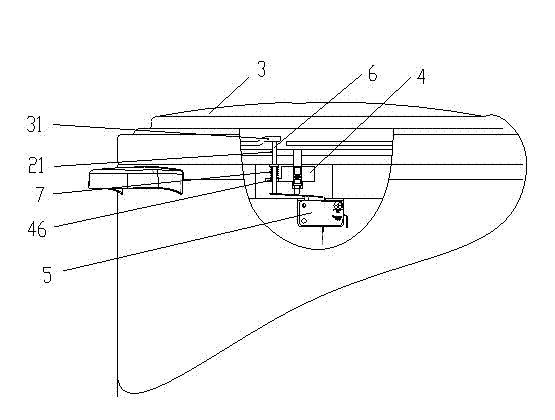

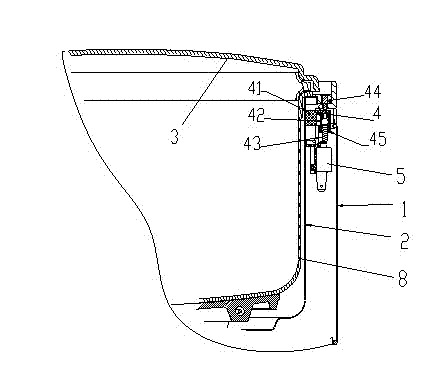

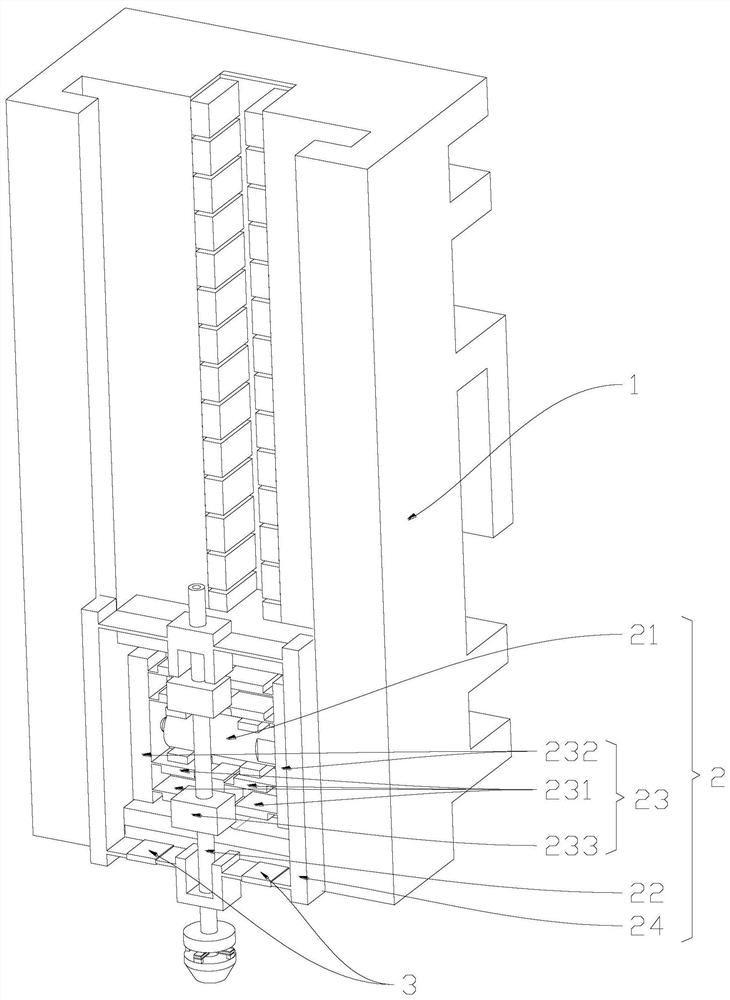

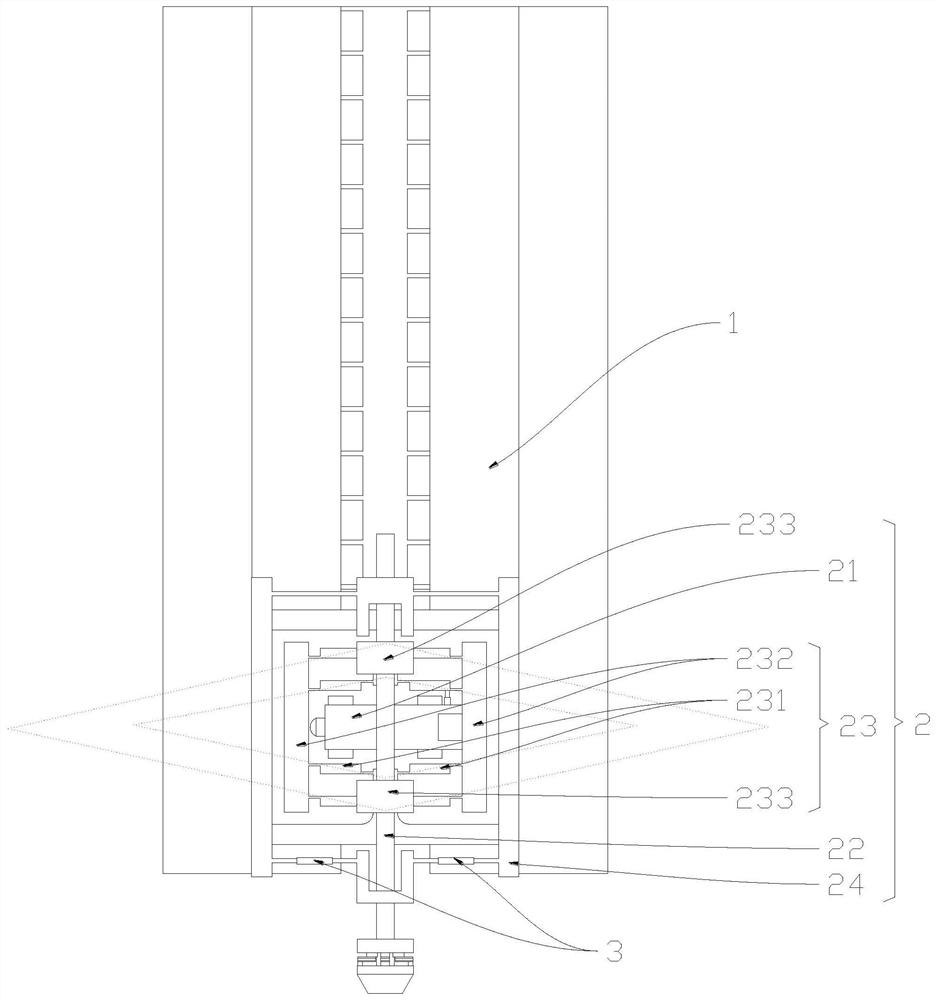

Lens feeding device capable of controlling force

PendingCN109368255ALarge range of controlControl contact forceConveyorsControl devices for conveyorsElectric machineryEngineering

The invention relates to a lens feeding device capable of controlling force. The lens feeding device comprises a clamping seat provided with an upper limiting block and a clamping jaw and further comprises a base, a voice coil motor, an encoder, a servo driver and a controller, wherein the base is arranged right below the upper limiting block; the voice coil motor and the encoder are fixedly arranged on the base and are in circuit connection with the servo driver; the servo driver is in circuit connection with the controller; the motor stator of the voice coil motor is fixed on the base; a workpiece placement seat is arranged at the top end of the motor rotor of the voice coil motor; an induction component of the encoder is fixedly connected with the motor rotor; and a sliding mechanism isarranged between the voice coil motor and the base. The lens feeding device is compact, small and exquisite in structural design, precisely controls workpiece impact force through controlling the movement speed of the motor rotor by stages, enlarges the control range, improves the feeding stability, reduces the damage rate and improves the applicability.

Owner:珠海市硅酷科技有限公司

Method for realizing slip measurement of film probe

PendingCN114188309AReliable electrical contactControl Measure SlipSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElastomerThin membrane

The invention relates to a method for realizing slip measurement of a thin film probe. The method is characterized in that an elastomer layer is arranged between a rigid acting surface in a thin film probe head and a thin film on which a probe is arranged; the elastic body layer is arranged on the axial plane of the probe, any axial line penetrating through the probe is taken as a boundary line, and the elastic force of one side of the elastic body layer is not equal to the elastic force of the other side of the elastic body layer, so that the probe can deflect during testing to generate measurement slippage so as to penetrate through or push away oxide on the surface layer of a tested chip, and more stable contact is realized.

Owner:MAXONE SEMICON CO LTD

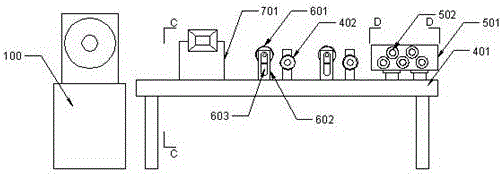

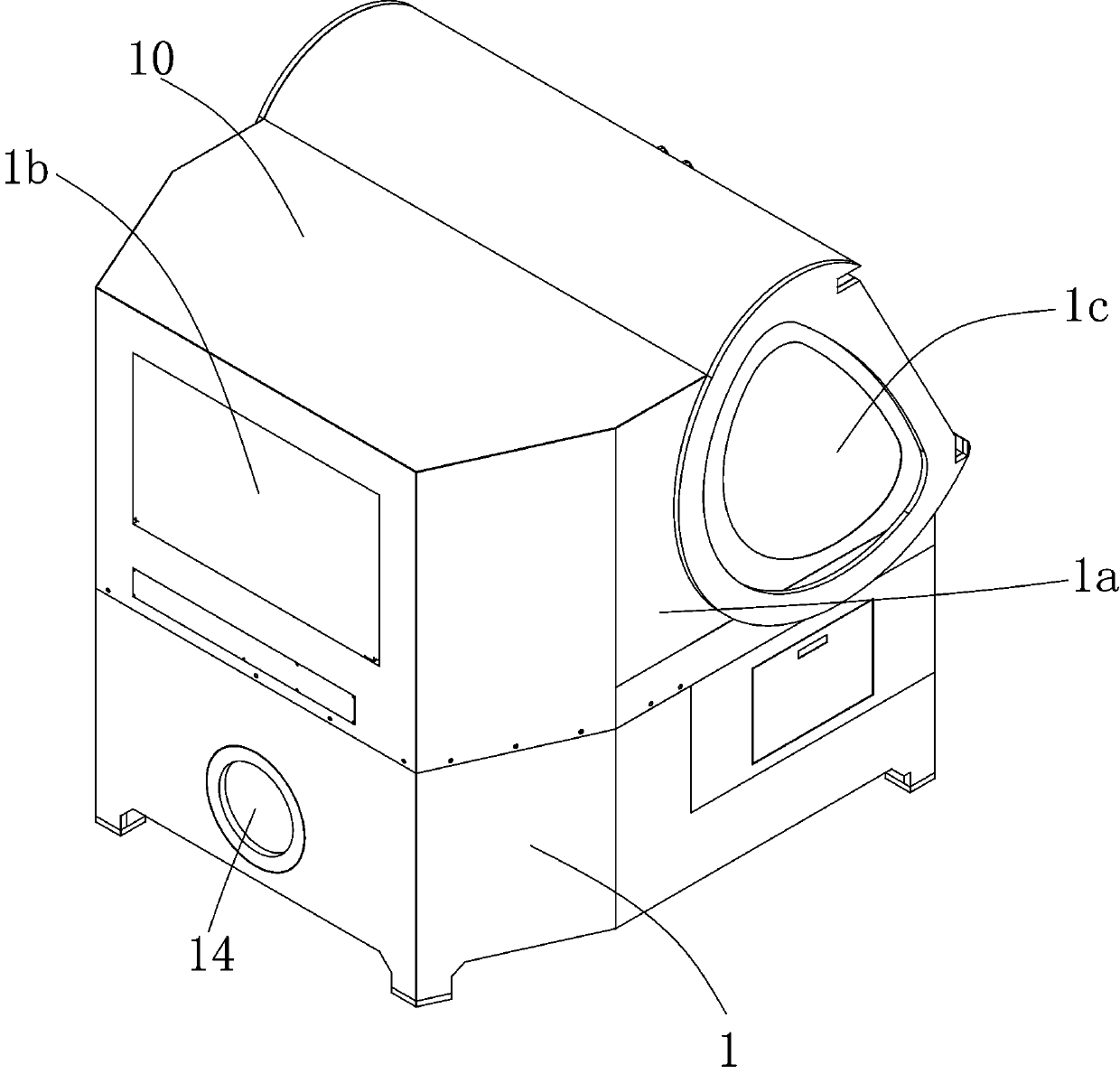

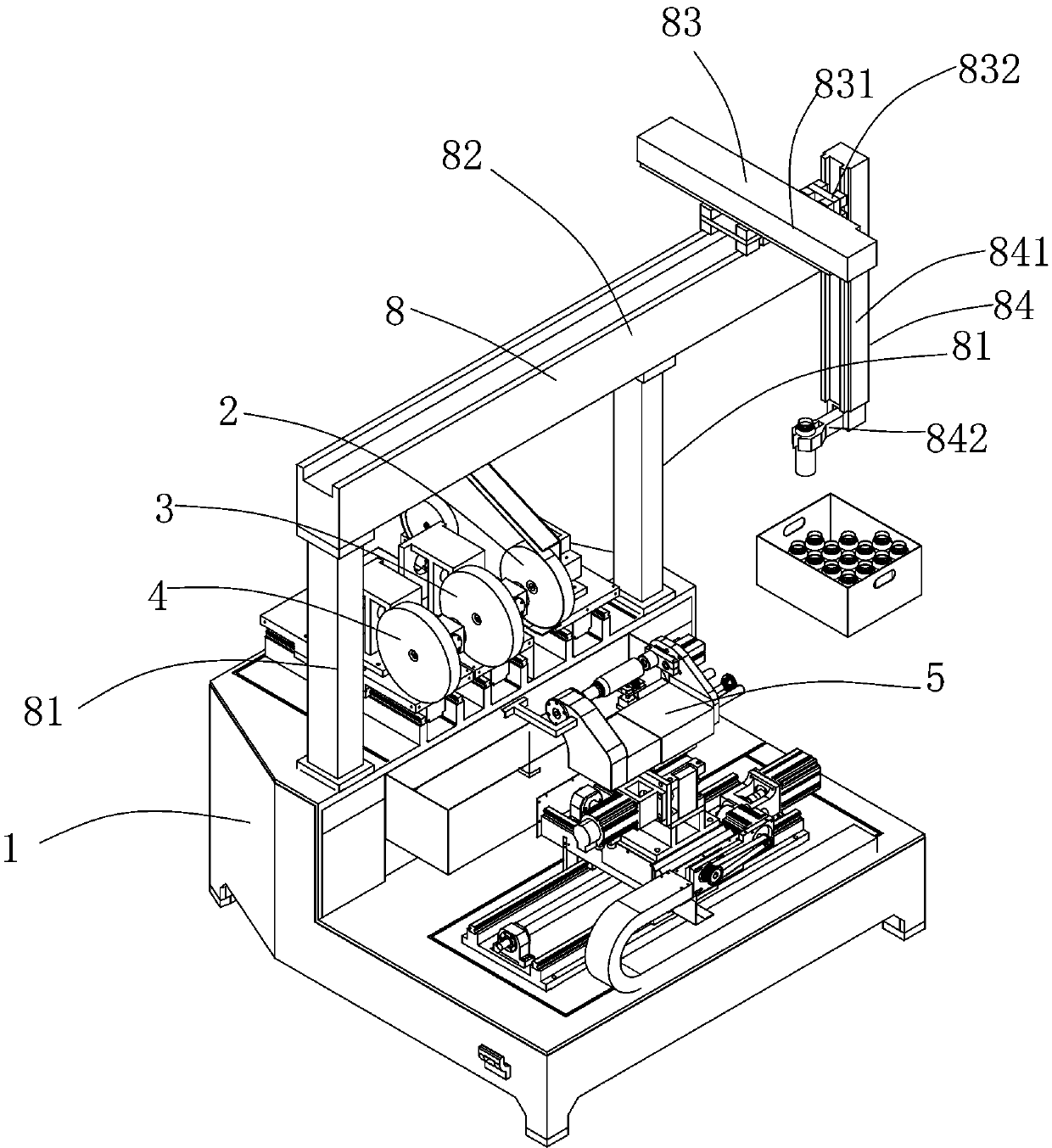

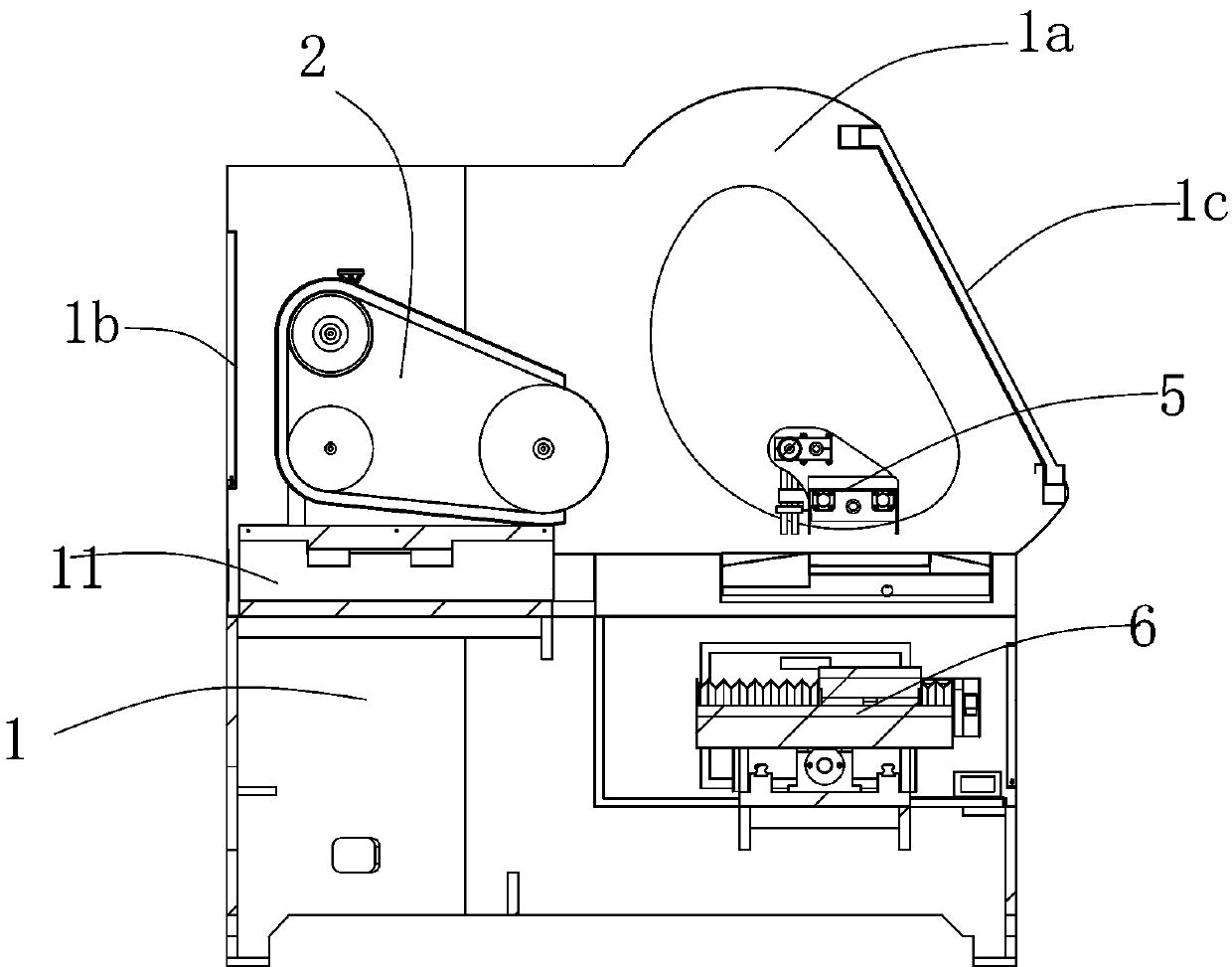

Cup body polishing machine and polishing strength control method thereof

PendingCN109968159AControl contact forceDirect response to frictionBelt grinding machinesAutomatic grinding controlEngineeringBelt grinding

The invention discloses a polishing machine. The polishing machine comprises a base; an abrasive belt grinding mechanism, a cloth wheel grinding mechanism and a cotton wheel grinding mechanism are arranged on one side of the base; a cup body fixing mechanism is arranged on the other side of base, the cup body fixing mechanism is driven by a four-axis linkage mechanism, and the four-axis linkage mechanism comprises a first guide rail arranged on the base in a driving mode; the first guide rail is slidably connected to a first platform, the first platform is driven by a first lead screw nut mechanism to move on the first guide rail, a second guide rail is arranged on the first platform, and a second platform is slidably connected to the second guide rail; and the second platform is driven bya second screw rod nut mechanism to move on the second guide rail, a driving mechanism is arranged on the second platform, and an output shaft of the driving mechanism is in a vertical position and is connected to the cup body fixing mechanism; and during use, the first platform drives the cup body fixing mechanism to move transversely, the second platform drives the cup body fixing mechanism tomove longitudinally, and the driving mechanism drives the cup body fixing mechanism to rotate.

Owner:金华市乙山知识产权服务有限公司

Two-wire test probe device and application method thereof

ActiveCN104251923BControl contact forceAvoid tie flowersElectrical measurement instrument detailsElectrical testingShielding blockContact force

The invention relates to a two-wire testing probe device. The two-wire testing probe device comprises a traction mechanism, a main body fixing seat, a testing probe and a photoelectric sensor, wherein the main body fixing seat can move under the drive of the traction mechanism; the testing probe comprises an elastic support and a probe which is arranged on the elastic support, and a protruding light shielding block is arranged on the elastic support; one side, close to the testing probe, of the photoelectric sensor is provided with a notch, and the photoelectric sensor can produce counter-emitted light which is emitted from one side of the notch to the other side of the notch; the light shielding block can stretch into the notch and shield the counter-emitted light, the elastic support is deformed during testing to change light amount of the shielded counter-emitted light, changing output voltage is produced by the photoelectric sensor and the traction mechanism controls the pressure applied by the testing probe to a printed circuit board according to the value of output voltage. The two-wire testing probe device can effectively control the contact force between the testing probe and the printed circuit board. The invention further provides a two-wire testing probe device application method.

Owner:HANS CNC SCI & TECH

A Force Feedback Closed-loop Control Composite Bonding Device

ActiveCN110034032BSmall stretchRelieve stressSolid-state devicesSemiconductor/solid-state device manufacturingLoop controlMagnetostrictive actuator

The invention discloses a force feedback closed-loop control composite bonding device. A micro-moving device is driven by a macro-moving device to perform transverse translation and vertical translation; the micro-moving device comprises a giant magnetostrictive actuator, and the length of the giant magnetostrictive actuator is changed to drive a mounting rod to move, and the telescopic amplitudeof the giant magnetostrictive actuator is very small, so that the giant magnetostrictive actuator is used for driving the mounting rod to accurately move in a small range; a strain gauge is used for detecting the contact force between the mounting rod and a substrate; the strain gauge is used for providing feedback for the micro-moving device, and the telescopic amount of the giant magnetostrictive actuator is controlled according to detection signals; when a chip is relatively far away from the substrate, the macro-moving device moves quickly, the macro-moving device is stopped when reachinga relatively close distance from the substrate, the micro-moving device drives the chip to move, and when the chip contacts the substrate, a contact force is generated, and feedback is formed throughthe contact force, so that larger pressure is avoided on the chip; and the macro-moving device or the micro-moving device is used for driving in different stages of mounting, so that the contact force is accurately controlled on the basis of guaranteeing the mounting efficiency, and the chips are prevented from being crushed.

Owner:GUANGDONG UNIV OF TECH

A device and method for robot force-controlled grinding of blades based on dragging and teaching

ActiveCN109434843BHigh degree of integrationImprove automationProgramme-controlled manipulatorControl systemControl engineering

The invention belongs to the related technical field of intelligent machining, and discloses a device and a method for force controlling polishing a blade through dragging a teaching robot. The devicecomprises the robot, a six-dimensional force sensor, a polishing mechanism, a position changing machine, and a robot control system; the six-dimensional force sensor is connected with a tail end executor of the robot and the polishing mechanism; the position changing machine is used for bearing the to-be-machined blade; the robot, the six-dimensional force sensor and the polishing mechanism are connected to the robot control system; the six-dimensional force sensor is used for measuring the contact force between the blade and the polishing mechanism in the blade polishing process, and transmitting the detected data to the robot control system; the robot control system is further used for receiving the tail end position information data of the robot, processing the received data to obtainthe corresponding control quantity, and then controlling the robot to drive the polishing mechanism to carry out corresponding motion. According to the device and the method, the skill requirement foran operator is reduced, and the machining consistency and the machining precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Solar LED street lamp with dust removal function and dust removal method thereof

PendingCN113623600AImprove lighting workImprove practicalityMechanical apparatusLighting elementsEngineeringDust control

The invention discloses a solar LED street lamp with a dust removal function and a dust removal method thereof, and relates to the technical field of solar street lamp cleaning devices. The solar LED street lamp with the dust removal function comprises a street lamp support, wherein an LED lamp and a sweeping mechanism are fixedly connected to the top end of the street lamp support; a solar panel is fixedly connected to the position, close to the back face, of the top end of the LED lamp and the sweeping mechanism; and the outer wall of the solar panel is fixedly connected with the outer wall of the street lamp support through the arranged LED lamp and the arranged sweeping mechanism. According to the solar LED street lamp with the dust removal function and the dust removal method of the solar LED street lamp, the LED lamp and the sweeping mechanism are controlled to operate through electric energy stored in the solar panel, the LED street lamp is cleaned, and therefore, the illumination work of the LED lamp is improved; and the LED street lamp can be cleaned in all directions through an arranged cleaning mechanism, so the situation that light of the LED street lamp is blocked due to too much dust is prevented, and the practicability of the solar LED street lamp is improved.

Owner:邵磊明

Pantograph dynamic operation performance control method and device

ActiveCN105652111BImprove flowPrecise control of contact forceTesting electric installations on transportPower current collectorsElectricityContact force

The invention provides a pantograph dynamic operation performance control method and device. The pantograph dynamic operation performance control method comprises the steps that a pantograph line aerodynamic performance test is performed so that aerodynamic performance parameters of a pantograph in different open directions and speed levels are generated; a pantograph and catenary current collection performance test is performed so that the pantograph and catenary current collection performance parameters of the pantograph in different operation lines and different open directions and speed levels are generated; a catenary contact force trend regression curve under different speed levels and different open directions is drawn by utilizing a quadratic polynomial curve regression method according to the pantograph and catenary current collection performance parameters and the aerodynamic data; and dynamic operation performance of the pantograph is controlled according to the catenary contact force trend regression curve. With application of the pantograph dynamic operation performance control method and device, the pantograph dynamic operation performance parameters of the pantograph can be accurately controlled so that indirect contact force of the pantograph and the catenary can be accurately controlled, and great current collection of the catenary and the pantograph can be guaranteed.

Owner:CHINA RAILWAYS CORPORATION +3

A device for removing snow from the ice surface of a fish pond

The invention relates to the field of snow clearing equipment, in particular to a snow clearing device for the ice surface of a fish pond, which includes a support frame, a moving mechanism, a left and right rotation mechanism, an up and down rotation mechanism, a cleaning mechanism, a snow pushing frame, a snow pushing frame retracting mechanism, an adjusting The worm and the mobile power supply move the device through the moving mechanism, clean through the cleaning mechanism, adjust the cleaning angle through the left and right rotation mechanism, adjust the cleaning strength through the up and down rotation mechanism, and use the snow pusher and the snow pusher retraction mechanism to clean the snow. The thick part is pushed to improve the efficiency of snow removal. The invention can clean the snow on the ice surface of the fish pond, reduce labor intensity, and save time and effort.

Owner:郑丛

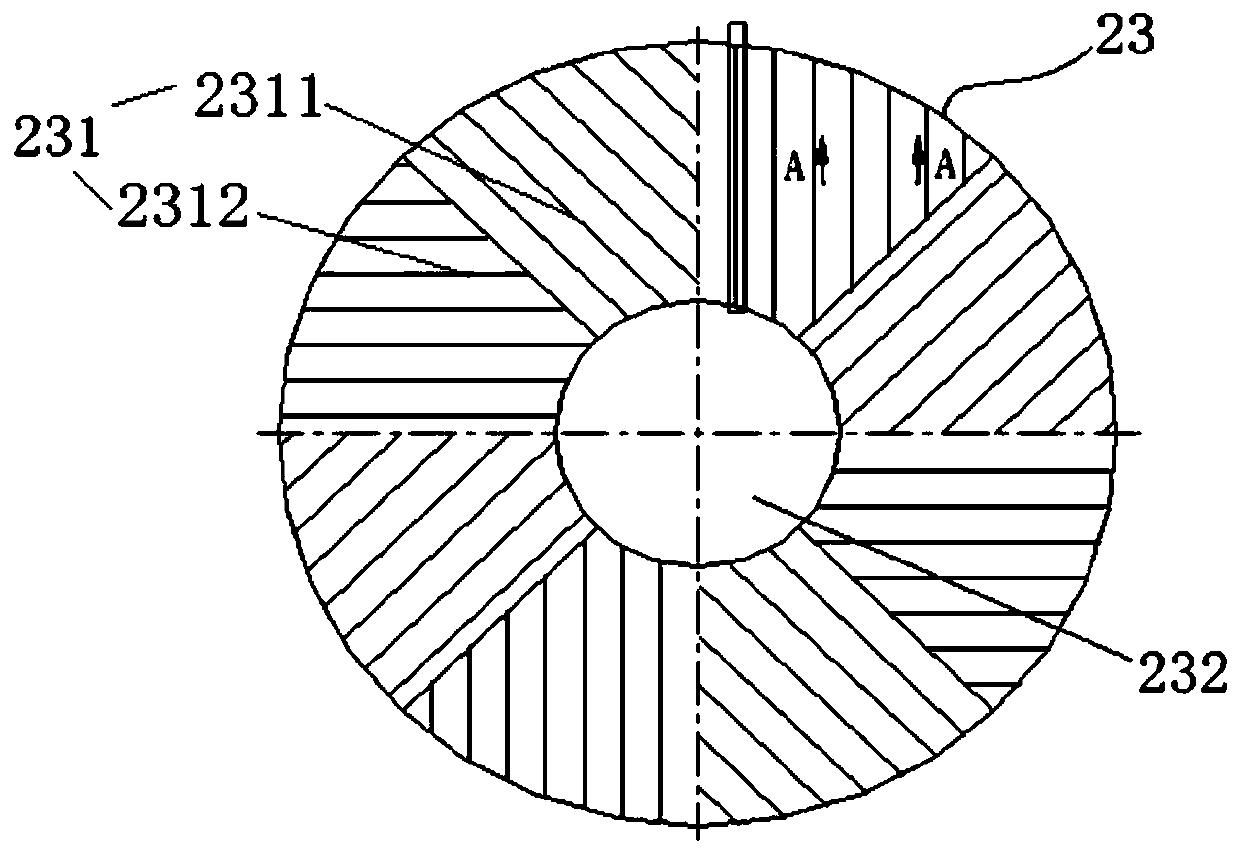

Dispensing roller, dispensing device and dispensing system

ActiveCN108940717BAvoid bumpingReduce contact areaLiquid surface applicatorsCoatingsCoating systemEngineering

The invention discloses a glue coating idler wheel, a glue coating device and a glue coating system. The glue coating idler wheel comprises an idler wheel body and at least one annular protrusion molded on the circumferential outer wall surface of the idler wheel body in a protruded manner, at least one side wall surface in the radial direction of the at least one annular protrusion appears as a first inclined surface, and the axial direction width of a first end surface, close to the idler wheel body, of the at least one annular protrusion is larger than that of a second end surface, away from the idler wheel body, of the at least one annular protrusion to make the at least one first inclined surface incline outwards from a second end towards a first end; the glue coating device comprisesthe glue coating idler wheel, a glue supplying mechanism and a supporting mechanism; and the glue coating system comprises the glue coating device and a rotating platform. According to the glue coating idler wheel, the glue coating device and the glue coating system, because the at least one annular protrusion is molded on the circumferential outer wall surface of the idler wheel body in a protruded manner, the at least one side surface in the radial direction of the at least one annular protrusion appears as the first inclined surface, therefore, in the glue coating process, point contact isformed between a glue body to be coated and the at least one annular protrusion of the idler wheel, abnormal bumping of the glue body to be coated can be effectively prevented, and meanwhile, the problem of glue overflow is avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

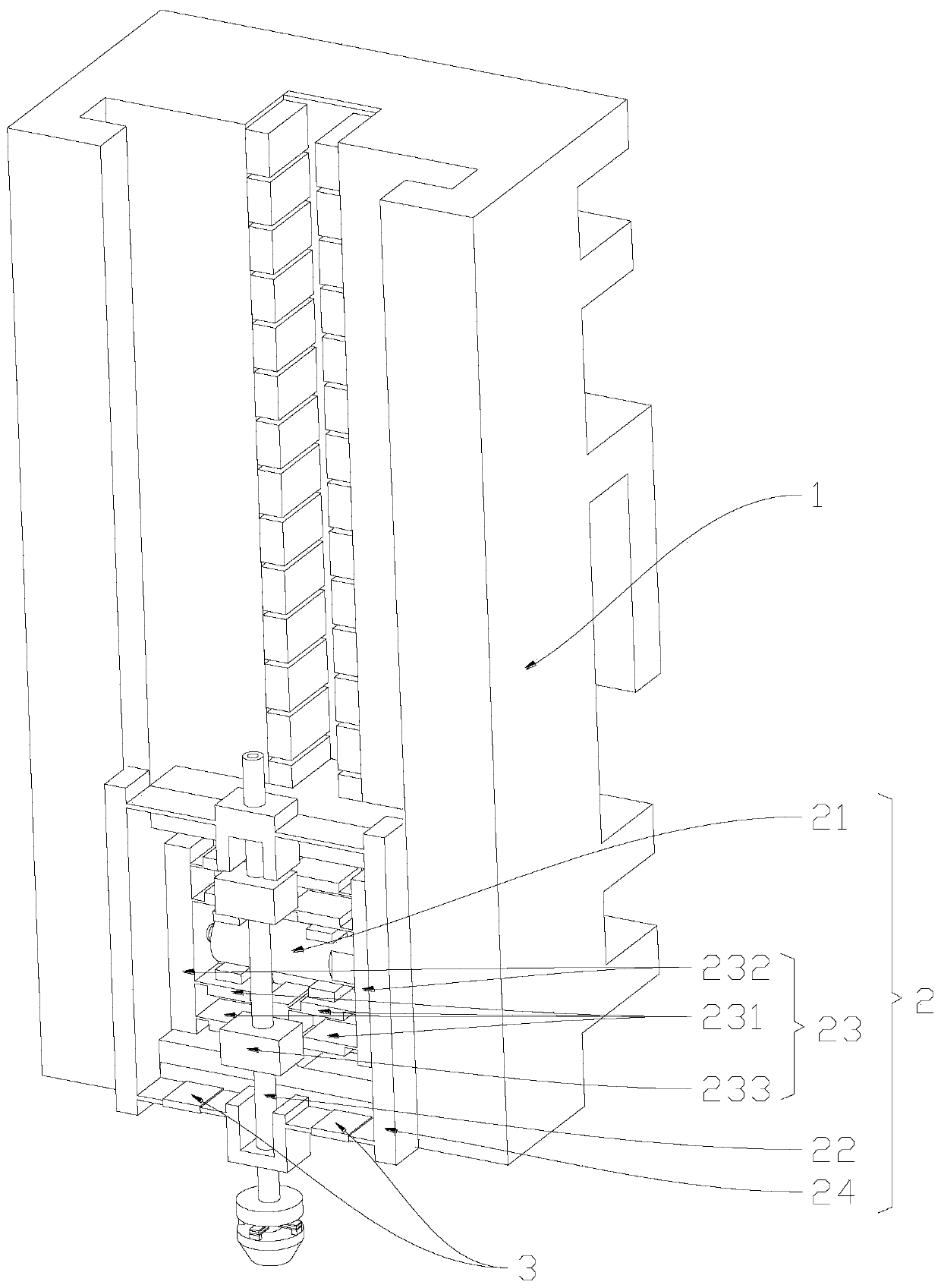

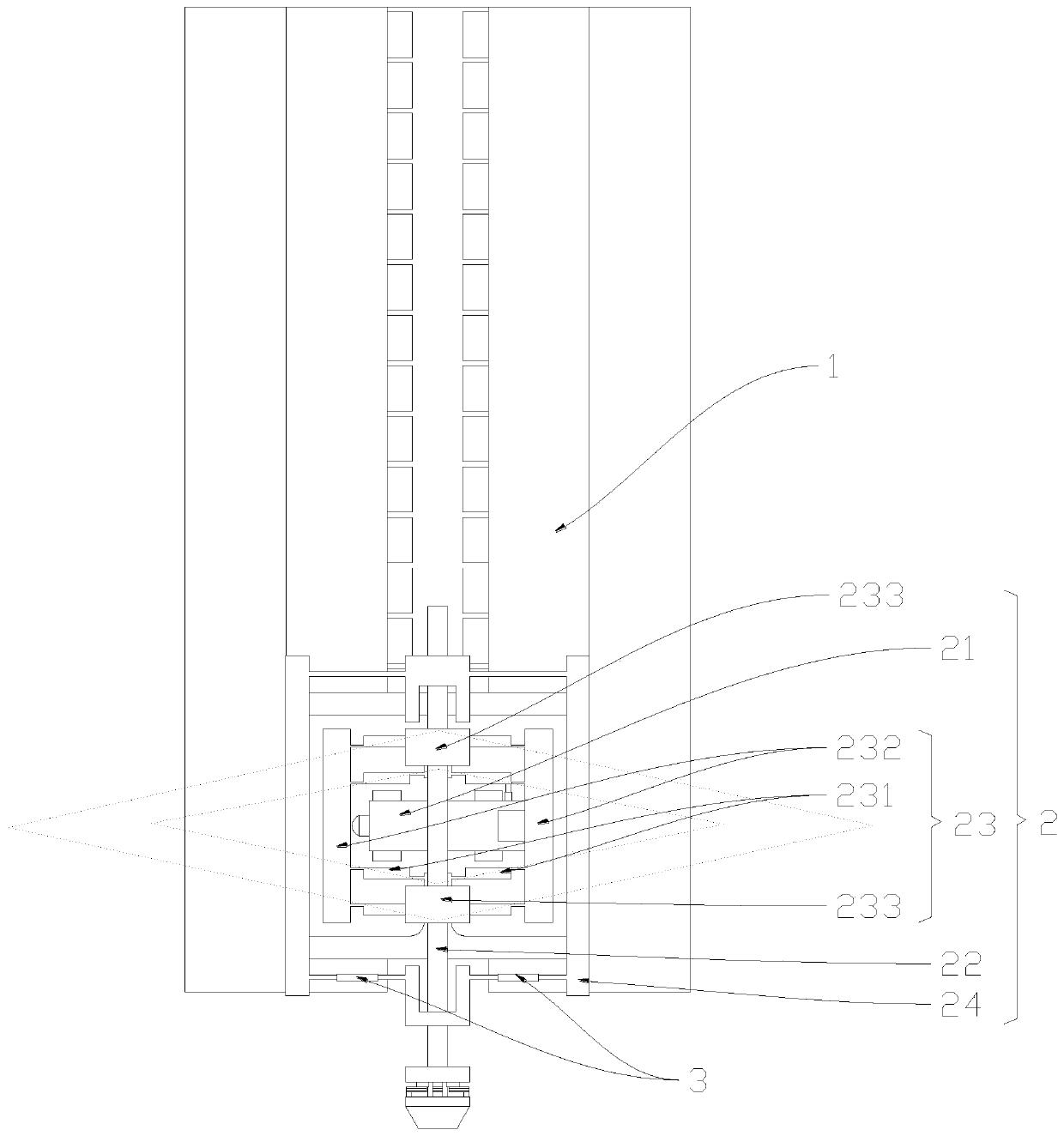

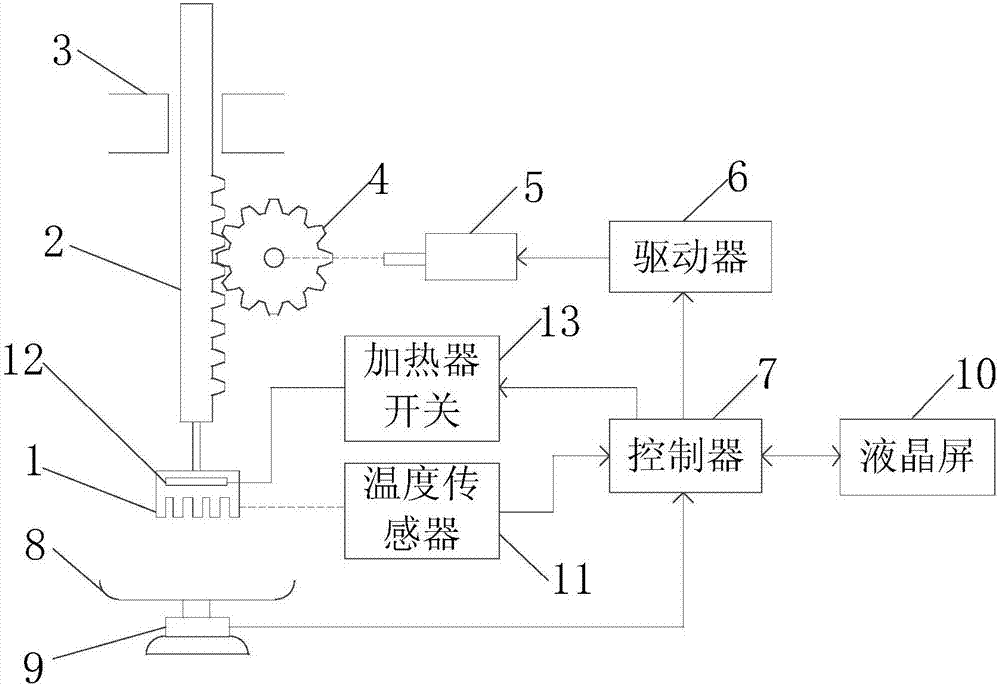

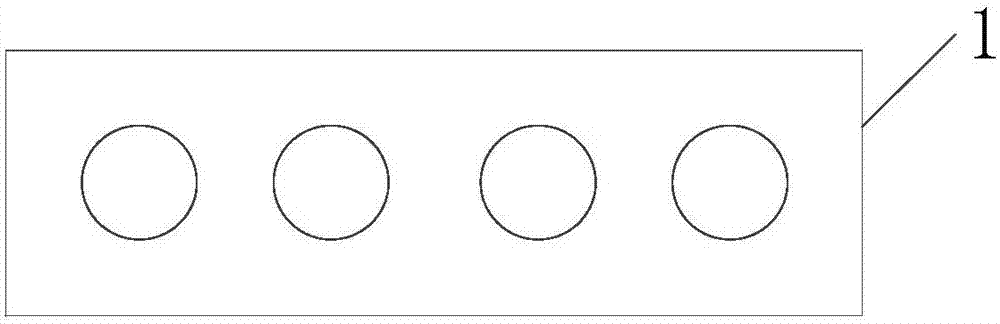

Burn and scald experimental device for animals

InactiveCN106236313BControl contact forceRecord contact forceSurgical veterinaryReciprocating motionEngineering

The invention relates to a burn and scald experiment device for an animal. The burn and scald experiment device comprises a scalding block, a driving rod, a limiting pair, a driving gear, a driving motor, a driver, a controller and a supporting plate, wherein the scalding block is used for burning or scalding the animal; the driving rod is in threaded connection with the scalding block, and is used for driving the scalding block to do reciprocating motion; a straight gear is arranged on the side surface of the driving rod; the limiting pair is used for limiting the driving rod; the driving gear is meshed with the straight gear on the side surface of the driving rod, and is used for driving the driving rod to move; the driving motor is used for driving the driving gear to move; the driver is used for controlling the driving motor to operate; the controller is used for controlling the driver, and receiving a signal of a weighing sensor; the supporting plate is used for placing the animal to be burnt or scalded; the weighing sensor is located below the supporting plate, and is used for detecting the change of force on the supporting plate. The burn and scald experiment device is animal burn and scald experiment equipment which can effectively control a contact area, record contact duration and control the contact force.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com