Comprehensive detection device for geometric parameters of conical ring

A geometric parameter and comprehensive detection technology, applied in the field of measurement applications, can solve problems such as low precision, high technical level requirements of operators, and low efficiency, and achieve high efficiency and precision, high matching accuracy, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

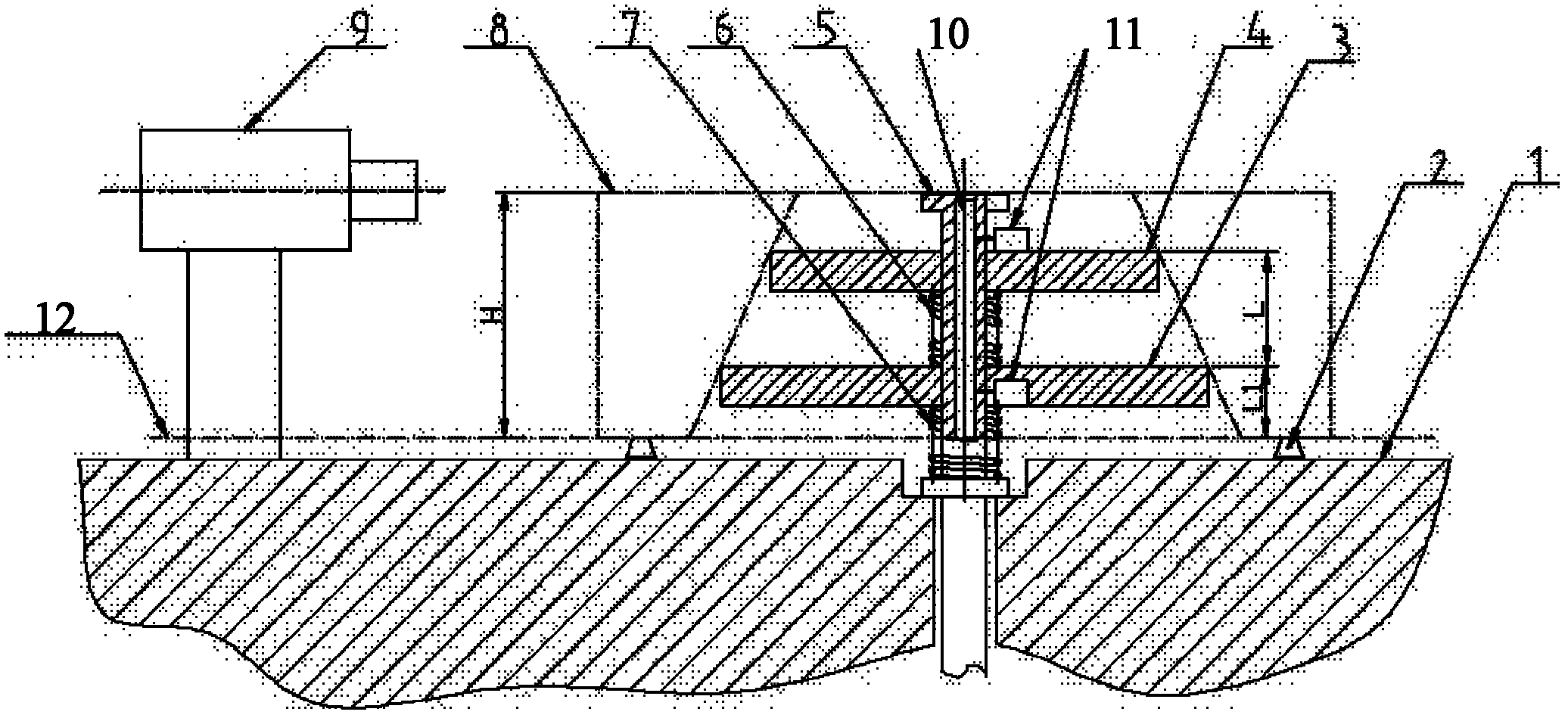

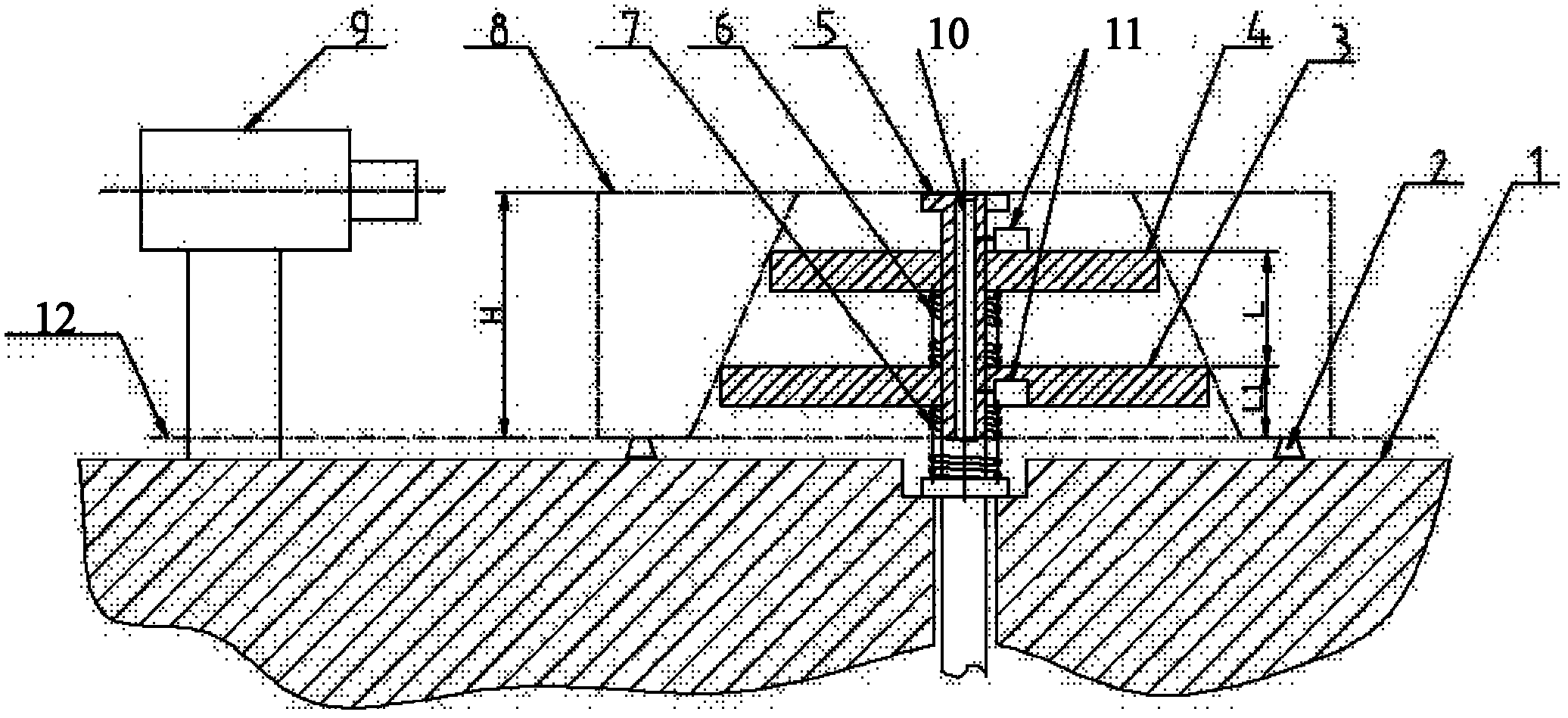

[0020] see figure 1 , the cone ring geometric parameter comprehensive detection device of the present invention comprises a base 1, a mandrel 5 is vertically arranged on the working surface of the upper end of the base 1, and the mandrel 5 is respectively equipped with a disc-shaped large probe 3 through a linear bearing from bottom to top. and the small measuring head 4, the large and small measuring heads 3 and 4 form a sliding pair between the linear bearing and the mandrel 5, the measuring head and the bearing are fixedly connected, and the gap fit of g6 / H7 is adopted between the bearing and the mandrel, so that They can only slide relative to each other and cannot rotate relative to each other. The first spring 6 is used to connect the large probe 3 and the small probe 4, and the second spring 7 is used to connect the large probe 3 and the mandrel 5; The CCD dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com