Winding device with support roller and pressing force-regulating device, and thread processing machine

A technology of winding device and control device, which is applied in the direction of thin material handling, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of unsuitable for precise control of contact force, temperature change error, large elasticity, etc., and achieve firm and Stable design, high load capacity, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

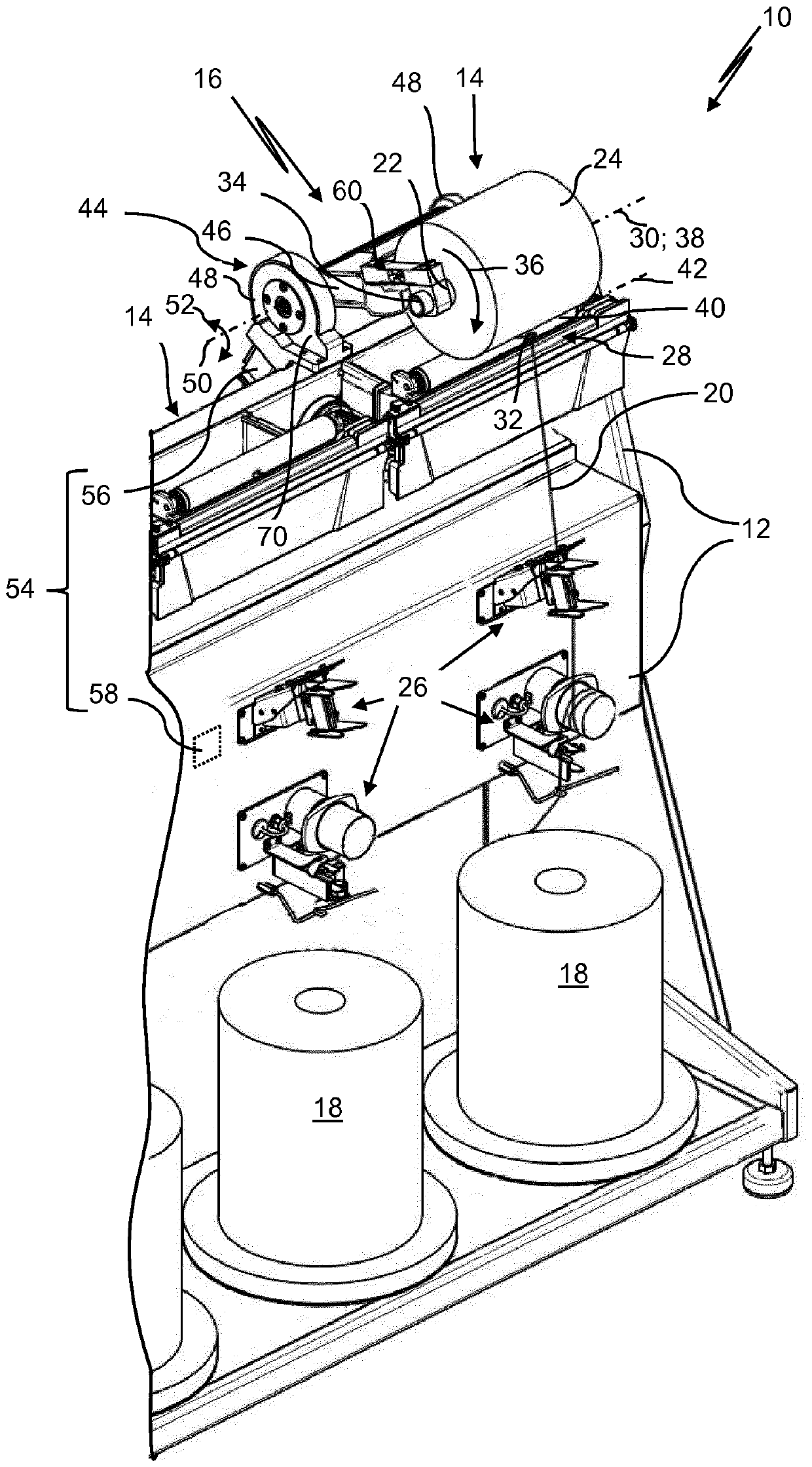

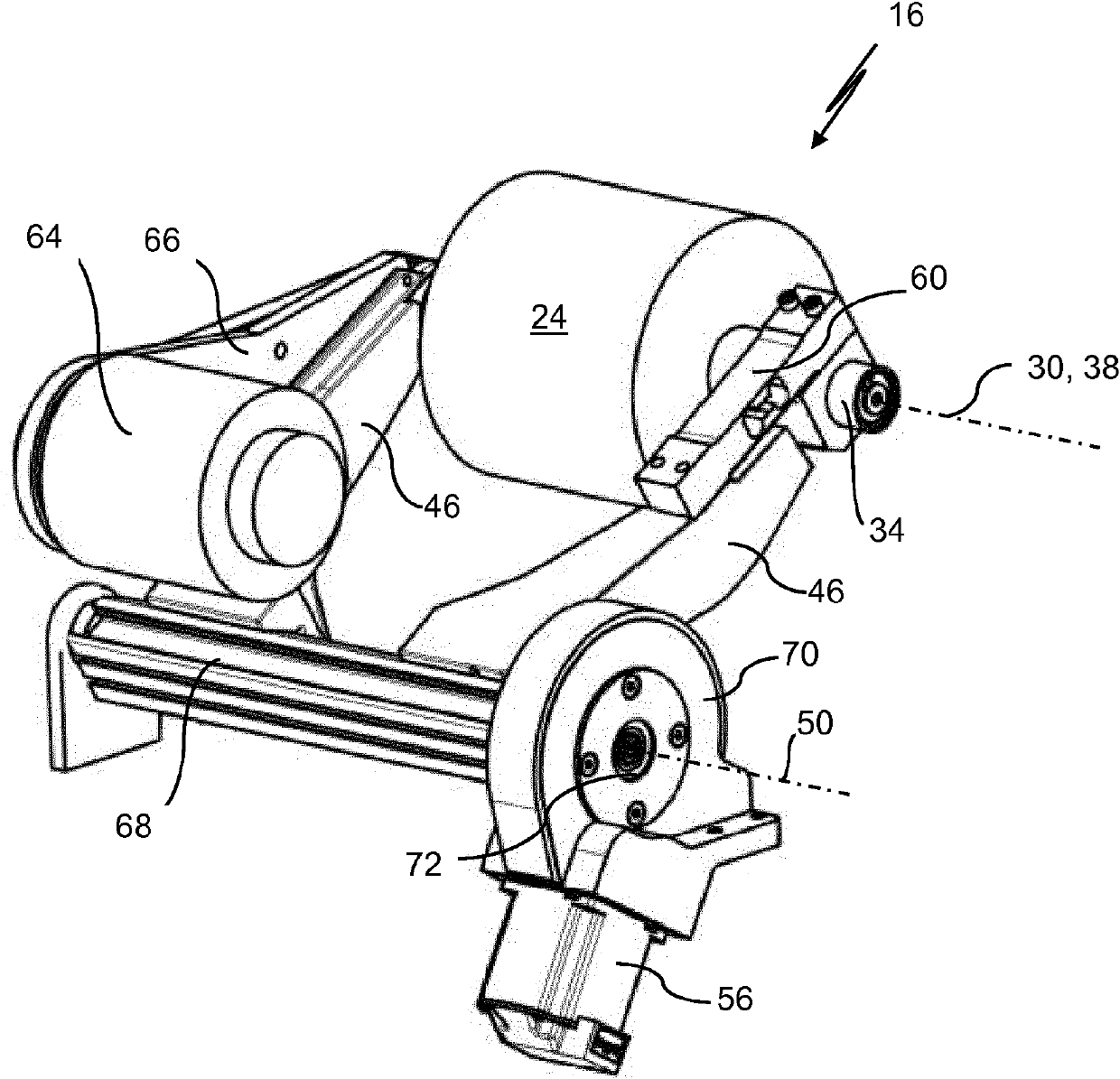

[0033] figure 1 A partial perspective view of the yarn processing machine 10 is shown. The yarn processing machine 10 has a machine frame 12 on which a plurality of winding heads 14 are arranged side by side. The winding heads 14 each have a winding device 16 for winding a yarn 20 provided on a supply package 18 onto a package tube 22 to form a yarn winding package 24 (i.e. , package being wound). Via the yarn guide mechanism 26 of the traversing unit 28 positioned on the machine frame 12, the yarn 20 traveling to the package tube 22 can be guided in a fixed direction relative to the package tube 22 in the direction of the longitudinal axis 30 of the package tube 22. The traversing unit 28 is reciprocally fed within a predetermined or variably predetermined angle range.

[0034] Here, the traversing unit 28 has, for example, a traction-guided thread guide 32 . According to exemplary embodiments not shown in detail in the figures, the traversing unit 28 may also be embodied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com