Preparation method of edge-carboxylated graphene

A technology of carboxylated graphene and edge, which is applied in the field of preparation of carboxylated graphene, can solve the problems of difficult preparation and achieve the effects of good stability, improved efficiency, and long-term stable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

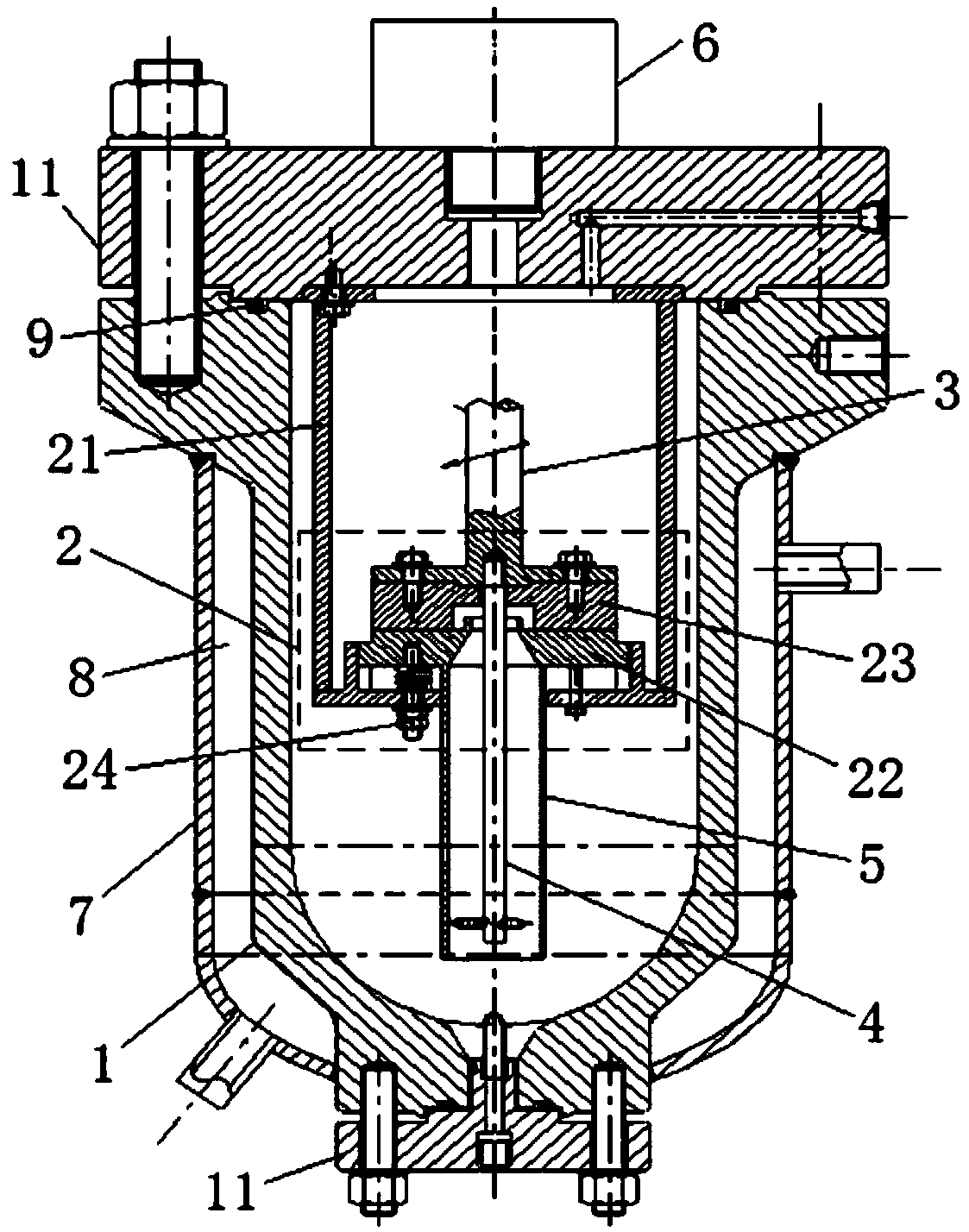

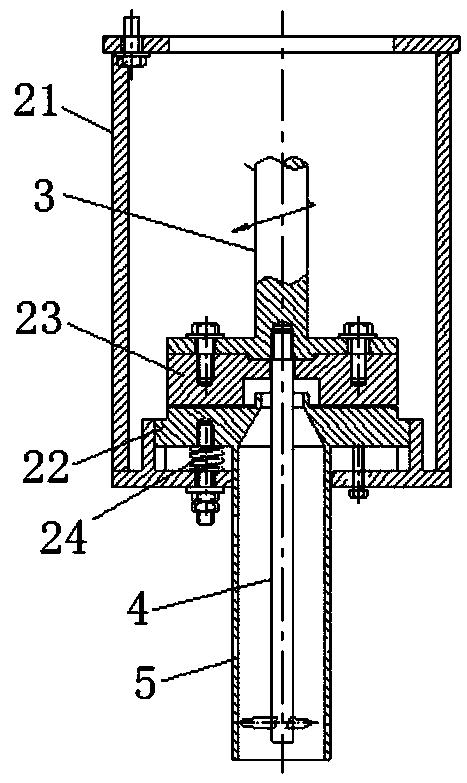

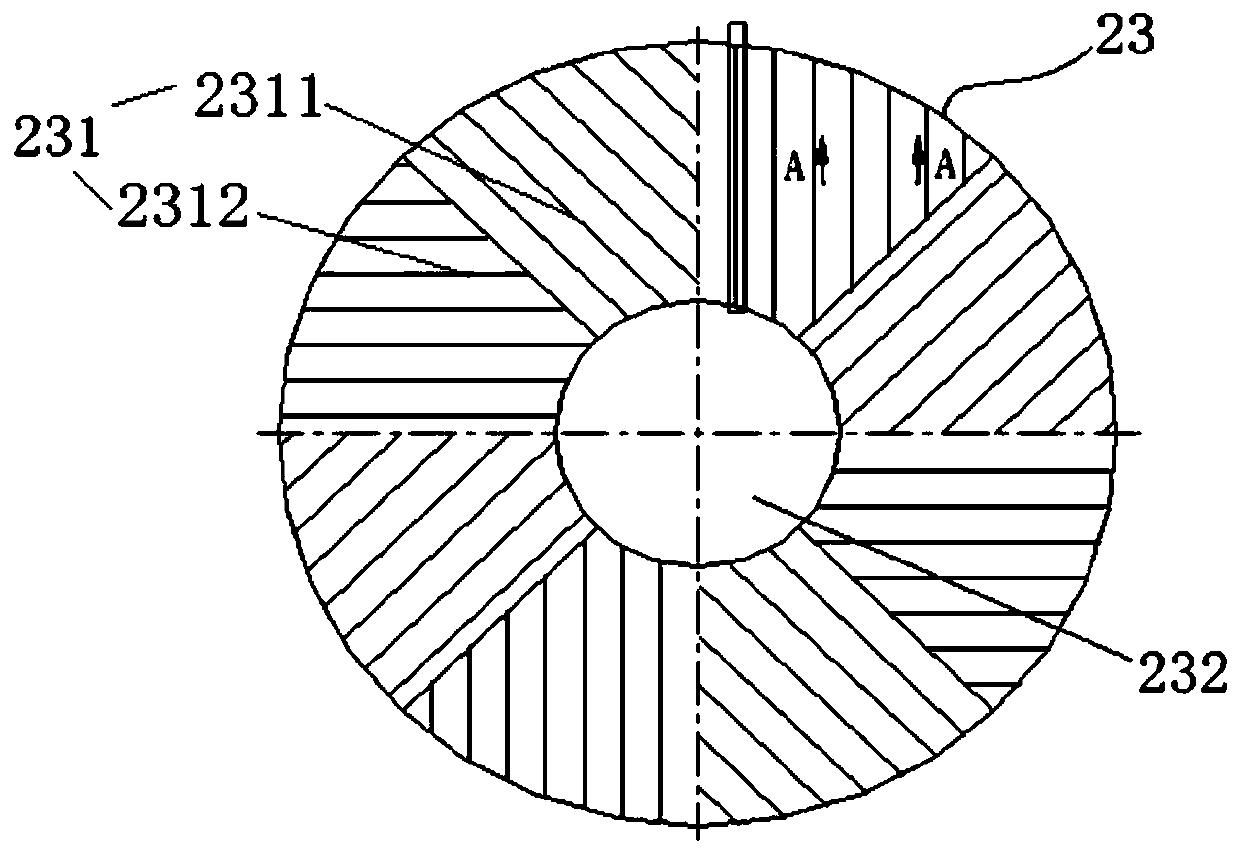

Method used

Image

Examples

Embodiment 1

[0069] 100g 32 mesh flake graphite powders are ultrasonically cleaned (washed once with water, washed twice with ethanol) to remove impurity substances and impurity elements, then place the graphite flakes in a high-pressure grinding pan kettle, seal the high-pressure grinding pan kettle, and then place the high-pressure The disc kettle was heated to 40°C and pumped in CO 2 Make the pressure in the high-pressure grinding disc kettle rise to 85atm, and the rotating speed is 500r / min. Use the shear force generated by the grinding disc to grind and peel off the graphite. After stirring for 24 hours, reduce the pressure to 1 atm within 10s, and take samples from the high-pressure grinding disc kettle. The edge carboxylated graphene is obtained.

[0070] Scanning electron microscope (SEM) is used to the obtained edge carboxylated graphene (such as figure 1 Shown) analysis, the diameter of graphene sheet is 5-20 μm, elemental analysis (XPS) characterizes, and oxygen content is 5.60...

Embodiment 2

[0072] 40g of expanded graphite is ultrasonically cleaned (washed once with water, washed twice with ethanol) to remove impurities and impurity elements, then place the expanded graphite in a high-pressure grinding still, seal the high-pressure grinding still, then heat the high-pressure grinding still to 40°C by pumping in CO 2 Make the pressure in the high-pressure grinding disc kettle rise to 85atm, and the rotating speed is 500r / min. Use the shear force generated by the grinding disc to grind and peel off the graphite. After stirring for 48 hours, the pressure will be reduced to 1 atm within 10s. Take samples from the high-pressure grinding disc kettle. The edge carboxylated graphene is obtained.

[0073] The prepared edge carboxylated graphene was analyzed by scanning electron microscope (SEM), and the diameter of the graphite flakes was 5-20 μm, characterized by elemental analysis (XPS), and the oxygen content was 7.83%.

Embodiment 3

[0075] 100g 32 mesh flake graphite powders are ultrasonically cleaned (washed once with water, washed twice with ethanol) to remove impurity substances and impurity elements, then place the graphite flakes in a high-pressure grinding pan kettle, seal the high-pressure grinding pan kettle, and then place the high-pressure The disc kettle is heated to 70°C, and CO is pumped in 2 Make the pressure in the high-pressure grinding disc kettle rise to 125atm, and the rotating speed is 1000r / min. Use the shear force generated by the grinding disc to grind and peel off the graphite. After stirring for 24 hours, the pressure will be reduced to 1 atm within 10s. Take samples from the high-pressure grinding disc kettle. The edge carboxylated graphene is obtained.

[0076] The obtained edge carboxylated graphene was analyzed by scanning electron microscope (SEM), and the diameter of the graphene sheet was 5-10 μm, characterized by elemental analysis (XPS), and the oxygen content was 13.40%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com