Method for realizing slip measurement of film probe

A technology of probe measurement and thin film, which is applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc. The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

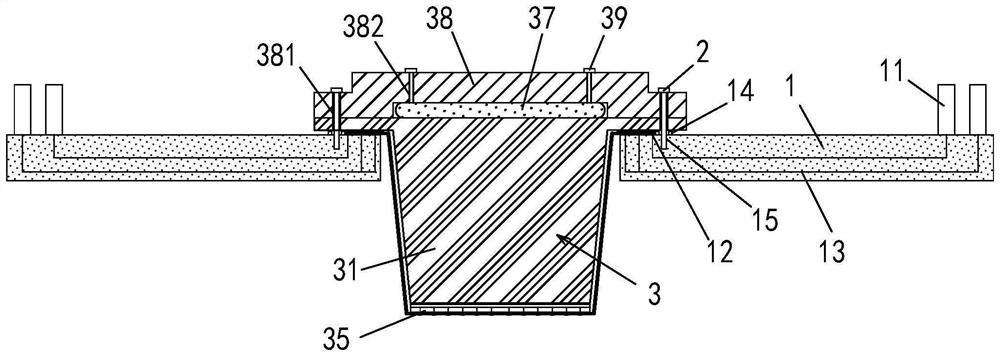

[0041] Embodiment: a kind of method that realizes thin film probe to measure slippage, see appendix Figure 1-6 Shown:

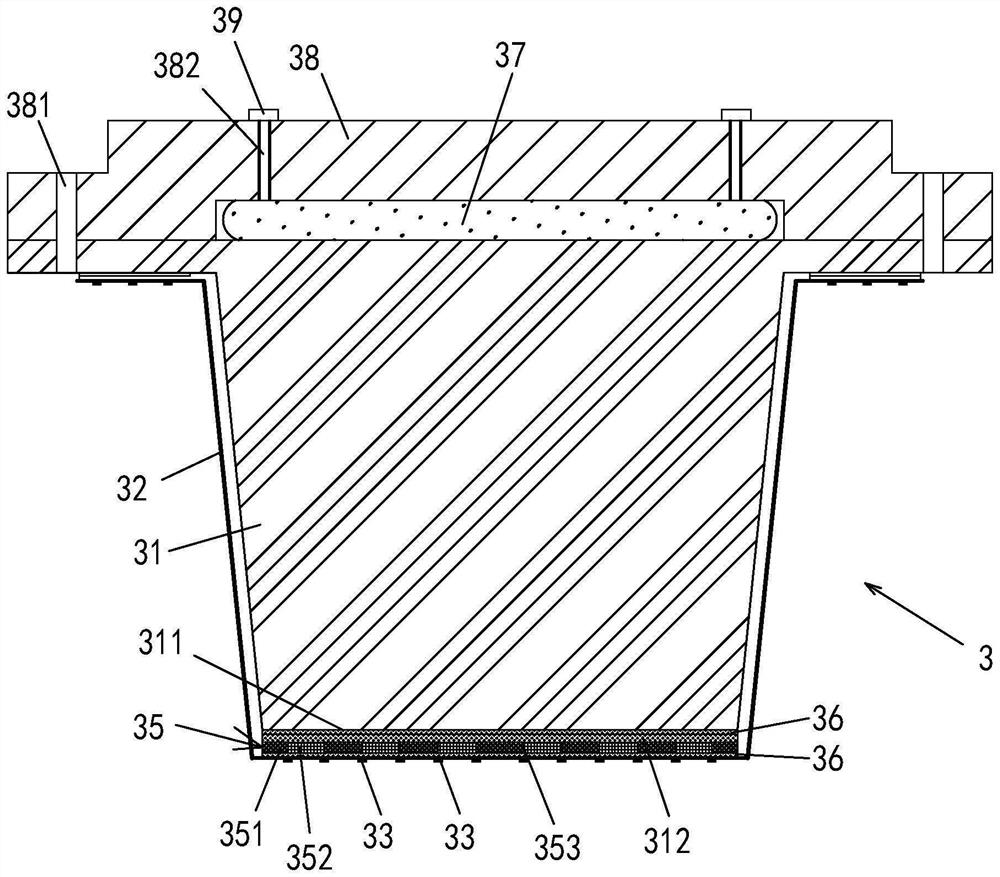

[0042] The film probe card generally includes a PCB board 1, connectors 2 and a film probe head 3; The film 32 on the film 311 , and the probes 33 and interconnection lines 34 arranged on the film 32 .

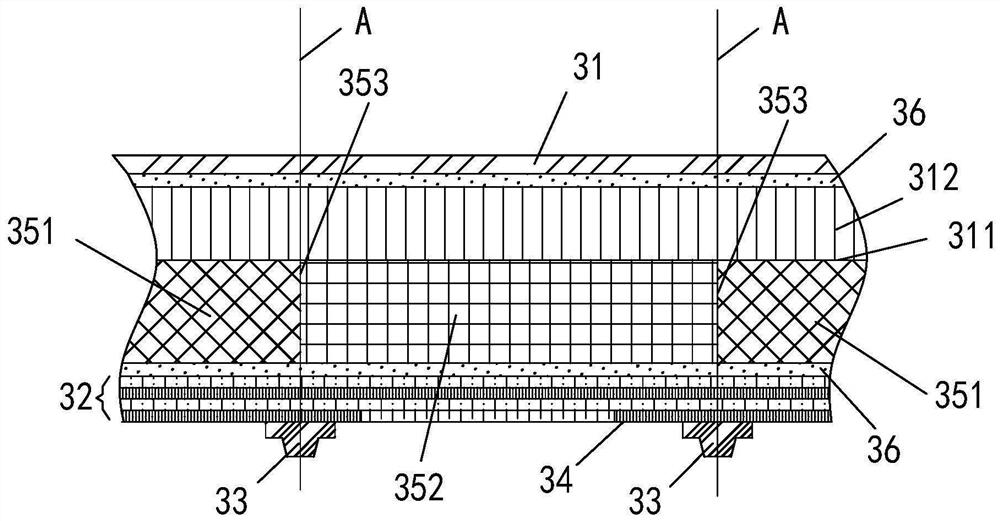

[0043] The method of this embodiment is to lay an elastomeric layer 35 between the rigid action surface 311 in the film probe and the film 32 on which the probe 33 is set; the elastomeric layer 35 is on the axial plane of the probe 33 to Any axial line passing through the probe is the boundary line A, and the elastic force on one side is not equal to the elastic force on the other side, so that the probe can be deflected during the test to produce measurement slippage.

[0044] Specifically, as shown in the figure, the elastic body layer 35 is formed by splicing two kinds of elastic bodies (first elastic body 351 and second elastic body 352 ) on a plane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com