Socket contact

A socket contact and contact piece technology, applied in the direction of contact parts, contact piece manufacturing, connecting device components, etc., can solve complex manufacturing, expensive and other problems, and achieve the effect of less wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

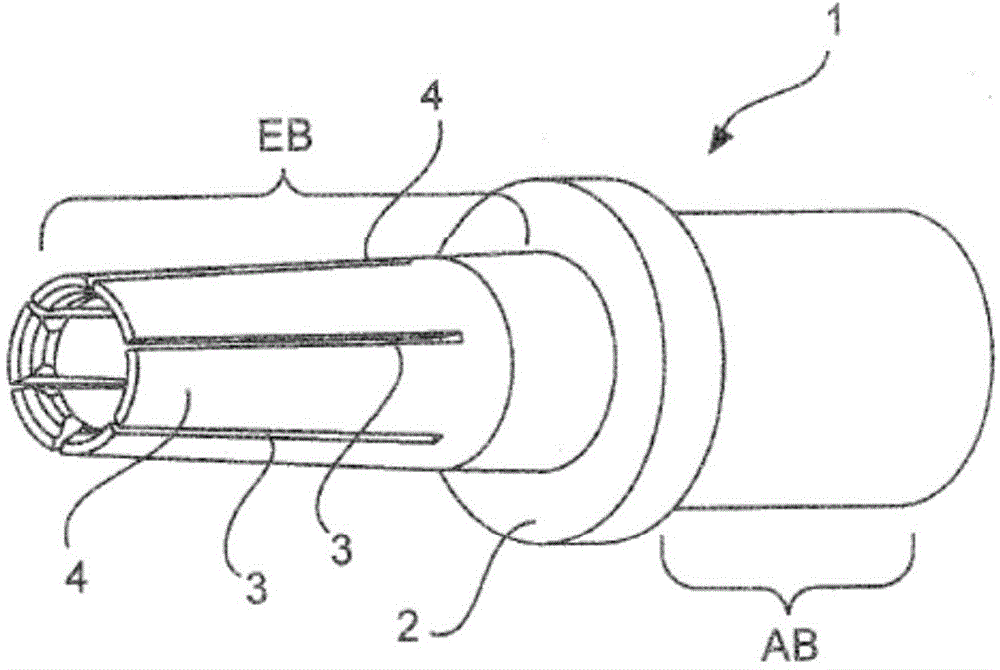

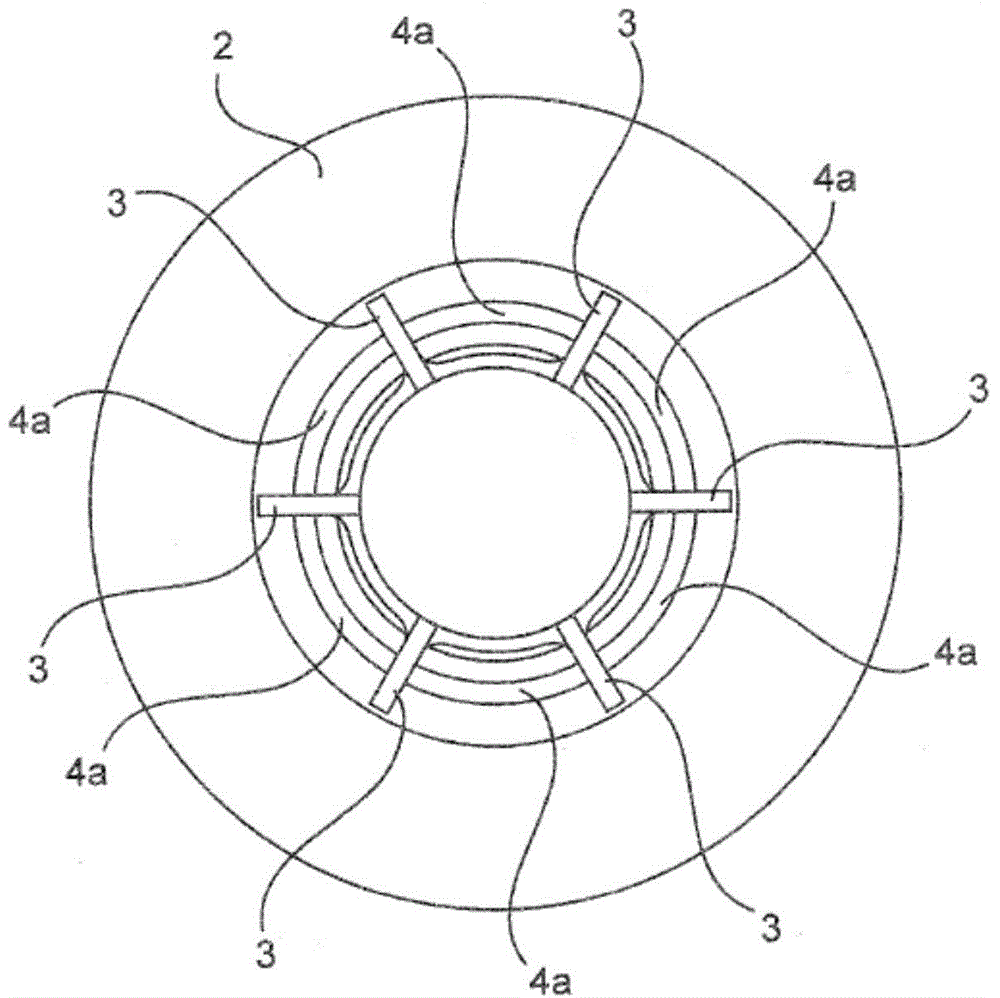

[0033] figure 1 A perspective view of an exemplary embodiment of a socket contact 1 according to the invention is shown. The socket contact 1 basically consists of a hollow cylinder made of an electrically conductive material such as sheet metal. Alternatively, the receptacle contacts may be machined from solid material. The hollow cylinder is interrupted by a substantially centrally arranged circumferential thickening 2 separating the connection area AB and the insertion area EB from each other. This thickening 2 serves to position the socket contact in the insulating body of the plug-in connector.

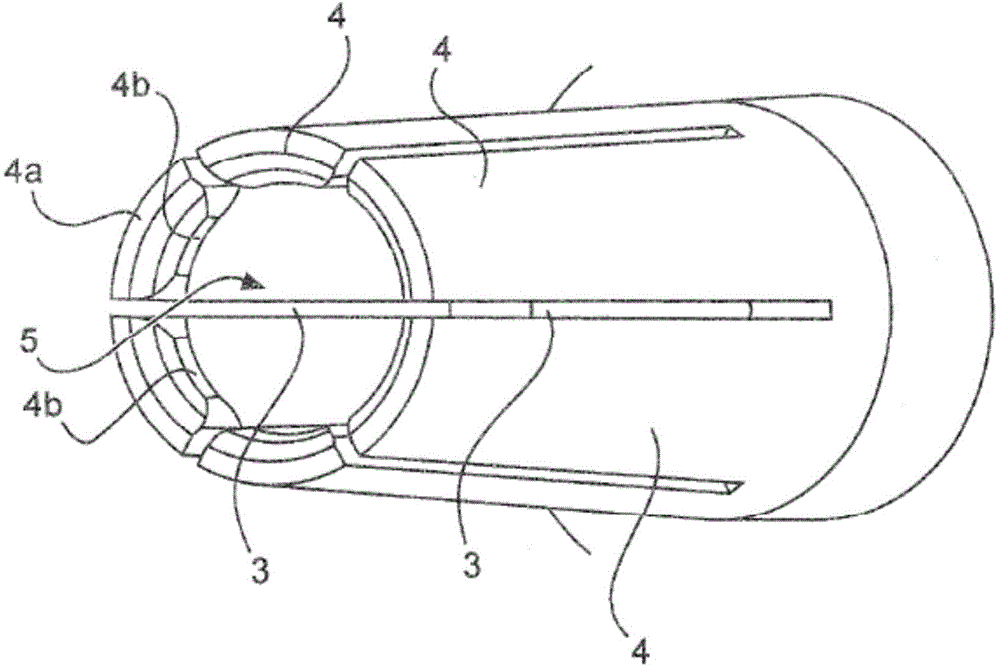

[0034] In the insertion area EB of the hollow cylinder, axial grooves 3 are introduced to form individual elastic arms 4 . The ends 4a of the spring arms 4 are bent towards each other in the radial direction. In the exemplary embodiment shown here, the end 4 a of the spring arm 4 surrounds the insertion opening 5 of the socket contact 1 .

[0035] At the end 4 a of the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com