Patents

Literature

58results about How to "Achieve pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

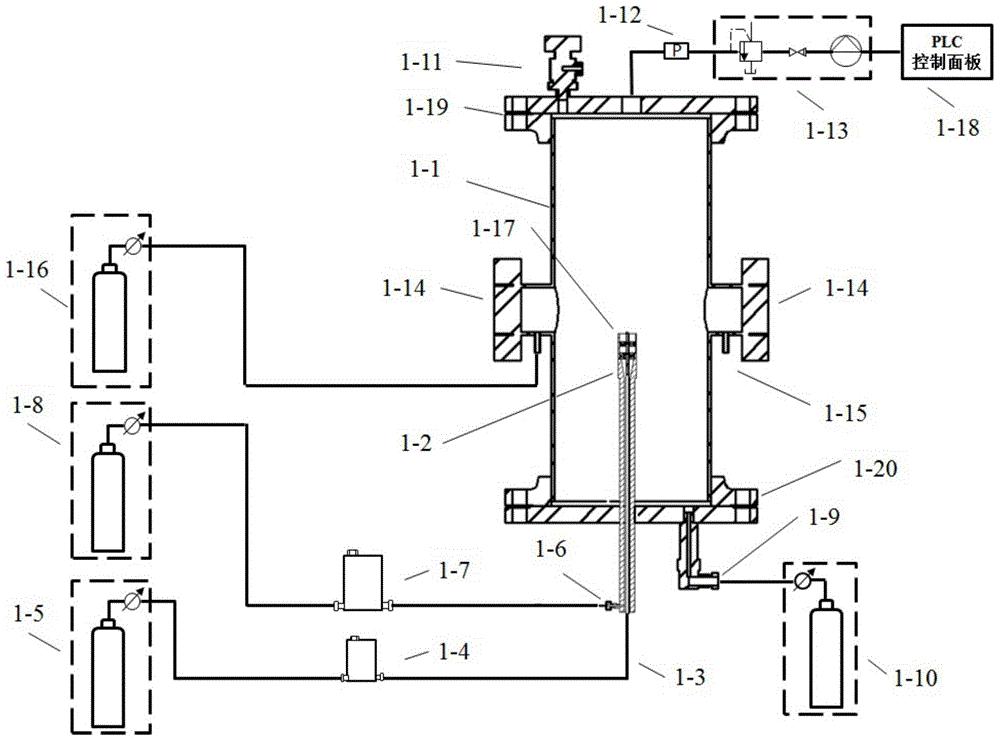

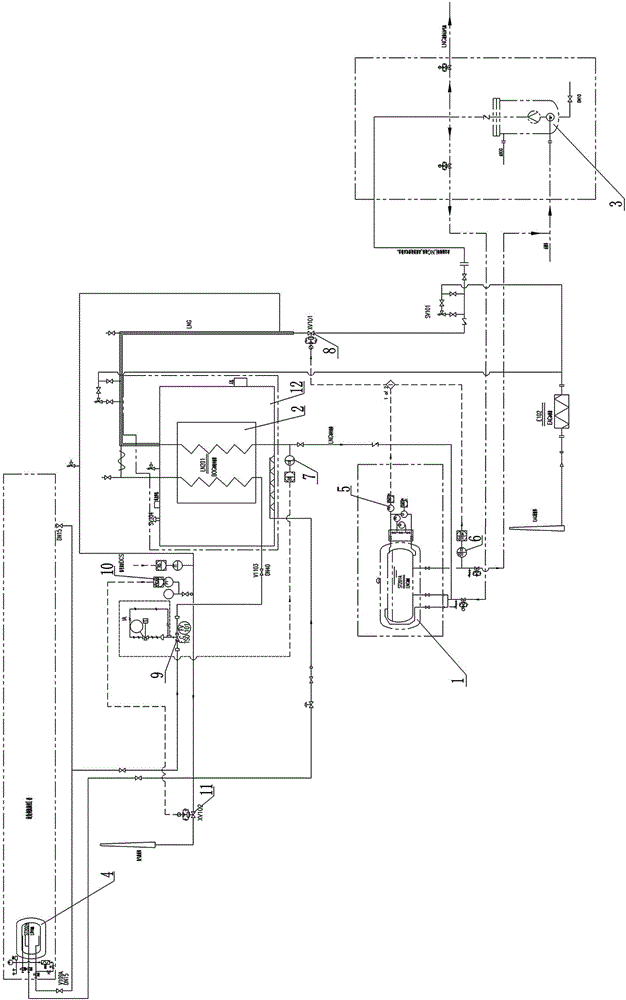

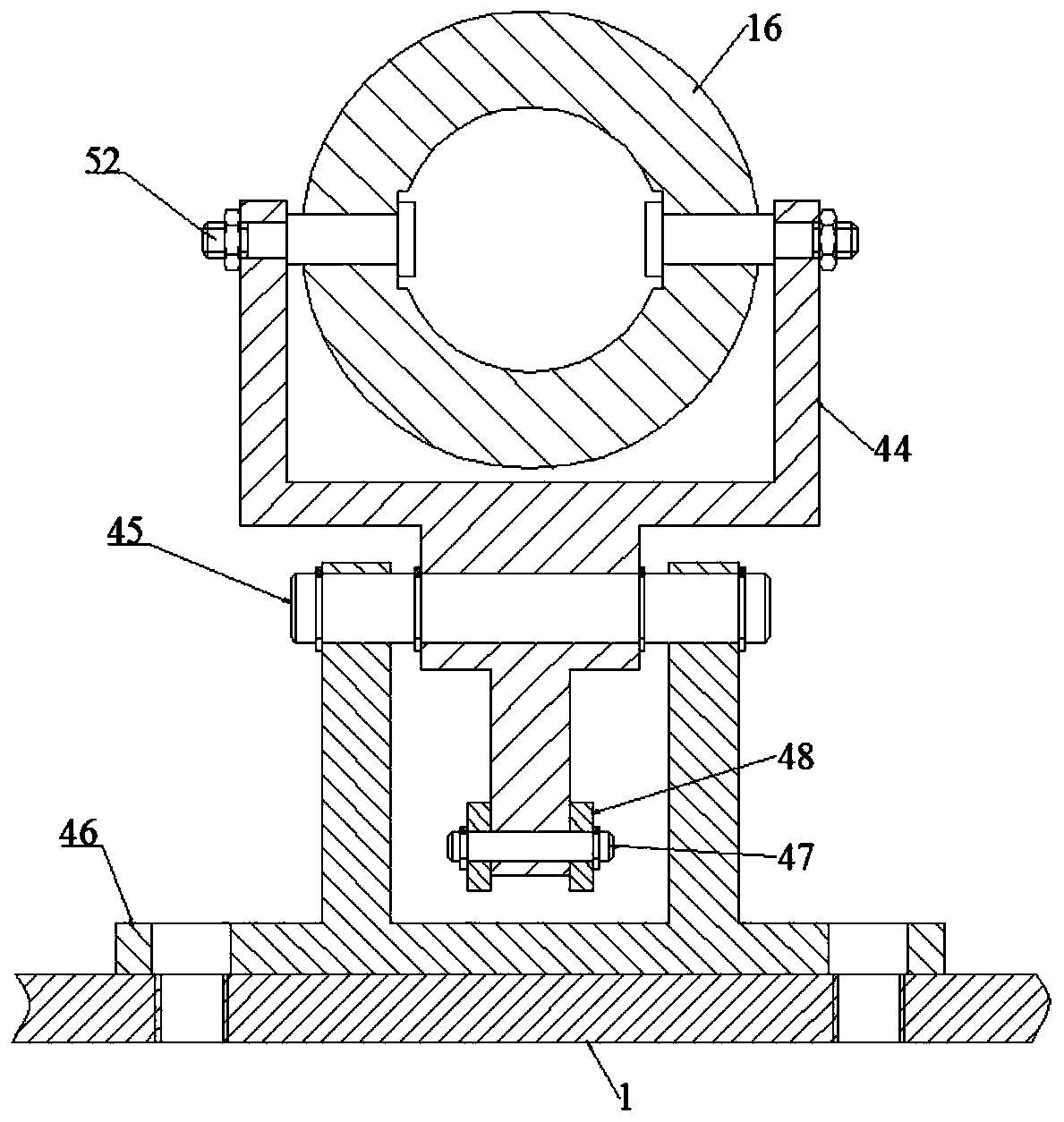

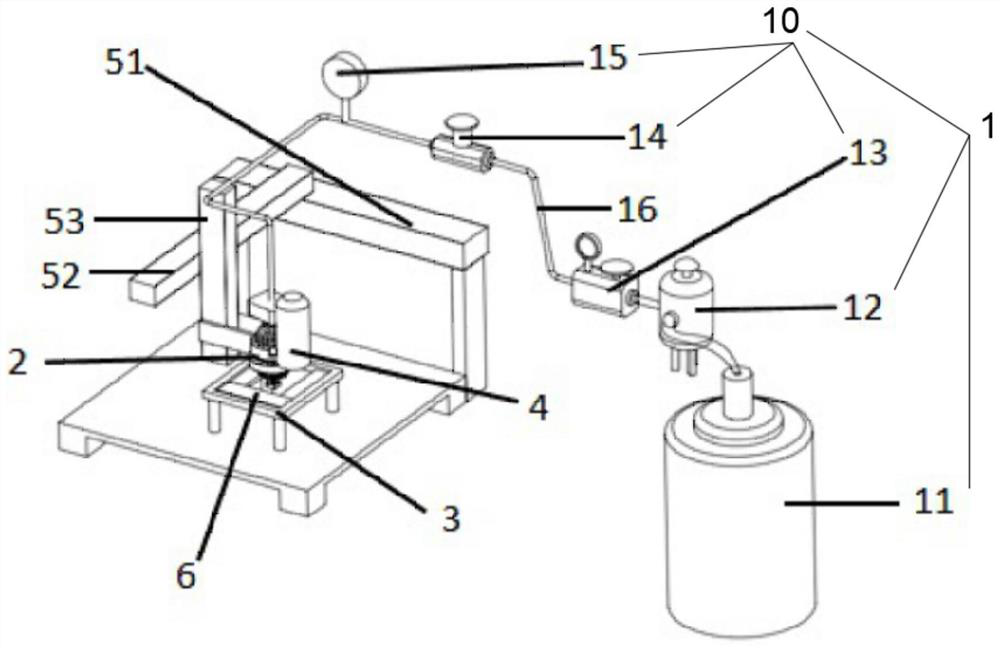

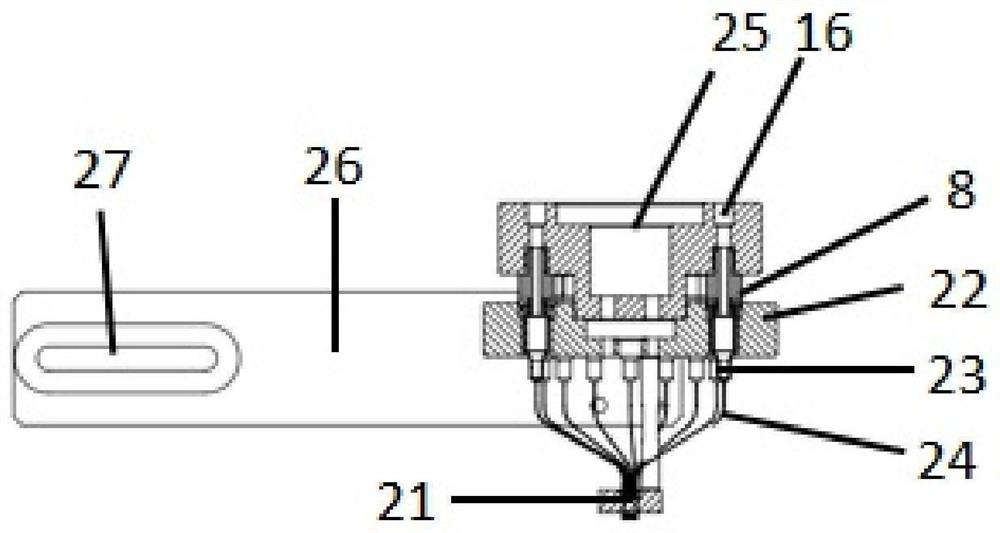

Combustion device for researching soot characteristics in low-pressure environment

InactiveCN103983738AAchieve pressure controlGuaranteed feasibilityChemical analysis using combustionDiffusion flamePressure stabilization

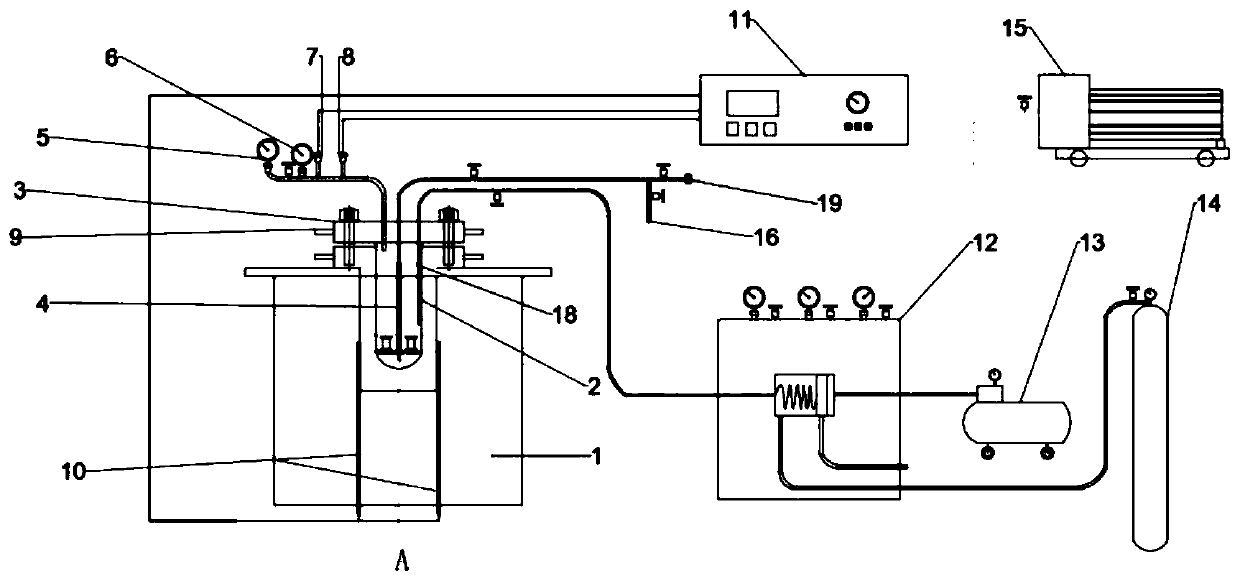

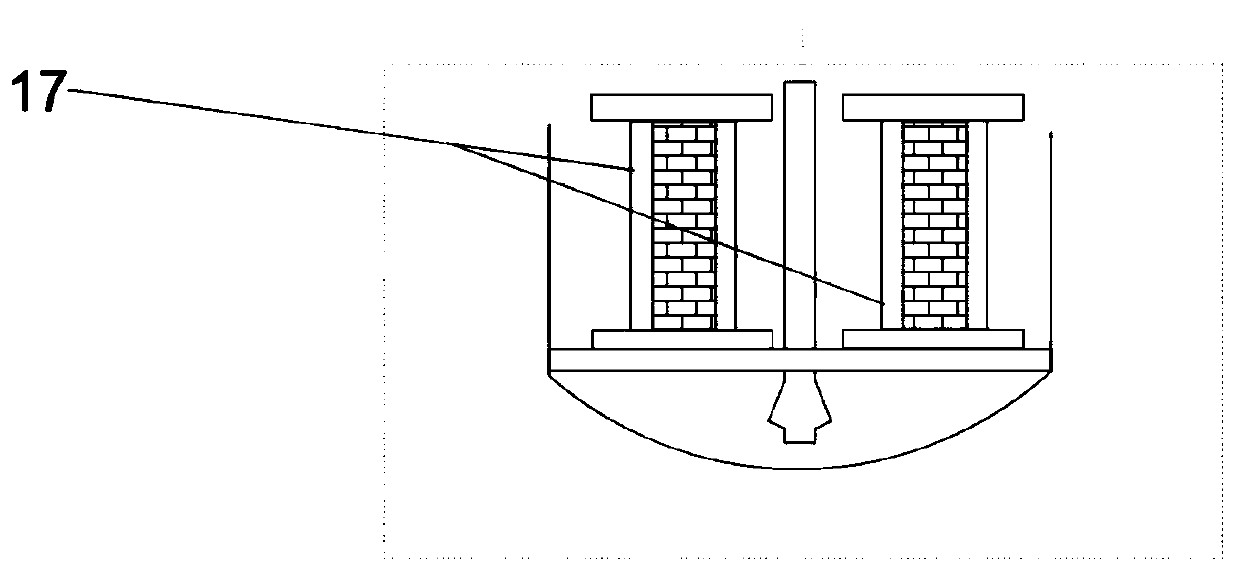

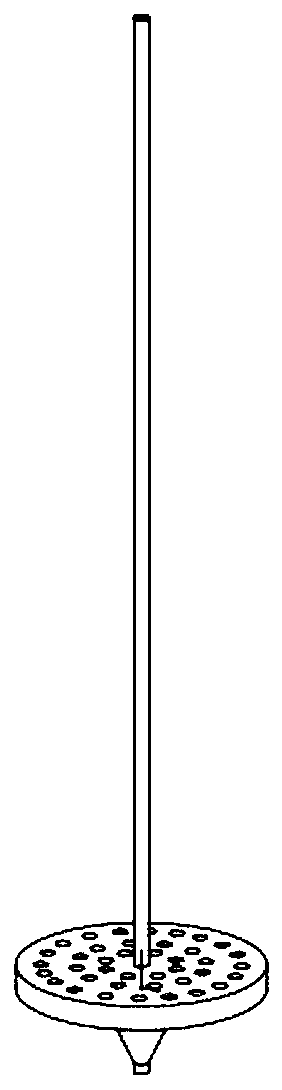

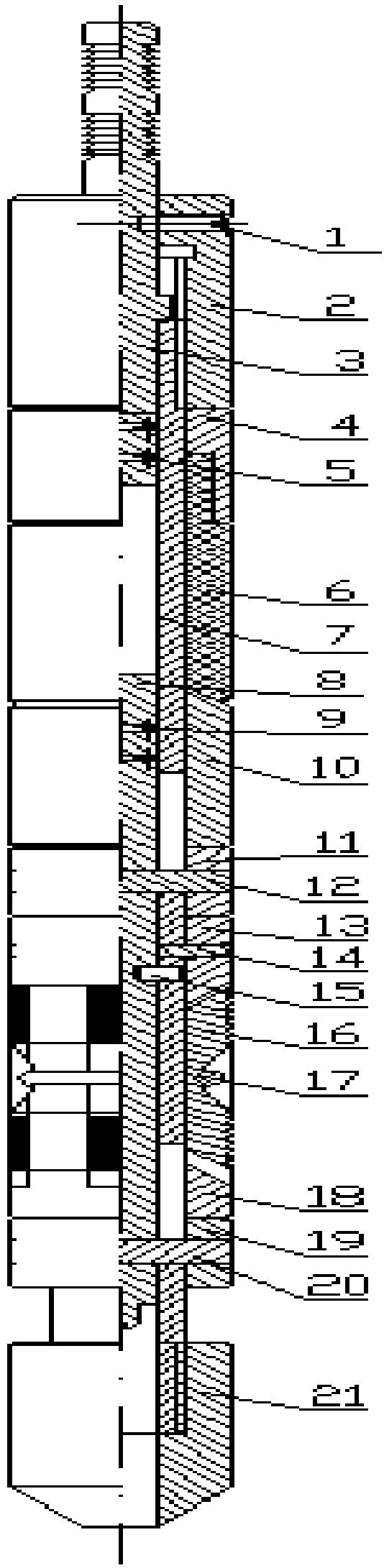

The invention provides a combustion device for researching soot characteristics in a low-pressure environment. The combustion device comprises a stainless steel low-pressure sealed cabin, a diffusion flame combustor, a gas mass flow control device, a high-voltage arc ignition device, an observation window, an auxiliary cleaning device, a digital display programmable logic controller (PLC), a vacuum pump group, an operating pressure stabilization device, a balance pressure air source and a detachable calibration tool clamping groove. The vacuum pump air exhaust and the balance pressure air source are simultaneously controlled through the control device in a low-pressure environment in the cabin, so that target pressure of the cabin is achieved. The inflow of two paths of gases of the combustor and the balance pressure air source is controlled by the gas flow controller, and after a pipeline is connected each time, the gas tightness at each joint of gas transport pipelines in the whole system is checked. A pressure meter is designed on a quick release upper flange plate. Operating pressure can be set and is dynamically monitored in real time through a PLC control interface, and the inflow of fuel gas, following wake air and the balance air source can be set.

Owner:UNIV OF SCI & TECH OF CHINA

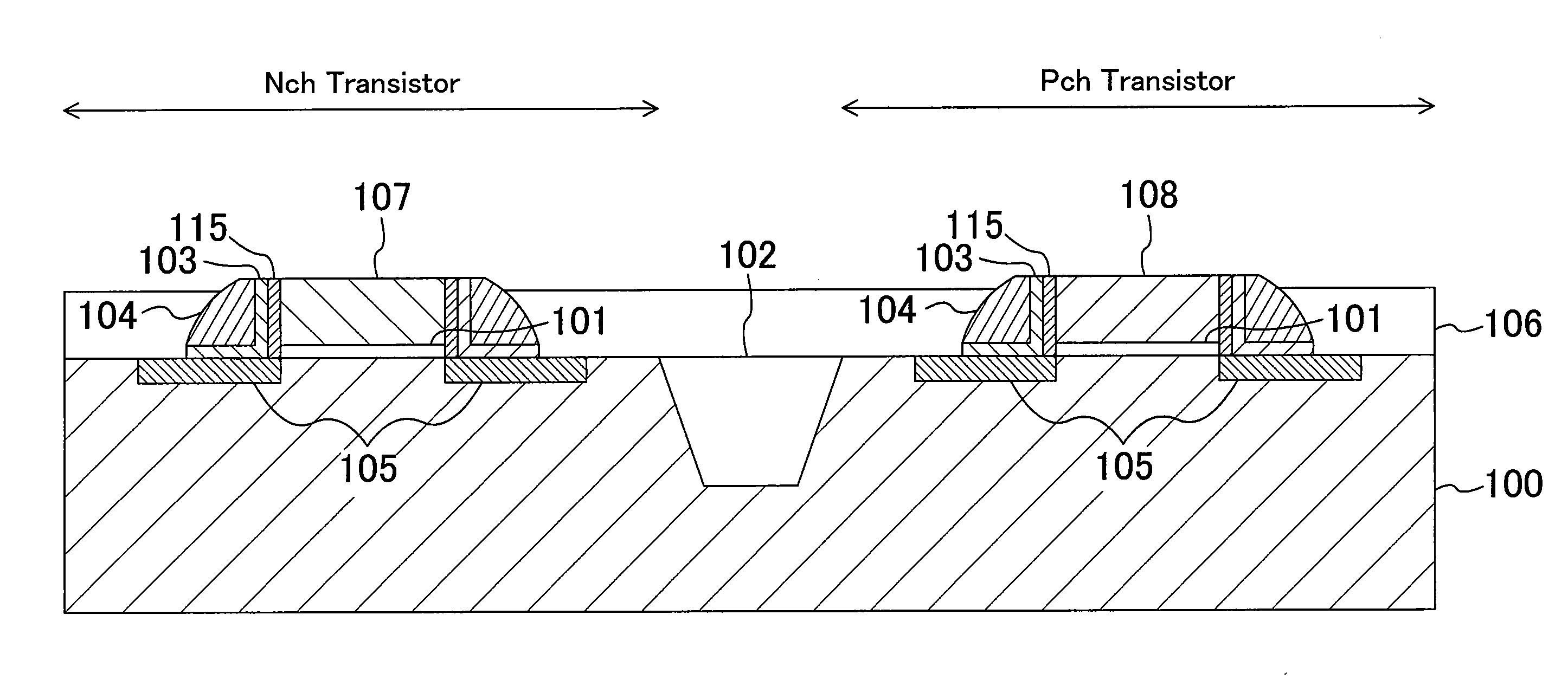

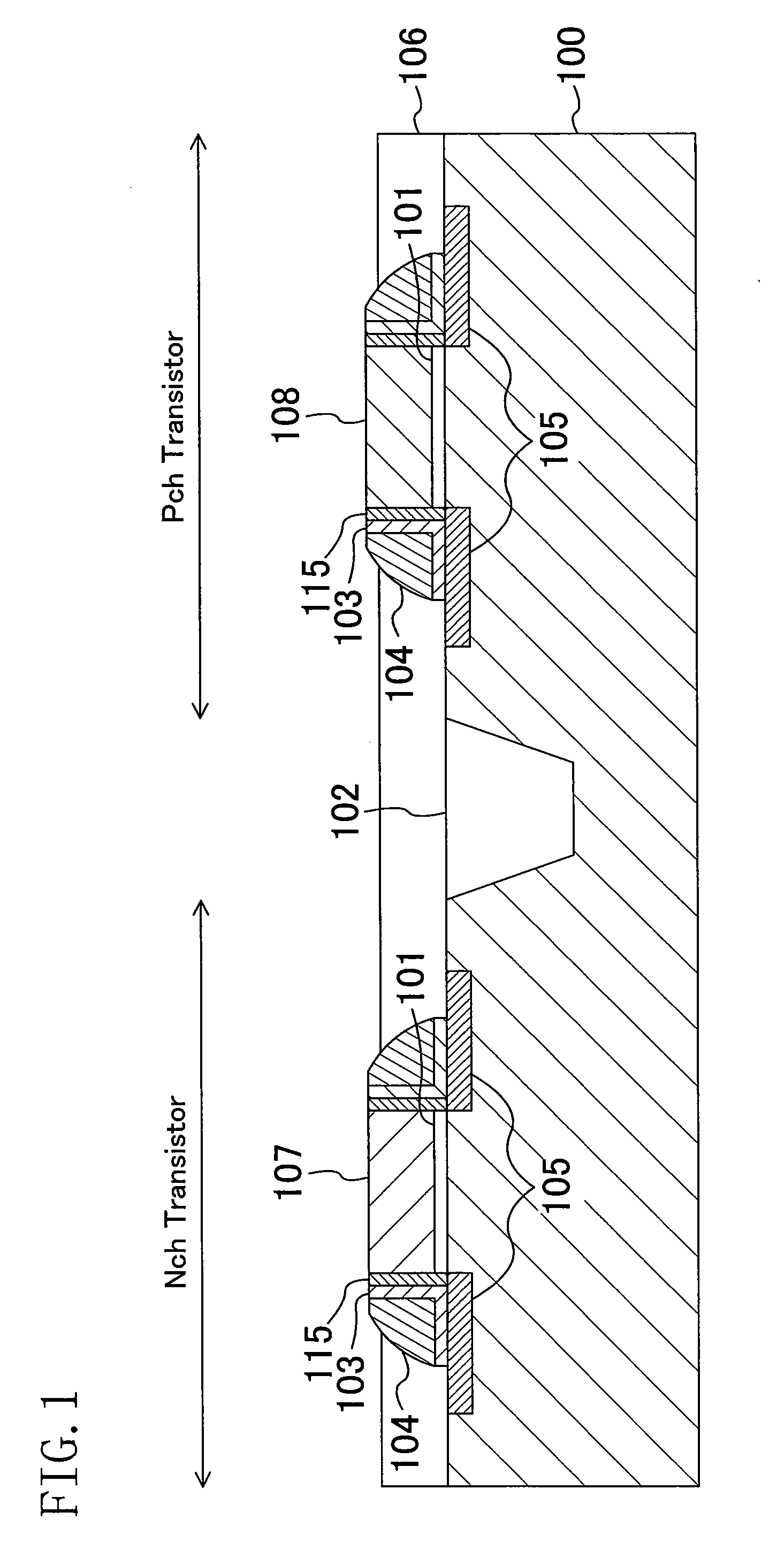

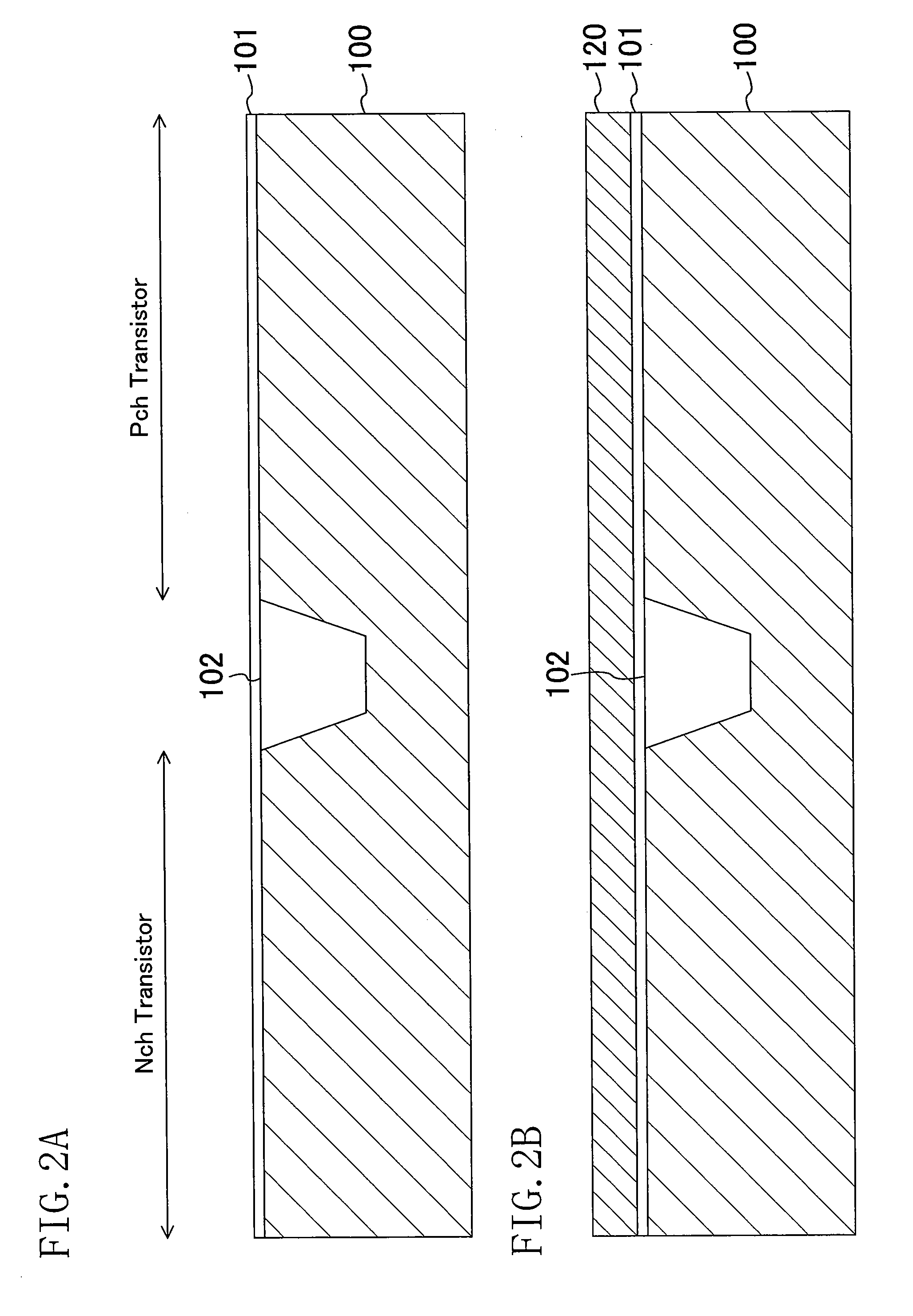

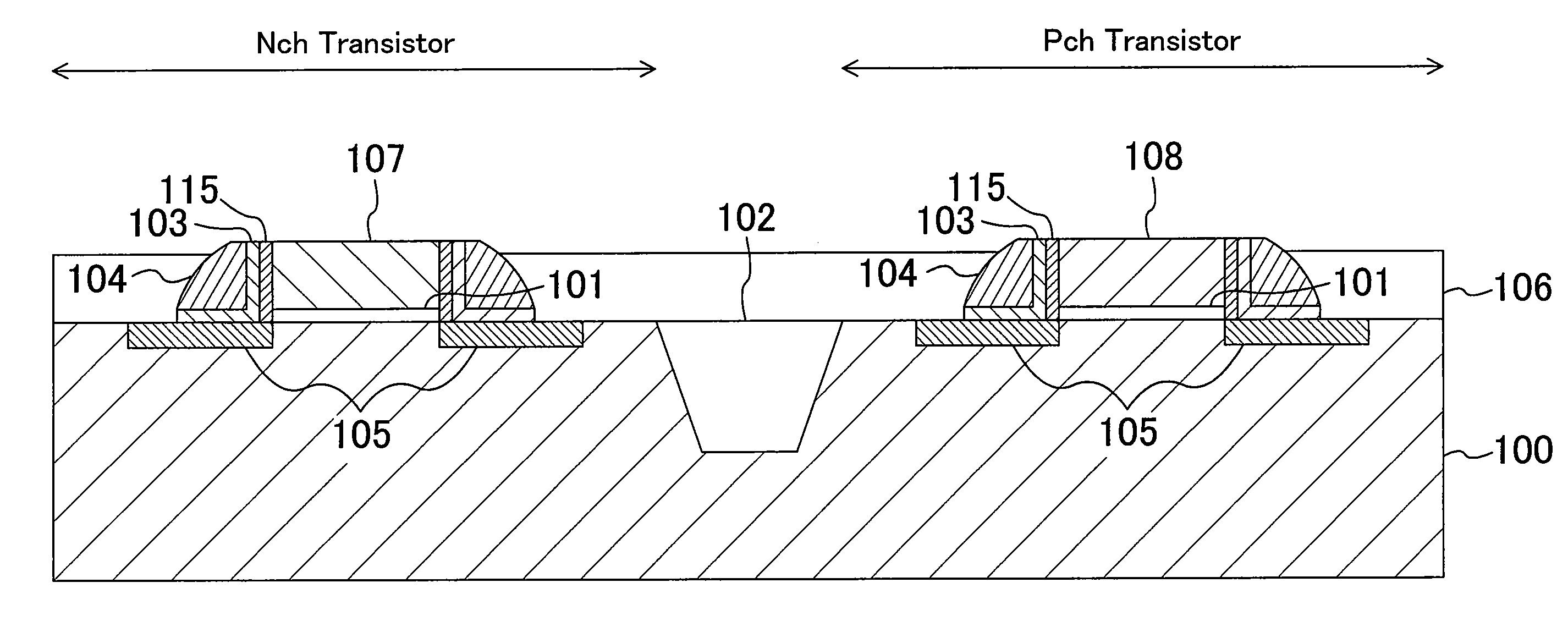

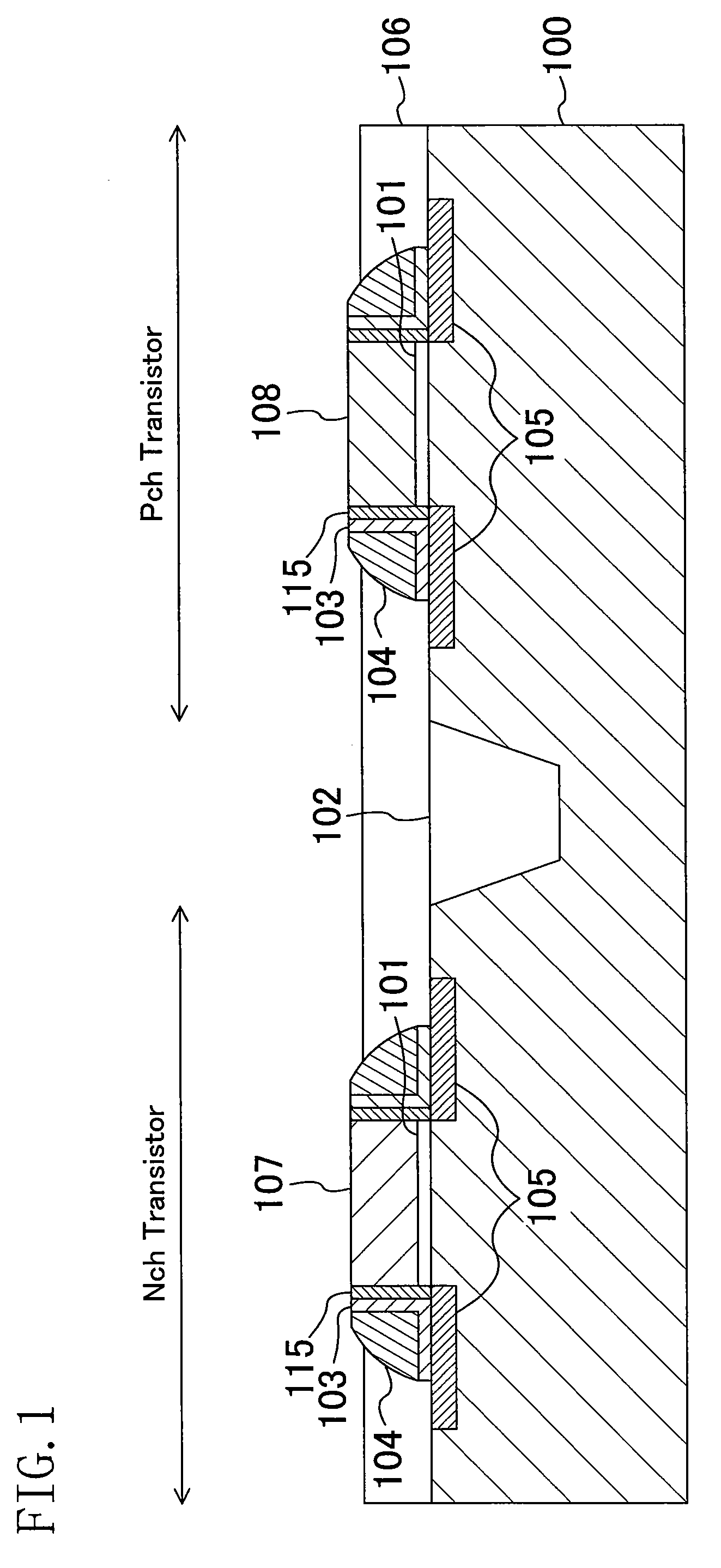

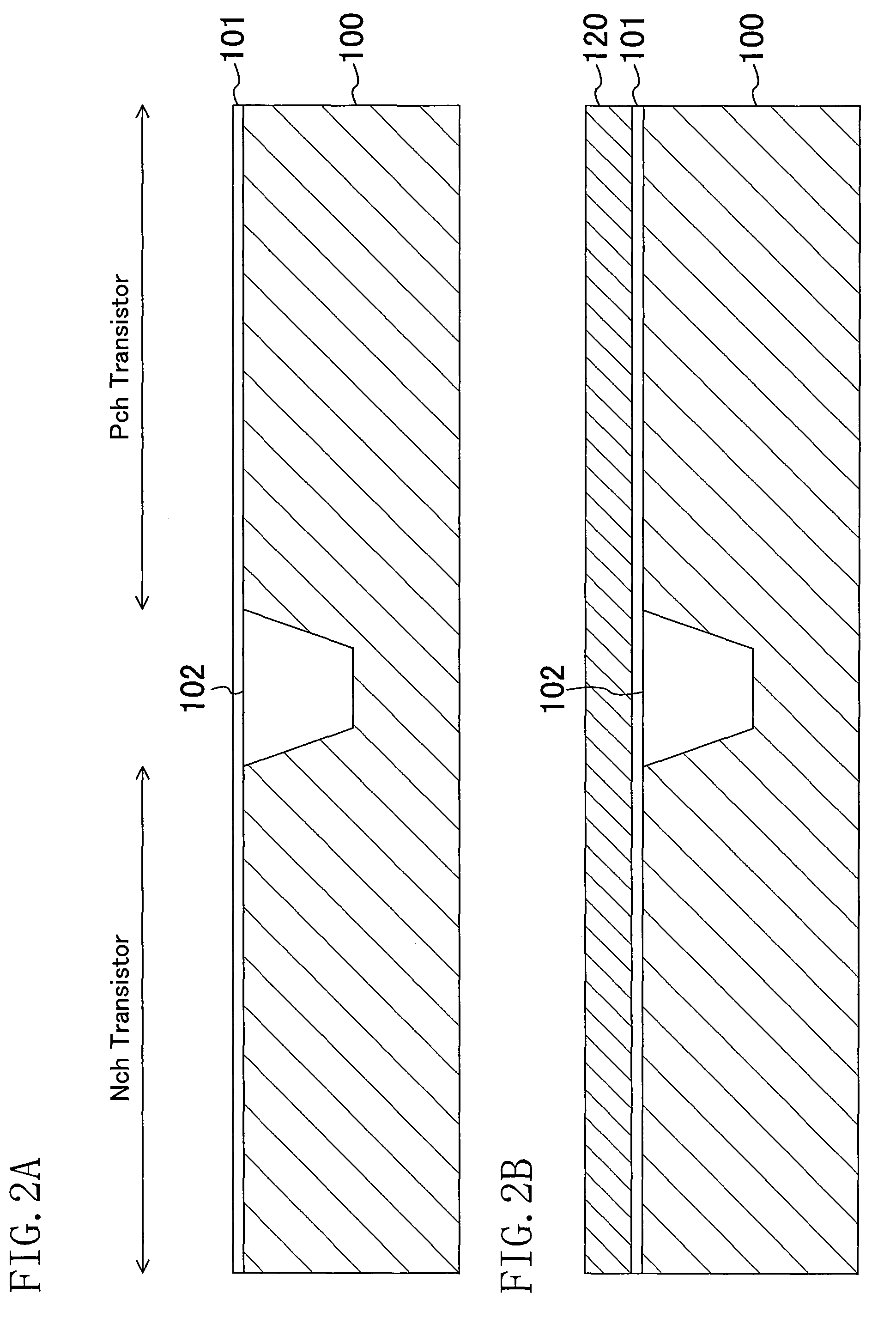

Semiconductor device and method for manufacturing the same

ActiveUS20080246102A1Enable stress controlImprove performanceTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device includes an Nch transistor having a first gate electrode and a Pch transistor having a second gate electrode. The first gate electrode and the second gate electrode are made of materials causing stresses of different magnitudes.

Owner:PANNOVA SEMIC

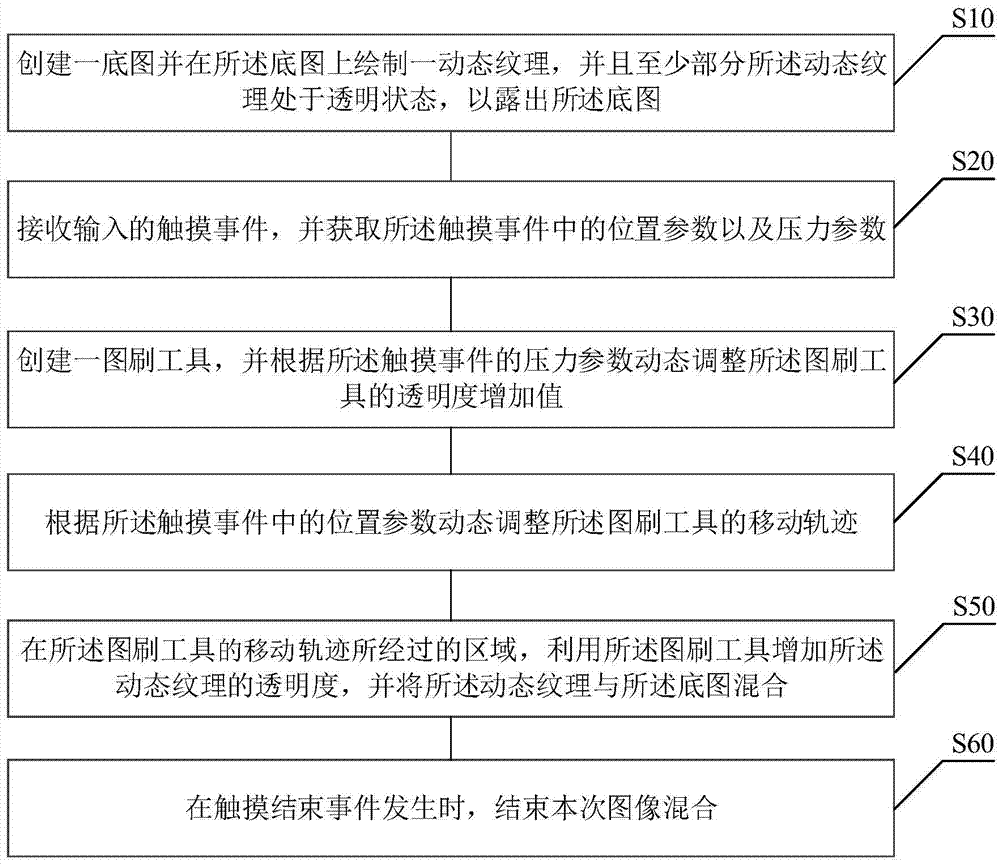

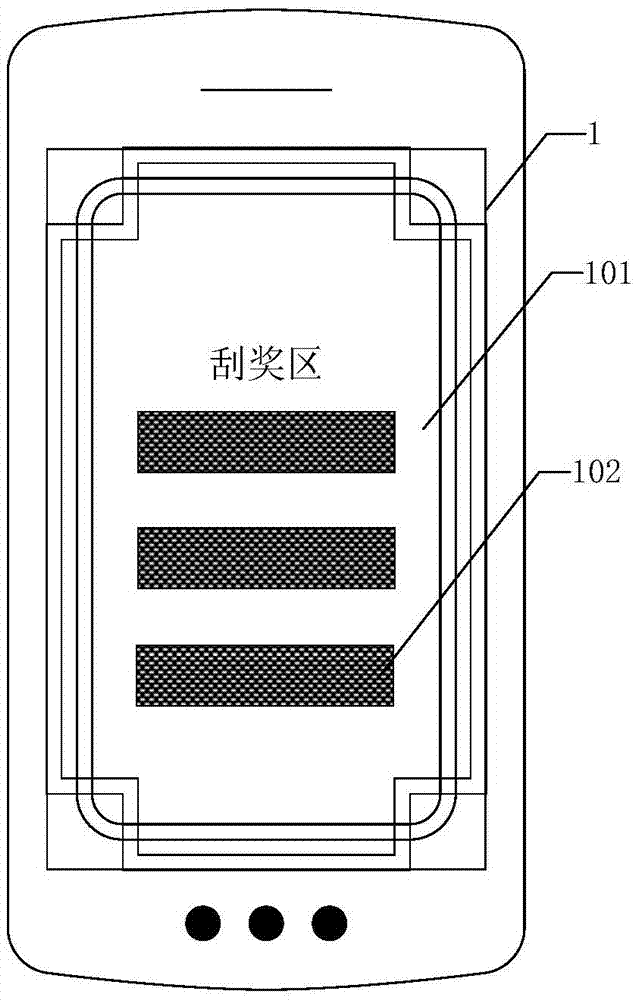

Image hybrid processing method and device

ActiveCN106933474ASolve the problem of single feedbackAchieve pressure controlInput/output processes for data processingComputer visionLocator Parameter

The invention relates to an image hybrid processing method and device. The method comprises the steps that a background base graph is created, a dynamic texture is drawn on the background base graph, and at least one part of the dynamic texture is not transparent; an input touch event is received, and position parameters and pressure parameters in the touch event are acquired; a graph brush tool is created, and a transparency increase value of the graph brush tool is dynamically adjusted according to the pressure parameters in the touch event; a moving trail of the graph brush tool is dynamically adjusted according to the position parameters in the touch event; and the graph brush tool is utilized to increase the transparency of the dynamic texture in a region which the moving trail of the graph brush tool passes through, and the dynamic texture and the background base graph are mixed. According to the method, the transparency increase value is adjusted according to the pressure parameters of pressing, and the trail is adjusted and erased according to the position parameters of pressing, so that true erasing operation with a pressure sense is simulated, and the feedback effect is more consistent with user operation.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

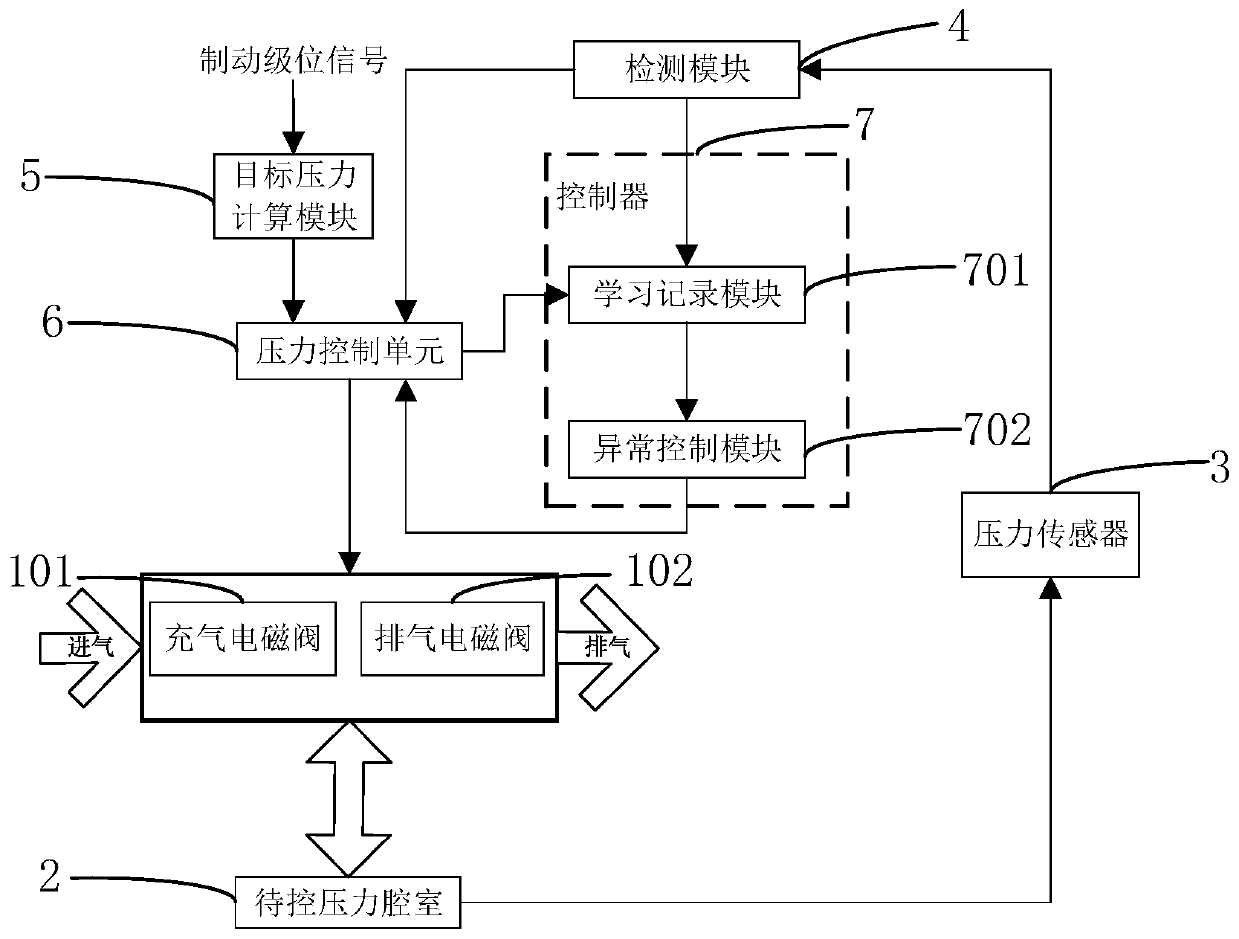

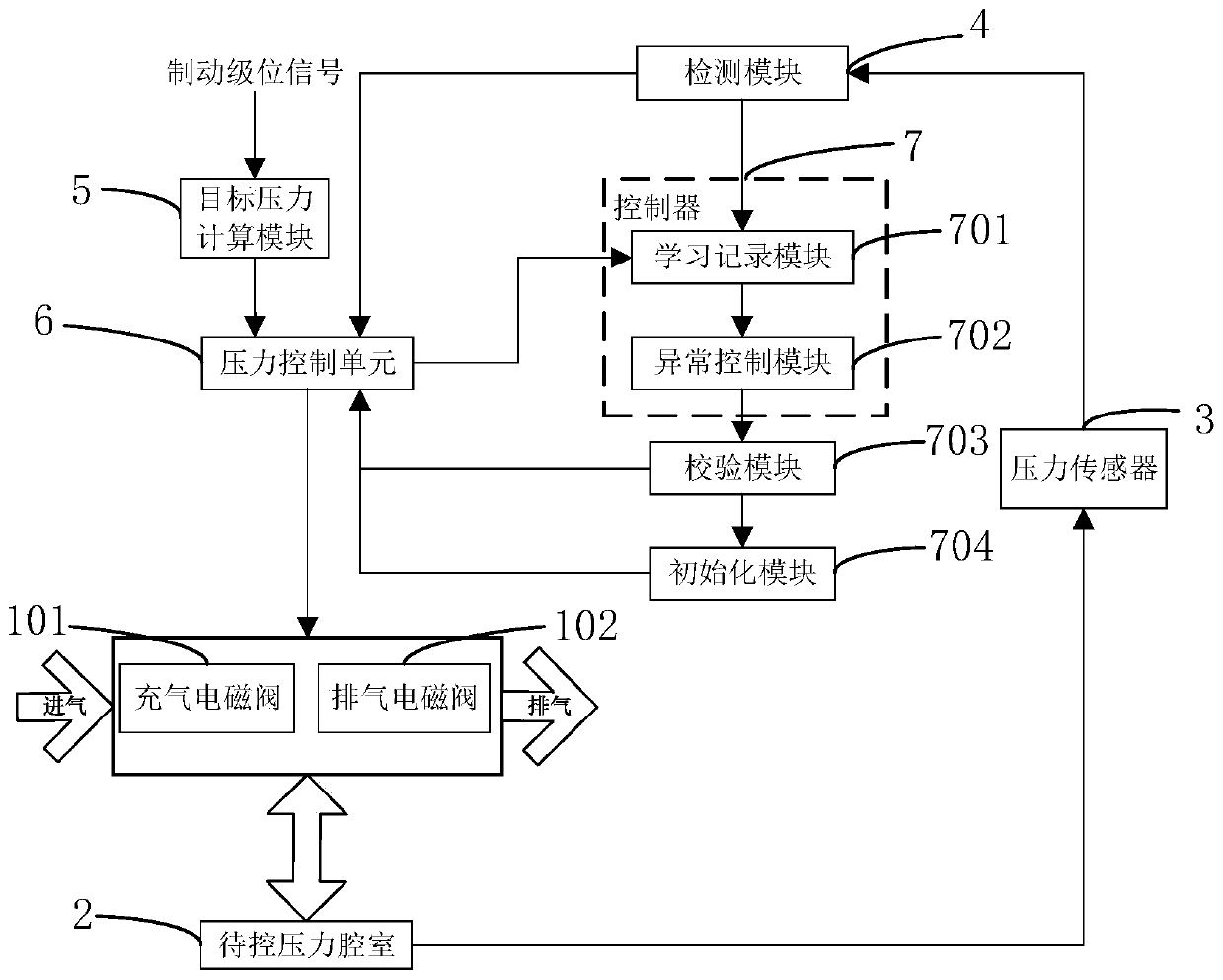

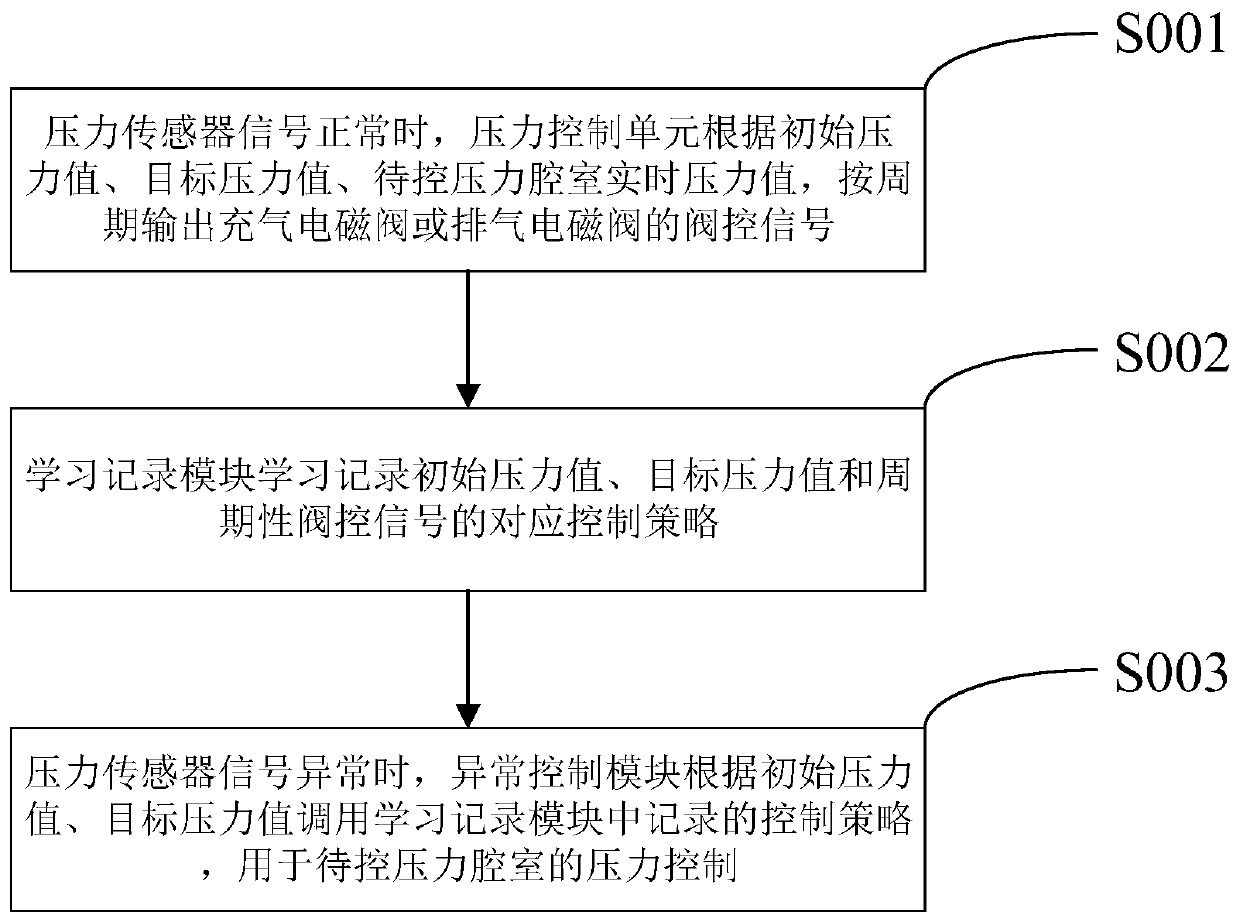

Air brake pressure control system and brake control method

ActiveCN110395242AEasy to controlControl module for precise controlBrake safety systemsElectricityControl system

The invention discloses an air brake pressure control system and a brake control method. The system comprises an air inflation electromagnetic valve, an exhaust electromagnetic valve, a pressure sensor, a detection module, a pressure control unit and a controller, wherein controller comprises a learning record module and an abnormal control module. According to the brake control method, a synchronous learning and a recording control strategy of the learning record module is utilized, when signals of the pressure sensor are abnormal, the abnormal control module calls the control strategy of thelearning record module, and the air inflation electromagnetic valve or the exhaust electromagnetic valve is controlled to gradually reach the target pressure according to the corresponding control strategy. Compared with a certain fixed state that a control electromagnetic valve is in the normal power or normal power loss, the pressure of a pressure chamber to be controlled is more accurate.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

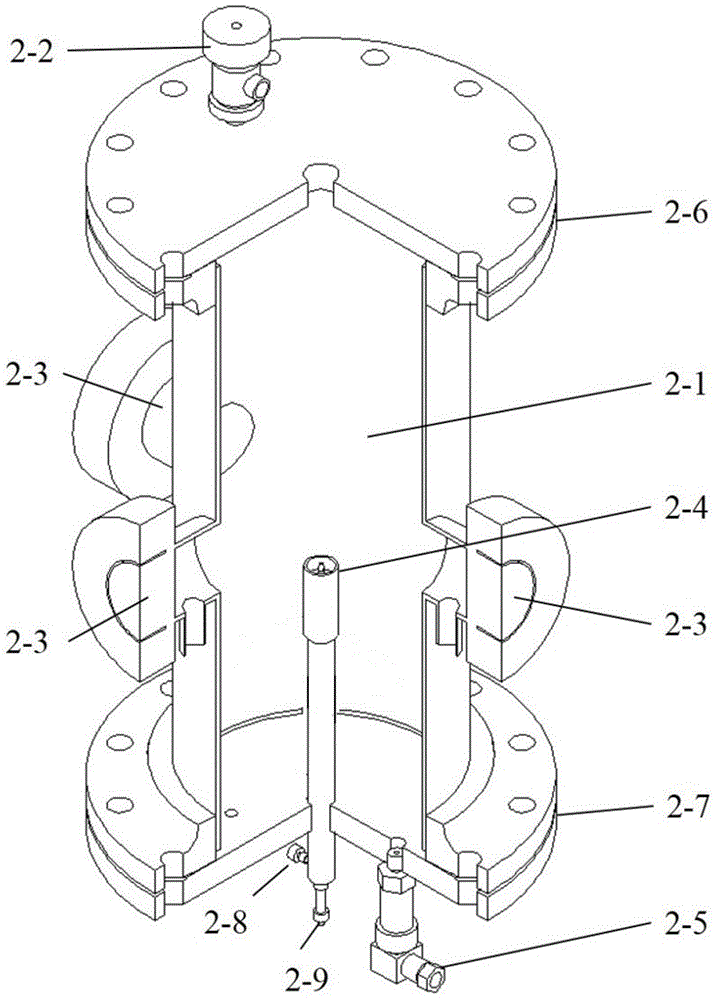

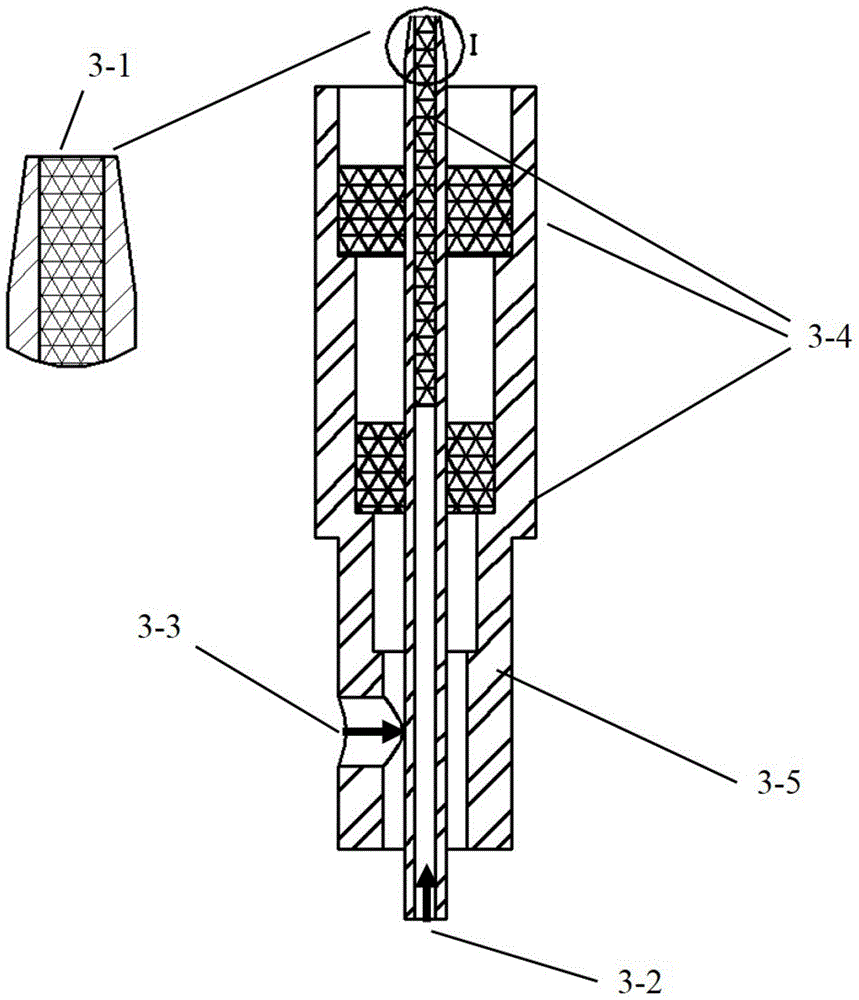

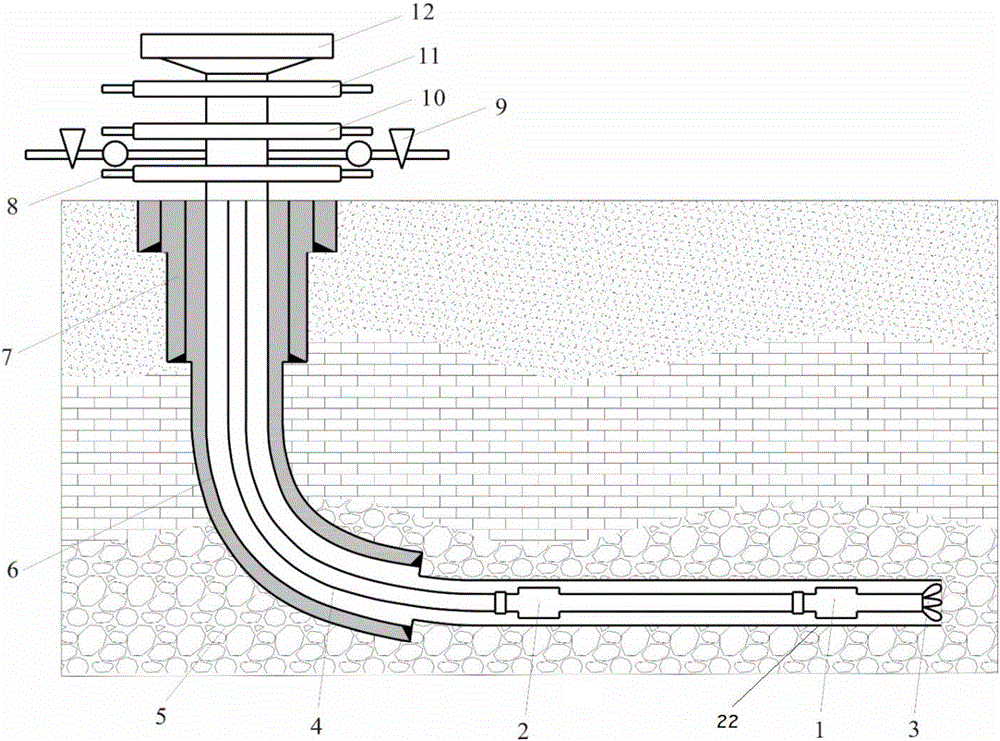

Indoor simulation device and method for supercritical water and shale reaction

ActiveCN111537697ACreate a gaseous environmentAvoid cloggingPreparing sample for investigationEarth material testingRock coreEngineering

The invention relates to an indoor simulation device and method for supercritical water and shale reaction. The device comprises a high-temperature and high-pressure reaction kettle, a vacuum pump, anair compressor, a booster pump and a heating device. The high-temperature high-pressure reaction kettle consists of a kettle body, a kettle cavity, a kettle cover, a rock core jacket and a filter screen bracket, wherein the kettle cavity is formed in the kettle body, the upper part of the kettle cavity extends out of the kettle body, the kettle cover is mounted at the top of the kettle cavity, pressure fluid is injected through a communication valve port to realize rock core confining pressure control and is placed on a filter screen bracket at the bottom of the inner side of the kettle cavity, and the filter screen bracket is vertically arranged in the middle of the bottom of the kettle cavity and used for placing a rock core jacket; the heating device is arranged on the outer side of the kettle cavity; a gas injection pipeline, a gas exhaust pipeline and a detection pipeline are arranged on the kettle cover, penetrate through the kettle cover from the kettle cavity and extend to theoutside, and the gas injection pipeline is connected with the booster pump. According to the invention, under a specific gas environment, a rock sample can react with water under the condition of exceeding the critical temperature and pressure of water, and indoor simulation of shale and supercritical water reaction is completed.

Owner:SOUTHWEST PETROLEUM UNIV

Method for controlling a compressor

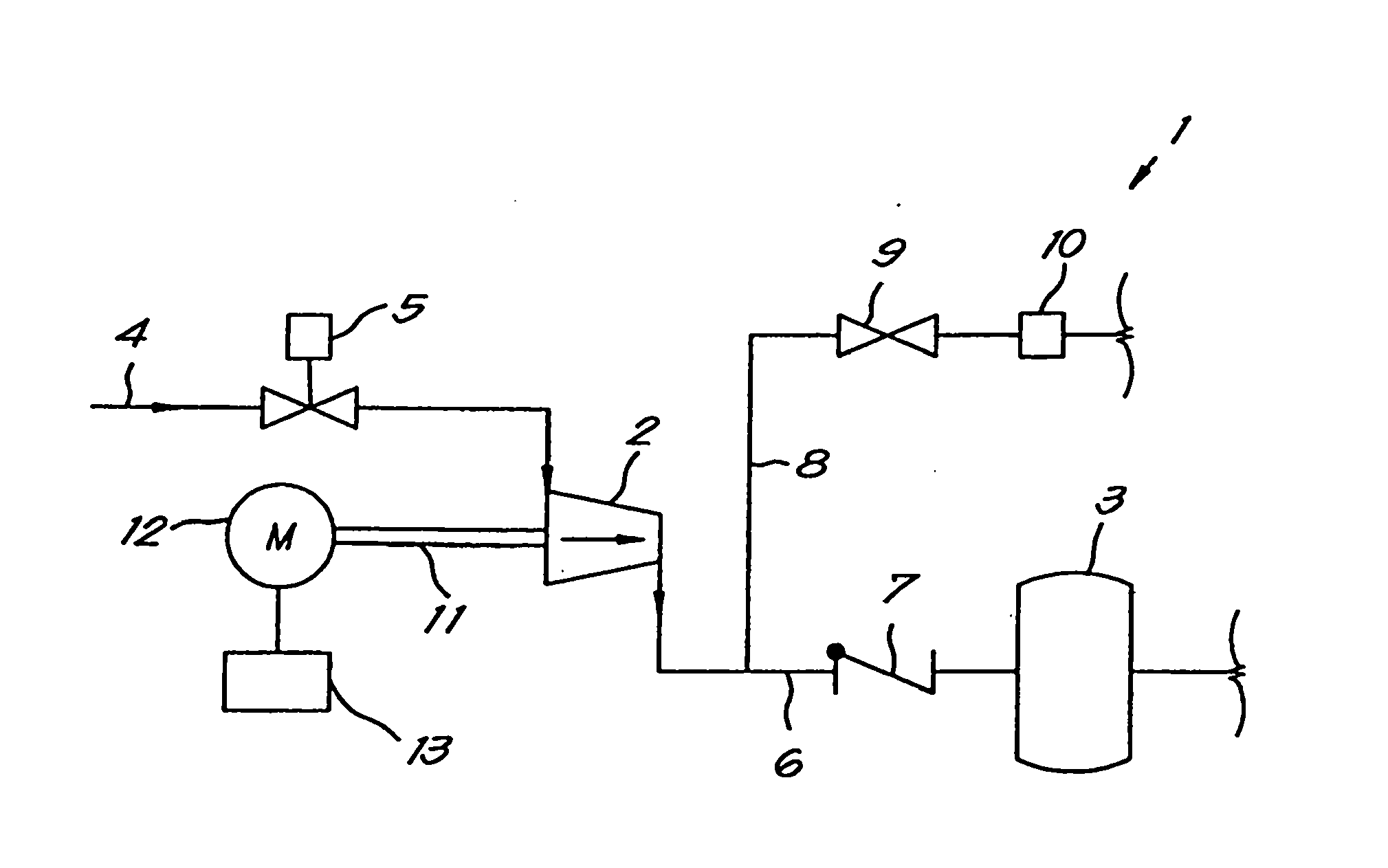

ActiveCN102918277AShorten the timeAchieve pressure controlWorking fluid for enginesEfficient regulation technologiesInlet pressureEngineering

Owner:ATLAS COPCO AIRPOWER NV

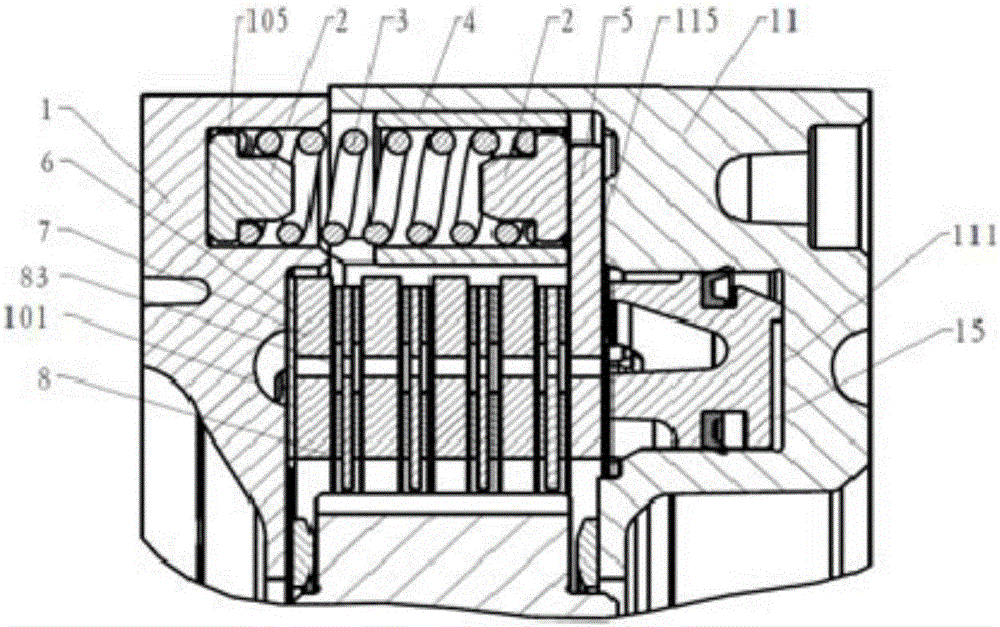

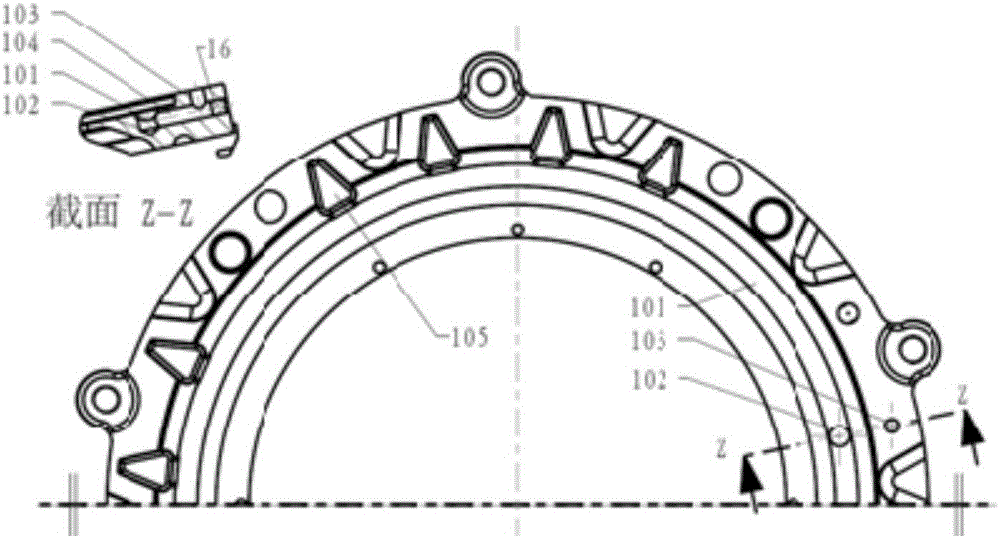

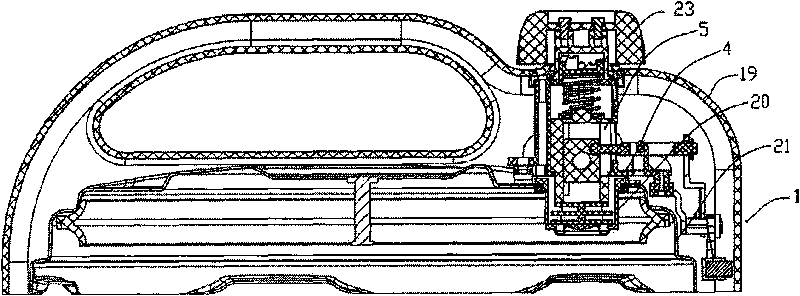

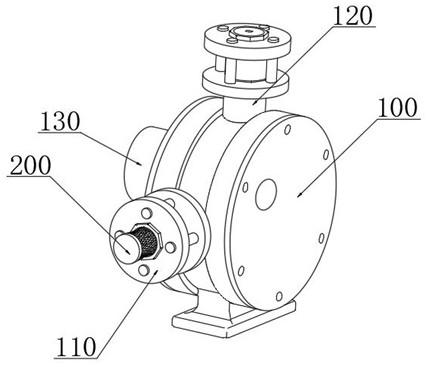

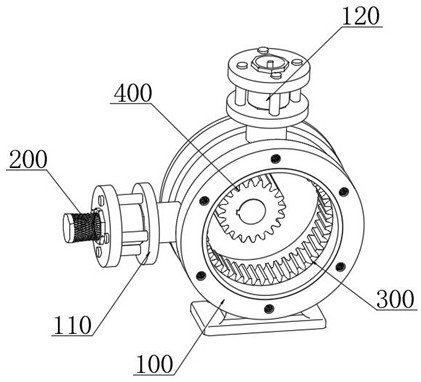

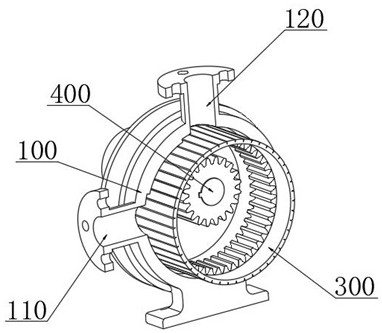

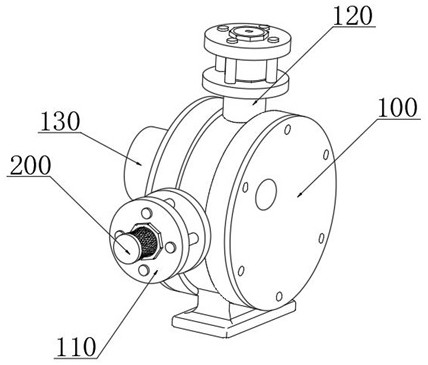

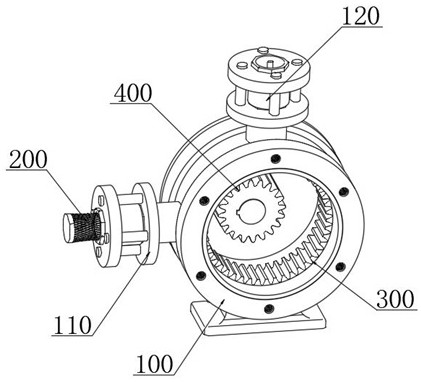

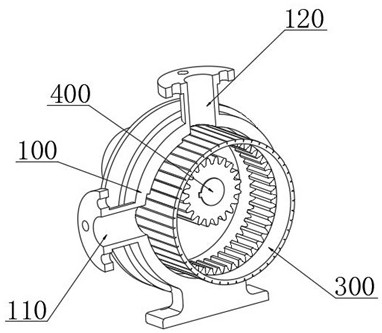

Brake

ActiveCN106641027AEasy to controlImprove efficiencyAxially engaging brakesBraking membersEngineeringPiston

The invention discloses a brake. The brake comprises a back plate shell body and a piston shell body which are connected together by fasteners. Pairing slices and friction slices are arranged alternatively in an installation space defined by the back plate shell body and the piston shell body. The pairing slices are installed in a key groove of the piston shell body through a first spline tooth on the pairing slice. Each friction slice comprises a base body located in the center and friction material arranged at both sides of the base body. The friction slice is mounted on a gear ring through an internal spline gear of the base body. A flow balance plate is arranged between the pairing slice at the outermost side and the back plate shell body. According to the brake, through the adding of the flow balance plate between the back plate shell body and the pairing slices, lubricating oil flow balance in the circumferential direction between the pairing slices and the friction slices is achieved. Because the lubricating oil circuit is an independent oil circuit, the lubricating oil circuit is controllable, when it is not needed to lubricate the brake, the lubricating oil circuit can be closed to reduce drag loss, and enhance the efficiency of a transmission.

Owner:SHAANXI FAST GEAR CO

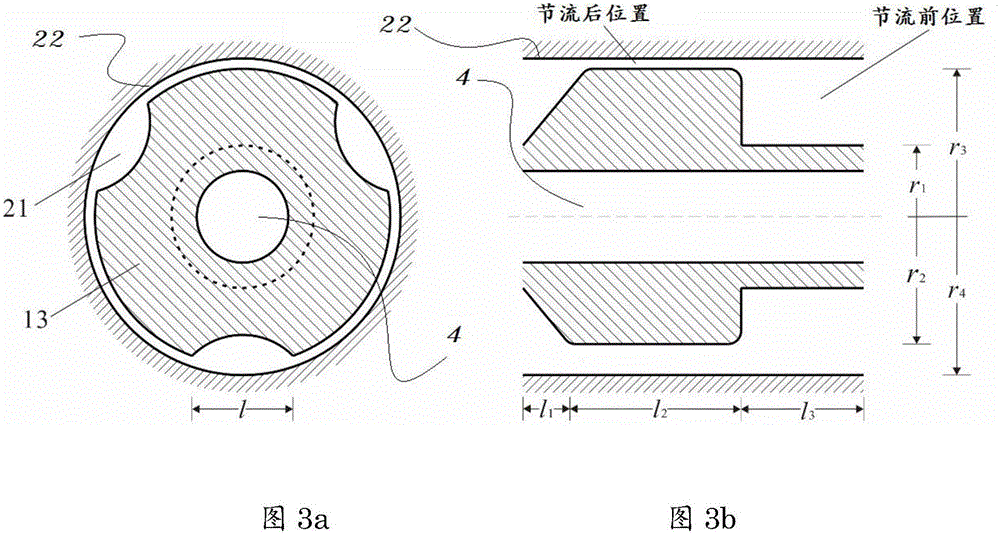

Measurement unit and overflow information recognition device and method

InactiveCN106401571AEasy to identifyAchieve pressure controlSurveyConstructionsTemperature differenceEngineering

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

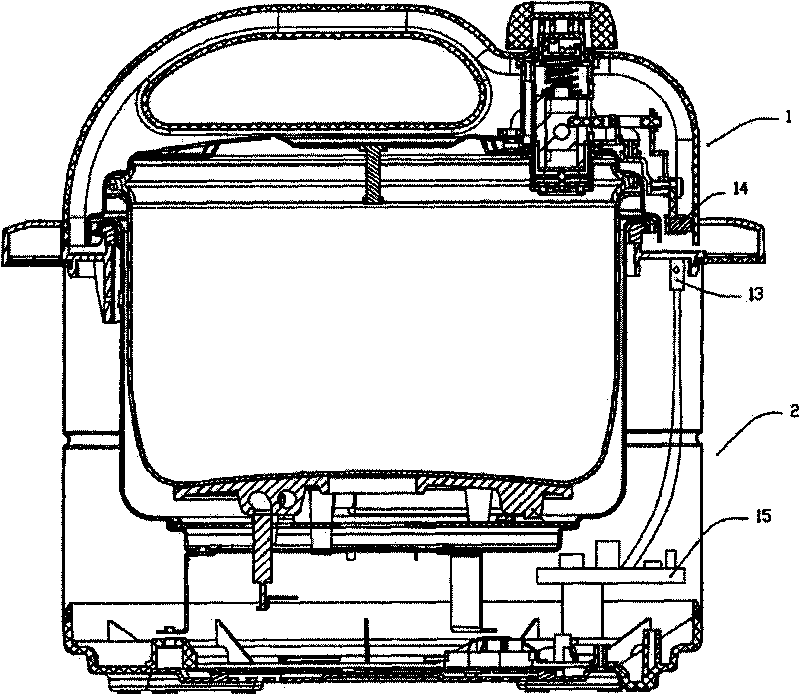

Multi-segmented pressure regulating electric pressure cooking saucepan

ActiveCN101721124APressure control action simplyNo malfunctionPressure-cookersElectricityPressure transmission

The invention relates to a multi-segmented pressure regulating electric pressure cooking saucepan, which comprises a pan cover, a pan body, an electric heating device and a control circuit. The pan cover is provided with a multi-segmented pressure regulating device which comprises a pressure setting device, a pressure conversion device and a shell; the pressure conversion device comprises a pressure transmission mechanism, a displacement jumping mechanism and a signal transmission mechanism; the pressure transmission mechanism comprises a pneumatic piece and a steam sealing sleeve; the displacement jumping mechanism comprises a jumping slide block and a connecting rod which are in movable connection; a jumping spring is arranged between the jumping slide block and the pneumatic piece; a positioning mechanism is arranged between the jumping slide block and the shell; the pneumatic piece is provided with a touch piece which enables the jumping slide block to act; and the signal transmission mechanism comprises a switch component which is electrically connected with the control circuit. The multi-segmented pressure regulating electric pressure cooking saucepan has the advantages of accurate and reliable pressure regulation and realization of multi-segmented pressure regulation.

Owner:JOYOUNG CO LTD

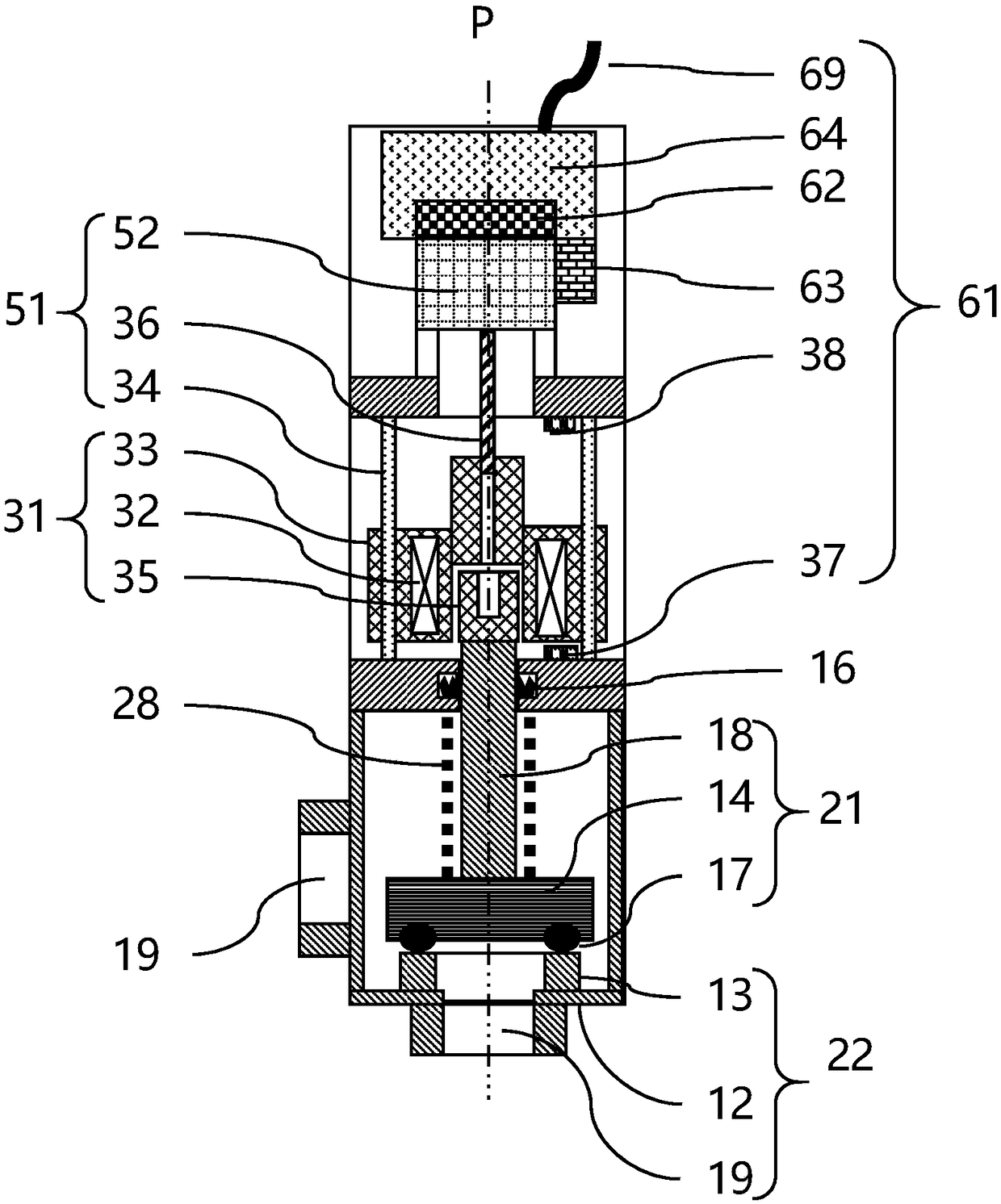

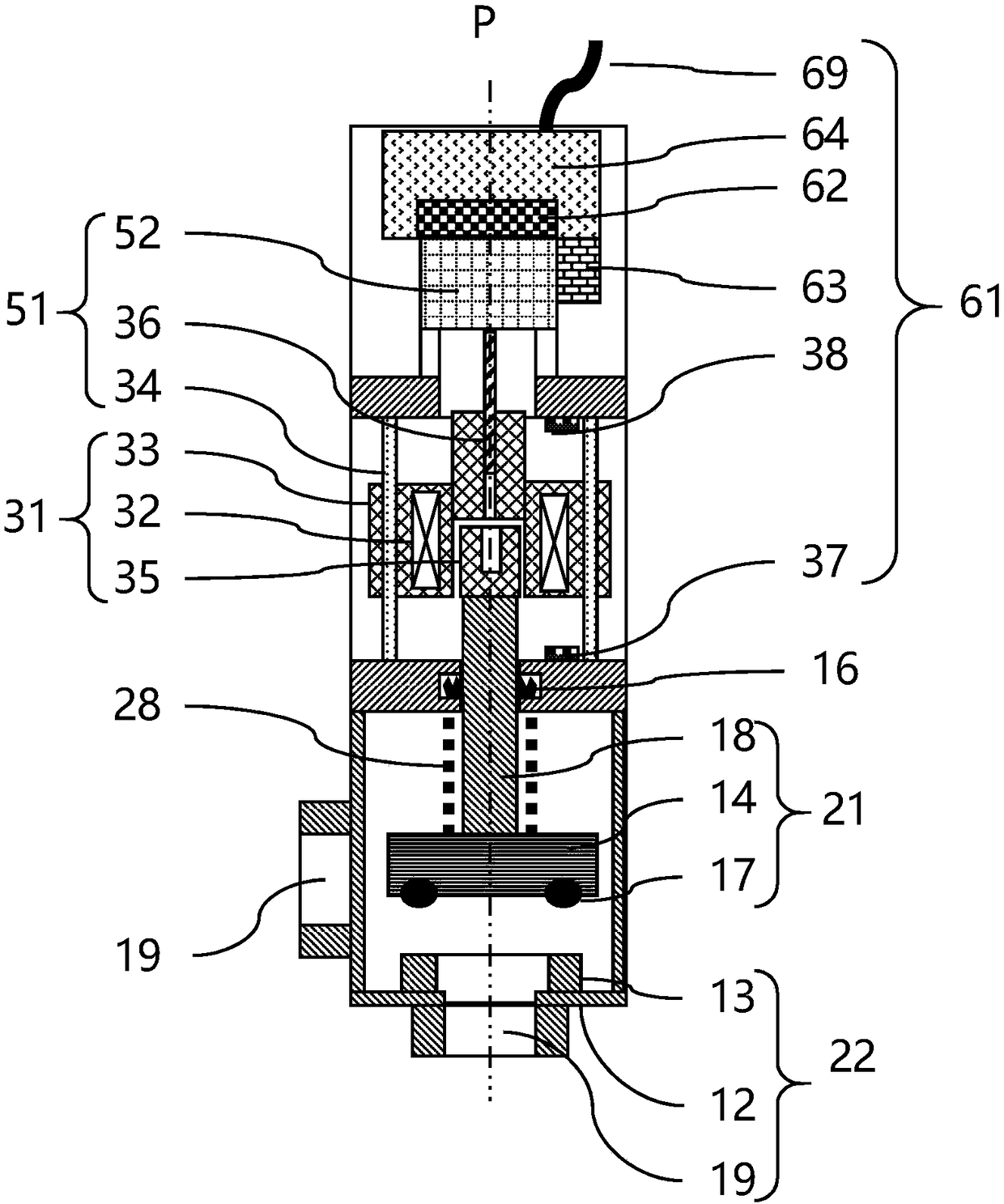

Vacuum pressure control valve

PendingCN108194677AQuick and safe closingLow access requirementsOperating means/releasing devices for valvesLift valveVacuum pressureEngineering

The invention relates to a lifting type pressure control valve with an isolating function used in vacuum equipment. A vacuum pressure control valve includes a valve body, a valve cavity is formed in the valve body which is provided with at least two joints which can enable the valve cavity to communicate with the outside, and the position, corresponding to at least one of the joints, in the valvecavity is provided with a valve seat; a valve core includes a valve plate and a valve rod which are fixedly connected with each other, a coupler includes a support and a coil and an armature which arefixed to the support, an opening actuator is used for driving a support of the coupler to move up and down, and the coupler is arranged above the valve body; and the valve core is arranged in the valve cavity, the valve plate is matched with the valve seat, and the valve rod penetrates through the valve body to be fixedly connected with the armature arranged above the valve body. According to thevacuum pressure control valve, the flow can be precisely regulated in the wide conductance range through a pure electric connection system, thereby realizing the precise pressure control, and achieving isolating and emergency power-lossing protection; and the vacuum pressure control valve is suitable for the exhausting control and the process pressure control from barometric pressure to lower middle vacuum.

Owner:苏州欧纳克纳米科技有限公司

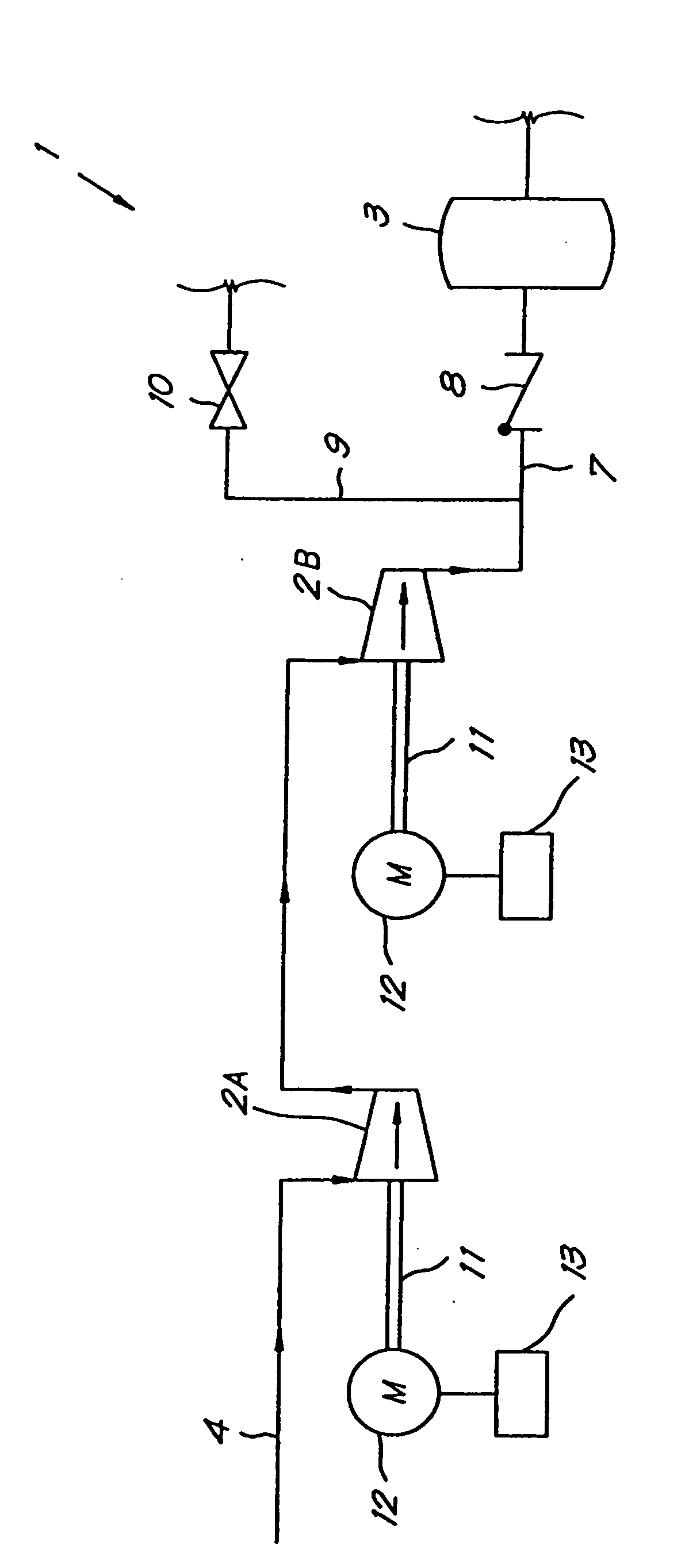

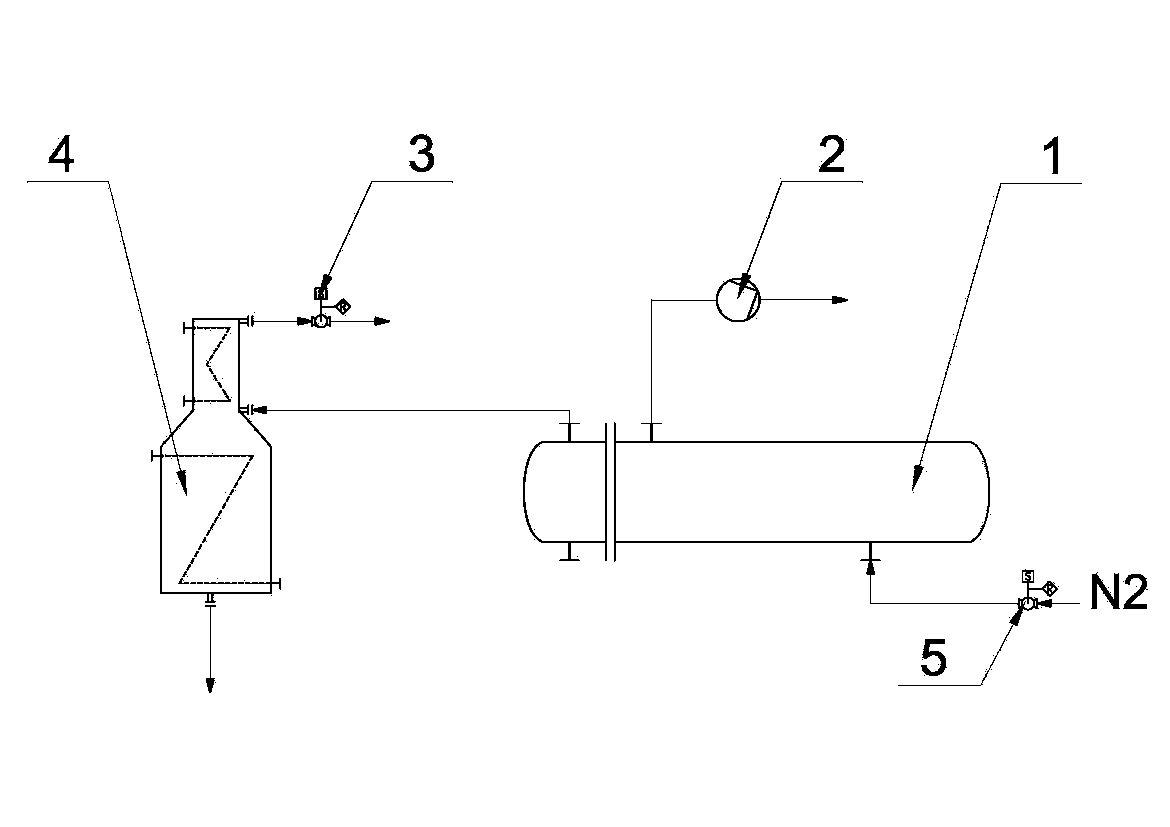

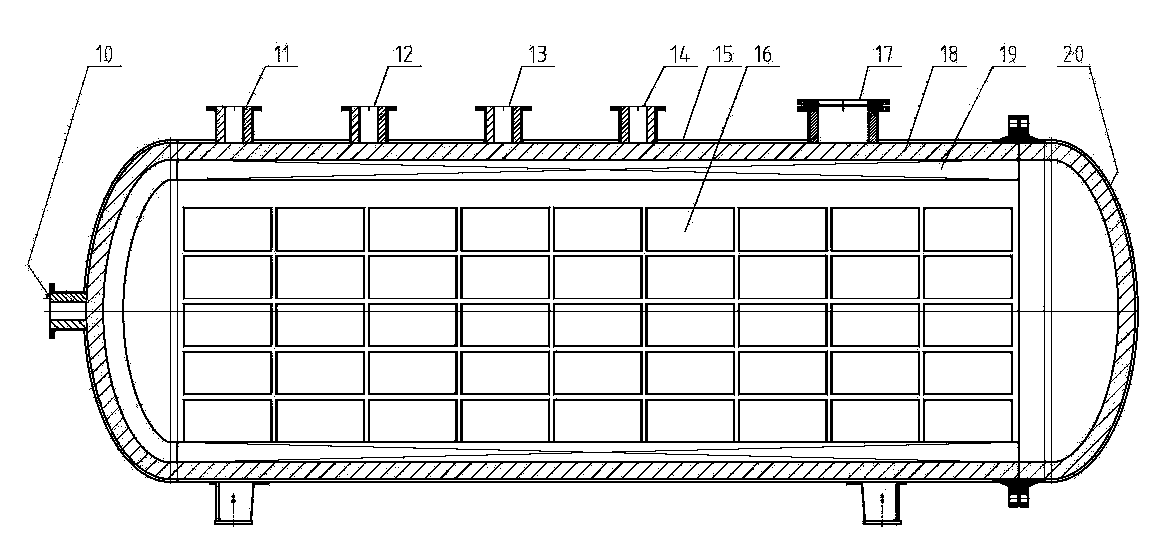

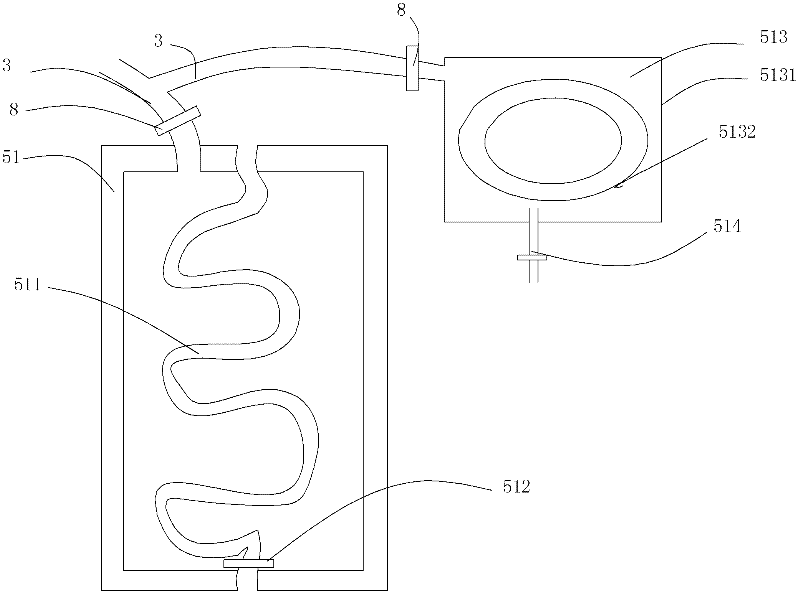

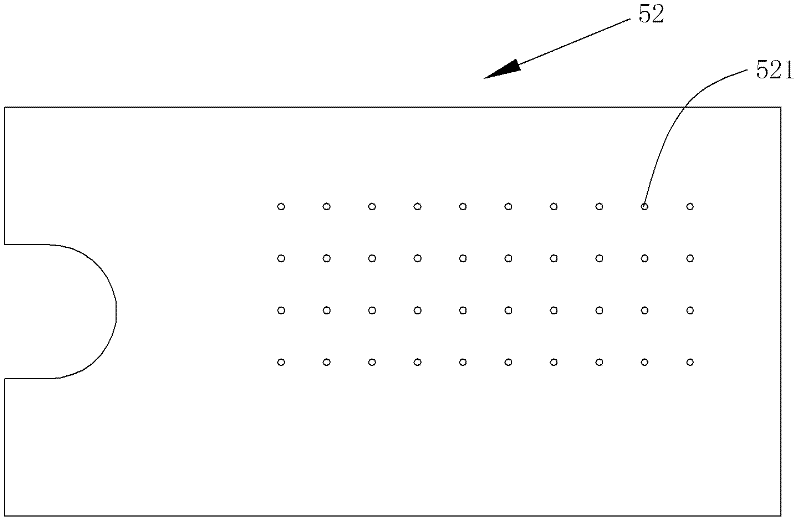

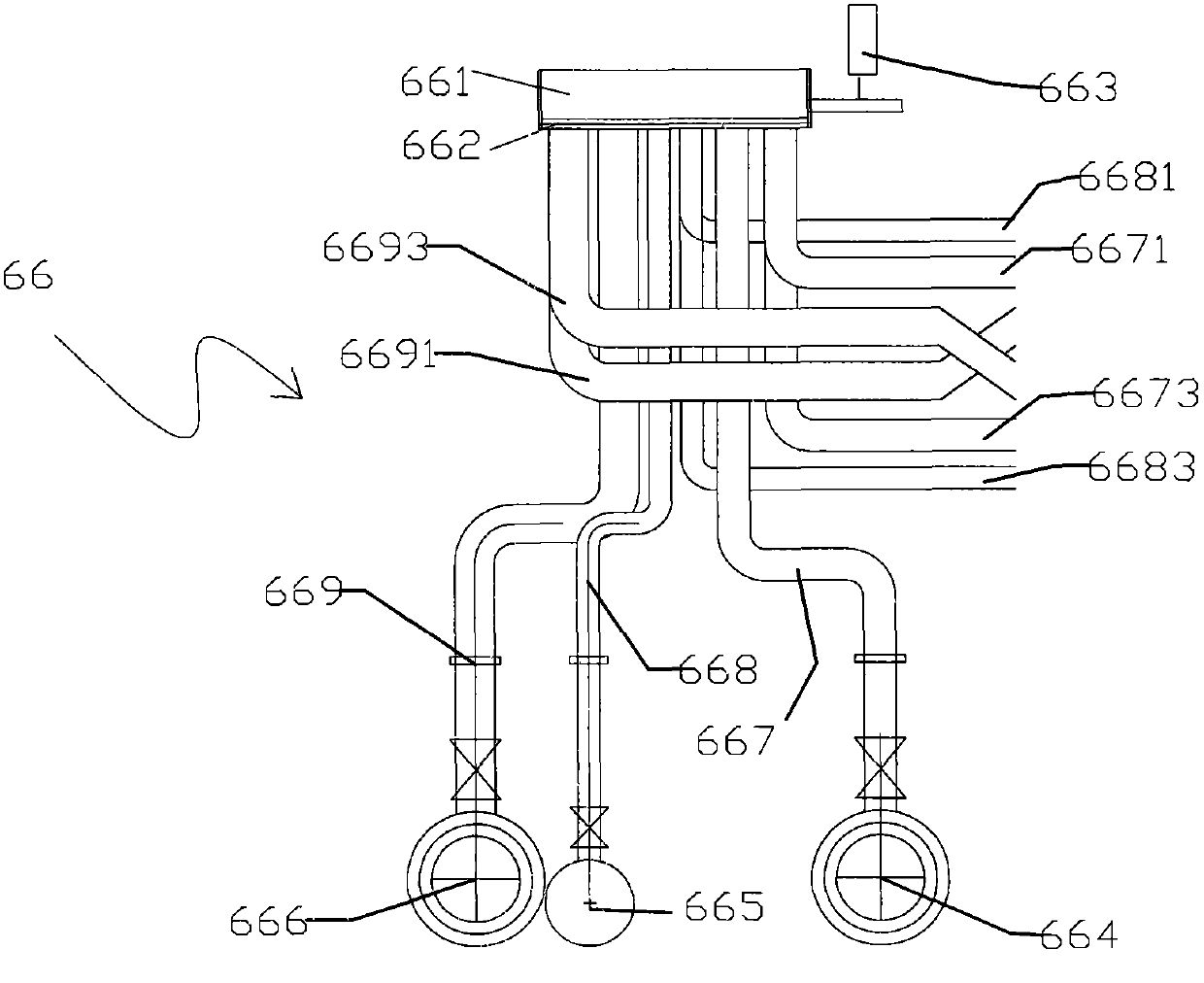

BOG condensation recycling system and method for LNG station

ActiveCN105135211AAvoid pollutionReduce one-time input costsContainer filling methodsPipeline systemsNitrogenNitrogen gas

The invention discloses a BOG condensation recycling system for an LNG station. A liquid inlet pipe of an immersed pump (3) is connected with a liquid drain pipe of an LNG storage tank (1) through a pipeline. A liquid drain pipe of the immersed pump (3) is connected with a gas filling machine through a pipeline and further connected with a heat source channel inlet of a BOG condensation recoverer (2) through a pipeline. A heat source channel outlet of the BOG condensation recoverer (2) is connected with a liquid drain pipe of a liquid nitrogen storage device (4) through a pipeline. A cold source channel outlet of the BOG condensation recoverer (2) is connected with a nitrogen blow-down pipe. The invention further discloses a method for recycling BOG. The BOG condensation recycling system and method have the beneficial effects that cost is reduced, zero discharge of BOG in the storage tank is achieved, energy is saved, and pollution to environment is avoided.

Owner:成都深冷科技有限公司

Semiconductor device and method for manufacturing the same

ActiveUS7884428B2Improve performanceAvoid performanceTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device includes an Nch transistor having a first gate electrode and a Pch transistor having a second gate electrode. The first gate electrode and the second gate electrode are made of materials causing stresses of different magnitudes.

Owner:PANNOVA SEMIC

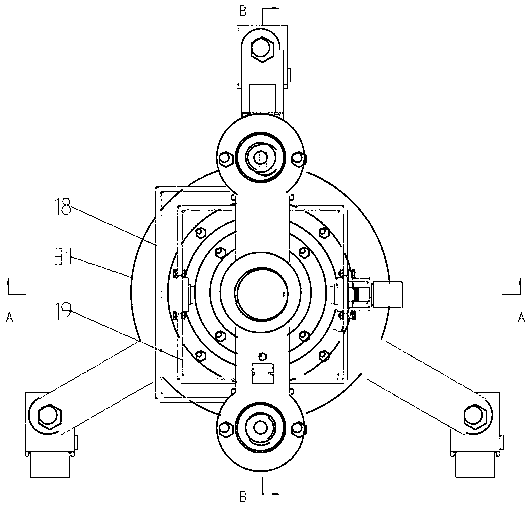

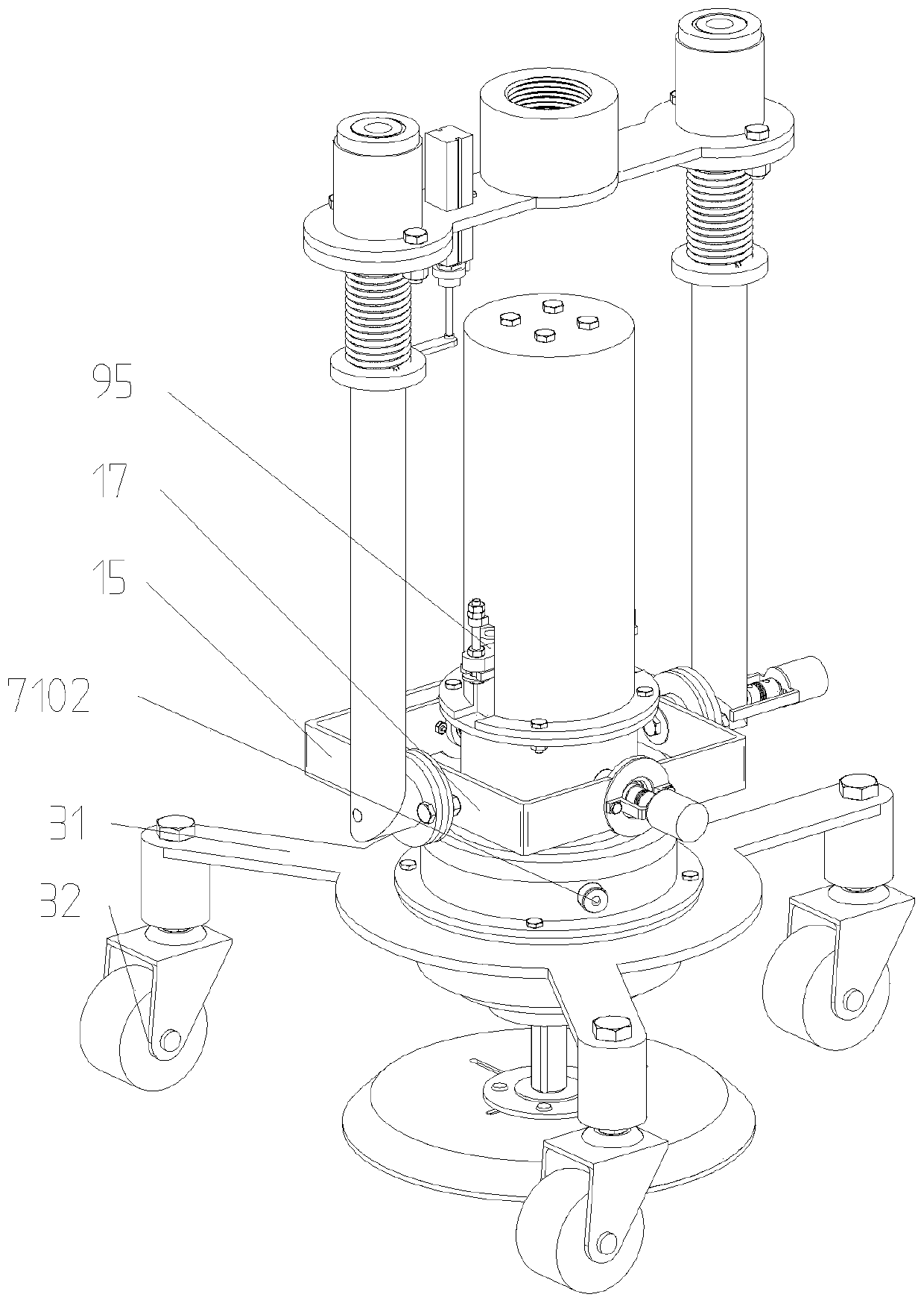

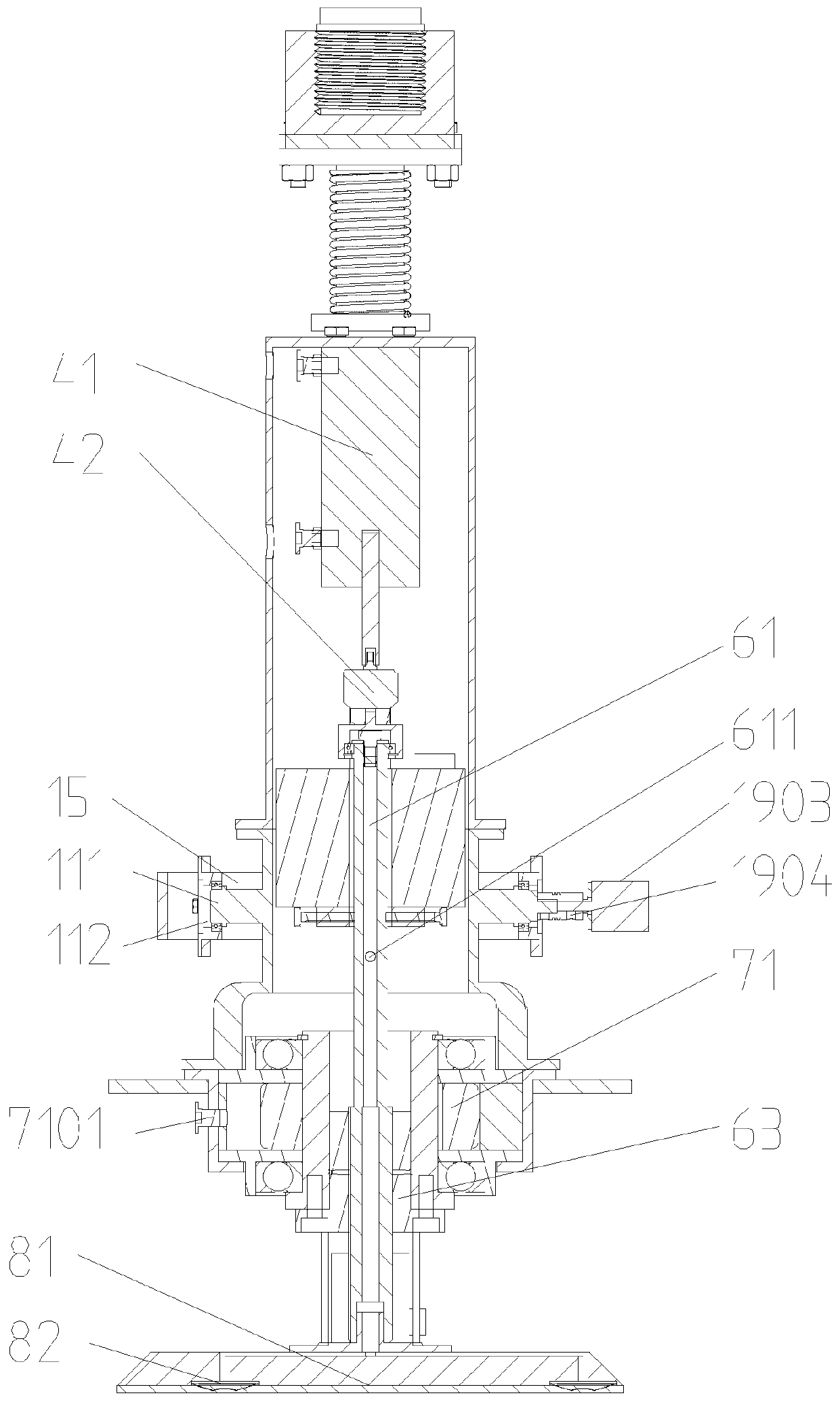

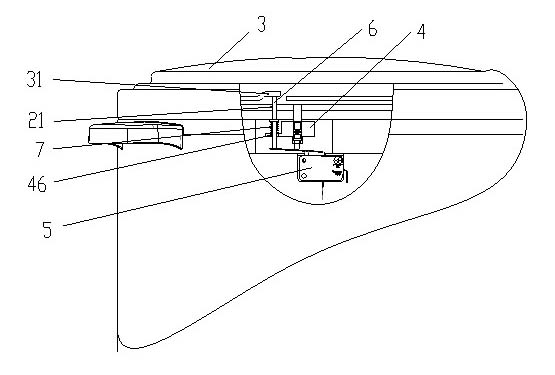

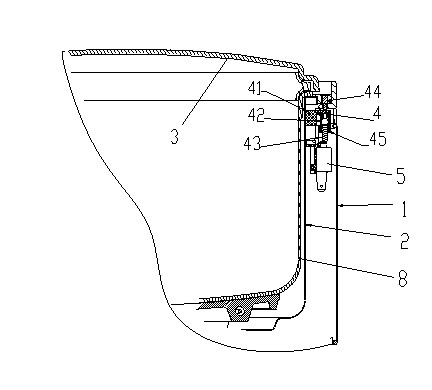

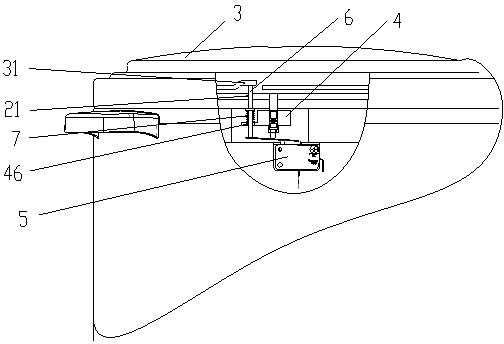

Airplane surface paint stripping and grinding device based on pressure intensity control

ActiveCN111390732AAchieve pressure controlImprove grinding effectGrinding machinesAircraft maintainanceMembrane switchEngineering

The invention discloses an airplane surface paint stripping and grinding device based on pressure intensity control and relates to the technical field of grinding equipment. The airplane surface paintstripping and grinding device based on pressure intensity control comprises a grinding unit, a telescopic limiting unit, at least three thin-film switches and a curved surface adaptation unit, wherein the grinding unit comprises a rotating assembly arranged in a lower shell, a ball spline shaft coaxially assembled with the rotating assembly and a grinding assembly at the lowest end; the driving end of the telescopic limiting assembly is coaxially assembled with the upper end of the ball spline shaft; the at least three thin-film switches are arranged at the grinding end of the grinding assembly; and the curved surface adaptation unit comprises a curved surface adaptation assembly movably connected with the lower shell and a guide assembly connected fixedly. According to the technical scheme of the airplane surface paint stripping and grinding device based on pressure intensity control, disclosed by the invention, the thin-film switches are mounted on a grinding head, and the effectivecontact area is measured in real time; and through combination with cylinder pressure, the pressure intensity of the grinding surface is controlled. The airplane surface paint stripping and grindingdevice based on pressure intensity control has the advantages of being controllable in pressure intensity of the grinding surface, wide in application range, good in grinding effect, simple in structure and low in cost.

Owner:CIVIL AVIATION UNIV OF CHINA

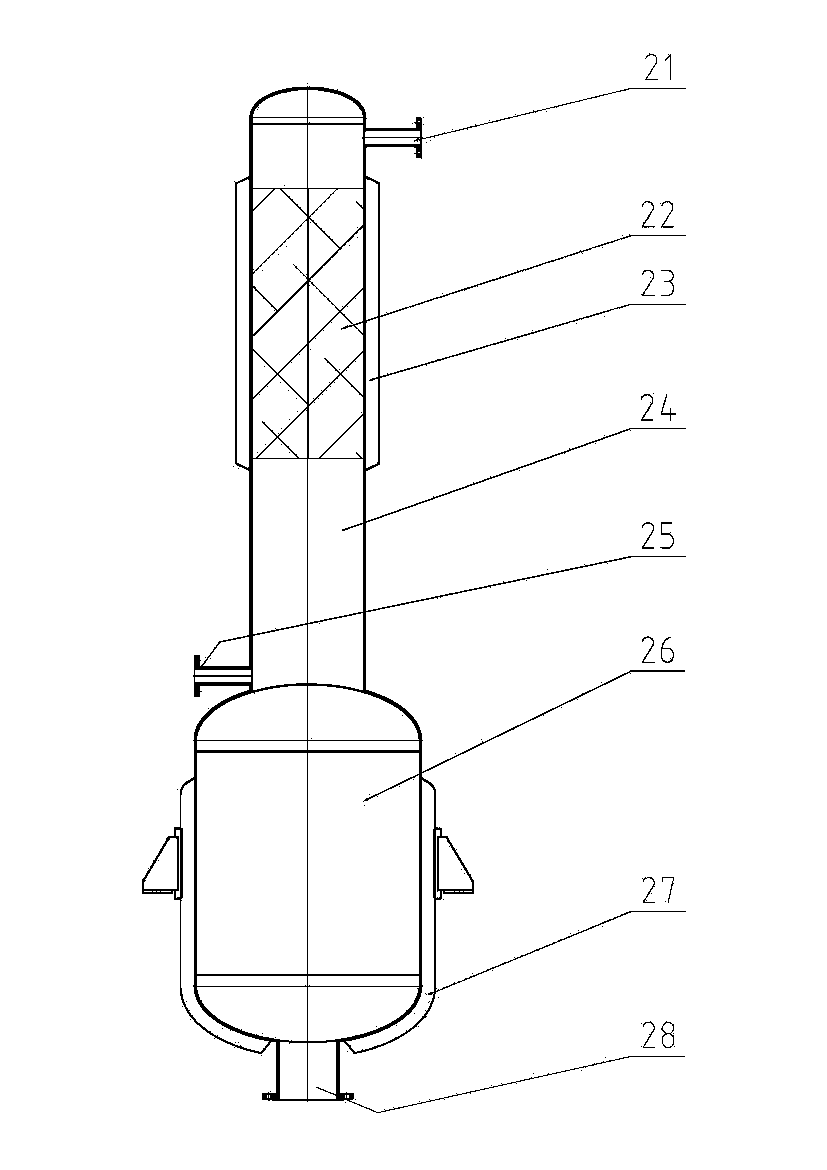

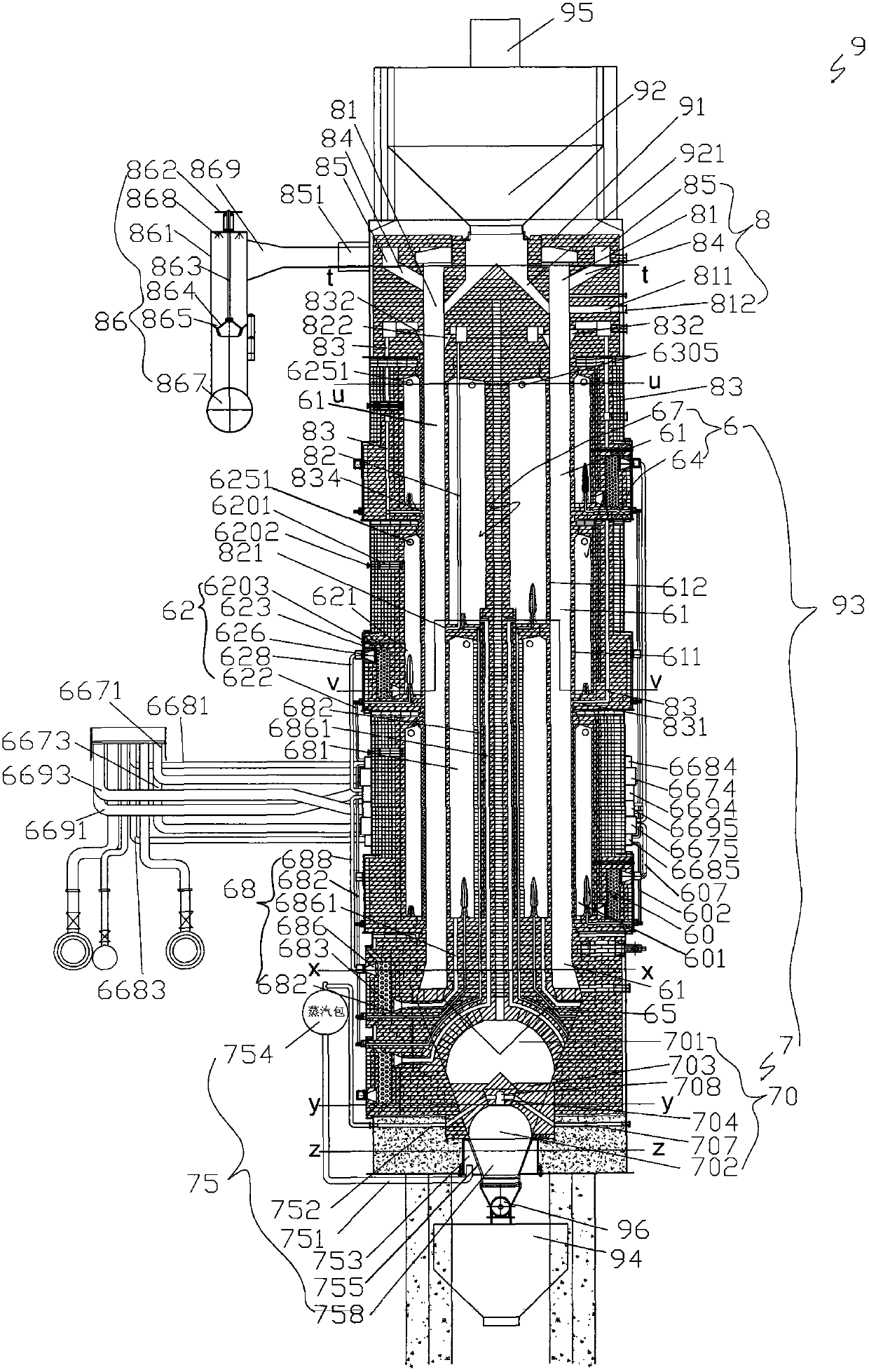

Carbon product roasting furnace

InactiveCN103787314AAchieve pressure controlAvoid enteringCarbon preparation/purificationThermal insulationAir tightness

The invention relates to an industrial furnace for roasting carbon products, which comprises a roasting pot, a condenser, a connecting pipe, a vacuum pump, and pressure control valves; The roasting pot comprises a housing, a cover, a gasket, a heating element, and a thermal insulation layer; the condenser comprises a container and a condensing tower; the pressure control valves are respectively mounted at a protective gas inlet of the roasting pot and a gas outlet at the top of the condenser, and can ensure the operation of the system at a micro-positive pressure. The connecting pipe is a metal pipe lined with a thermal insulation layer. During system operation, vacuum-pumping is carried out firstly to discharge all the air, and protective gas is injected; during the whole roasting period, the system is maintained to be airtight so as to realize effective control of the roasting atmosphere. The roasting furnace of the invention solves the problems of difficult roasting of large-size carbon products, large pollution, and the like.

Owner:成都润封电碳有限公司

Constant-tension taping machine

PendingCN111354517ASimple structural designHigh real-time feasibilityInsulating conductors/cablesFriction torqueEngineering

The invention provides a constant-tension taping machine which comprises a base plate, a tape releasing device, a taping device and a controller. A main shaft is rotationally arranged at an upper endof a fixed seat and is in transmission connection with a first driving mechanism, the tape releasing device is fixedly arranged at a right end of the main shaft, an inner shaft is rotationally arranged in the main shaft and is provided with a wire passing hole, and one end and / or two ends of the inner shaft are fixedly connected with the base plate; the tape releasing device comprises a tension adjusting mechanism, a left baffle, a tape storage barrel and a right baffle. The left baffle, the tape storage barrel and the right baffle are sequentially connected to the right end of the main shaftin a sliding and sleeving mode, the right baffle is in transmission connection with the main shaft through a key body, and the tension adjusting mechanism can control tension on a discharged tape material by adjusting pressure exerted on two end faces of the tape storage barrel by the left baffle and the right baffle. The taping device is fixedly arranged at a right end part of the main shaft. According to the taping machine, the same transmission system is adopted for the tape releasing device and the taping device, and the controller applies friction torque to the tape storage barrel in realtime through the tension adjusting mechanism so as to achieve the constant control over the tension value of released tape material.

Owner:江苏安澜万锦电子股份有限公司

Sample application instrument

PendingCN111665111ASolve technical problemsLower requirementPreparing sample for investigationMedicineApparatus instruments

The invention relates to the technical field of medical instruments, and discloses a sample application instrument, which comprises a gas path module and a liquid path module comprising a liquid storage bin and a liquid conveying pipe. The gas path module is communicated with the liquid storage bin, and one end of the liquid conveying pipe is communicated with the liquid storage bin; the gas pathmodule adjusts the air pressure in the liquid storage bin so as to control liquid discharging of the other end of the liquid conveying pipe. According to the sample application instrument disclosed bythe invention, the liquid outlet of the liquid conveying pipe in the liquid path module is controlled by arranging the gas path module, the sample liquid is promoted to flow out of the liquid conveying pipe by utilizing micro-pressure, the sample liquid is controlled by the air pressure, and is contacted with a sample application plate at the dripping moment to form an array, so that sample application is completed. The sample application instrument simultaneously solves the technical problems of a non-contact injection sample application instrument and a contact needle sample application instrument, a semi-contact sample application method is innovated, and the sample application method has the advantages of large sample point volume, low requirement on sample application environment andhigh sample application speed, a problem of abrasion of a needle head of a sample application needle is solved, and the sample application instrument is suitable for large-scale industrial production.

Owner:SHANGHAI BAIO TECH

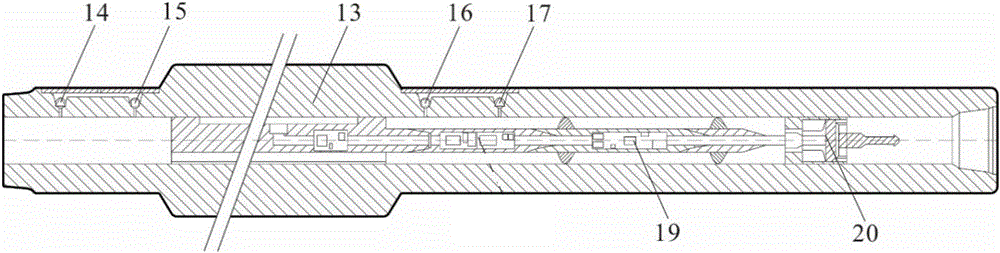

Blocking tool in oil pipe

ActiveCN110965957ASeat hanging depth adjustableGood stabilitySealing/packingPipeMechanical engineering

The invention discloses a blocking tool in an oil pipe for operation under pressure. A deblocking spear rod is arranged in a central pipe in a penetrating manner; an unsealing pin is fixed on the upper end cap, and the upper end cap is fixed on the central pipe; a sealing rubber cylinder is limited on the central pipe by a rubber cylinder gland; the central pipe is a hollow pipe body; a linkage plunger is arranged in the lower end of the central pipe in a penetrating mode and is sealed to form a sealed cavity; a first connecting shaft penetrates through a through hole of a rubber sleeve expansion sealing push ring, a first key groove type through hole and a through hole of the linkage plunger, and is fixed connected with the rubber sleeve expansion sealing push ring; the rubber cylinder expansion sealing push ring and the linkage plunger are connected and move synchronously; an anchor tile conical base is sleeved and fixed on the central pipe through a locking pin, a setting pin limitsrelative movement of the linkage plunger and the central pipe, a slip is embedded between the anchor tile conical base and the conical body, and a second connecting shaft penetrates through a throughhole of an anchor tile propelling ring, a second key groove type through hole and a through hole of the linkage plunger to be fixedly connected with an anchor tile propelling ring. According to the invention, the self-setting can be realized, and the salvage can also be realized.

Owner:PETROCHINA CO LTD

Distributed control air mattress

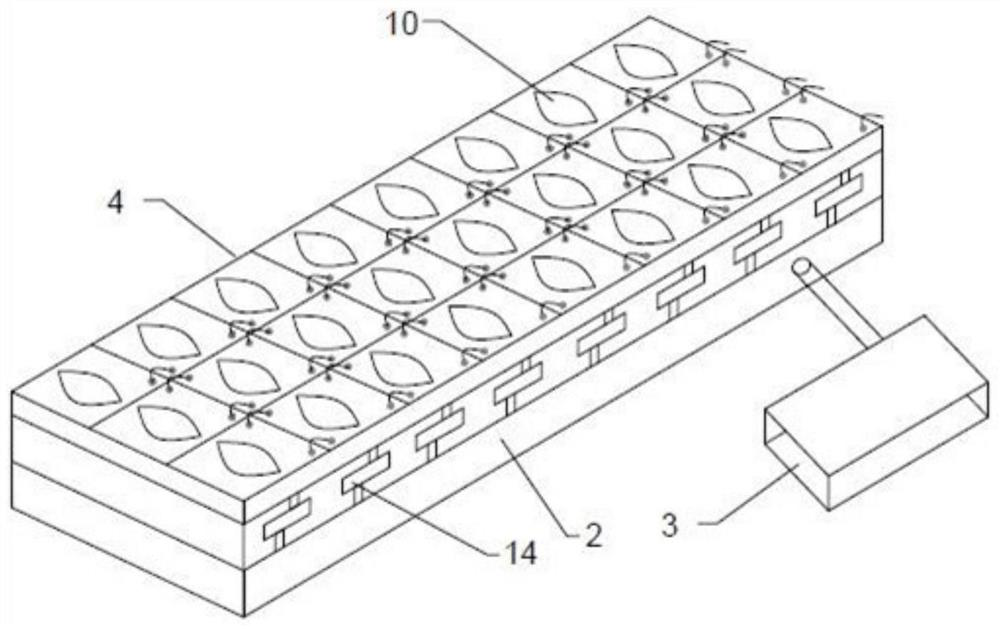

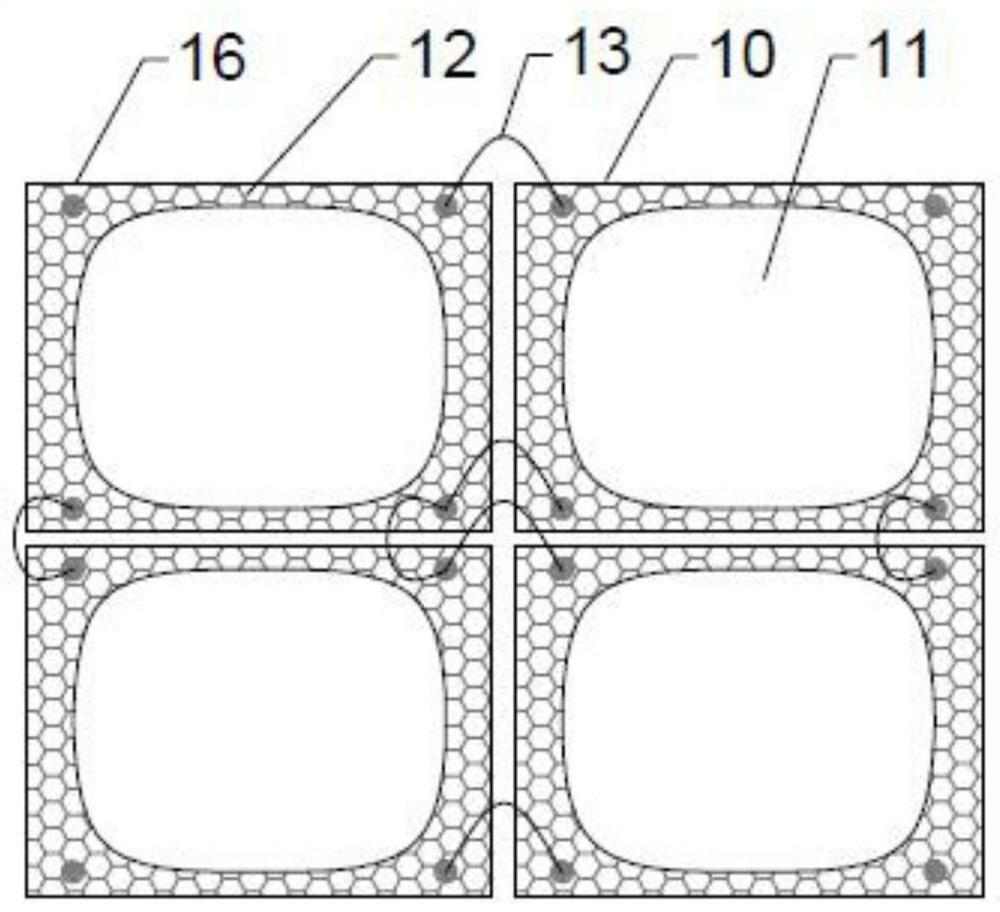

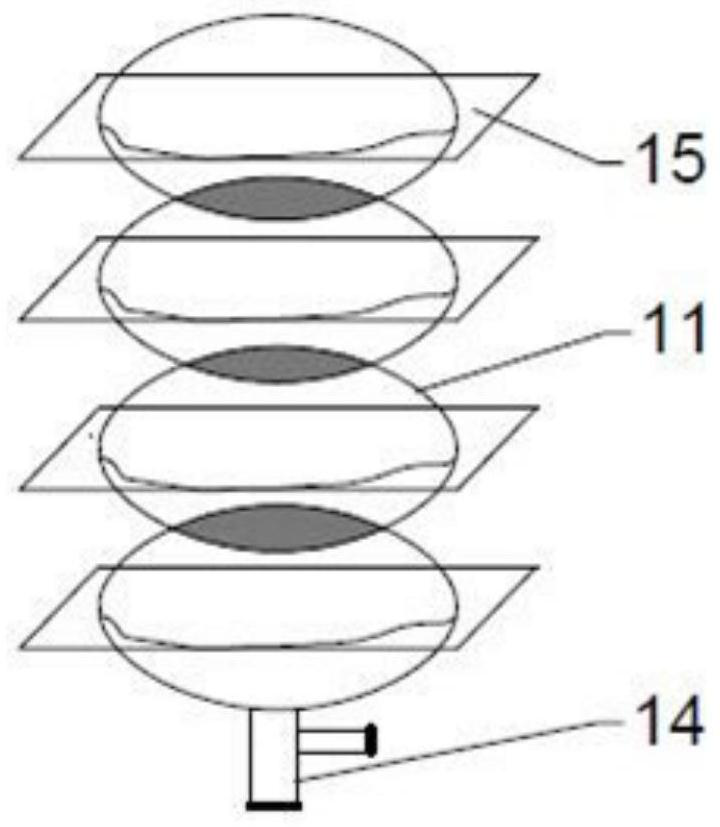

The invention discloses a distributed control air mattress. The air mattress comprises air bag module units which are arranged in rows and columns and are connected into a whole through threads, eachairbag module unit comprises at least two directional deformation airbags of which the height can be changed without changing the length through the change of air pressure, and soft films wrapping theperipheries of the directional deformation airbags, and each airbag module unit is provided with an electromagnetic air valve; the directional deformation air bags are sequentially stacked up and down, and pressure sensors are arranged on the air bag module units. The distributed control air mattress has the advantages that multiple functions are achieved, and the height and hardness of the air bag module units can be changed by intelligently adjusting the pressure of the air storage cushion; maintenance is convenient, dismounting and mounting are convenient, and when the air bag module unitsare damaged, replacement or maintenance is very convenient; the air bag module unit is matched with pressure adjustment of a human body, the softness and hardness of the air bag module unit are changed by changing internal pressure, the height of the air bag module unit is changed to adapt to shapes, positions and gravity distribution of different human bodies, and more comfortable and healthiersleep quality is achieved.

Owner:广东珞珈睡眠科技有限公司

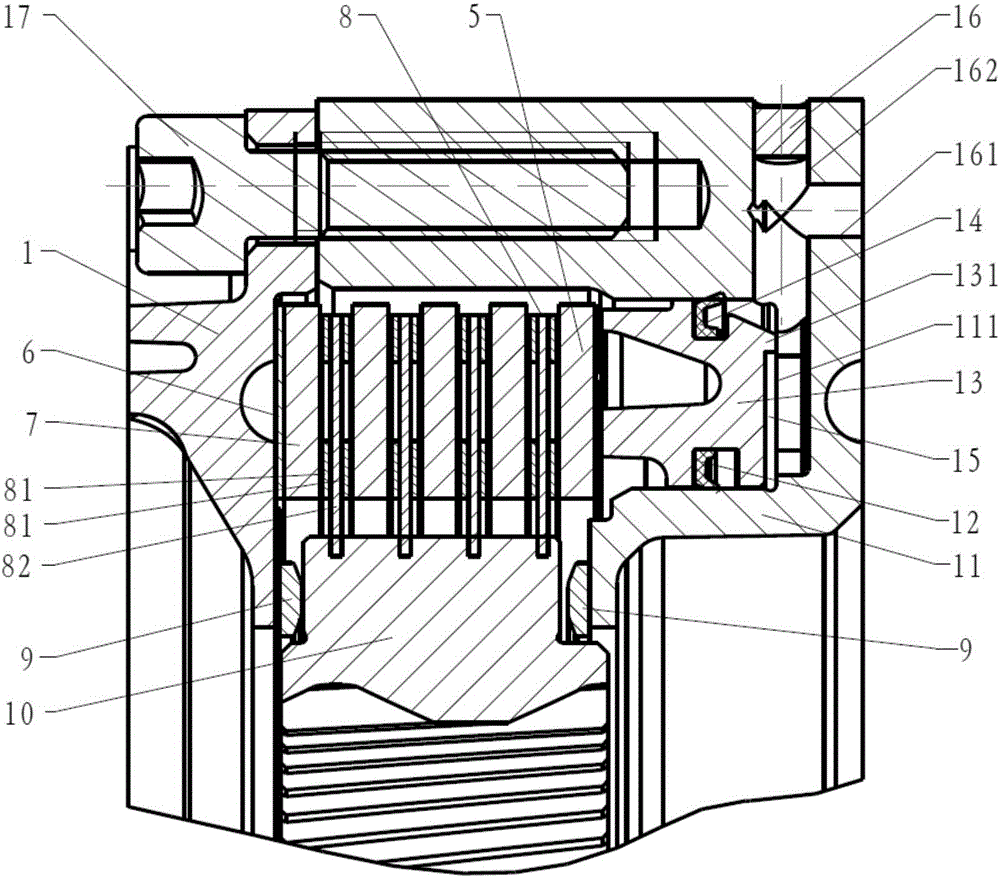

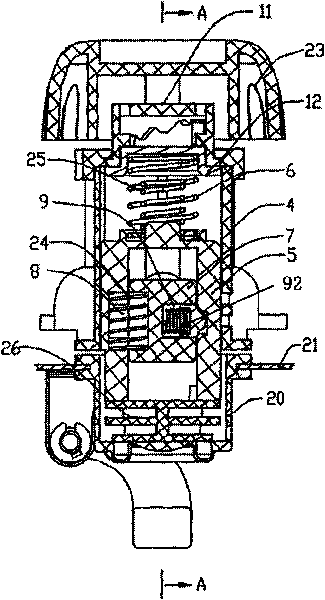

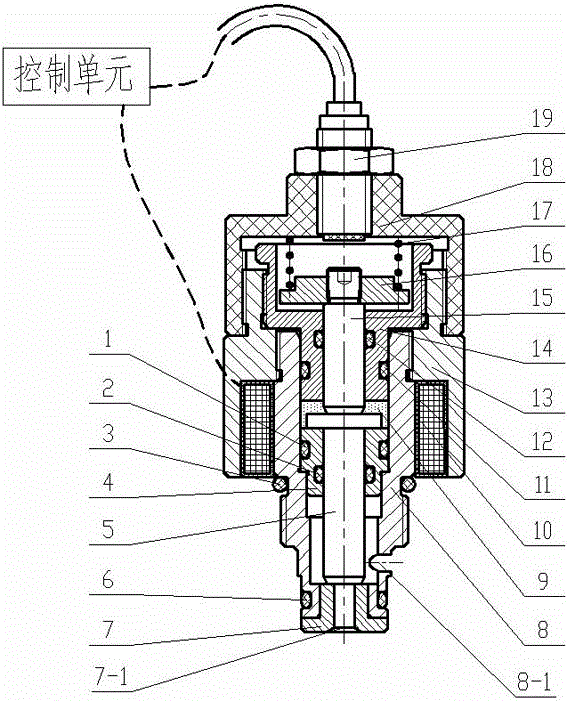

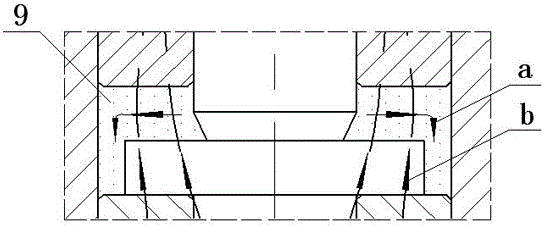

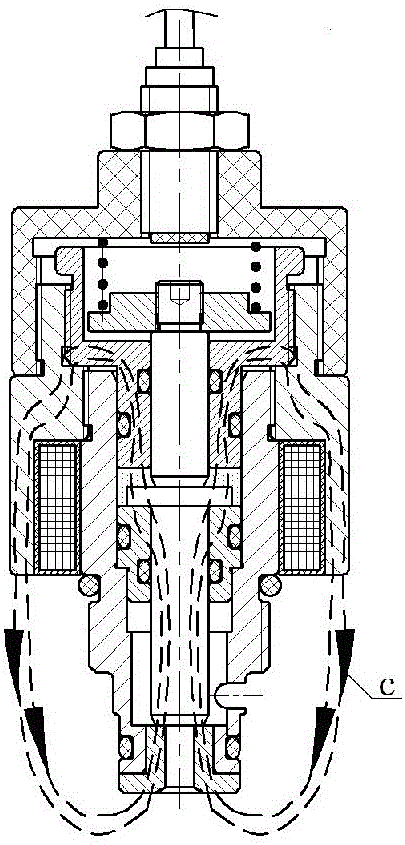

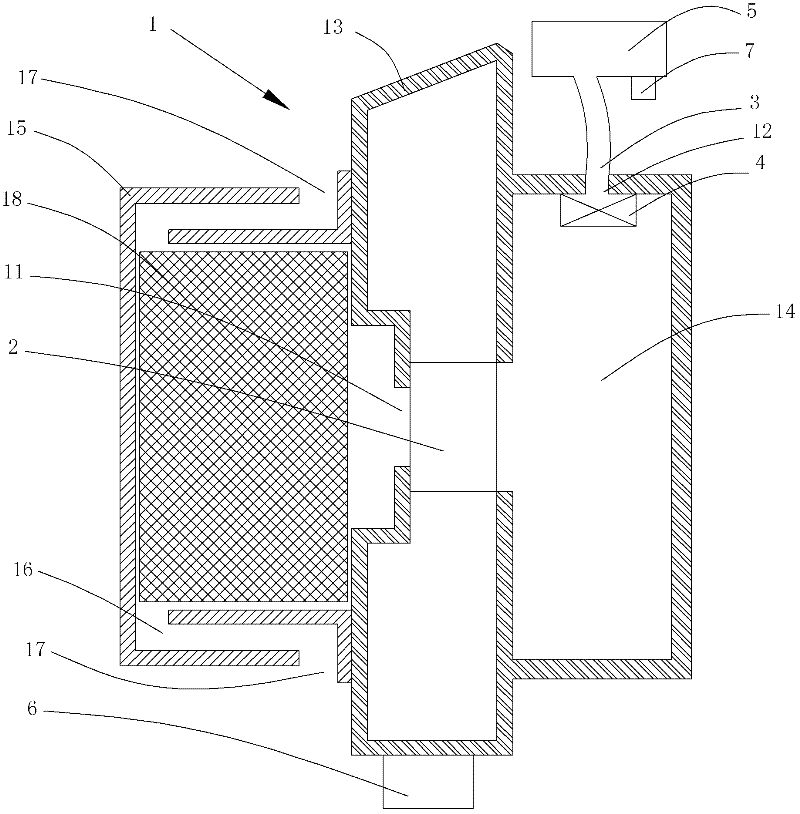

Magnetorheological Pressure Control Valve

ActiveCN103591363BControl yield strengthControl forceOperating means/releasing devices for valvesSpringsMagnetorheological fluidSystem pressure

The invention relates to a pressure control valve, in particular to a magnetorheological pressure control valve for achieving hydraulic system pressure control through a force required to start the control valve. The pressure control valve comprises an inner valve body, a valve core, a blanking cap, a main valve body, a working chamber containing magnetorheological fluid, a coil assembly composed of a coil and a magnet separation jacket, an outer valve body, an upper valve body, a thrust shaft, a spring seat, a reset spring, an end cap, a travel switch sensor and a plurality of rubber seal rings. The magnetorheological pressure control valve is simple in structure, convenient to manufacture, high in energy efficiency and quick in pressure response and stepless and intelligent control of system pressure can be achieved.

Owner:浙江孔辉汽车科技有限公司

Medical body temperature maintaining mechanism

The invention discloses a medical body temperature maintaining mechanism, which comprises a shell provided with an air inlet channel, and another shell provided with a filtering channel, wherein one end of an air inlet of the air inlet channel is provided with a PTC (Positive Temperature Coefficient) heater, the other end of the air inlet is provided with a direct current air pump, one end of thefiltering channel is communicated with the air inlet, the other end of the filtering channel is communicated with the outer world, a filter screen is arranged in the filtering channel, an air outlet is provided with a blast tube, the other end of the blast tube is connected with a protective blanket with a cavity or a semienclosed warm box, an air outlet end of the blast tube is respectively provided with a control valve, a spirally arranged clamp slot used for fixing an infusion tube in the warm box, and a flow control valve for controlling liquid flow in the infusion tube, a plurality of air vents are distributed on the protective blanket, the shell is provided with a control component for adjusting the output power of the PTC heater and the air pump, the warm box and the protective blanket are provided with temperature sensors used for measuring the temperature of air of the protective blanket and the temperature in the warm box, and the temperature sensors, the PTC heater and the air pump are respectively electrically connected with the control component.

Owner:GUANGDONG FOOD & DRUG VOCATIONAL COLLEGE

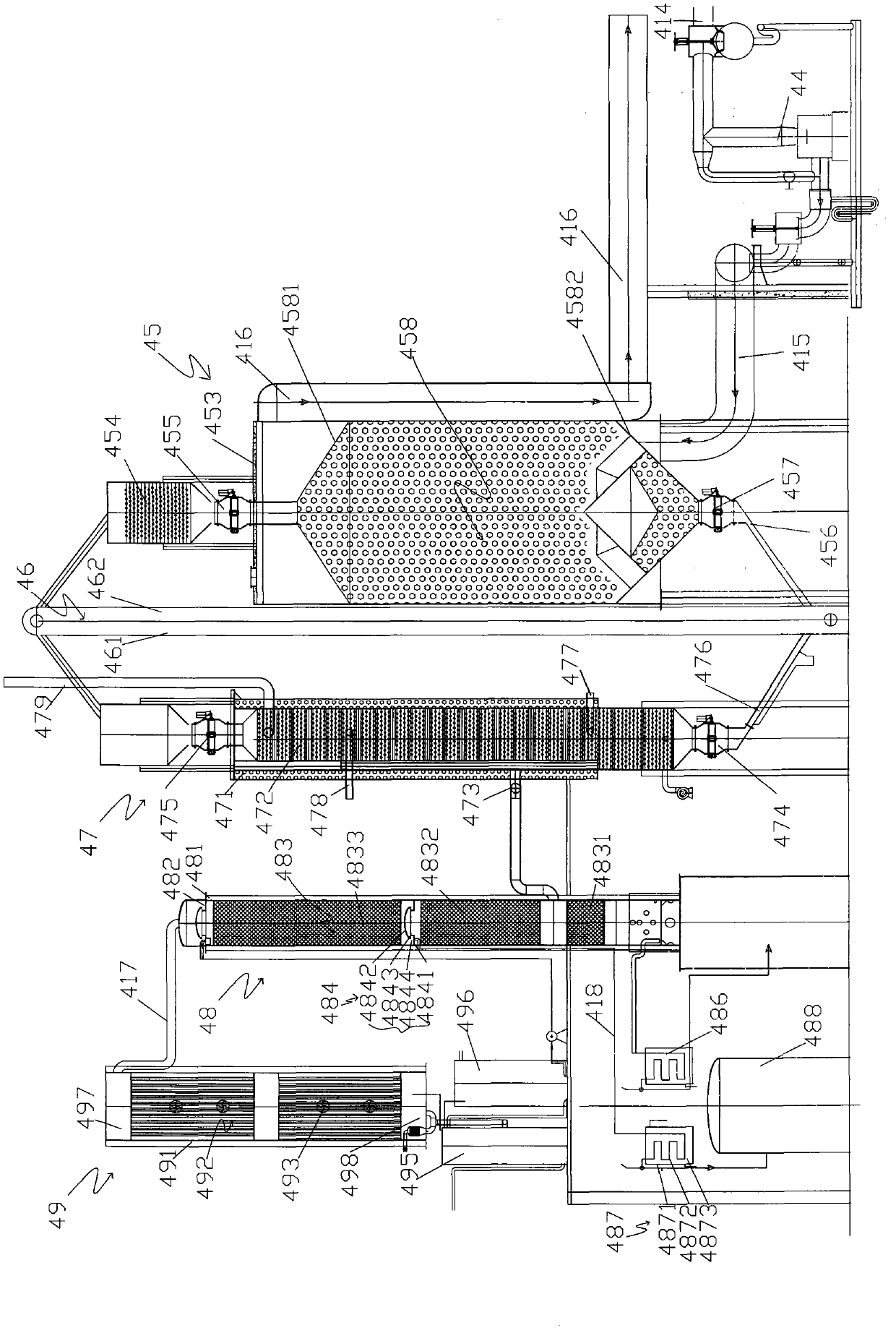

Gangue pyrolysis gasification raw gas purification combustion recycle method

ActiveCN103275765AAchieve pressure controlEfficient combustionCombustible gas coke oven heatingCombustible gas productionWater vaporProduct gas

The invention discloses a gangue pyrolysis gasification raw gas purification combustion recycle method. The method comprises the following steps of 1, through purified-gas thermal-storage heat-exchange alternant combustion carried out by an external gas heating device and an internal gas heating device of a gangue pyrolysis device, providing a heat source to gangue pyrolysis in a pyrolysis gasification chamber in a high temperature environment, 2, through a water gas reaction device, feeding high temperature water vapor into the pyrolysis gasification chamber from the lower part so that the high temperature water vapor contacts with the high-temperature gangue pyrolysis products in the pyrolysis gasification chamber and undergoes a water gas reaction to produce water gas, 3, exporting the raw gas which comprises the gas produced by gangue pyrolysis and the water gas produced by the water gas reaction, 4, feeding the raw gas into an active parching recoverer, carrying out active coke adsorption, and transporting the adsorbed clean gas into the external gas heating device and the internal gas heating device for combustion by clean gas output pipes. Through utilization of combustion of carbon, oil and gas in gangue, a cost is reduced.

Owner:SHANXI XINLI ENERGY TECH

Detector for detecting pressure and whether cover is closed in place of electric pressure cooker

ActiveCN102113818AGuarantee the safety of useAchieve pressure controlPressure-cookersEngineeringPressure controlled ventilation

The invention discloses a detector for detecting the pressure and whether a cover is closed in place of an electric pressure cooker, which comprises an outer pot, a cover and a pressure regulator with an ejector rod. A switch is fixed on the outer pot, corresponding to a part below the pressure regulator. The ejector rod moves vertically to penetrate through a through hole of the pressure regulator and a through hole in the edge of the outer pot. One end of the ejector rod is contacted with the switch, and the other end of the ejector rod protrudes from the edge of the outer pot. The cover is closed in place. The guide slot of the cover is positioned right above the end of the ejector rod. The pressure regulator is composed of a casing, a spring, an ejector pin and a screw rod. The casing is provided with a through hole. The two ends of the through hole are provided with inwardly extending steps. The ejector pin is installed in the through hole. The step on the ejector pin is limited by the step on one end of the through hole, while one end of the ejector pin is contacted with the switch after passing through the through hole. One end of the spring is sheathed on the ejector pin, while the other end of the spring is sheathed on the step of the through hole on the casing. The detector is characterized by being low in cost and having multiple functions of safeguard, and can be suitable for the pressure control and the safeguard for opening and closing the cover of the electric pressure cooker.

Owner:MIDEA GRP CO LTD

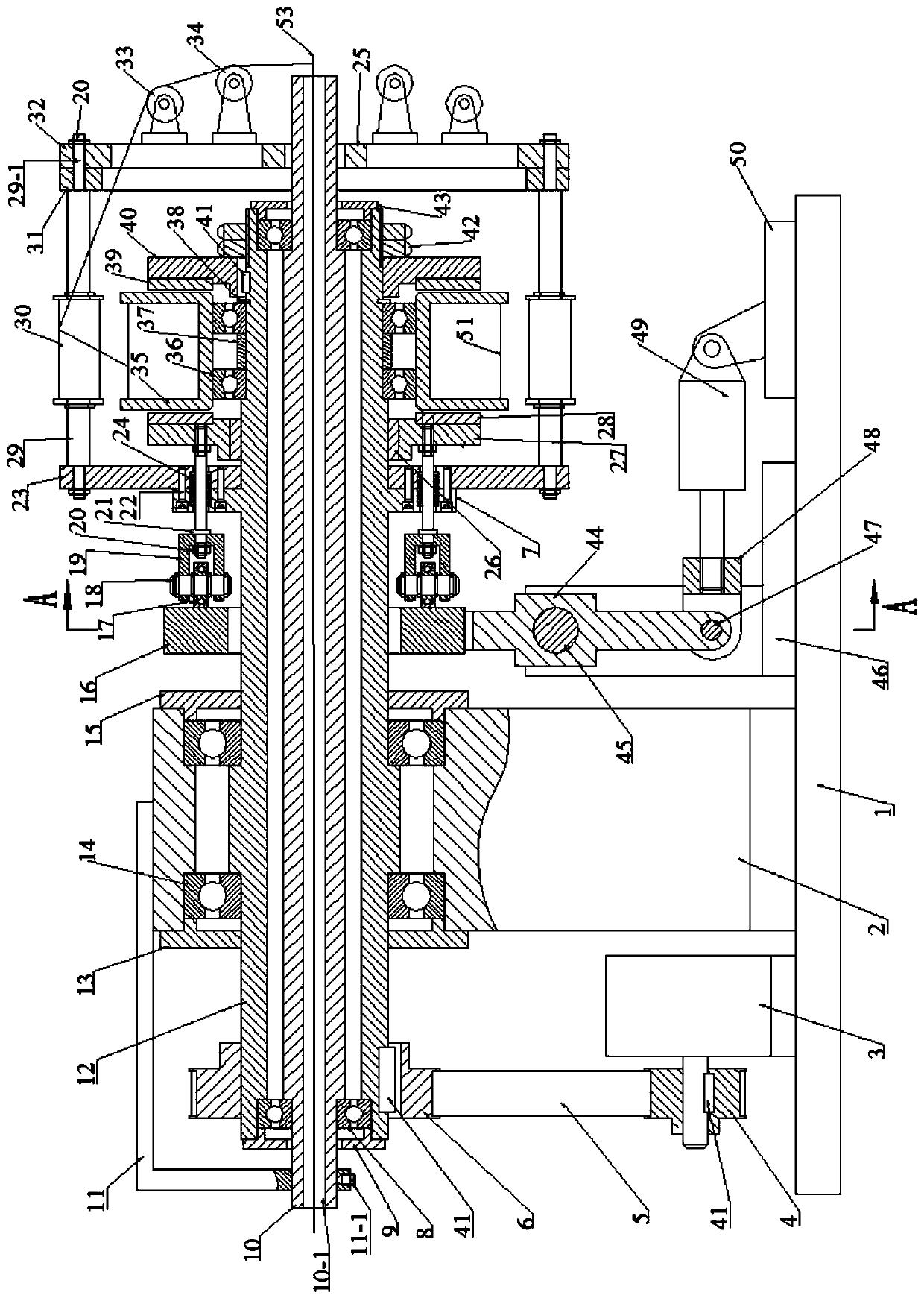

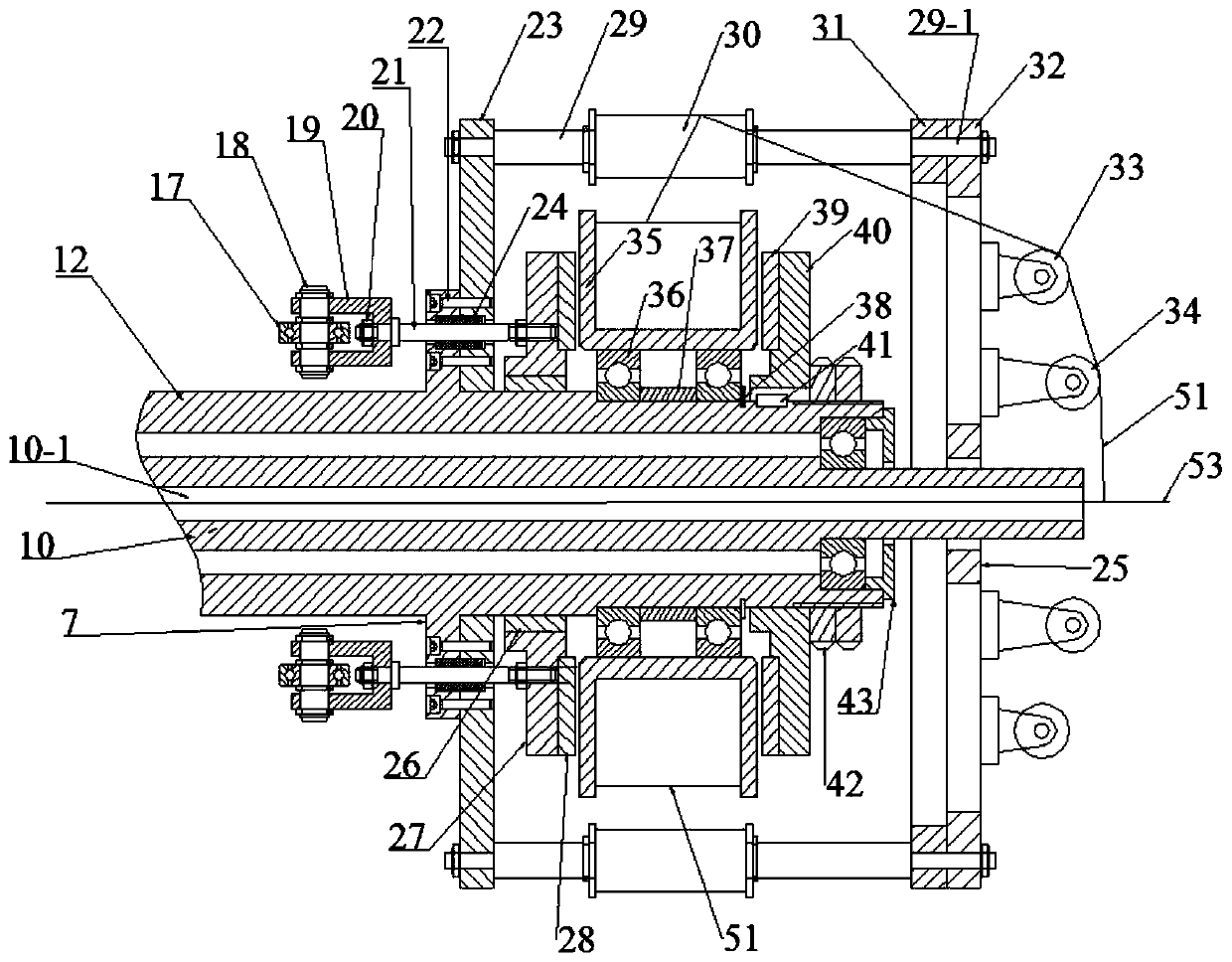

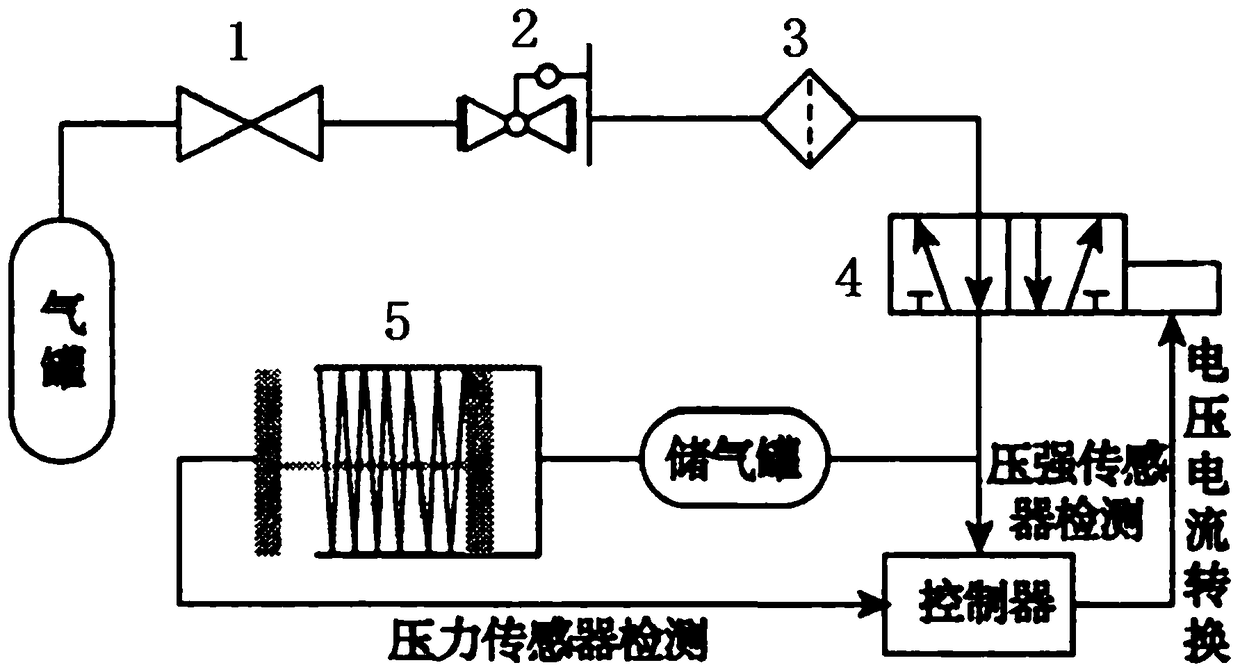

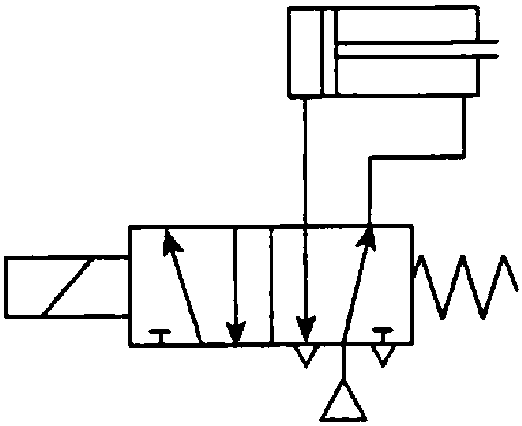

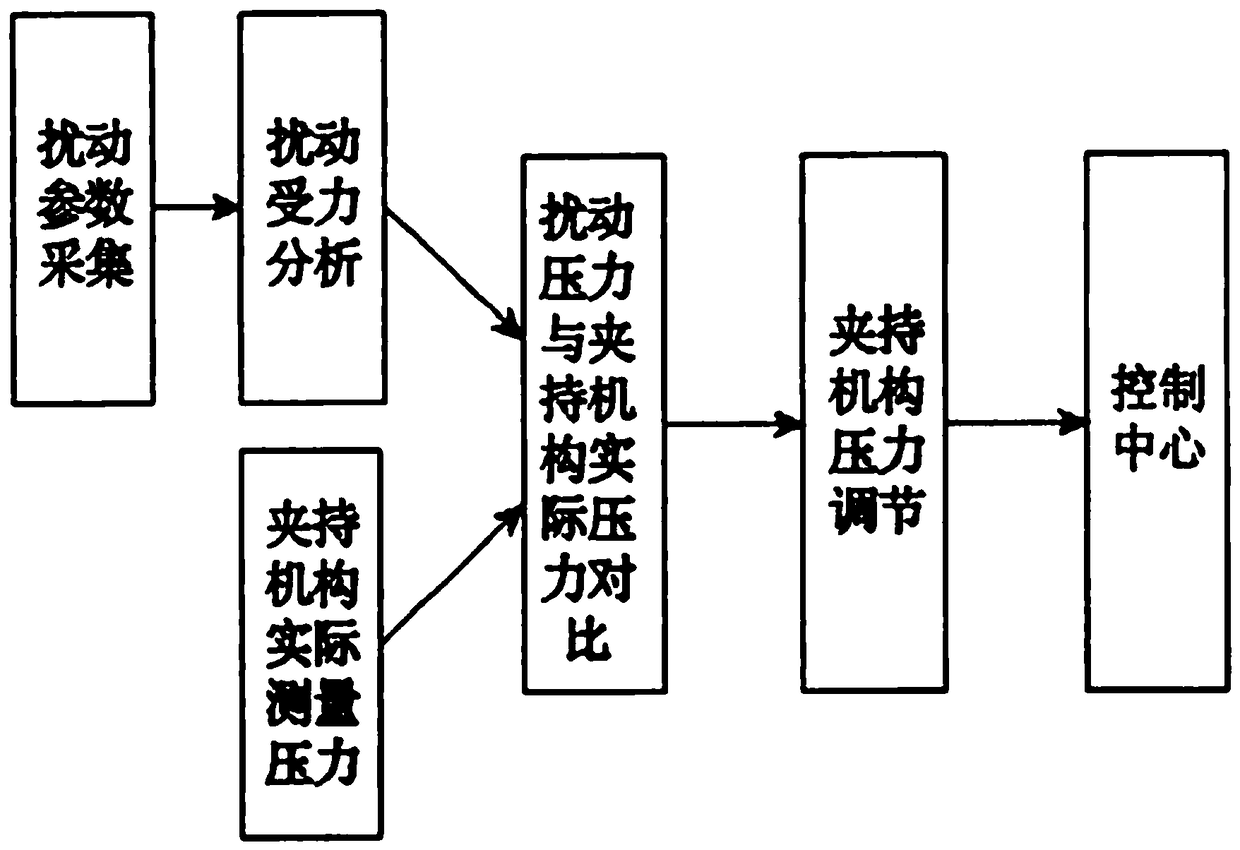

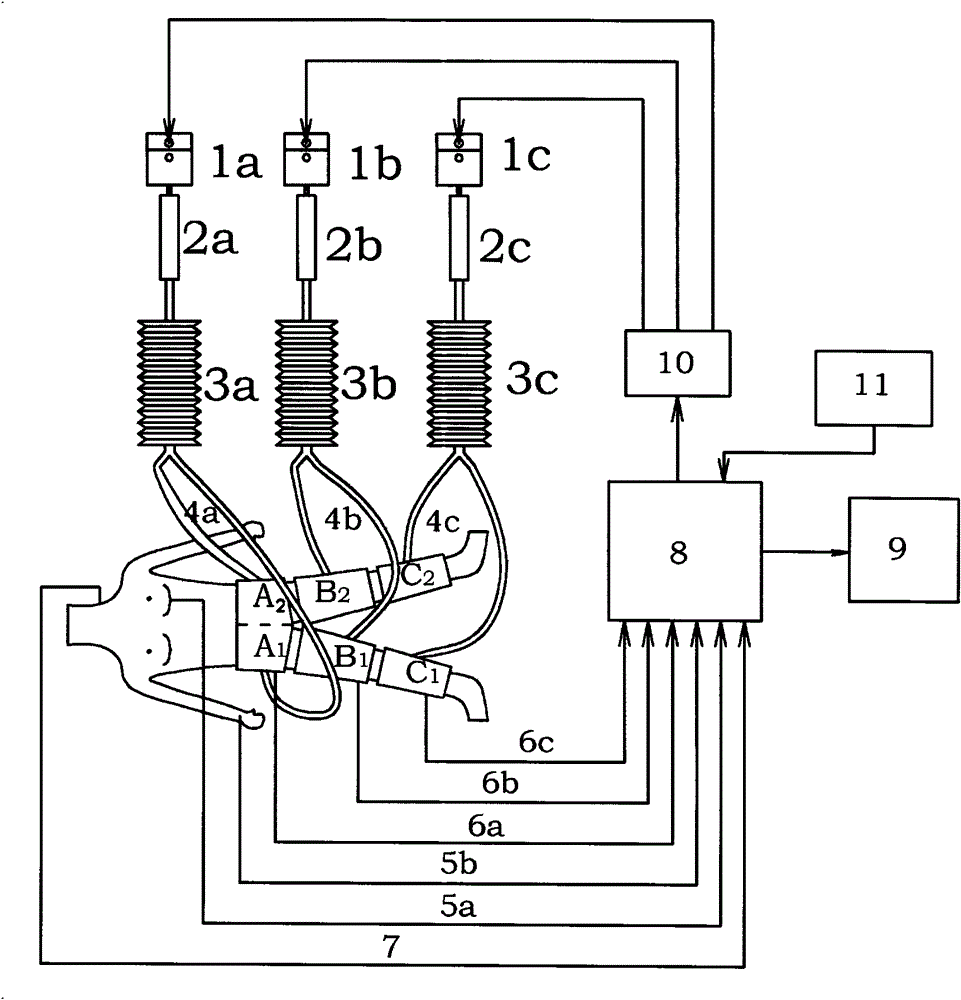

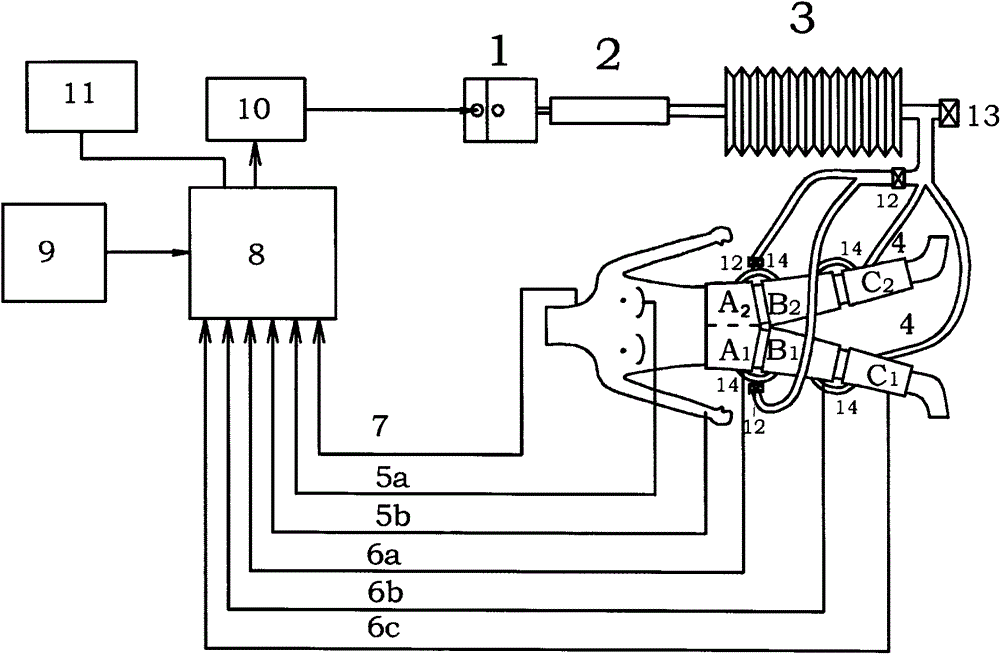

Pressure compound control system of clamping mechanism of line patrol robot

InactiveCN108081292AAchieve pressure controlImprove stabilityManipulatorNonlinear modelControl system

The invention discloses a pressure compound control system of a clamping mechanism of a line patrol robot. The system uses a proportional electromagnetic valve, a piston cylinder and a pressure sensorfor building a clamping mechanism pneumatic closed loop; and through analysis of the system working principle, a nonlinear model of a pneumatic pressure control system is built to realize stable andquick output of output pressure of the clamping mechanism. The system can realize high-precision and high-stability pressure control of the clamping mechanism; the output pressure of the system is within 0-550 N; the pressure fluctuation is lower than 5 N; and in a disturbance state, self deviation can be timely corrected, so that stable operation of the robot is guaranteed, and the control requirements of the line patrol robot to the clamping mechanism in the working state are met.

Owner:赵江涛

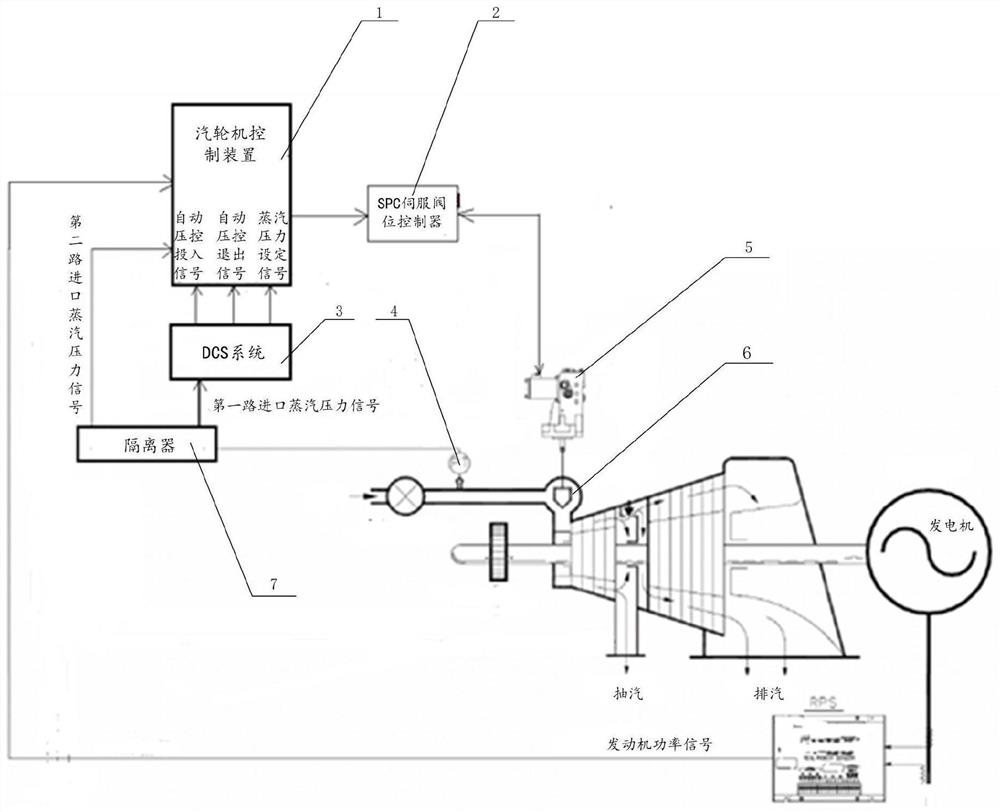

Constant-pressure operation control method for steam turbine generator unit

InactiveCN113006885ARealize automatic steam pressure controlAchieve pressure controlMachines/enginesEngine controlSteam pressureProportion integration differentiation

The invention discloses a constant-pressure operation control method for a steam turbine generator unit. The constant-pressure operation control method comprises the following steps: transmitting an inlet steam pressure signal of a steam turbine inlet steam pressure sensor to a steam turbine control device; providing an inlet steam pressure setting signal, an automatic pressure control input signal and an automatic pressure control exit signal for the steam turbine control device by a control system; comparing the received inlet steam pressure signal with the inlet steam pressure setting signal by the steam turbine control device; after PID (Proportion Integration Differentiation) operation, providing an amplified output valve position instruction signal for a servo valve position controller; comparing and amplifying the received output valve position instruction signal and a feedback signal of a governing valve actuator by the servo valve position controller; outputting a governing valve instruction signal to a governing valve; changing the opening degree of the governing valve; dynamically regulating the steam pressure at the inlet of a steam turbine; and operating the steam turbine generator unit under a constant pressure. According to the constant-pressure operation control method, automatic steam pressure control of the steam turbine generator unit is achieved, and constant-pressure operation of the steam turbine generator unit is achieved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Postoperative breathable binding device for surgery

ActiveCN112137798ADressing pressure controlEasy to operateTourniquetsBandagesNursing careBiomedical engineering

The invention relates to a postoperative breathable binding device for surgery, which comprises a positive pressure assembly and an auxiliary pressure assembly. The positive pressure assembly comprises a pressing plate and a telescopic rod, the telescopic rod is connected with a dressing pad through an inserting block, the pressing plate is connected with the auxiliary pressure assembly through anadjusting assembly, the auxiliary pressure assembly comprises a pressure regulating plate, and a plurality of air bags are sequentially arranged in the pressure regulating plate, and connected with an air pipe through a pressure regulating valve. The pressure regulating assembly comprises a first rod connected with the pressure plate and a second rod connected with the pressure regulating plate,and the first rod and the second rod are movably connected through a moving part. According to the binding device provided by the invention, the wound can be pressurized and covered with adjustable force through the positive pressure assembly, and muscles around the wound can be pressed at different degrees of pressure values through the auxiliary pressure assembly, so that corresponding binding and pressing adjustment is carried out according to the position of the wound and nursing requirements of a patient, and data control of binding pressure is achieved; the positive pressure assembly andthe auxiliary pressure assembly can be detached and separated, and dressing replacement is easy.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

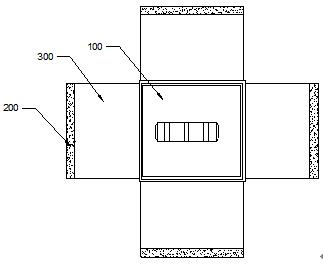

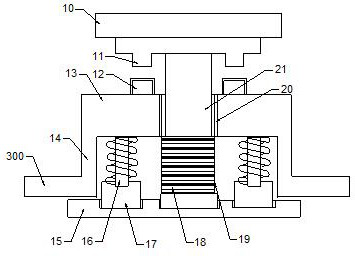

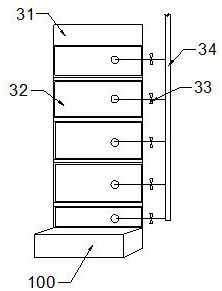

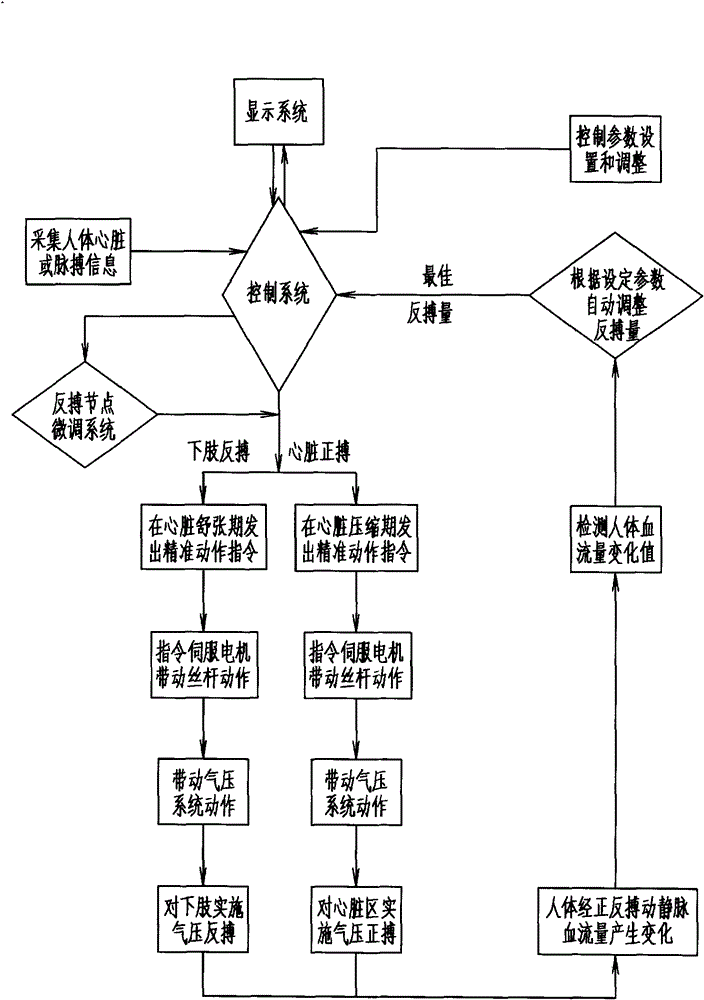

Closed pneumatic type in-vitro positive pulsation and counter pulsation device for servo control and action

InactiveCN102166157BPrevent leakageRealize the right strokeElectrotherapyArtificial respirationClosed loopEngineering

The invention discloses a closed pneumatic type in-vitro positive pulsation and counter pulsation device for servo control and action. The device is formed by adding an in-vitro positive pulsation system of a chest cardiac area into an in-vitro counter pulsation system; a servo motor is provided with a ball screw to form a power system; a closed pressure deformation transmission device is used for transmitting pressure to a human body through the ball screw and pneumatic pressure packets to realize positive pulsation and counter pulsation; and relevant information is acquired, and the positive pulsation and the counter pulsation are precisely controlled through a control system. Compared with the prior art, the closed pneumatic type in-vitro positive pulsation and counter pulsation devicecomprises the following outstanding characteristics that: a cardiac positive pulsation system is added to completely realize the positive pulsation and the counter pulsation; a closed pneumatic system is simple and practical; closed pneumatic pressure is combined with a servo system to simply realize precision and controllability; the closed loop control of the positive pulsation and the counter pulsation is realized by blood flow detection; the pressure control of pneumatic packets is realized by pressure detection so as to control the amount of the positive pulsation and the counter pulsation; and a set of servo pneumatic system is used for the counter pulsation to three groups of pneumatic pressure packets, electrocardial detection is replaced by pulse detection, and the device is convenient to use and has a simple structure.

Owner:卢健

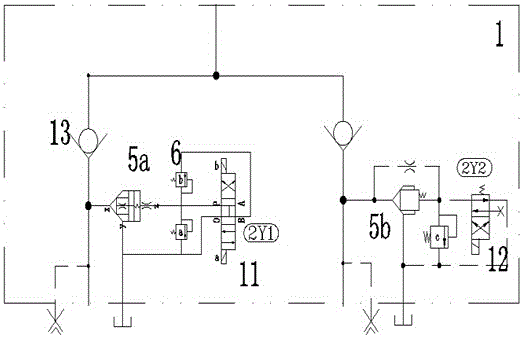

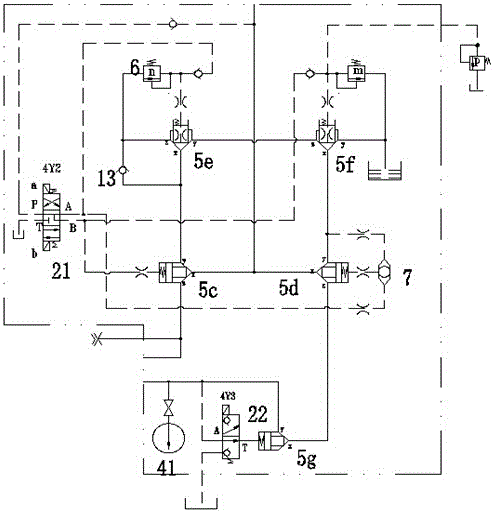

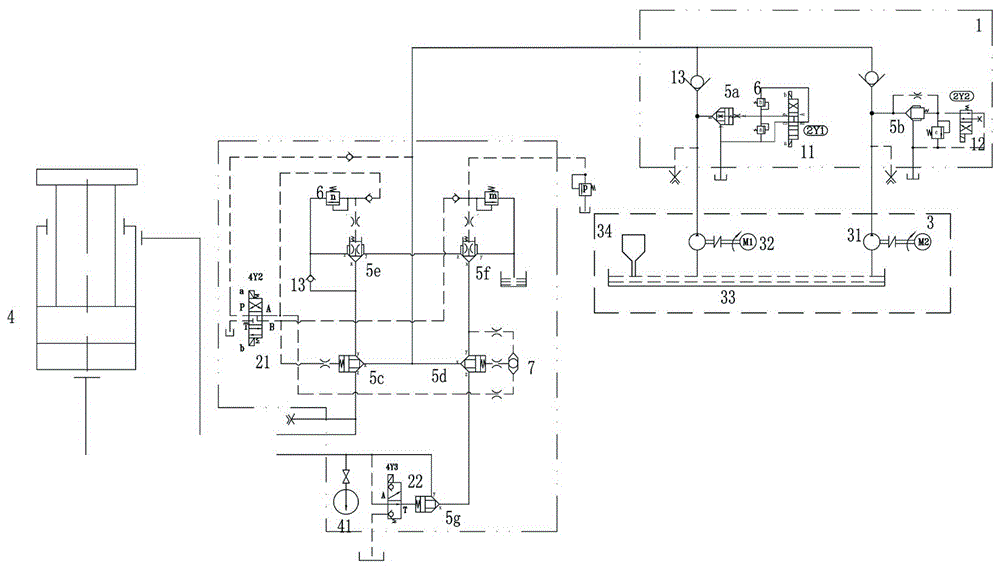

Jacking cylinder control hydraulic system

InactiveCN106438524AControl pressure stabilityContinuous pressure monitoringServomotor componentsServomotorsAir filterConstant stress

The invention relates to a jacking cylinder control hydraulic system. The hydraulic system comprises a power control valve block, a jacking cylinder control valve block, a foundation device and a jacking cylinder; the foundation device, the power control valve block, the jacking cylinder control valve block and the jacking cylinder are serially connected in sequence; a pressure gauge is arranged in the connecting place between the jacking cylinder and a y oil port of an insertion piece g for continuously monitoring the port pressure of the whole jacking cylinder to control the pressure stability of the jacking cylinder; an air filter is arranged on an oil tank of the foundation device for reducing the probability of feeding dust or impurities in air into the oil tank to prevent the conditions of pipe blockage and unstable pressure caused by a lot of dust entering the oil tank; and through simple connection between control valves and pipes, the pressure control of the jacking cylinder is realized, the uniform pressure distribution can be continuously and stably provided, and the pressure testing data is more precise.

Owner:NANTONG GAOYE HEAVY IND CO LTD

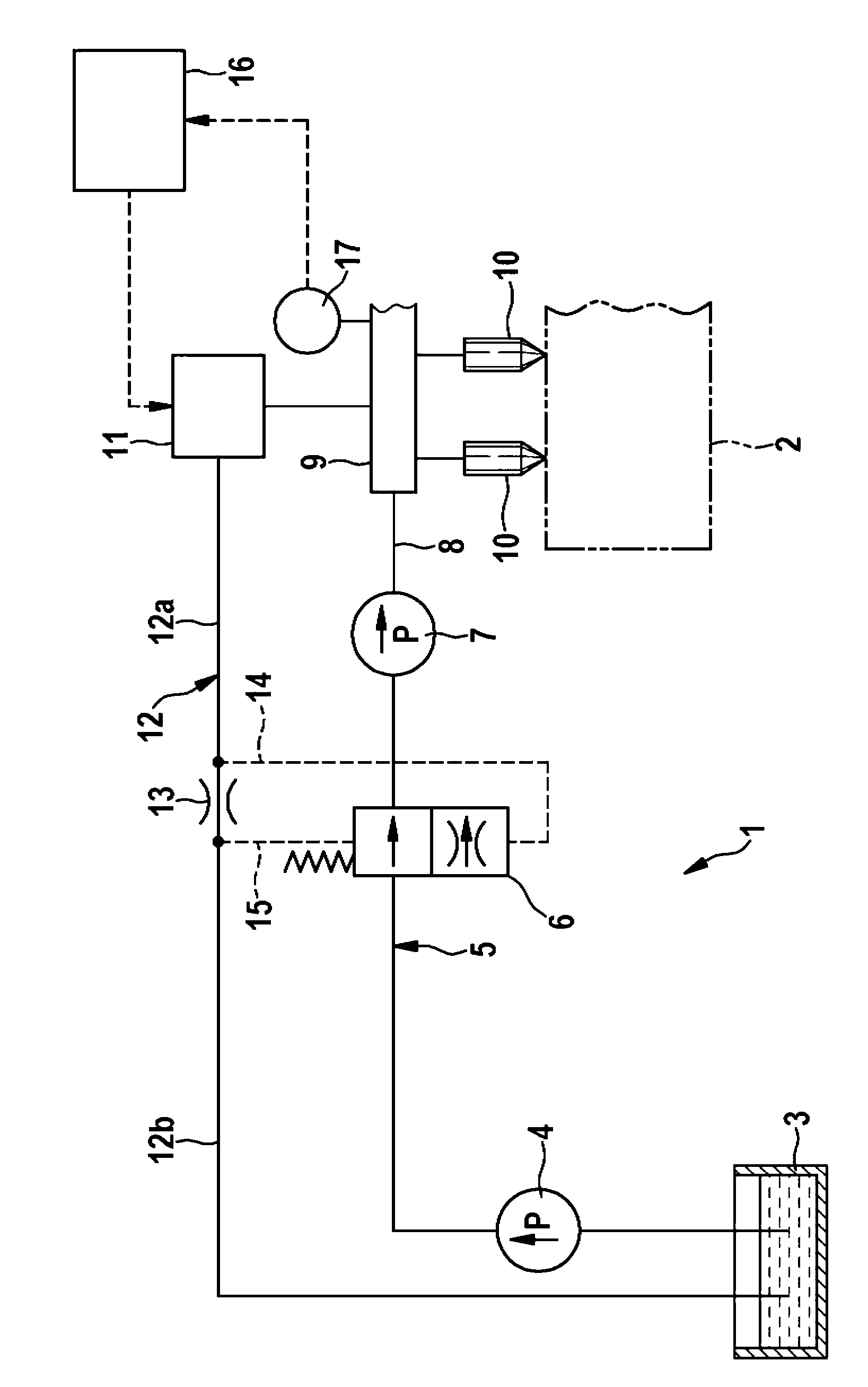

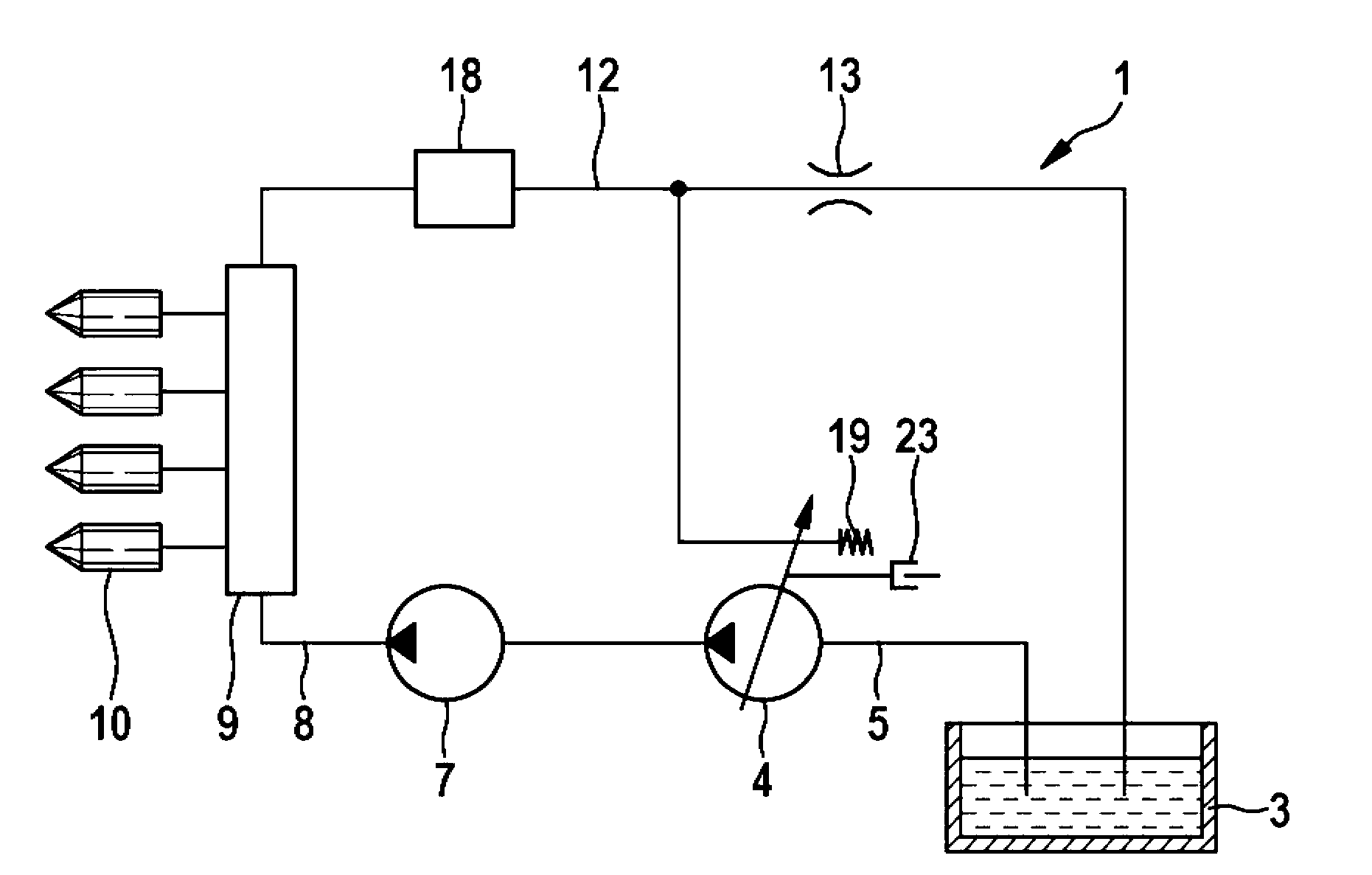

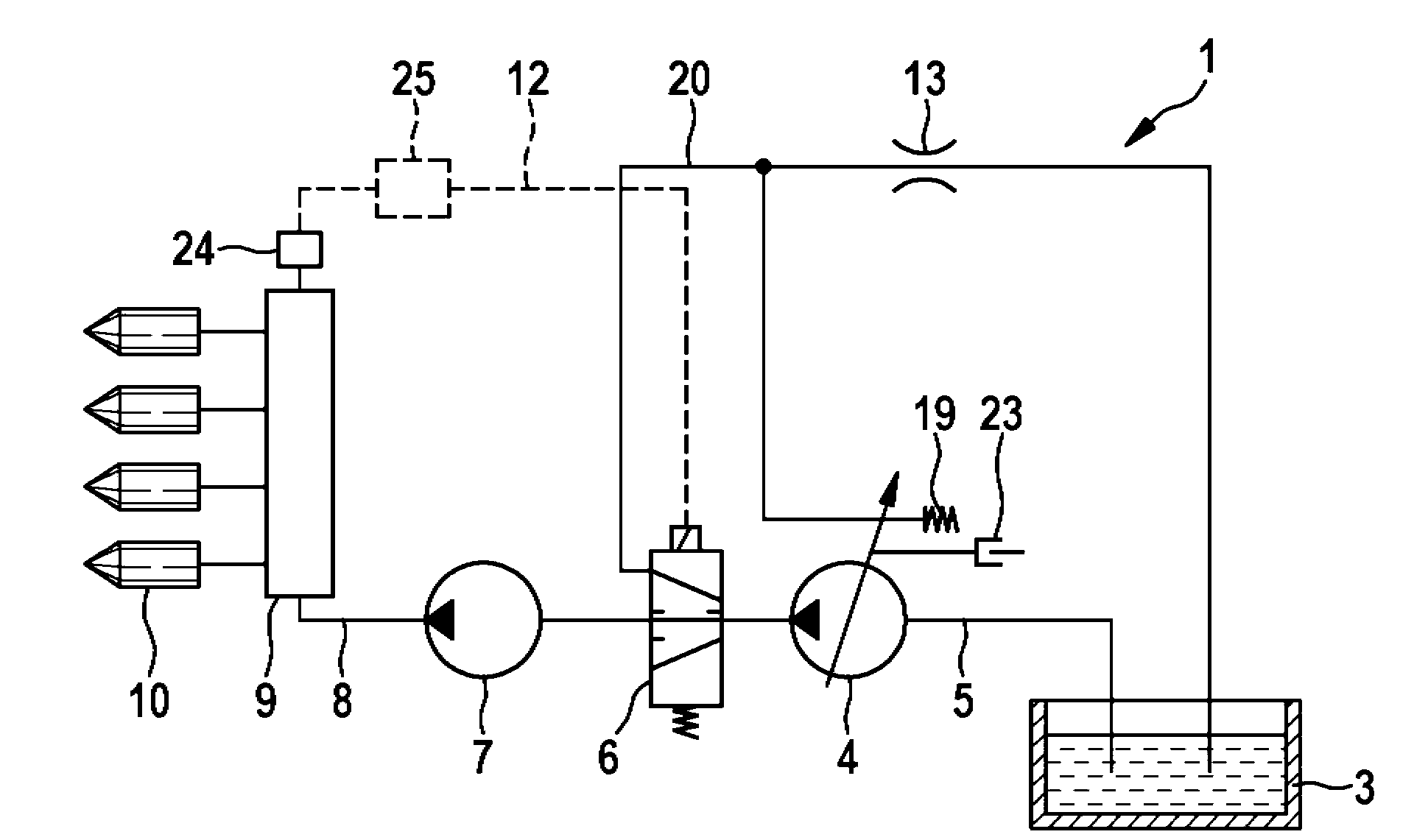

Fuel injection system

InactiveCN103228904AImprove power efficiencyReduce power lossMachines/enginesFuel injecting pumpsCommon railEngineering

The invention relates to a fuel injection system of an internal combustion engine, in particular a common rail injection system, comprising a mechanical fuel delivery pump, which supplies fuel to a high pressure pump via a low pressure line. The high pressure pump feeds highly pressurized fuel to a high pressure accumulator via a high pressure line, wherein the delivery volume of the fuel delivery pump can be regulated via a pressure controller.

Owner:ROBERT BOSCH GMBH

Scaling powder fluid pressure control device

ActiveCN114226907AAvoid Stressful InteractionsConstant fluid pressureSoldering auxillary devicesElectric machineryEngineering

The invention discloses a scaling powder fluid pressure control device which comprises a pressure stabilizing pump box, a defoaming valve set and an active conveying assembly, a conveying cavity is formed in the pressure stabilizing pump box, the surface of the pressure stabilizing pump box is provided with an inlet end and an outlet end which are communicated with the interior of the conveying cavity, and a driving motor is fixedly installed on one side of the pressure stabilizing pump box; the output end of the driving motor is fixedly sleeved with a driving gear sleeve located in the conveying cavity. According to the invention, the active pressure compensation structure is arranged, and the pressure stabilizing pump box and the active conveying assembly are used for isolating and blocking liquid flow movement at two ends, so that mutual influence of pressure of liquid flows at two ends is avoided; positive pressure pushing of liquid flow is conducted through constant-speed movement of the driving motor by means of cavity changes between the driving conveying assembly and the inner wall gap of the pressure stabilizing pump box, so that the fluid pressure at the scaling powder outlet end is kept constant, and pressure control can be achieved by adjusting the power rotating speed of the driving motor.

Owner:FRD SCI & TECH (JIANGSU) CO LTD

A flux fluid pressure control device

ActiveCN114226907BAvoid Stressful InteractionsConstant fluid pressureSoldering auxillary devicesPressure stabilizationElectric machinery

Owner:FRD SCI & TECH (JIANGSU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com