Method for controlling a compressor

A compressor, inlet pressure technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as high manufacturing cost, low dependence on centrifugal compressors, high complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

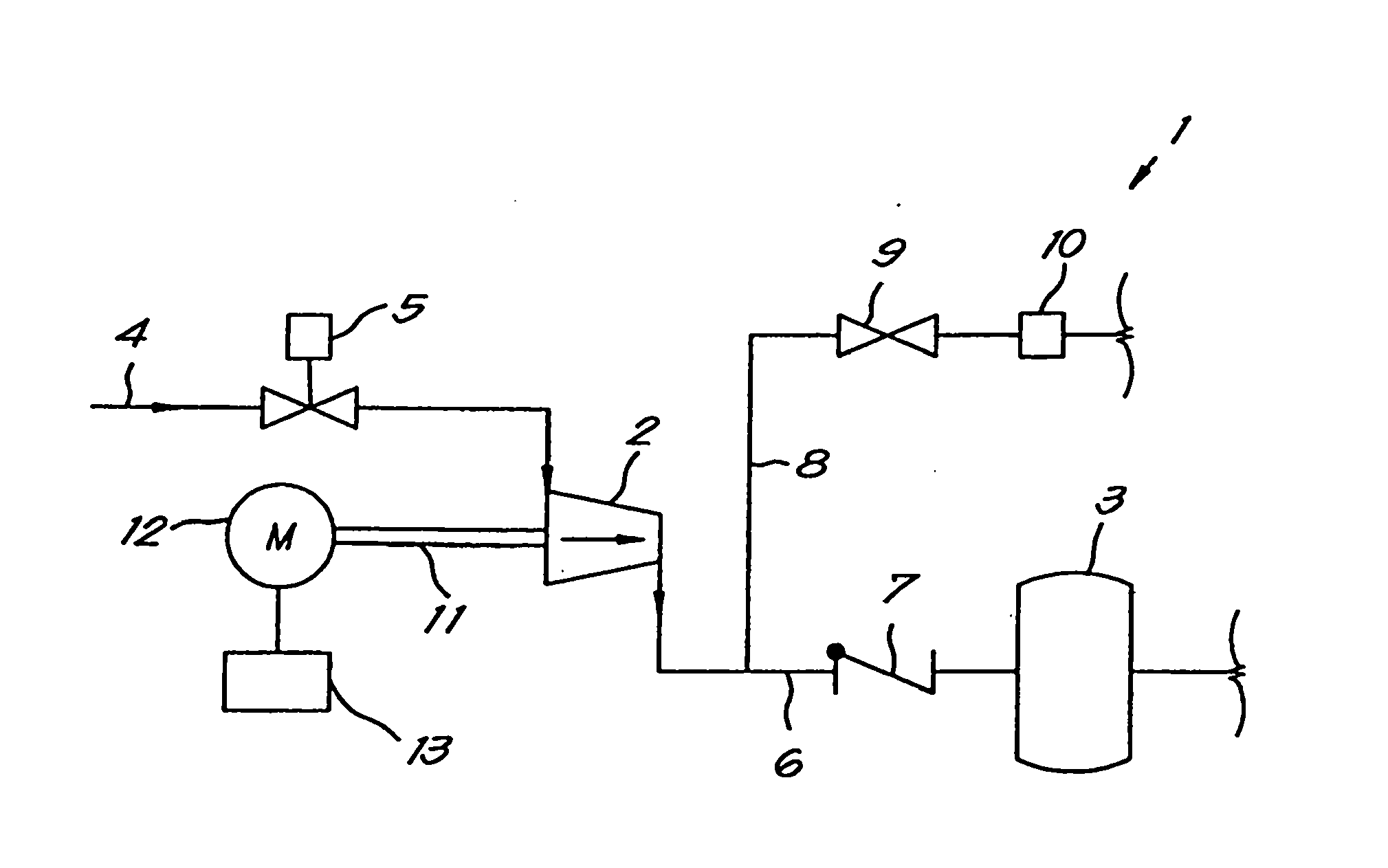

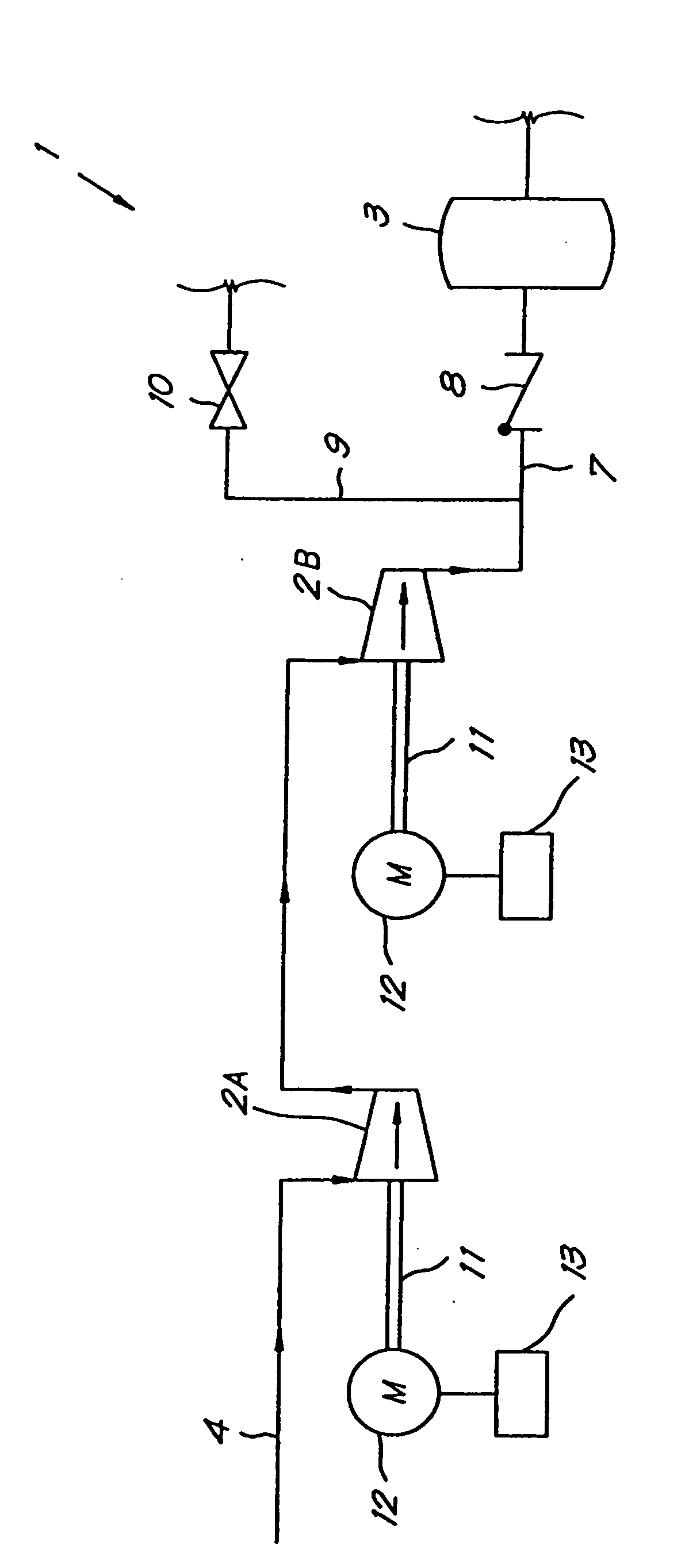

[0035] figure 1 A compressor 1 is shown, comprising, in this non-limiting example, only one compressor unit 2 (in the present solution said compressor unit is of the turbo type), which contributes to Compressed gas is supplied by a pressure network 3 which is connected to one or more compressed gas consumers.

[0036] An inlet pipe on the inlet side of the compressor unit 2 is provided with an inlet valve 5 , said inlet pipe being connected to the gas to be compressed inlet of the compressor unit 2 .

[0037] In this solution, the inlet valve 5 is configured such that it allows a certain minimum flow of gas to flow through the compressor unit 2 even in the fully closed state, but this configuration is not necessary. According to a modification not shown in the drawings, such an inlet valve 5 can be realized, for example (but not necessarily) by configuring the inlet valve 5 as a shut-off valve with a bypass pipe passing through it, and when the shut-off valve is fully closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com