Magnetorheological Pressure Control Valve

A pressure control and magneto-rheological technology, applied in the field of pressure control valves, can solve the problems that it is difficult to achieve rapid pressure, stepless changes, high requirements on the valve core spring, and small valve core movement, so as to achieve high energy utilization efficiency, Small value change, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

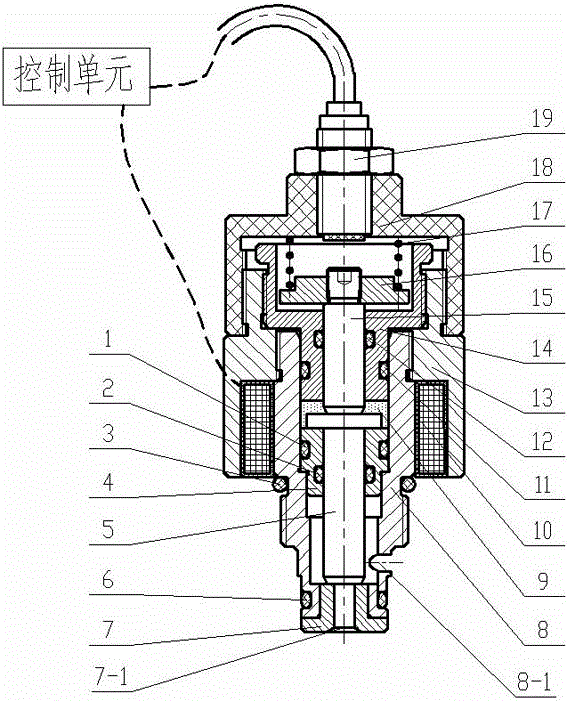

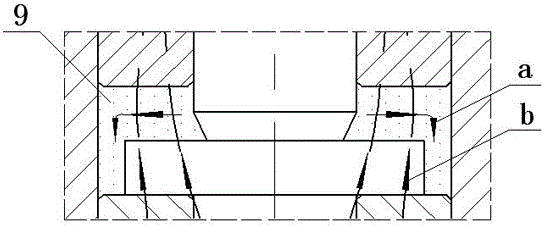

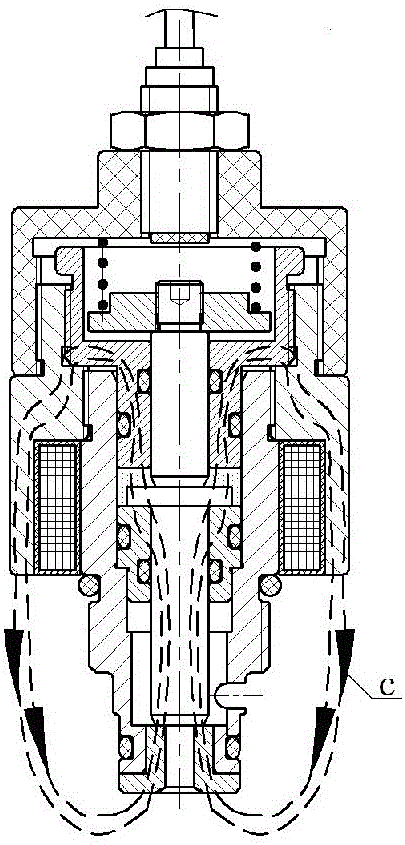

[0015] attached by figure 1 As shown: the magnetorheological pressure control valve includes: inner valve body 4, valve core 5, plug cover 7, main valve body 8, working chamber 9 (with magnetorheological fluid inside), coil assembly 10 (including coil and isolation Magnetic jacket), outer valve body 13, upper valve body 14, thrust shaft 15, spring seat 16, return spring 17, end cover 18, travel switch sensor 19 and multiple rubber sealing rings (1, 2, 3, 6, 11 , 12). The travel switch sensor 19 and the end cap 18 are threadedly connected to the upper end of the end cap 18, and the end cap 18 is an insulating material; The valve body 14 is threadedly connected to the upper and outer sides of the upper valve body 14, the upper valve body 14 is arranged on the inner side of the main valve body 8 and is provided with a rubber sealing ring 11 between the main valve body 8, the outer valve body 13 and the upper valve body 14 All are magnetically conductive materials; the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com