Control method for high-strength steel straightening and leveling unit

A technology of unit control and high-strength steel, applied in elongation control, metal rolling, manufacturing tools, etc., can solve the problems of high residual stress level and uneven heating of high-strength steel products, so as to reduce the residual stress level and ensure the performance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

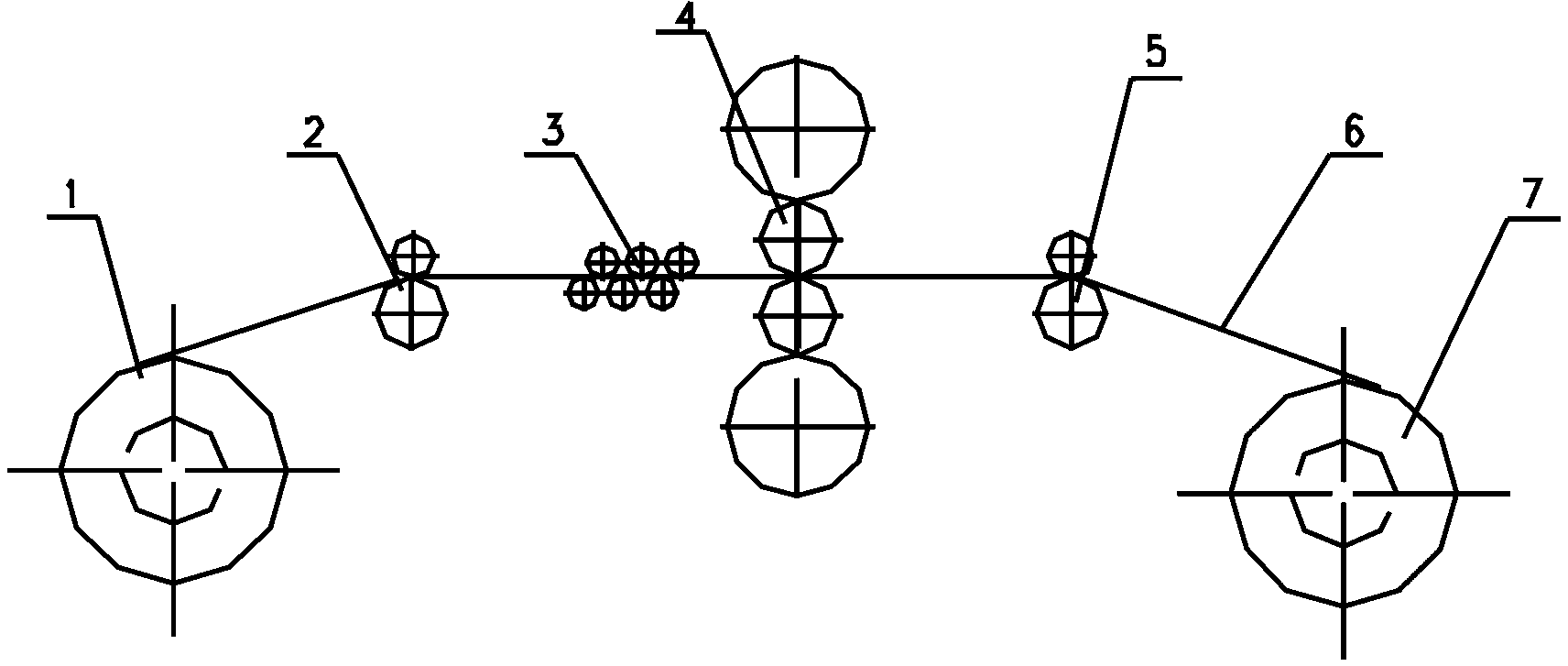

[0024] High-strength steel straightening and leveling unit control method, using such as figure 1 The straightening and leveling unit shown is for high-strength steel treatment, which is characterized in that the total elongation of the high-strength steel in the process section is controlled for the straightening and leveling unit, and the reciprocating bending action of the leveler is used to fully reduce the residual stress level of the hot-rolled high-strength steel. The real-time dynamic adjustment capability of the temper mill can effectively control the yield strength of hot-rolled high-strength steel; specifically, it includes the following steps:

[0025] Firstly, the total elongation of the unit is set according to the required yield strength of the strip product at the end of the process section; then, the set value of the total elongation is assigned to the straightening machine and the tempering machine to pre-set the straightening and leveling process; after that...

Embodiment 2

[0028] Embodiment 2: On the basis of the above-mentioned embodiment 1, 80% of the total elongation setting value is distributed to the straightener 3, and the pressing depth of the upper roller of the straightener is set in a preset manner; the total elongation 20% of the rate setting value is assigned to the tempering machine 4 to pre-set the rolling force; Feedback the deviation signal to the rolling force control system of the temper mill 4, and ensure the stability of the total elongation of the process section through the adjustment of the rolling force of the temper mill 4, so as to fully reduce the residual stress level of the strip and at the same time ensure that the product performance quality.

Embodiment 3

[0029] Embodiment 3: On the basis of the above-mentioned embodiment 1, 70%~90% of the total elongation is allocated to the straightener 3, and the pressing depth of the upper roller of the straightener is set in a preset manner; the total elongation The remaining proportion of the ratio is assigned to the tempering machine 4 to pre-set the rolling force; when there is a deviation between the total elongation of the strip processed in the straightening and leveling process section and the total elongation set value, the deviation signal Feedback to the rolling force control system of the temper mill 4 to ensure the stability of the total elongation of the process section through the adjustment of the rolling force of the temper mill 4, thereby fully reducing the residual stress level of the strip and at the same time ensuring the performance and quality of the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com