Patents

Literature

78results about How to "Guaranteed performance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

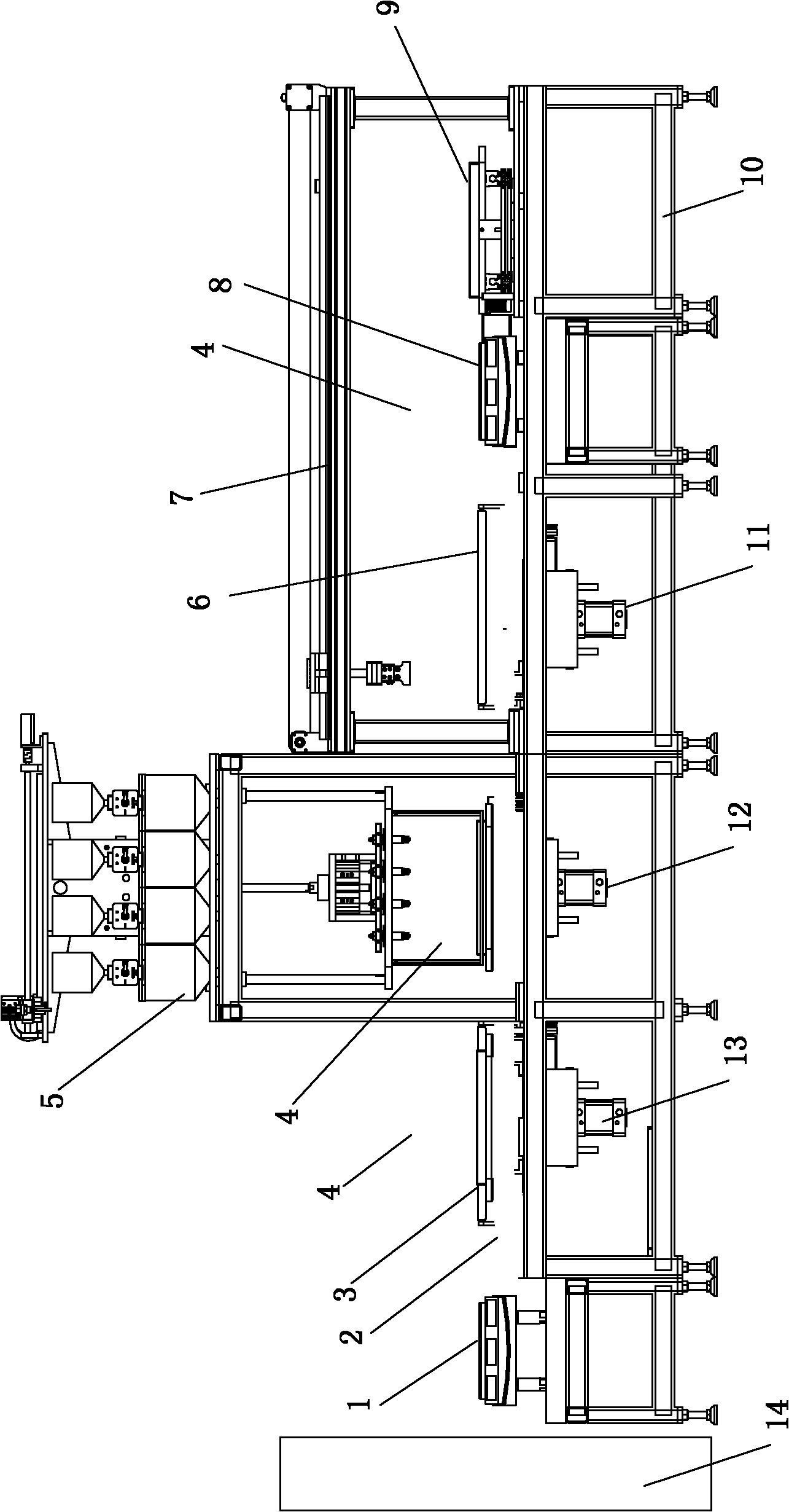

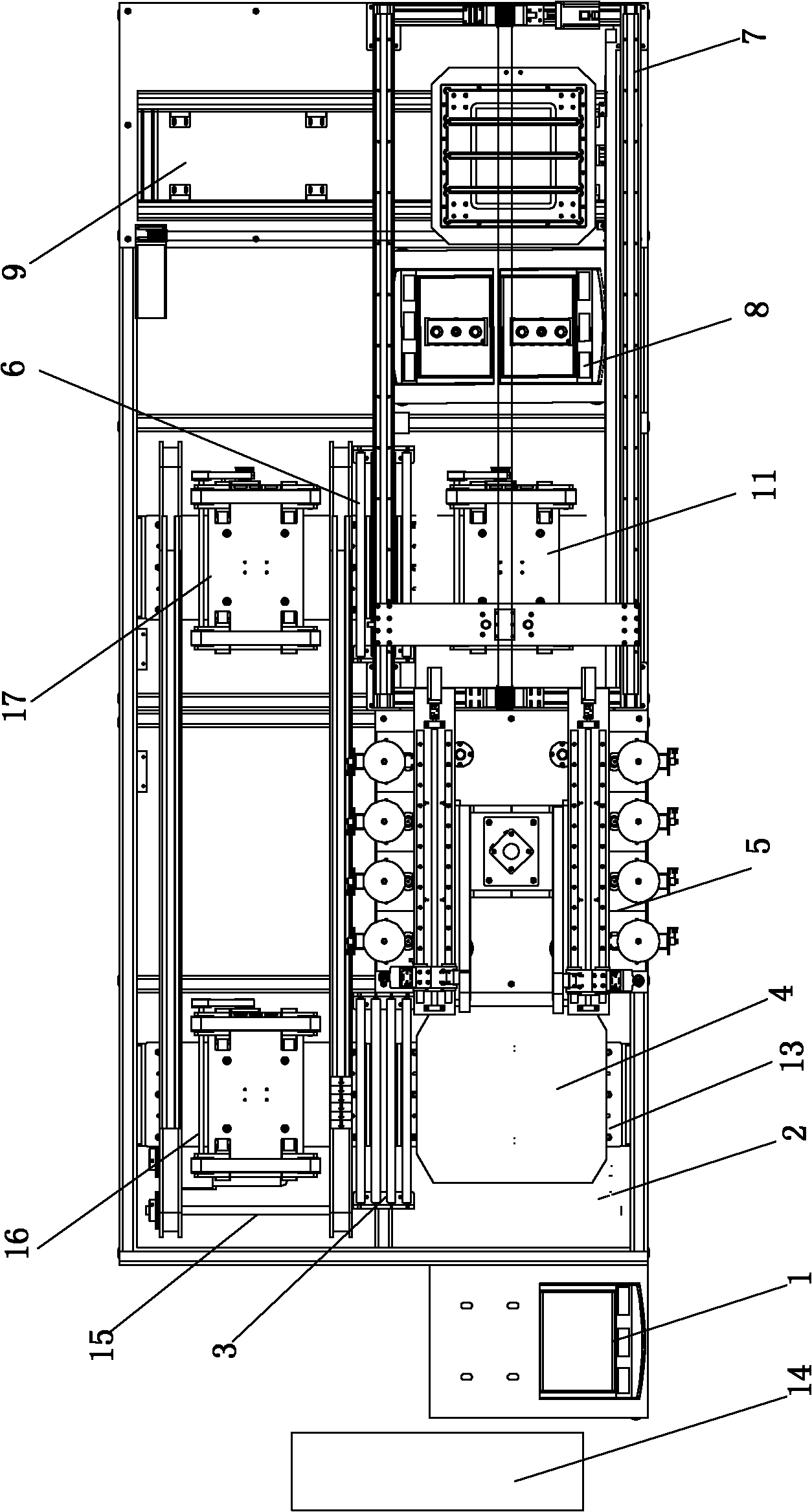

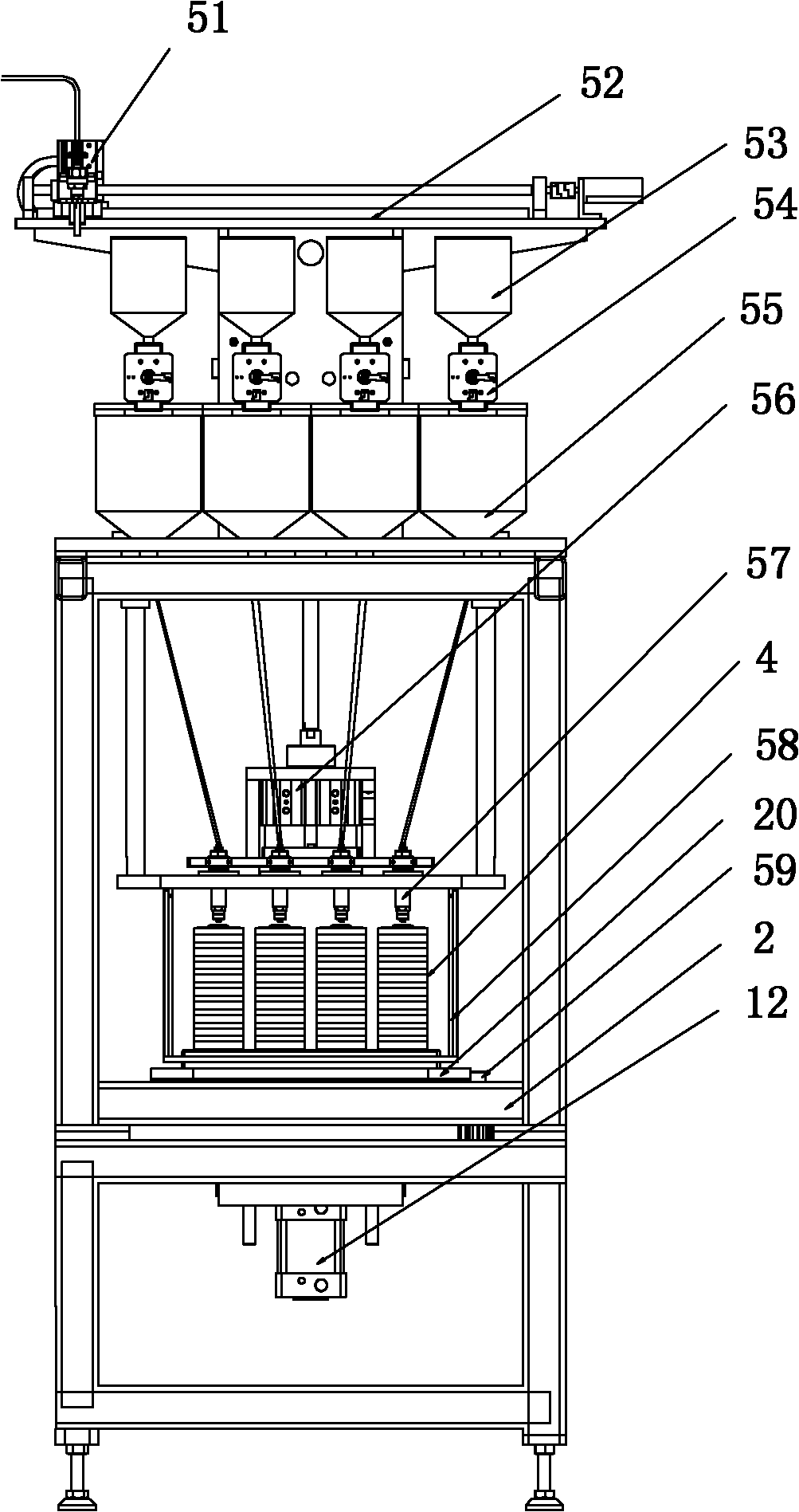

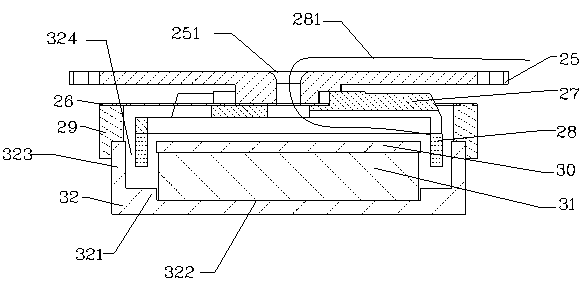

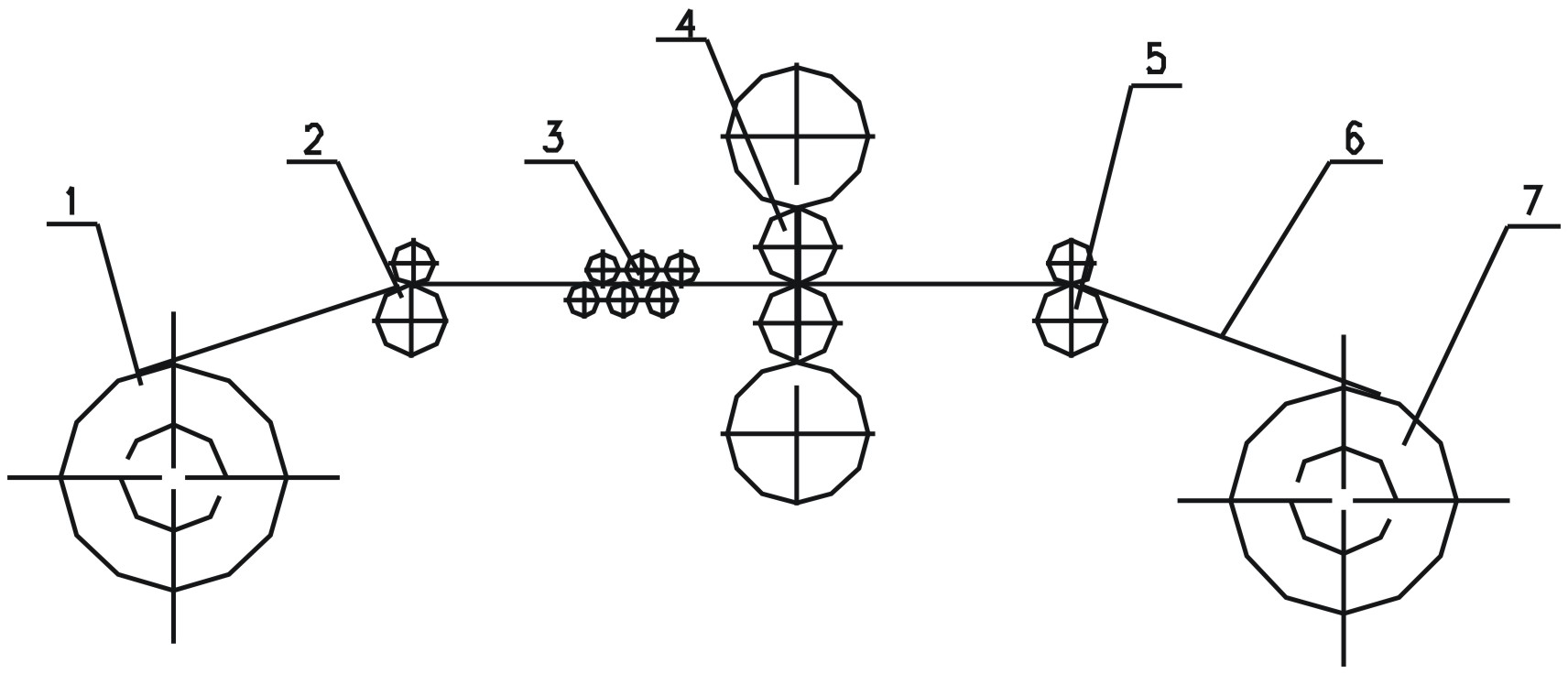

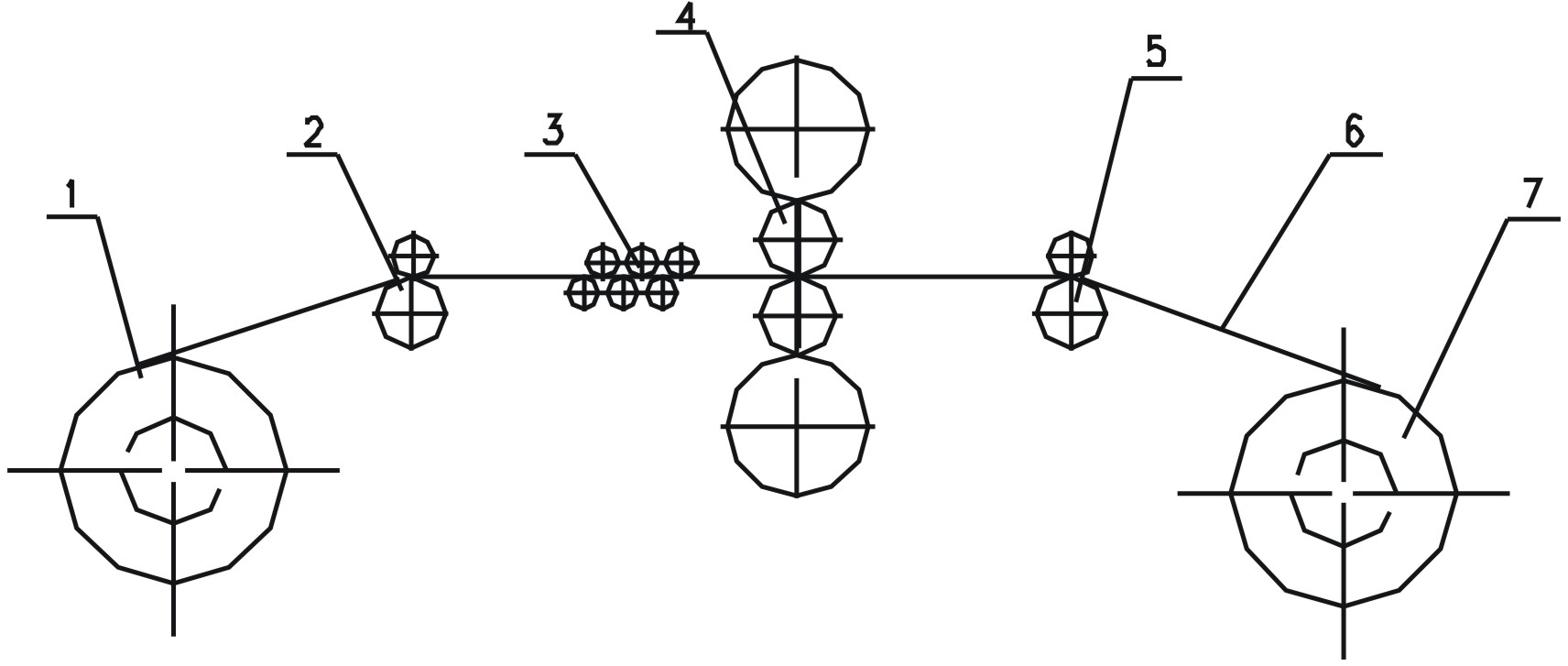

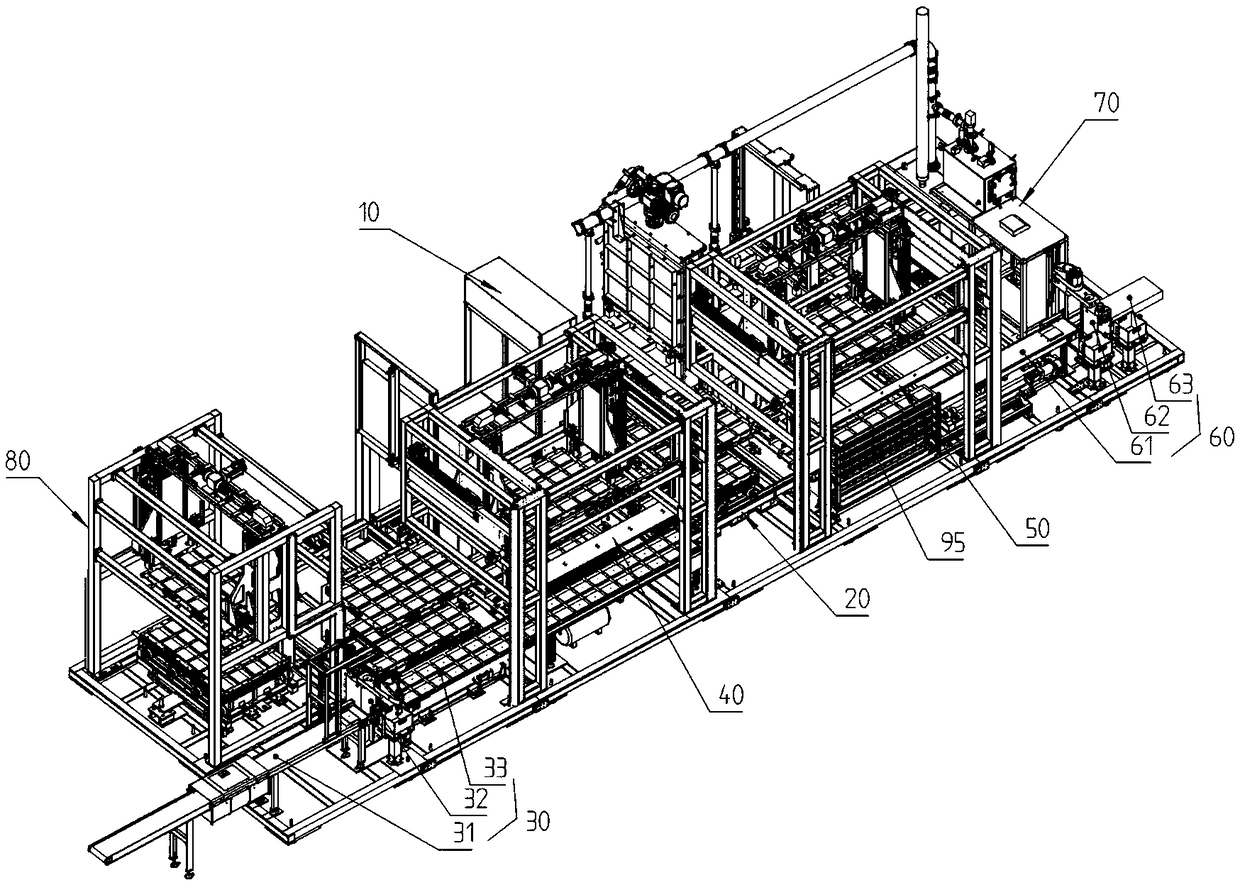

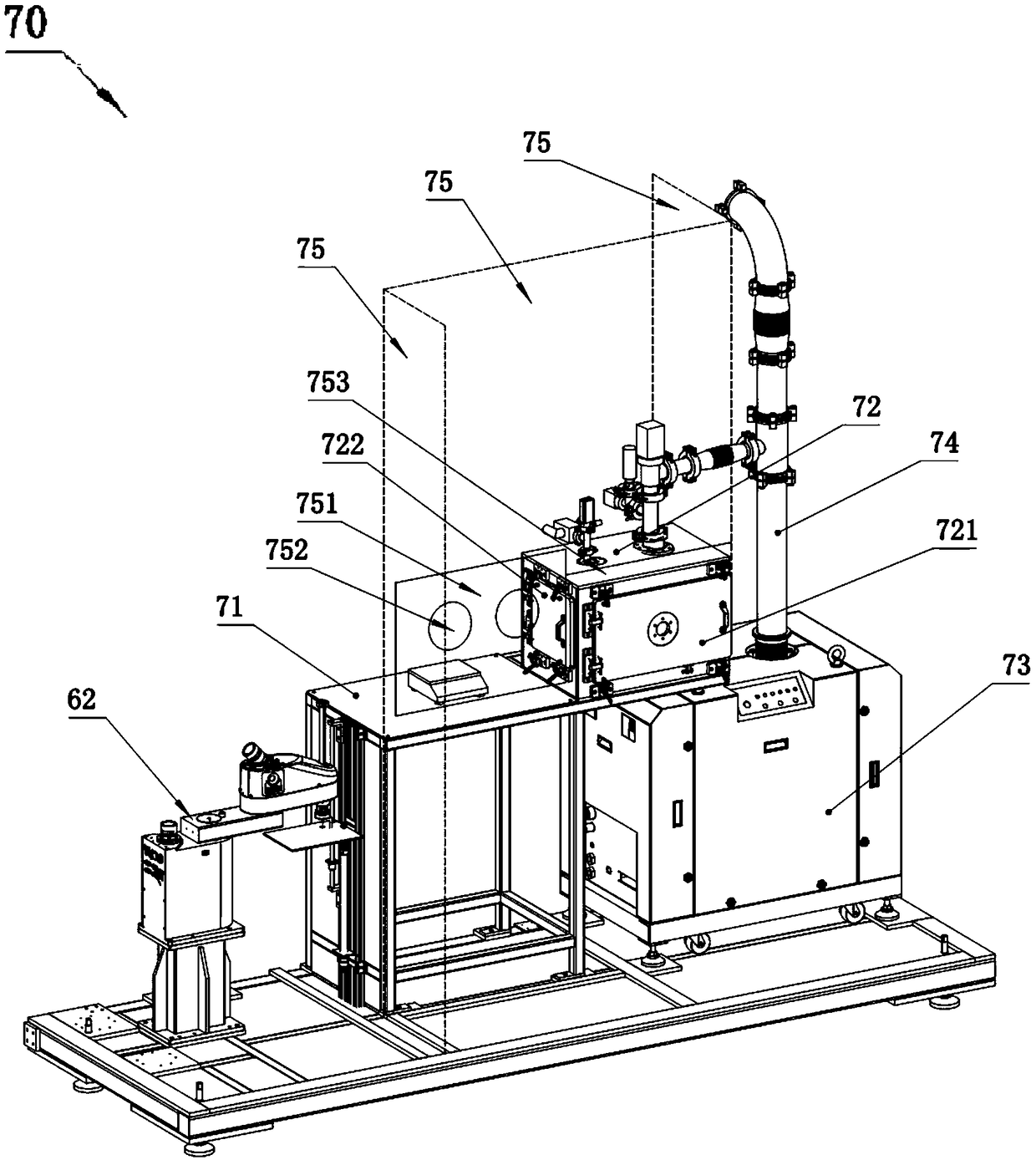

Automatic filling machine for battery and battery filling method

InactiveCN102148349ARealize automatic flow operationCompact machine designCell component detailsBuffer tankEngineering

The invention discloses an automatic filling machine for a battery and a battery filling method. The filling machine comprises a rack, a front weighing device arranged on the rack, a filling conveying line, an evacuation filling device, a discharging device, a rear weighing device and a control module. The filling machine also comprises a carrier backflow mechanism which comprises a carrier conveying line parallel to the filling conveying line and carrier transfer devices arranged at two ends of the filling conveying line and the carrier conveying line; and the evacuation filling device comprises a filling nozzle, a driving part for driving the filling nozzle to move, a filling cup communicated with the filling nozzle, a filling buffer tank communicated with the filling cup and a sealing cylinder for sealing the filling nozzle and the battery in the sealing cylinder. In the invention, automatic operations of battery conveying, filling, evacuation and discharging are ensured, the machine design and process layout are compact, the vacuum and high-pressure circulating alternate filling method is adopted, and the full absorption and filling precision of electrolyte of the battery are ensured.

Owner:GEESUN AUTOMATION TECH

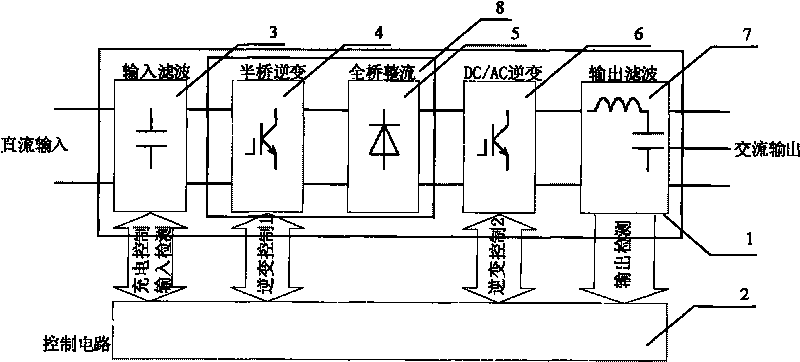

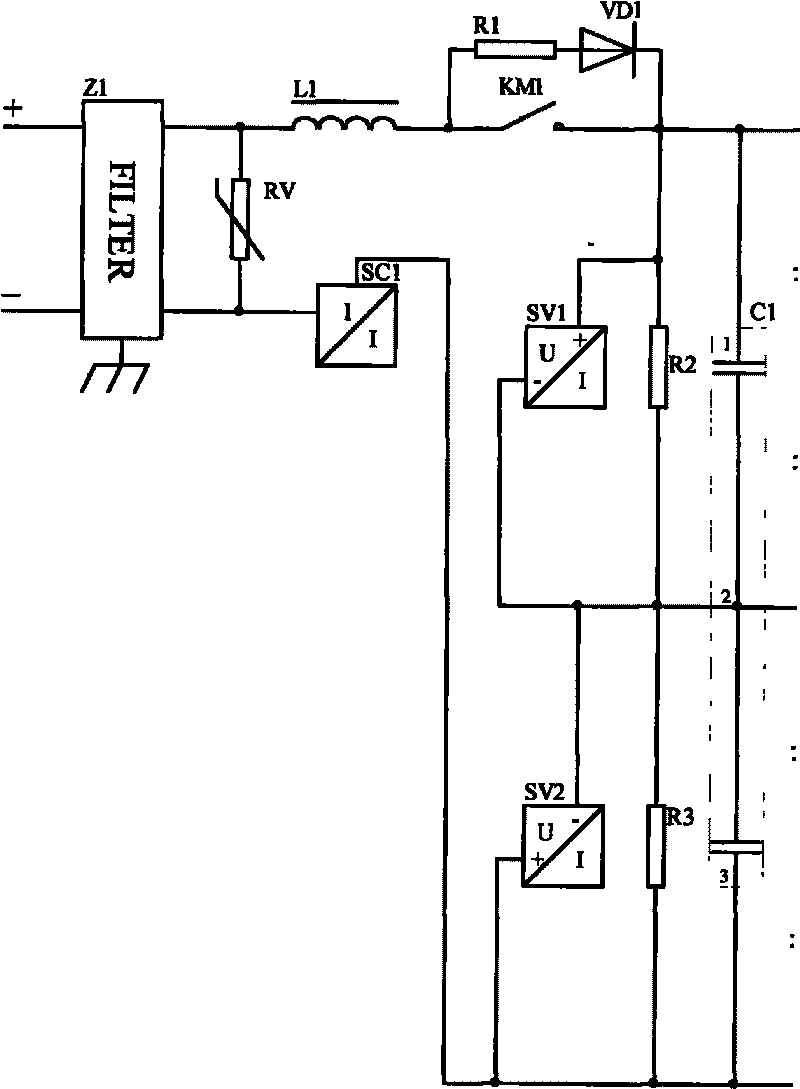

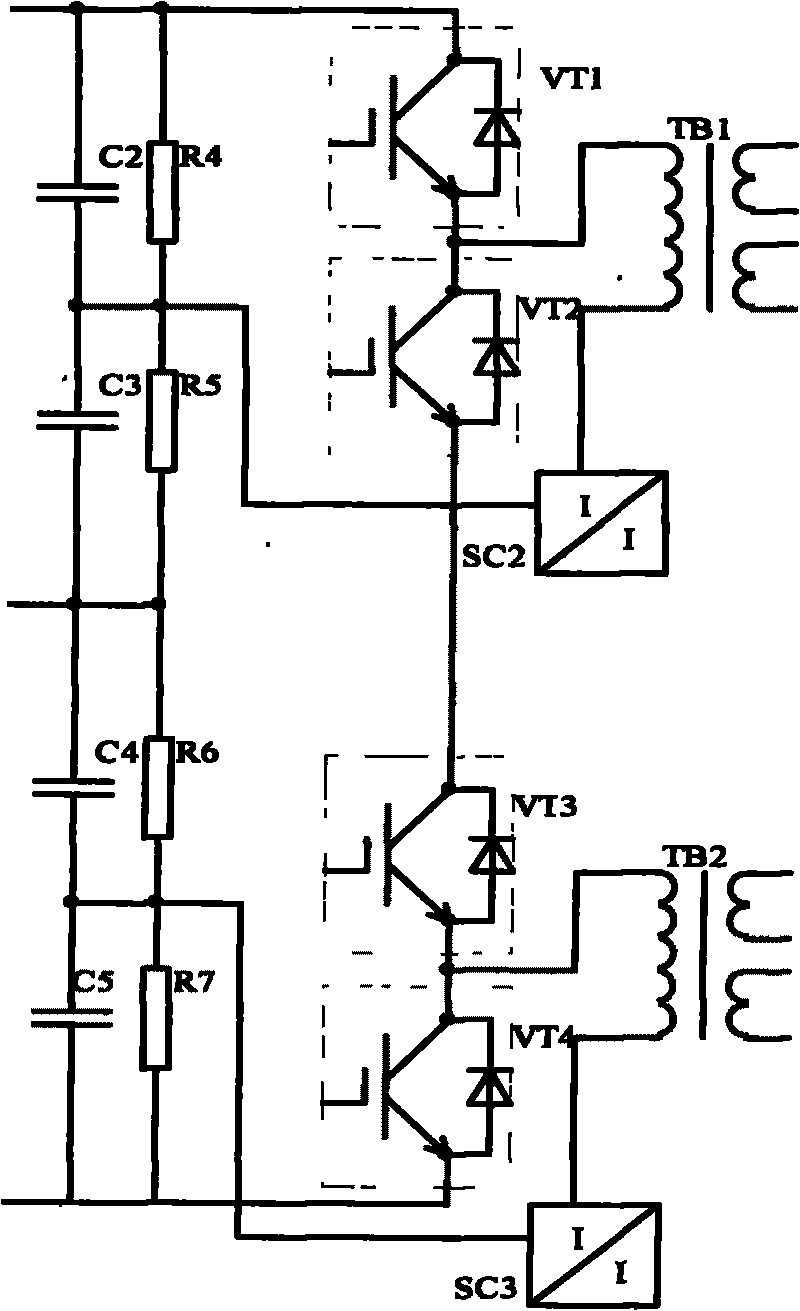

Three-phase auxiliary inverter

InactiveCN101697458AReduce voltage stressGuaranteed performance qualityAc-dc conversionDc-dc conversionTransformerFull bridge

The invention discloses a three-phase auxiliary inverter, which comprises a main circuit and a control circuit, wherein the control circuit detects and controls the main circuit; the main circuit comprises an input filtering circuit, a DC / DC conversion circuit, a DC / AC inverter circuit and an output filtering circuit; and the DC / DC conversion circuit comprises a half-bridge inverter circuit adopting a high-frequency transformer and a full-bridge rectifier circuit. When the inverter is on, the control circuit performs system self-checking, the main circuit works under the condition of no fault, the input filtering circuit filters an input power supply and closes a short-circuit contactor after the charging is finished, the control circuit sends a half-bridge inverter pulse, the DC / DC conversion circuit works and converts the input direct current power supply into a steady intermediate direct current voltage, then the steady intermediate direct current voltage is inverted into a three-phase SPWM wave through the DC / AC inverter circuit, and the three-phase SPWM wave is filtered into a three-phase sine wave through the output filtering circuit and supplies the electricity to a three-phase load. The implementation of the three-phase auxiliary inverter reduces the voltage stress borne by switching devices, and reduces the weight and the volume of power supplies.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

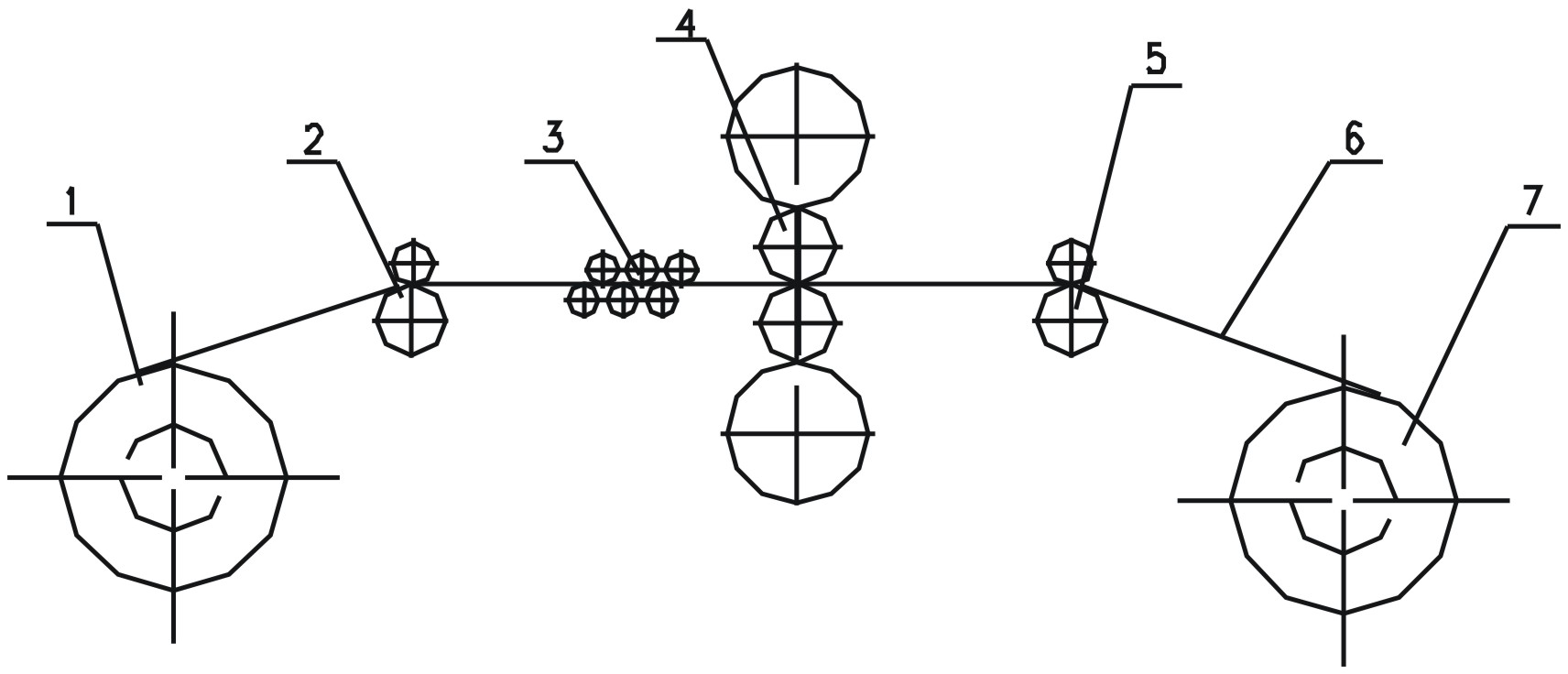

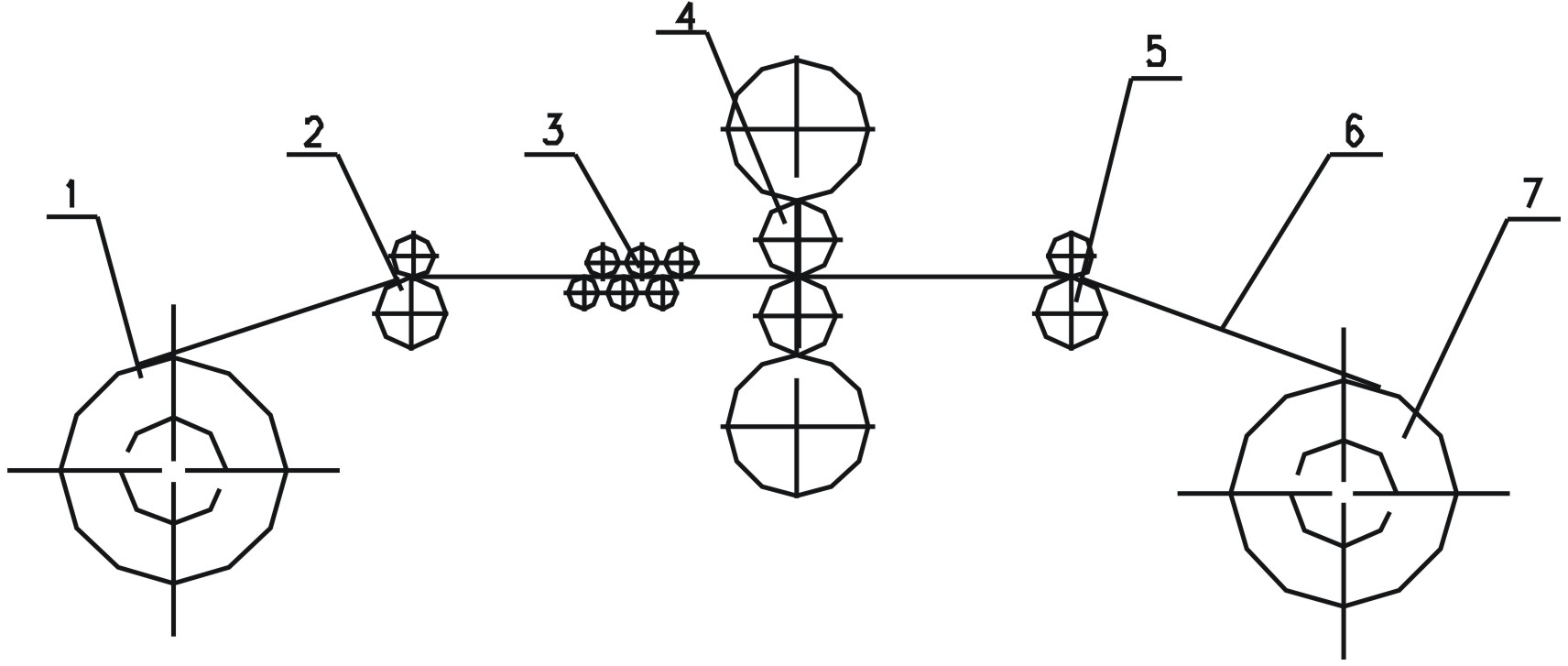

Straightening and leveling process for hot-rolled high-strength steel

ActiveCN102626726AReduce residual stress levelsResidual Stress Level GuaranteeMetal rolling arrangementsUltimate tensile strengthMechanical engineering

The invention relates to a straightening and leveling process for hot-rolled high-strength steel. The straightening and leveling process is characterized in that: hot-rolled high-strength band steel is fed into a straitening machine and a leveling machine in sequence. The process comprises the following specific steps of: firstly, setting the total elongation rate of a unit according to yield strength needed by a band steel product on the tail of a process section; secondly, distributing a total elongation rate set value to the straitening machine and the leveling machine for presetting the straightening and leveling process; thirdly, detecting the total elongation of detected and processed band steel in real time; and lastly, comparing the total elongation of the detected and processed band steel with the total elongation rate set value, dynamically adjusting the rolling force of the leveling machine in real time to ensure that the total elongation rate of a band steel product on the tail of the process section is constant, lowering the residual stress level of the band steel by using the straightening machine, and ensuring the performance quality of the band steel product on the tail of the process section. Due to the adoption of the process, the internal residual stress level of the hot-rolled band steel can be lowered fully, and the performance quality of a hot-rolled high-strength steel product is improved effectively.

Owner:WISDRI ENG & RES INC LTD

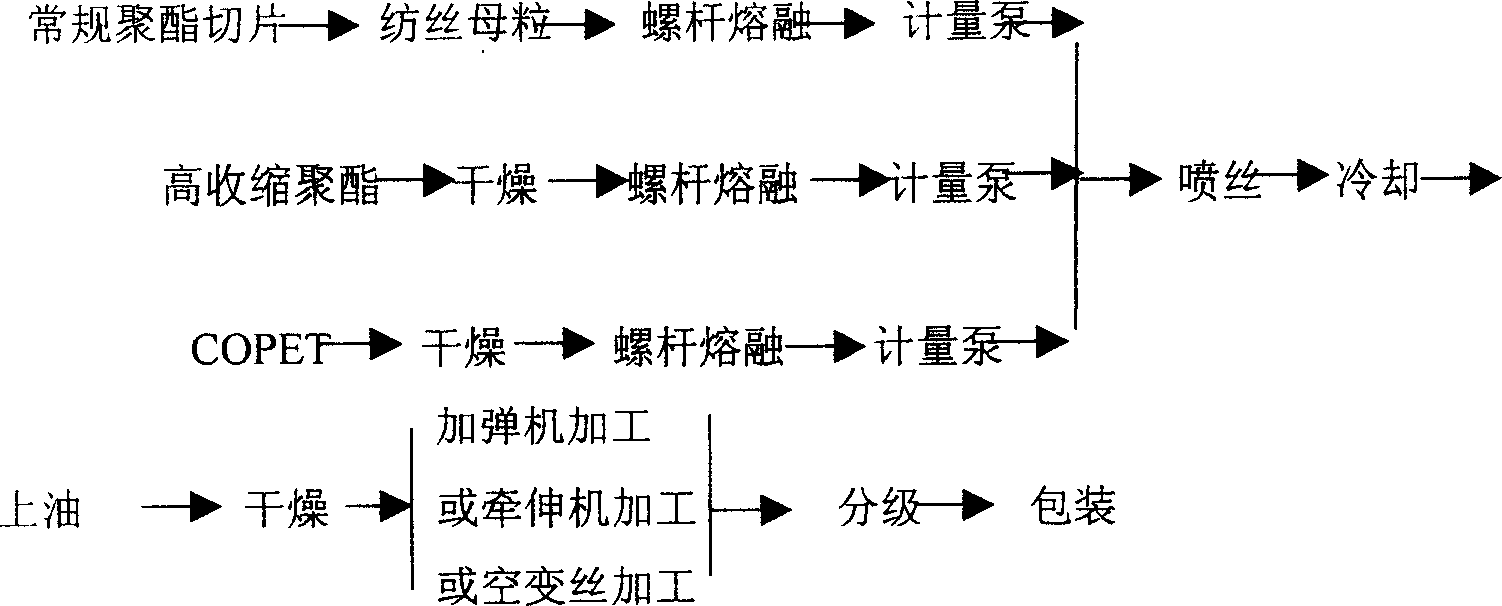

Ultrafine hetero composite elastic fibre and its manufacturing method

InactiveCN1693546ASoft touchComfortable to wearMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterTextile technology

The invention relates to a superfine hetero composite elasticized fiber and its manufacturing method, special spinning equipment, spinning art and the related technique, uses routine polyester slice, highly contractive polyester, and so on as raw materials to prepare spinning solution, makes multicomponent composite spinning on the spinning solution and water soluble polyester, and then elasticizes to make a superfine isomeric composite elasticized fiber finished product, where single silks of the fiber are distributed like an island, and by post processing, the fineness of the fiber is up to 0.01-0.001 dan, and besides, the fiber has the superfine, different-contractive and different section properties. The fabric produced by this fiber has handwriting effect, especially soft handing, and humidity absorbing property up to and even over that of natural fiber, full, comfortable and good-air permeability; and the surface of the fabric has a shine like silk and good dyeing property. This fiber can be widely applied to the industries of machine weaving, knitting, silk manufacturing, etc., to manufacture minic, high grade clothing, blood filtering material, etc.

Owner:JIANGNAN UNIV

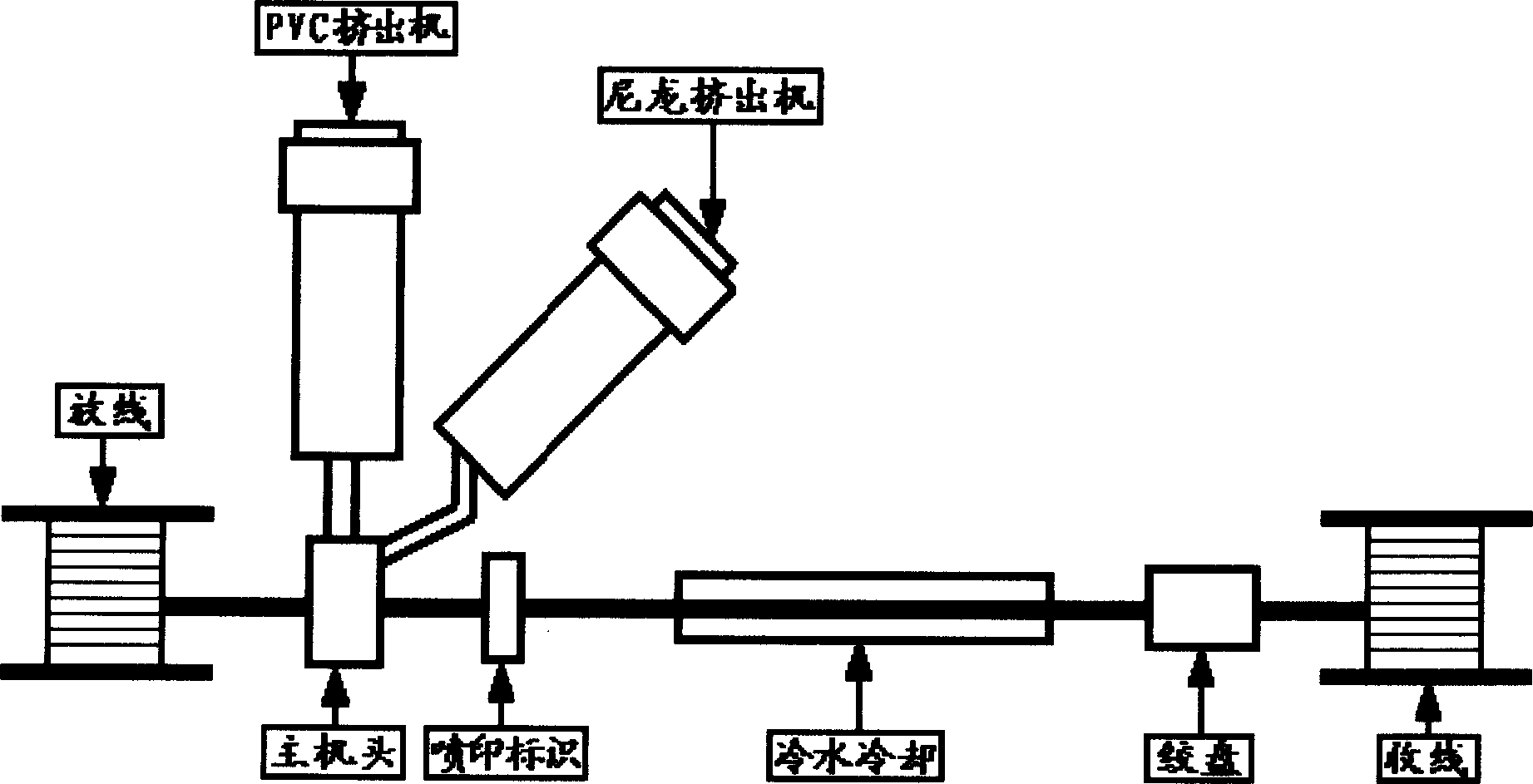

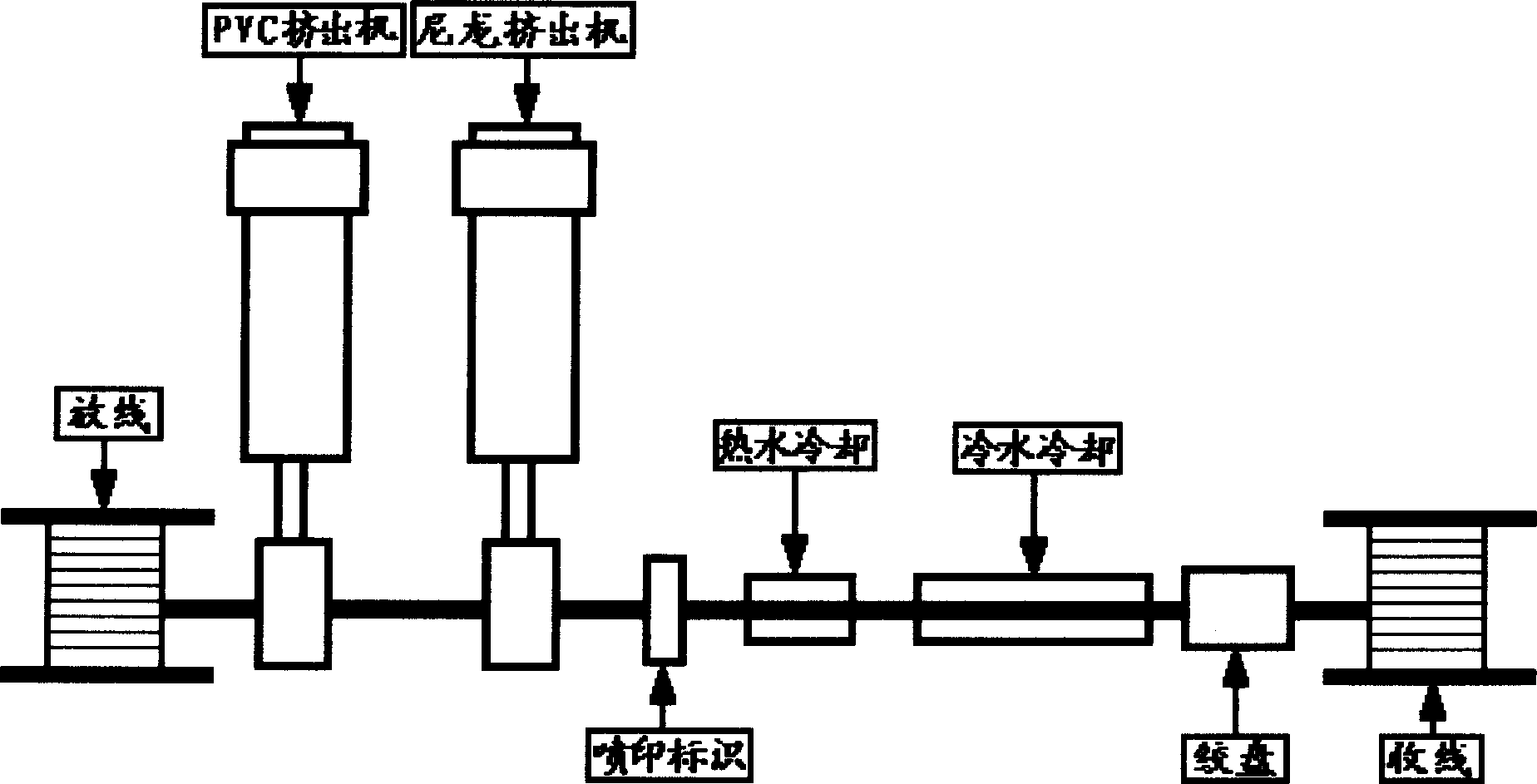

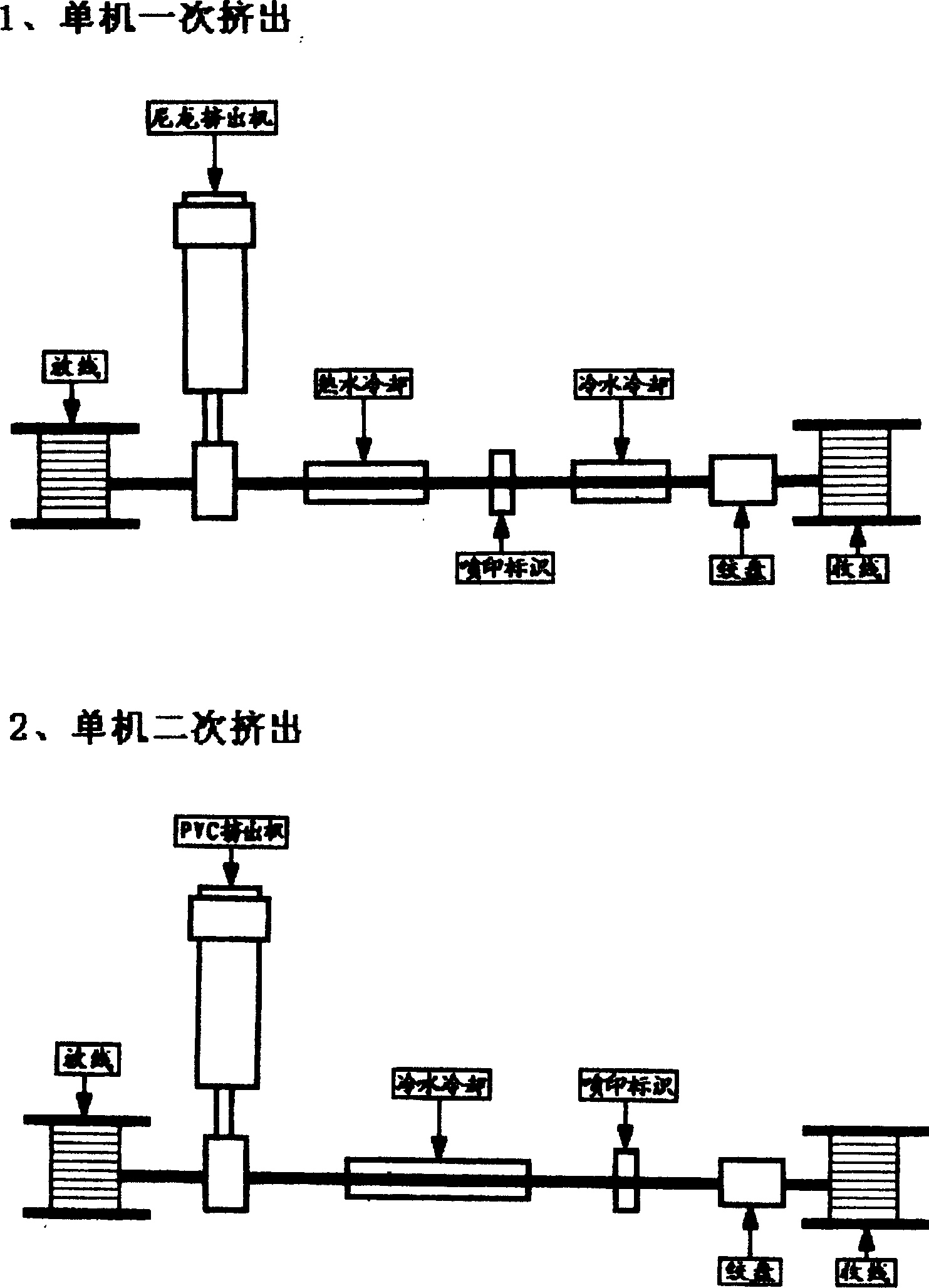

Technology for producing PVC insulated nylon flexible wire using double machine extruding method

InactiveCN1595547AAccelerated agingAvoid stayingInsulated cablesCable/conductor manufactureProduction linePolyvinyl chloride

Disclosed is a technique using dual-machine extrusion method to produce polyvinyl chloride insulating nylon jacket electric wire. Make nylon and polyvinyl chloride separately melt by nylon extruding machine and PVC extruding machine, which are separately injected into different ingates and channels of shunt in prime machinery head, firstly polyvinyl chloride is extruded and then nylon to form tightly connected insulating layer of polyvinyl chloride and nylon jacket layer covered on it. Polyvinyl chloride insulating nylon jacket electric wire is formed through word sprinkling, cooling and taking up of capstan. It has the advantages of increased smoothness and mechanical performance of electric wire surface, simplified technique, shortened production line, prolonged wire service life and excellent safety and reliability.

Owner:湖北红旗电缆有限责任公司

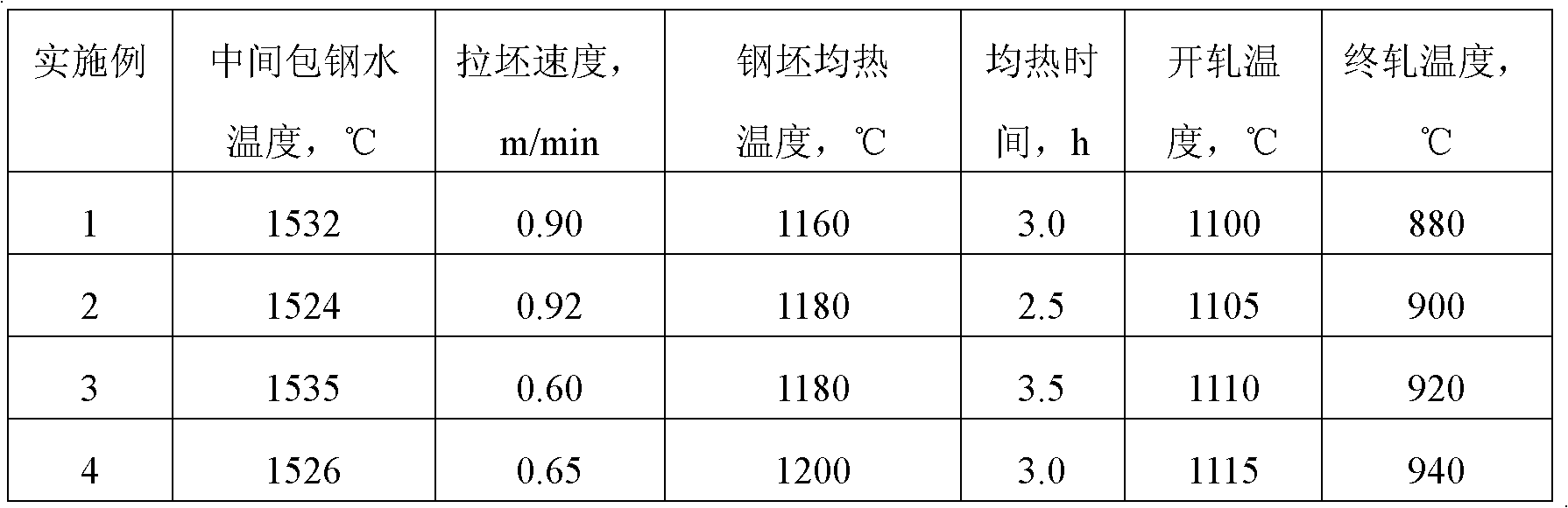

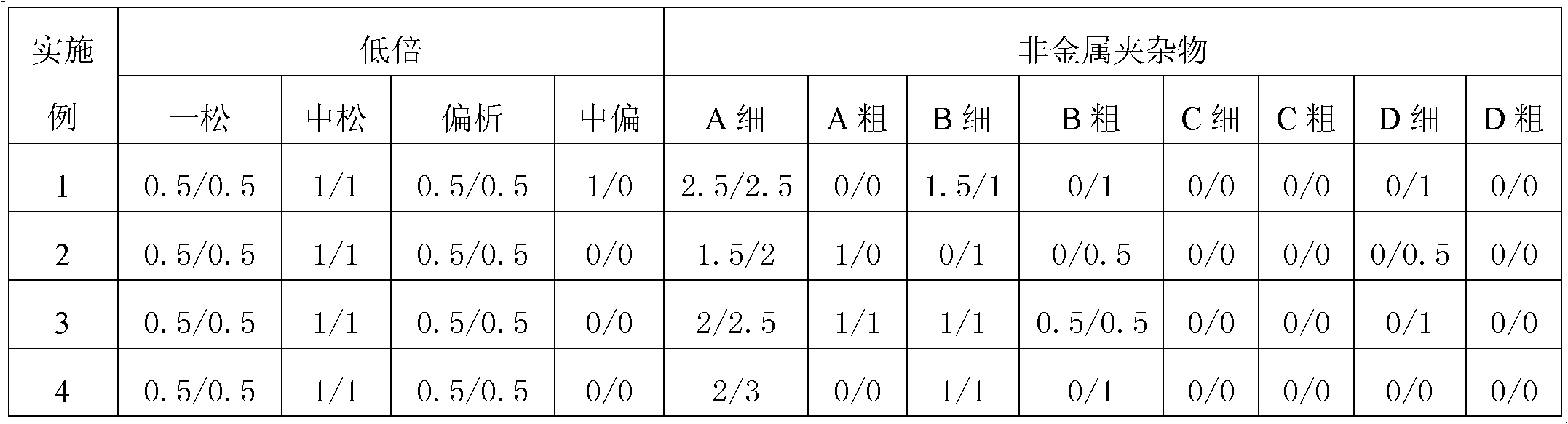

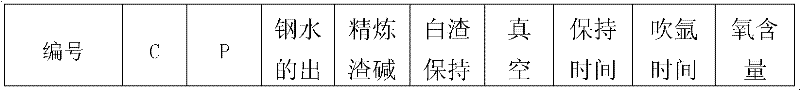

MnCr carburized gear steel and its production method

The invention relates to a MnCr carburized gear steel and its production method, the MnCr carburized gear steel comprises the following components by mass percentage: 0.25-0.30% of C, less than or equal to 0.12% of Si, 0.60-0.80% of Mn, 0.80-1.10% of Cr, less than or equal to 0.035% of P, 0.020-0.050% of S, 0.020-0.055% of Al, less than or equal to 20ppm of [O] and the balance of Fe and inevitable impurities. By using an electric furnace smelting, the end point [C] is 0.10-0.15%, [P] is less than or equal to 0.015%, [Si] is less than or equal to 0.05%, and the tapping temperature is 1630-1680DEG C. The method comprises the steps of LF refining, adjusting slag by using carbon powder; feeding aluminum line, calcium line and sulfur line; vacuum treating; soft blowing argon; continuously casting a blank, controlling the tundish temperature at 1520-1540 DEG C, and strictly controlling the casting speed according to different blank types. The isothermal temperature, heating time and rolling temperature can be strictly controlled during the rolling process; thereby a hot-rolled round steel is prepared.

Owner:LAIWU IRON & STEEL GRP

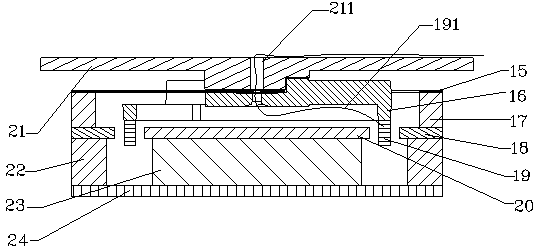

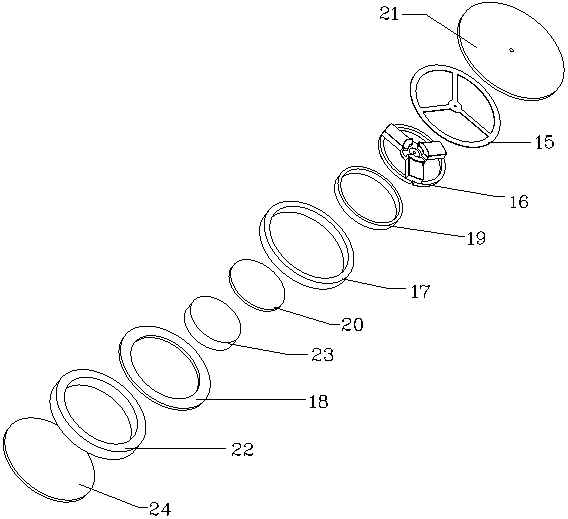

Bone-conduction headset device with single magnet and processing method thereof

ActiveCN103079135ASimple structureGuaranteed performance qualityEarpiece/earphone attachmentsEngineeringBone conduction hearing

The invention discloses a bone-conduction headset device with a single magnet and a processing method thereof. The device comprises a vibration system consisting of a vibration transmitting sheet and a vibration plate, wherein a voice coil is fixedly arranged on the vibration plate; an outer magnetic conduction plate is further arranged; a magnet is arranged on the outer magnetic conduction plate; an inner magnetic conduction plate is arranged on the magnet; a gap is formed between the inner magnetic conduction plate and the outer magnetic conduction plate; and the voice coil is arranged in the gap. According to the bone-conduction headset device with the single magnet and the processing method thereof, the single magnet and the outer magnetic conduction plate which is arranged integrally are adopted, so that the structure of a product is simplified, a processing method for assembling the magnet without magnetizing during processing and magnetizing the magnet after assembling can be realized, the production efficiency is increased, and the product yield is increased.

Owner:SHENZHEN VOXTECH CO LTD

Steel for high-strength mining machine and manufacturing method thereof

The invention relates to a steel for a high-strength mining machine, which comprises the following components in percentage by weight: 0.32-0.39% of C, 1.10-1.40% of Si, 0.80-1.10% of Mn, 0.005-0.020% of P, 0.001-0.025% of S, 1.10-1.40% of Cr, 0.01-0.20% of Cu, 0.01-0.30% of Ni, 0.010-0.060% of Al, 5-20*10<-6> of O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the steel for a high-strength mining machine. The steel provided by the invention has excellent comprehensive properties; and the cutting picks of the manufactured heading machine satisfy the operational requirements for large-size mining machines, and enhance the coal production efficiency and economic benefit.

Owner:LAIWU IRON & STEEL GRP

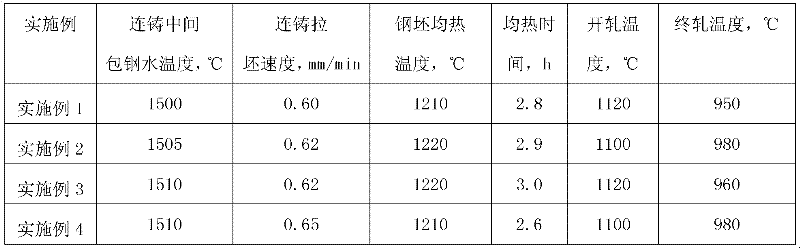

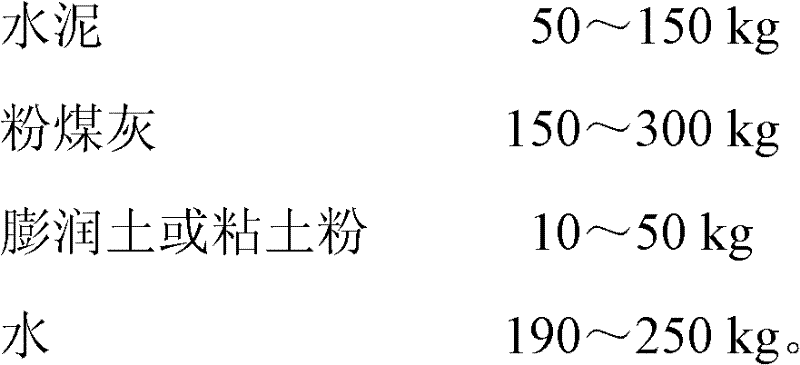

C10 self-compacting concrete and preparation method for same

InactiveCN102503271AImprove cohesionTake advantage ofSolid waste managementWork performanceCompressive strength

The invention discloses C10 self-compacting concrete and a preparation method for the same. The concrete in per cubic meter comprises components in weight of 50-150kg of cement, 150-300kg of fly ash, 10-50kg of bentonite or clay and 190-250kg of water. The compression strength value of the concrete in 28 days ranges from 9MPa to 18MPa, and the initial slump of the concrete exceeds 250mm. In the concrete, a small amount of cement is utilized, a great amount of fly ash is mixed, cohesiveness of the concrete is enhanced by the bentonite or clay powder, and the use amount of aggregate is reasonably adjusted, so that activity effect of the aggregate in the concrete is fully utilized, the working performance and the construction quality of the aggregate are guaranteed, waste resources are effectively utilized, and production cost and environmental pollution are reduced. The C10 self-compacting concrete is wide in application, can be applied to various project positions, and is particularly applicable to projects of a temporary structure and an underground reinforced structure.

Owner:GUANGDONG FOUND NEW CENTURY CONCRETE

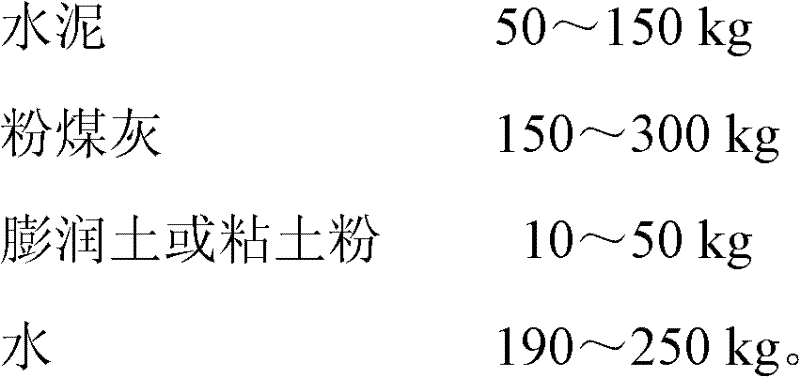

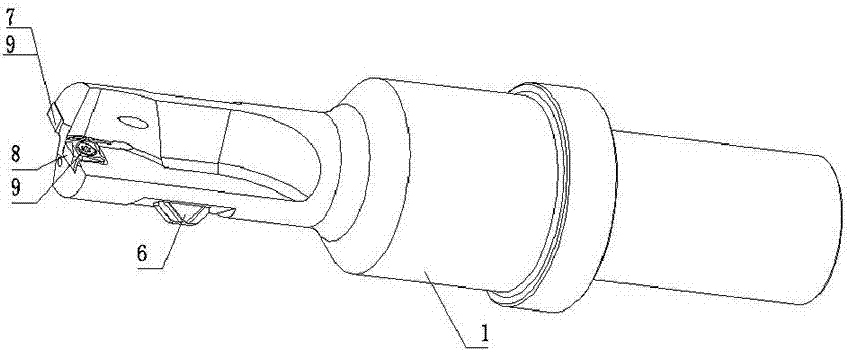

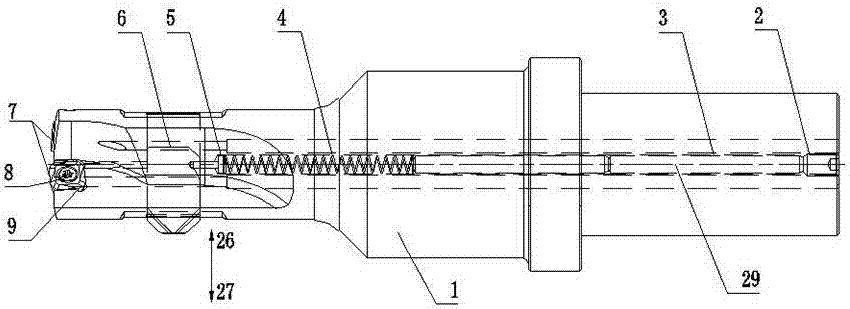

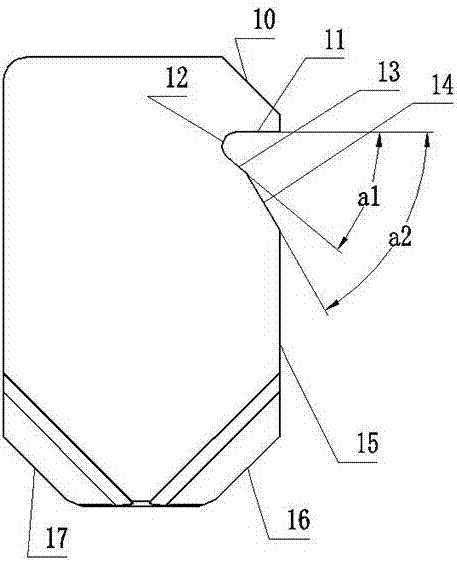

Double-face chamfering and drilling tool

InactiveCN106903352AEasy to processImprove processing efficiencyTransportation and packagingTrepanning drillsDrill holeEngineering

The invention discloses a double-sided chamfering drilling tool, which comprises a cutter body, a chamfering blade and a drilling blade, the end of the cutter body is provided with a blade platform, and the end of the cutter body is provided with a blade Install the horizontal hole, the right end of the cutter body is provided with a clamping part, the inside of the cutter body is provided with an axial hole, one end of the extension rod is positioned and installed in the axial hole by a set screw, and the other end of the extension rod is connected with a spring , the spring is connected with the limit pin; the drilling blade is mounted on the blade platform through a compression screw; a groove is provided in the longitudinal direction of the chamfering blade, and the lower end side wall of the groove is a first inclined plane The chamfering insert has a front chamfering edge and a reverse chamfering edge on the cutting surface. The chamfering insert is installed in the horizontal hole of the insert, and the limit pin is inserted into the groove to lock the chamfering insert. Lock and limit. The beneficial effects of the invention are: convenient processing, double-sided chamfering processing, high processing efficiency and good processing quality.

Owner:四川天虎工具有限责任公司

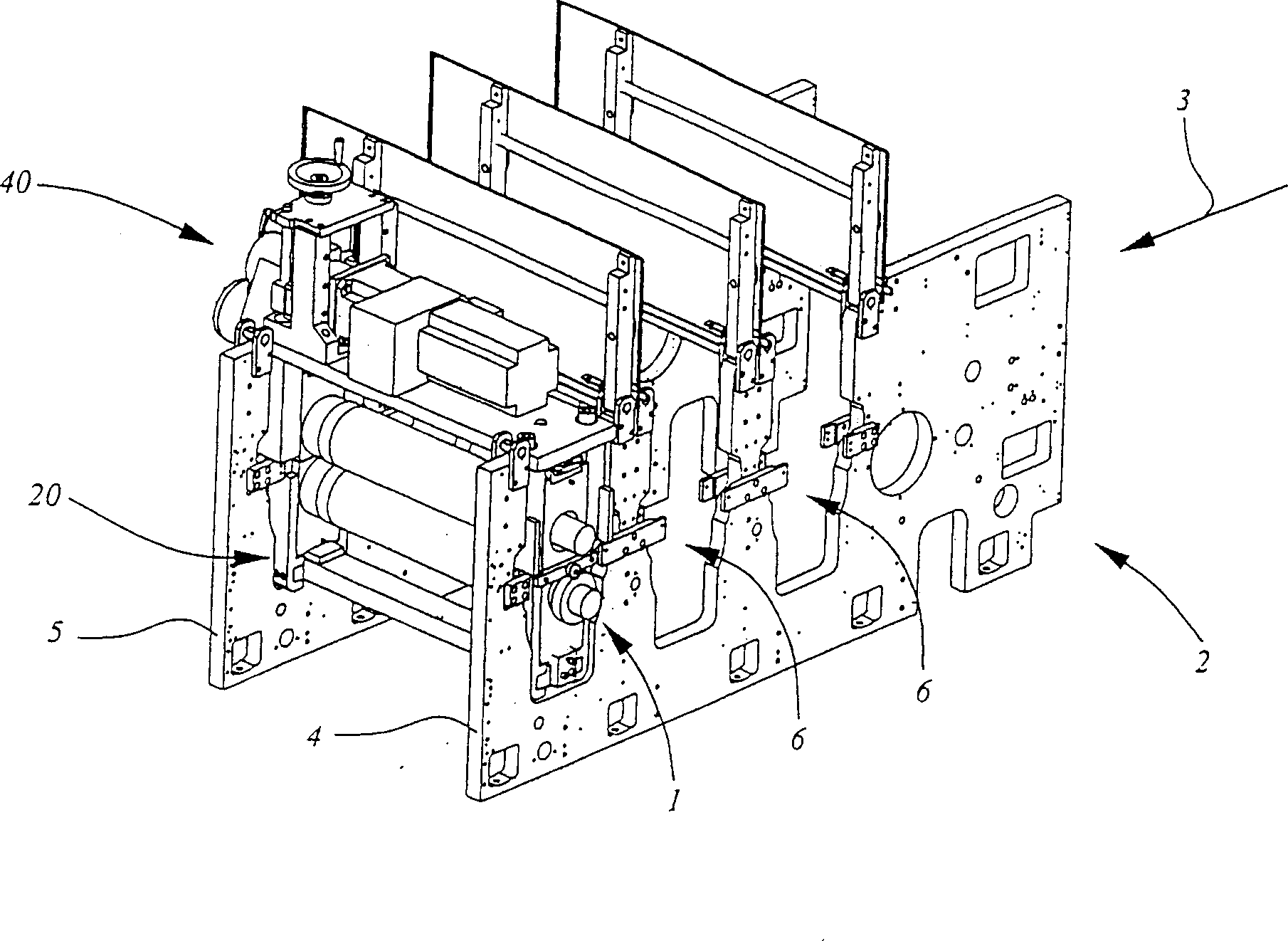

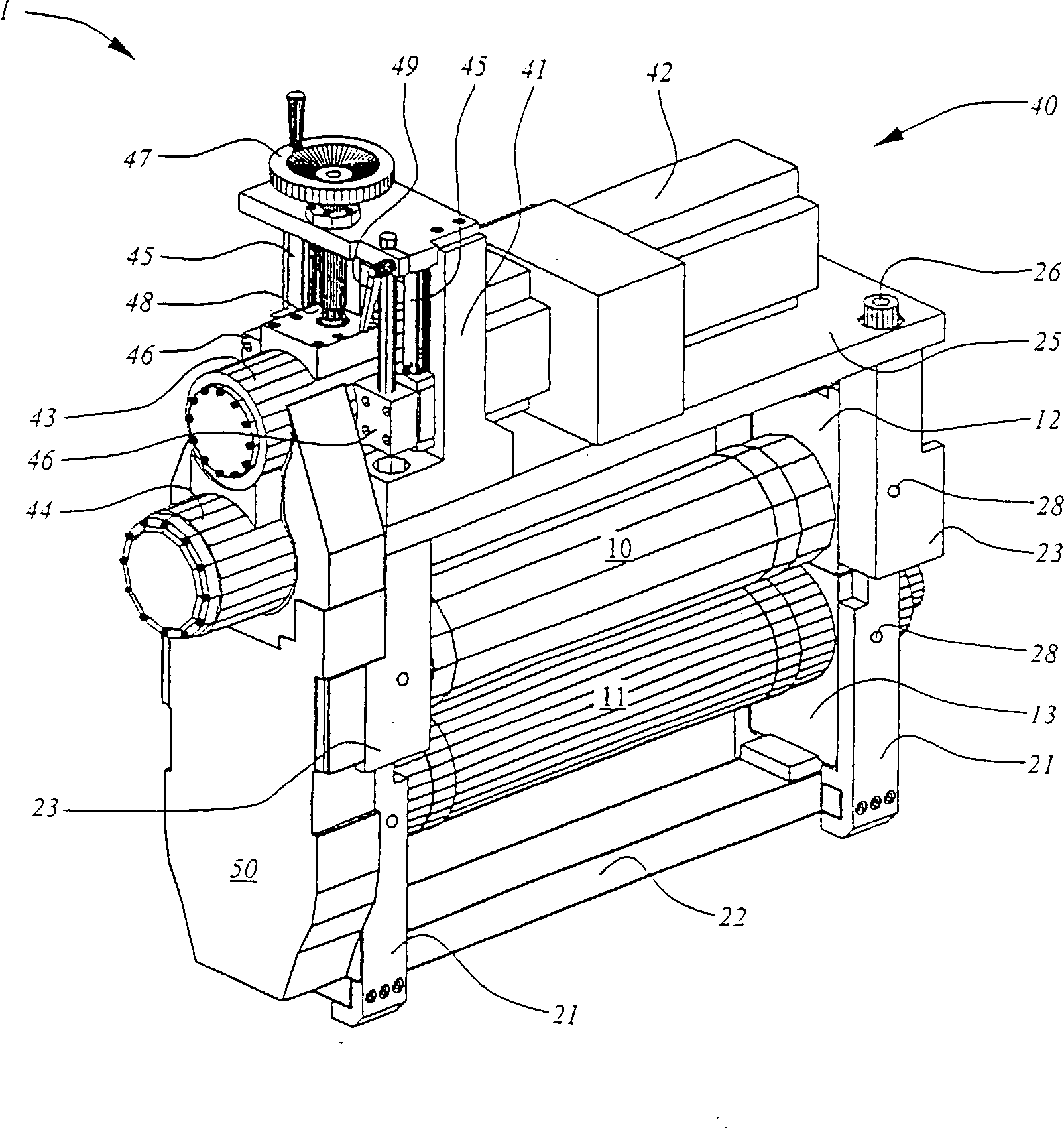

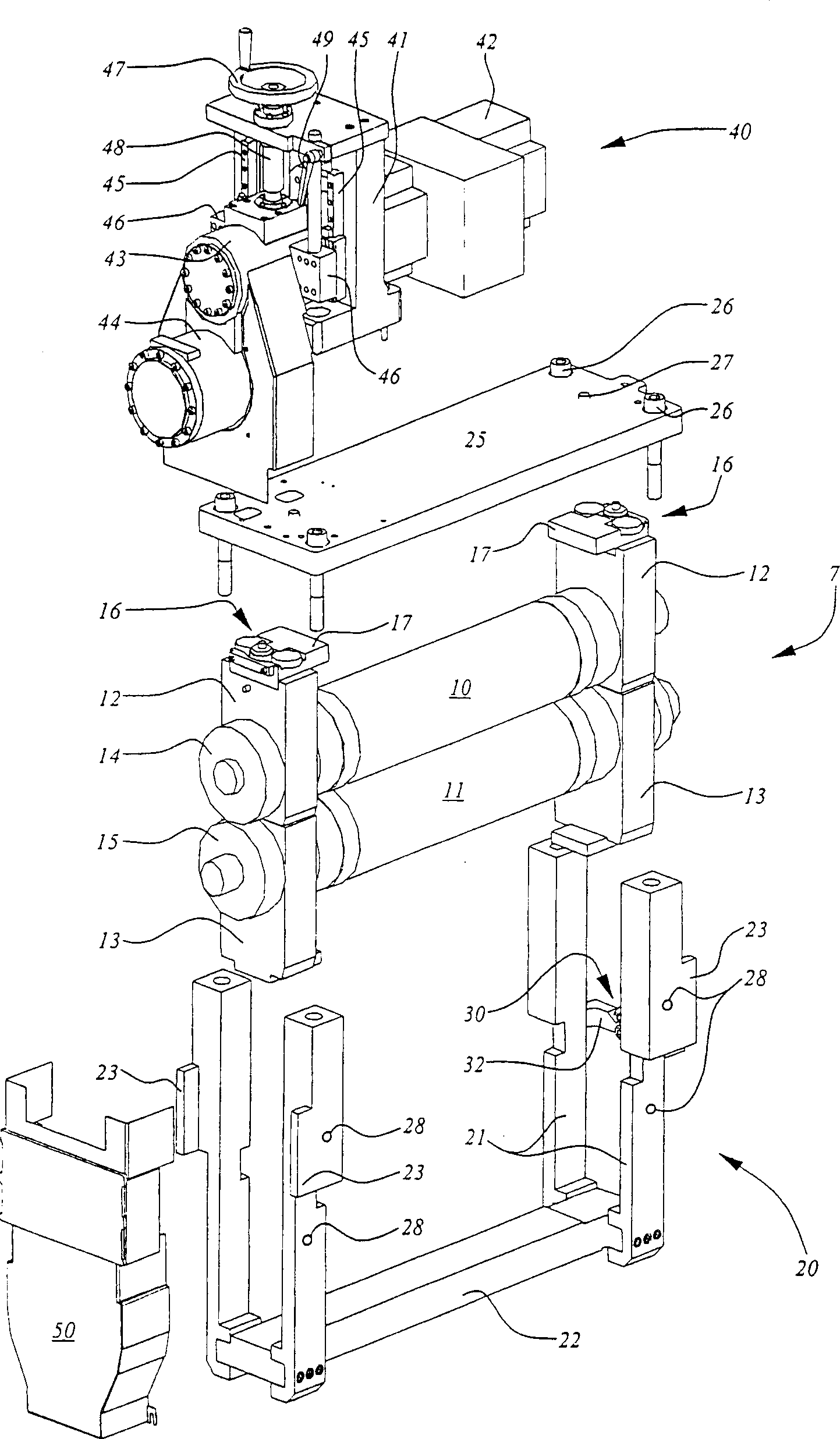

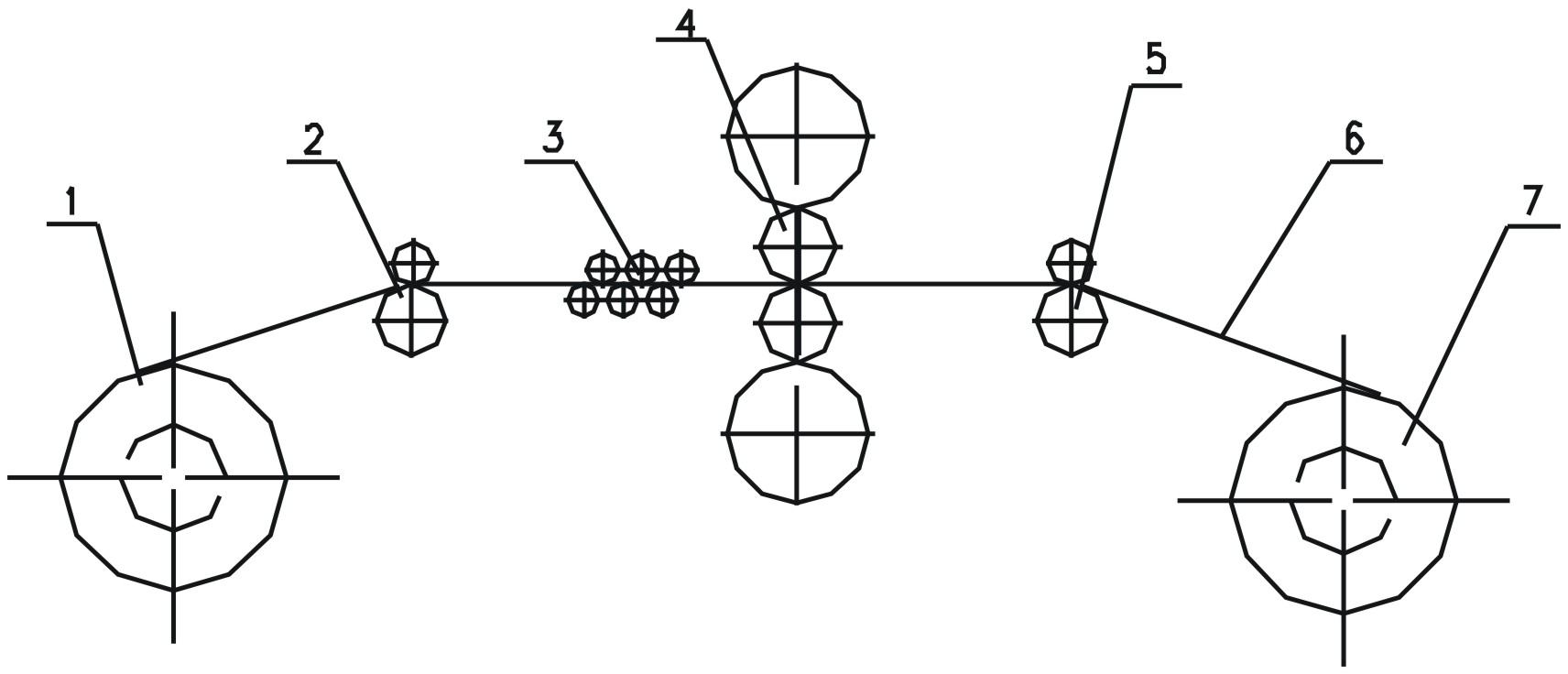

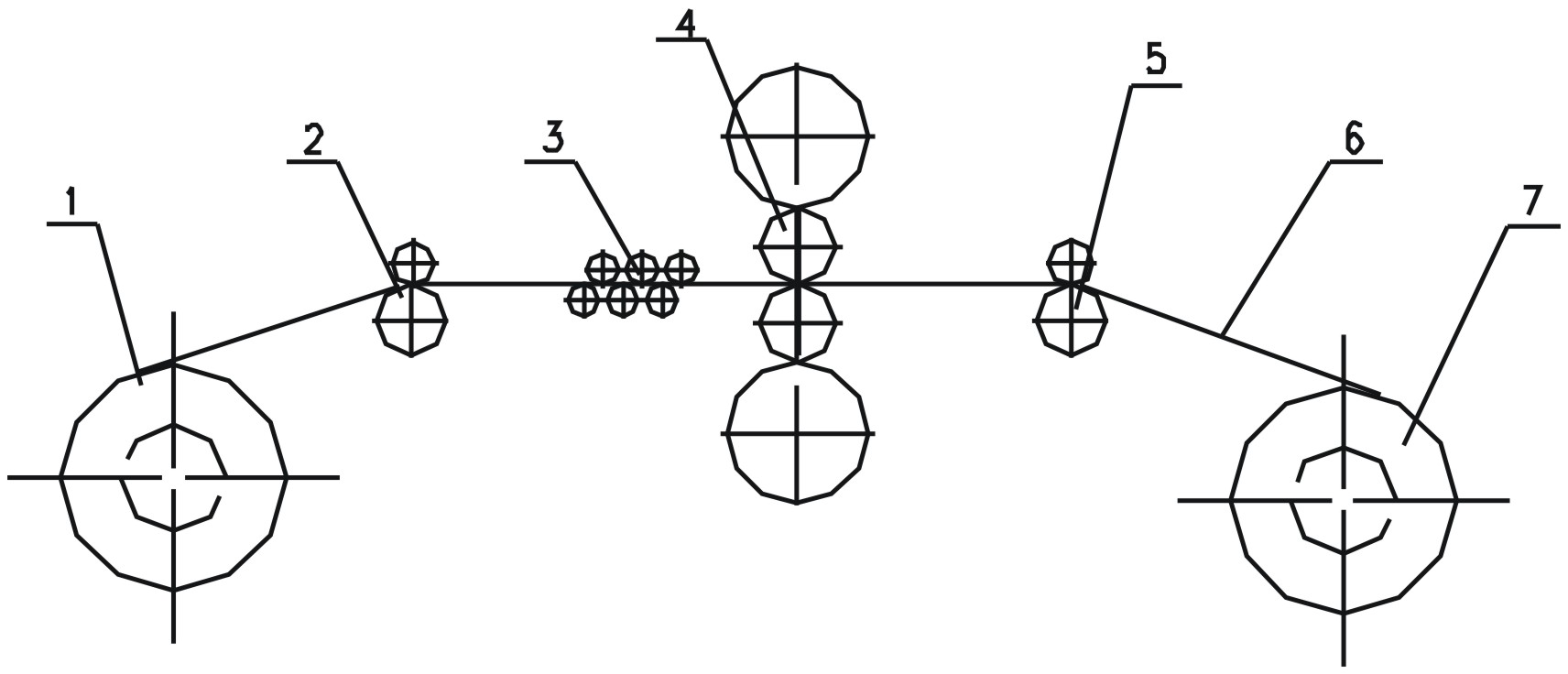

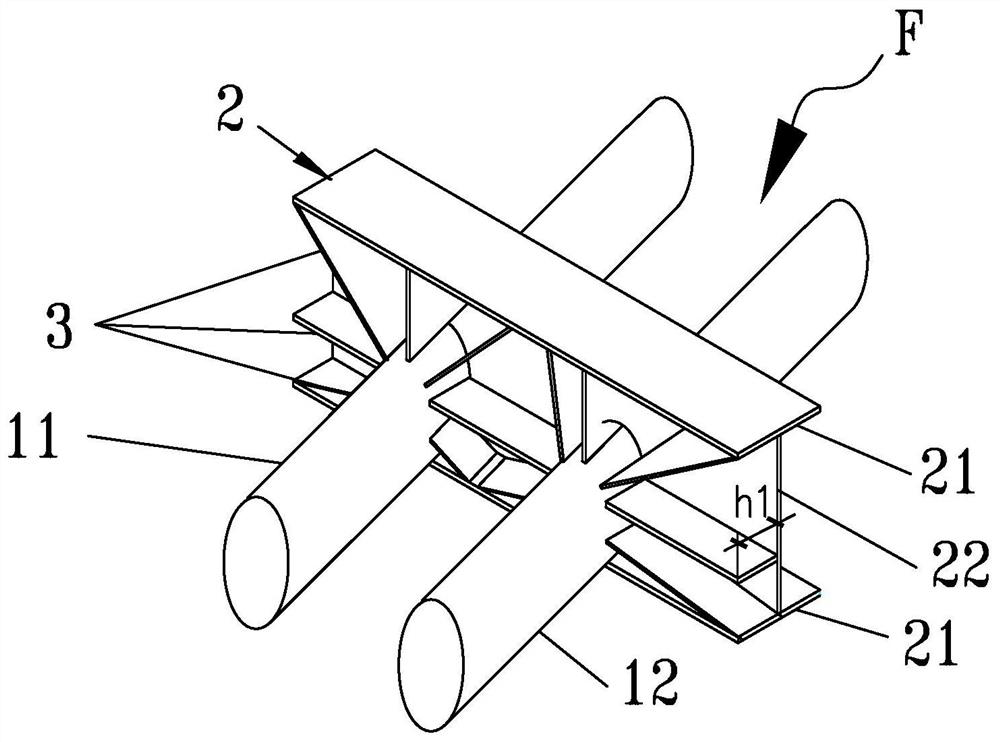

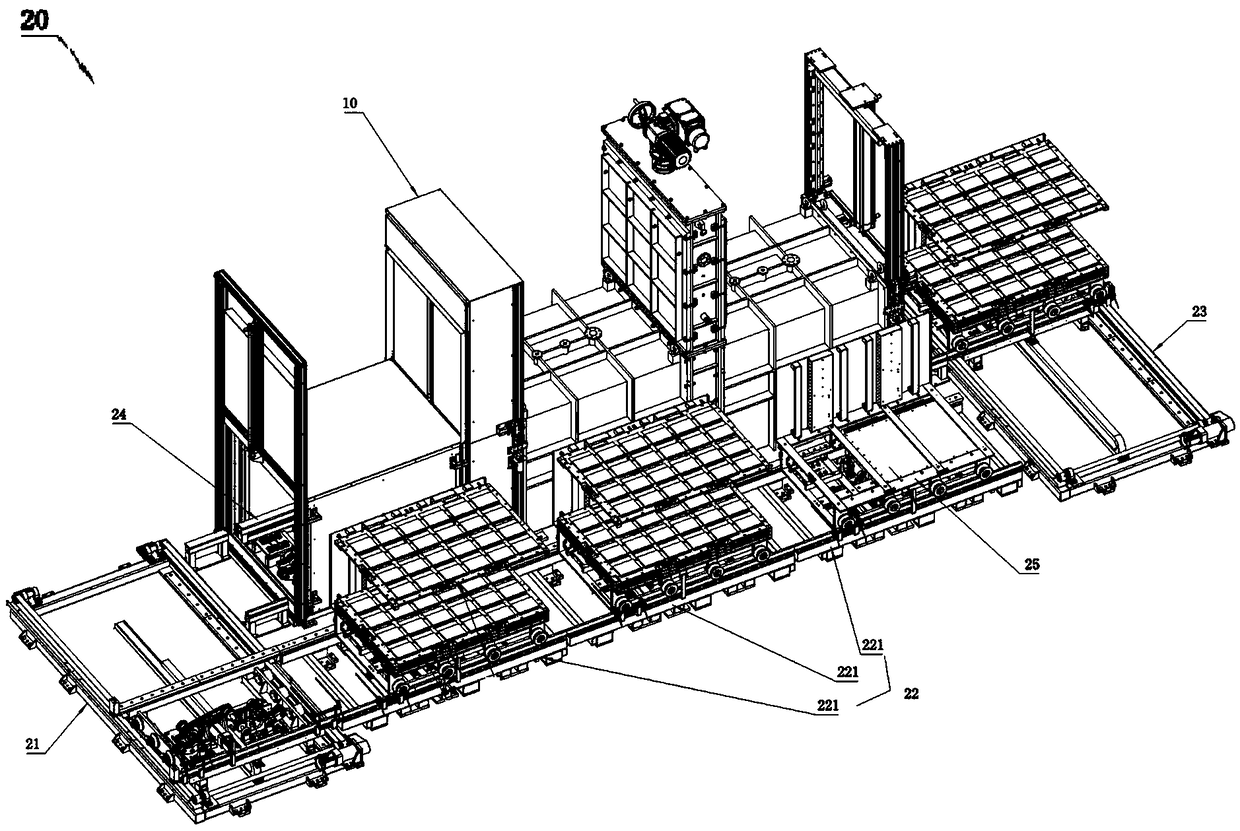

Device for rotary working into coil or piece material

InactiveCN1433945AFair useShorten the timeBox making operationsPaper-makingEngineeringElectric motor

The device for rotary converting a web or sheet matter equips a processing station arranged in a machine (2) particularly producing packagings by means of cylindrical tools (10, 11). These tools are arranged in a cassette (7) and rotated by a driving device (40) equipped with a motor (42). The cassette (7), coming from an extrinsic equipment to that which normally equips the machine (2), is placed in another so-called adaptive cassette (20), which is removable and secured to the driving device (40). The latter is arranged on the adaptive cassette (20).

Owner:BOBST SA

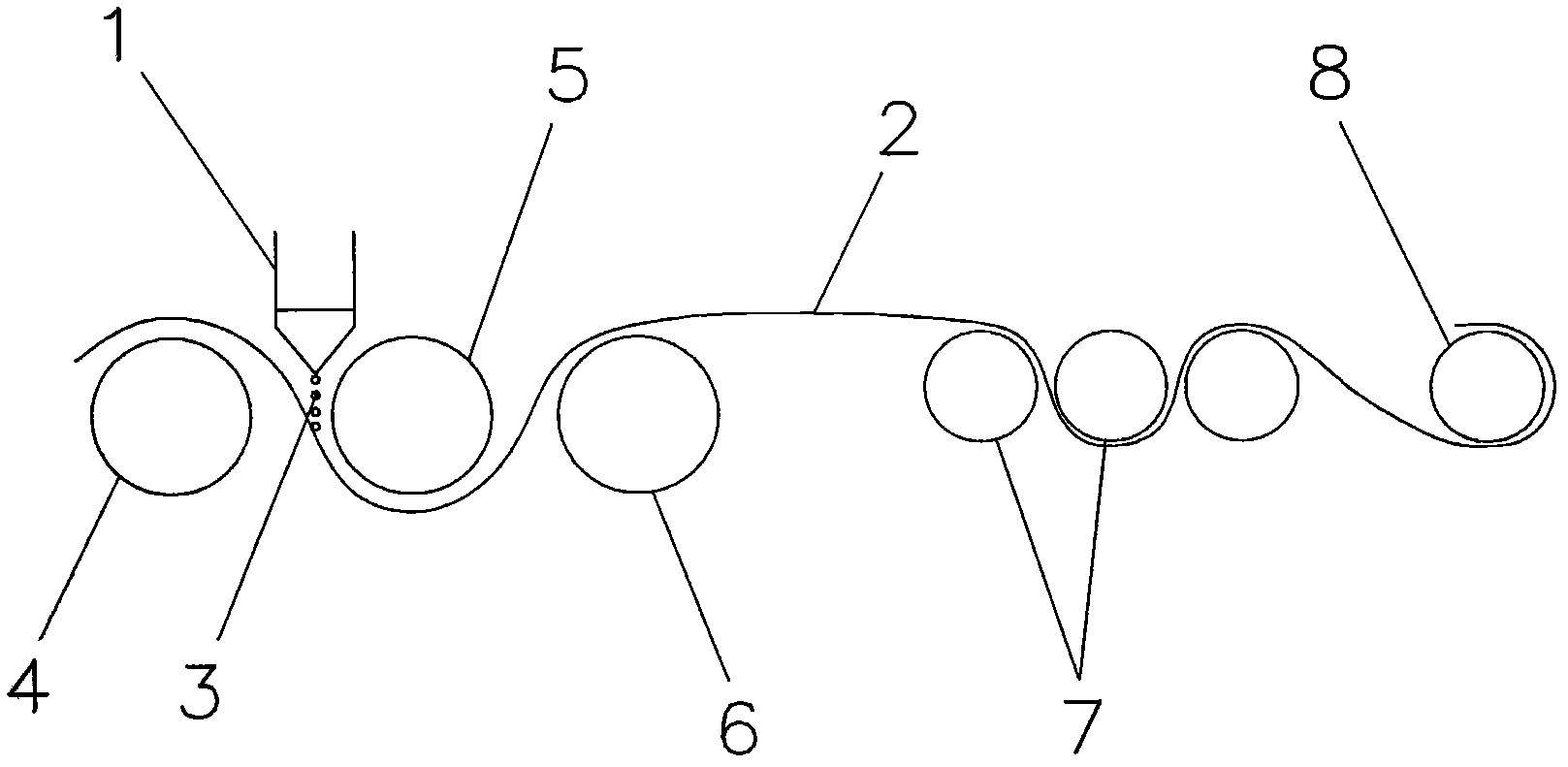

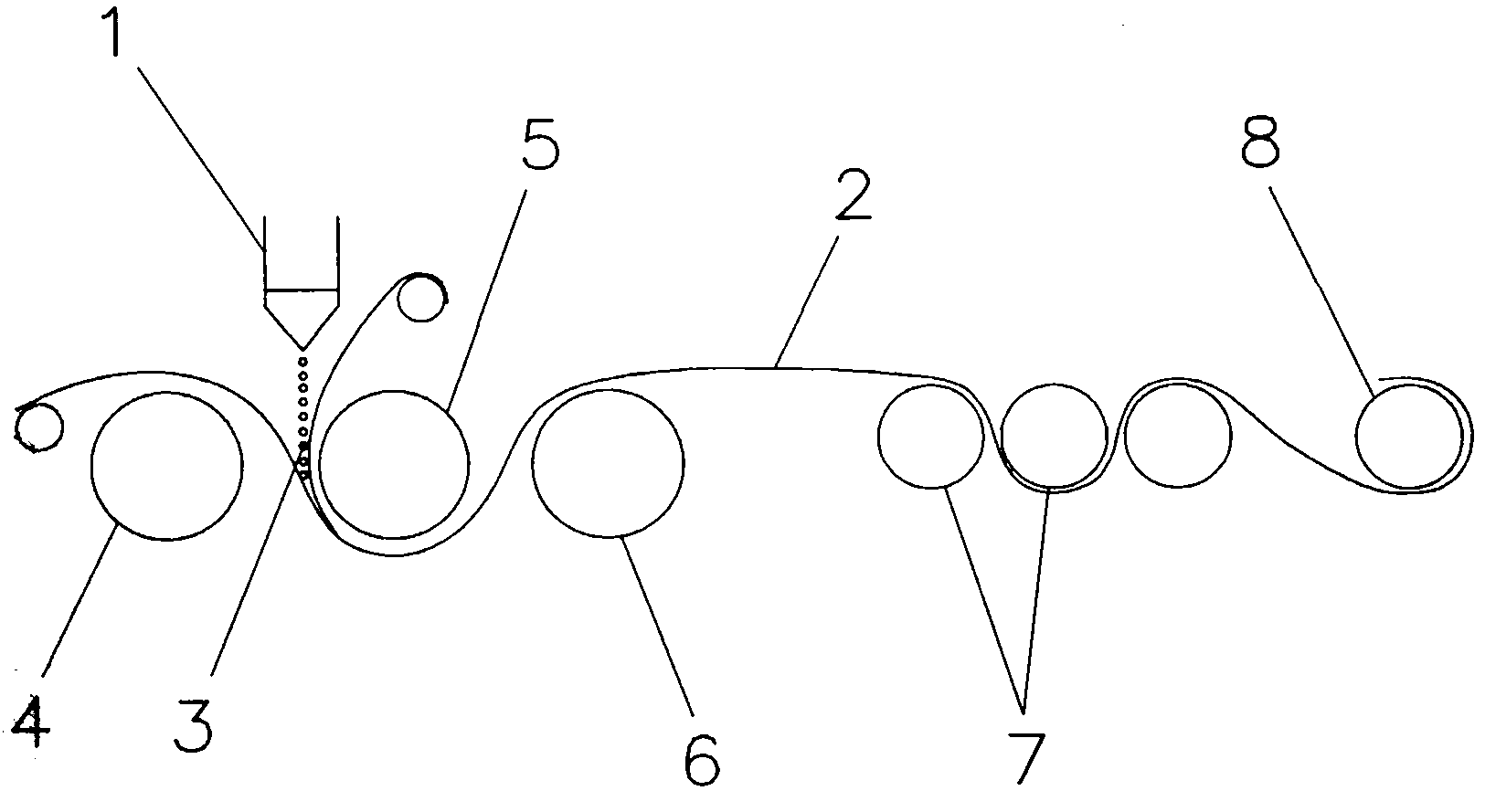

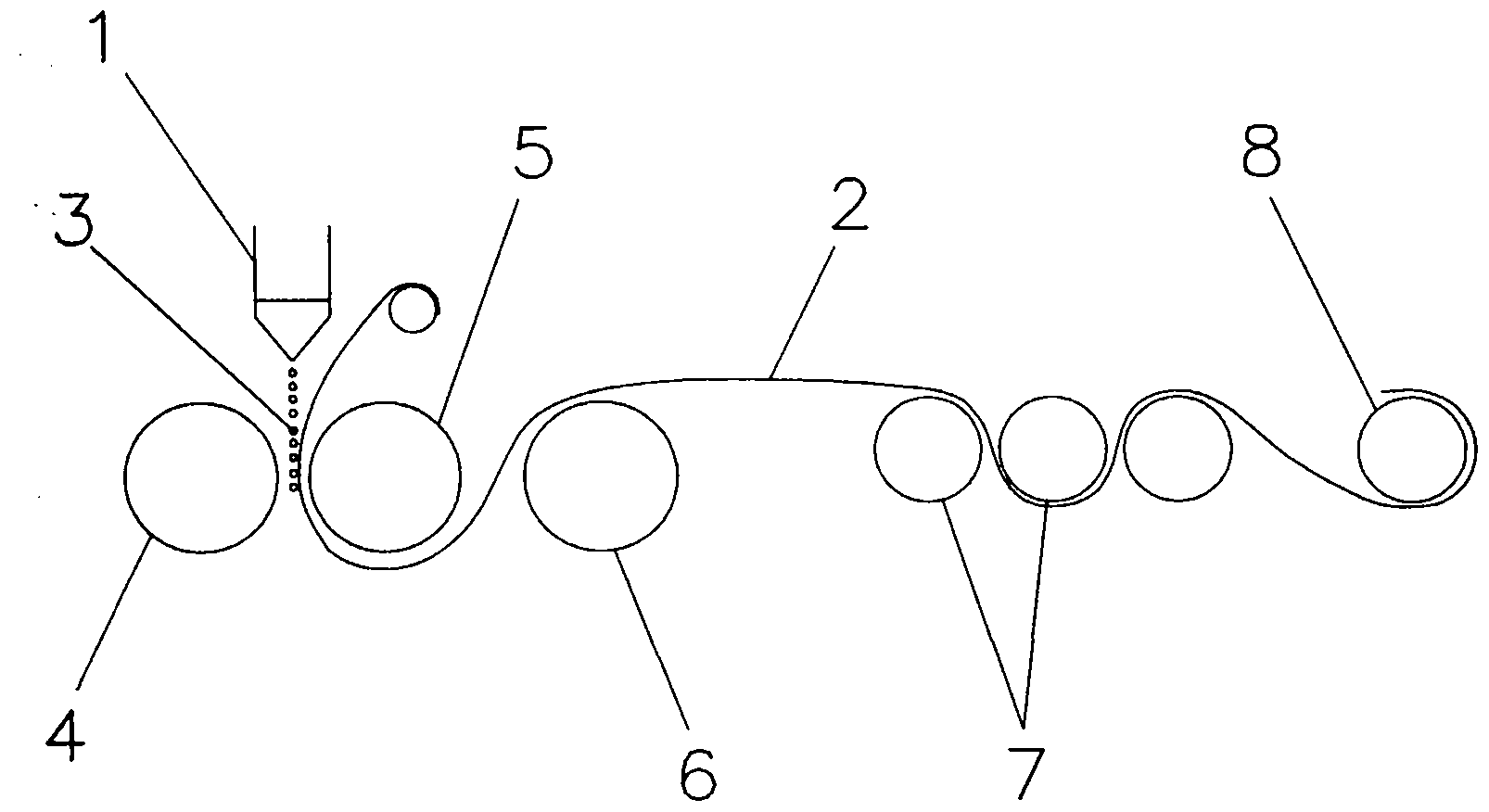

Production technology of non-sewn hot-melt adhesive film

InactiveCN102423917APerformance quality impactGuaranteed performance qualityFlat articlesThermoplastic polyurethaneEngineering

The invention relates to the technical field of a production technology of a hot-melt adhesive and particularly relates to a production technology of a non-sewn hot-melt adhesive film. The production technology mainly comprises the following steps: enabling TPU (thermoplastic polyurethane) hot-melt adhesive raw material particles to enter into an extruding machine from a hopper and be processed into an adhesive material, sending the adhesive material into a die head of an extruding machine via a screw rod, enabling the adhesive material to be attached on attaching paper on an embossed wheel after being extruded by the die head, and enabling a rubber roller to move forward and tightly press the embossed wheel; and enabling the adhesive material and the attaching paper to pass through the embossed wheel, then forming a hot-melt adhesive film sheet, pulling out the hot-melt adhesive film sheet via a forming wheel, enabling the hot-melt adhesive film sheet to pass through a traction wheel, then winding via a winding wheel, and finally producing the coiled non-sewn hot-melt adhesive film. As for the production technology of the non-sewn hot-melt adhesive film, bonding can be avoided during winding, a cooling facility does not need to be increased, the cost is lower, and the performances and the quality of the adhesive material are higher; furthermore, a product is smooth and aesthetic.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

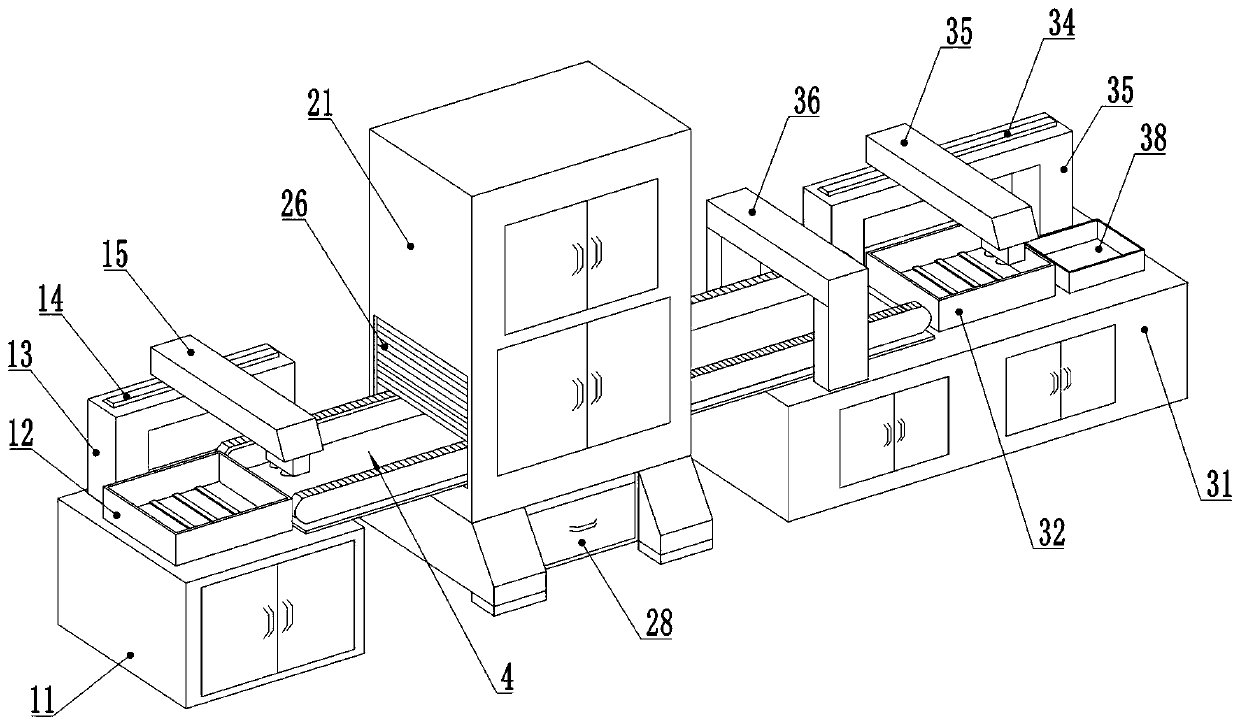

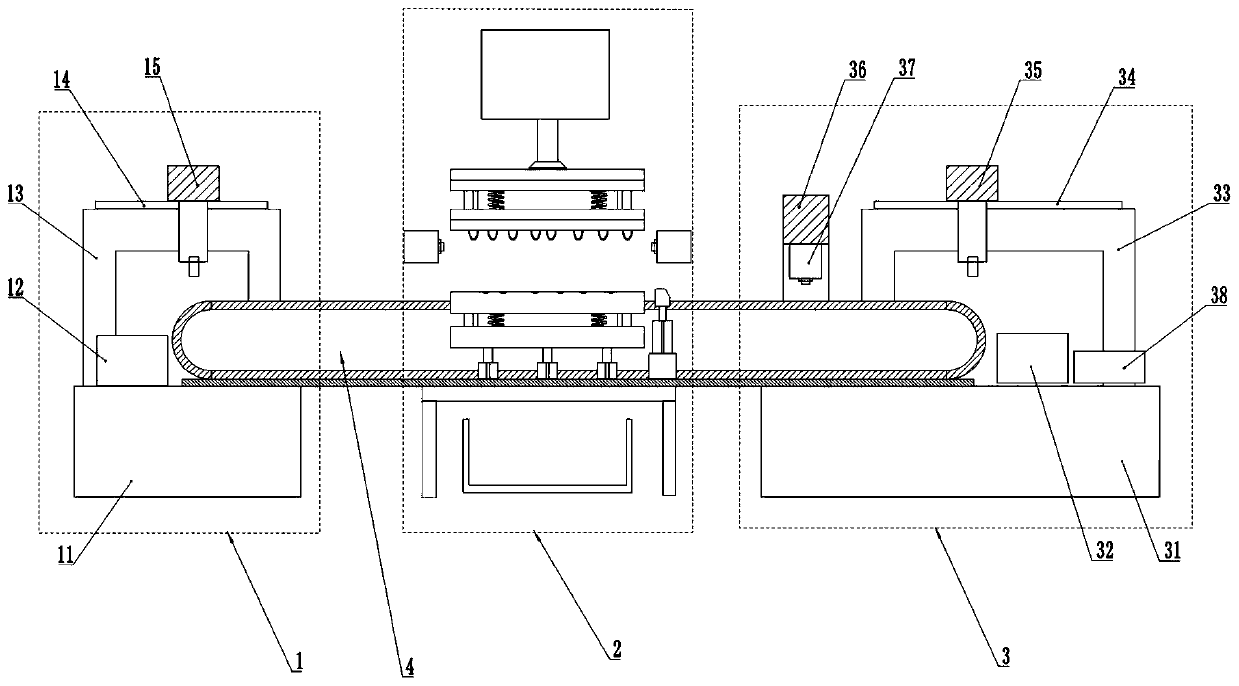

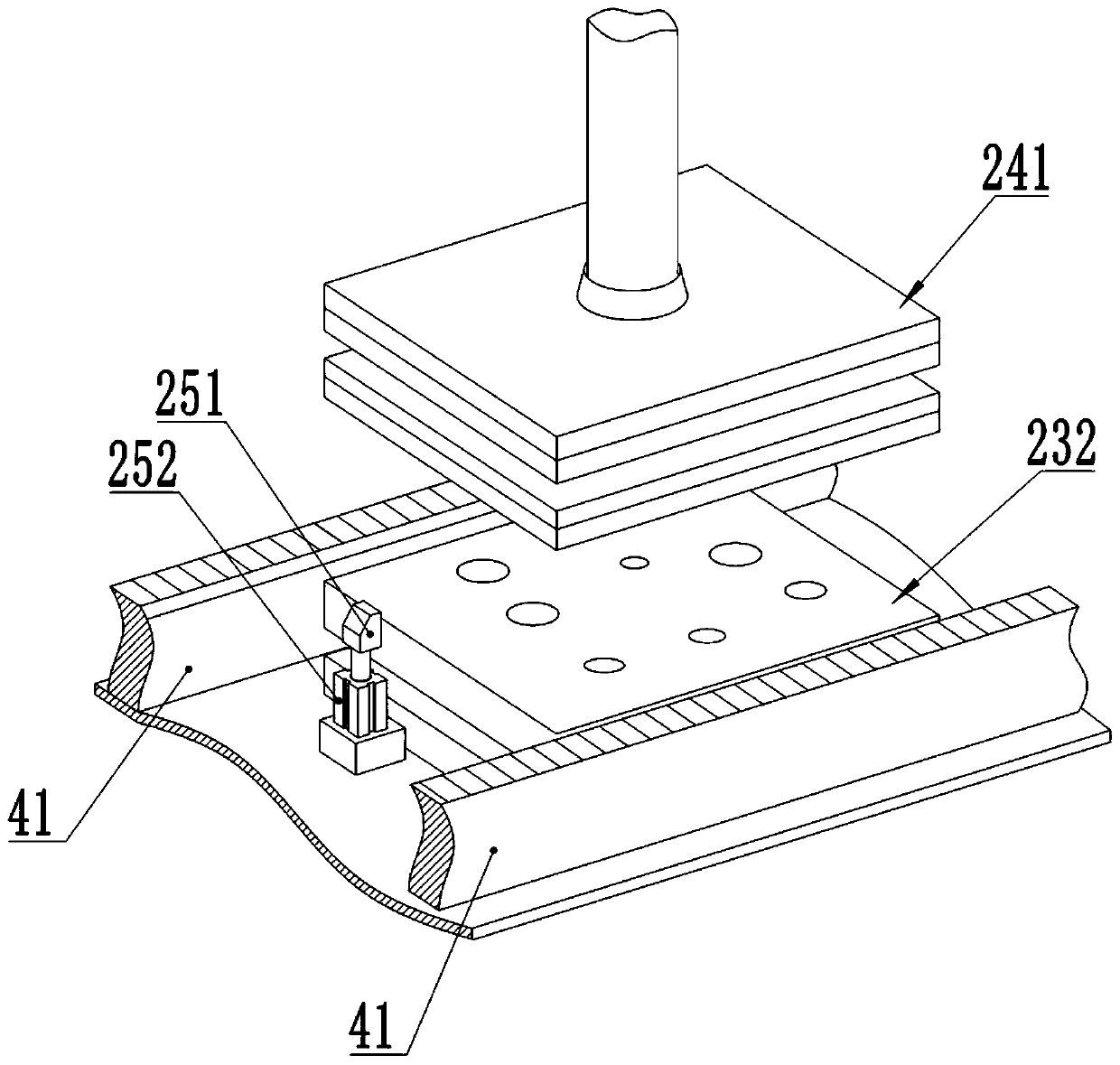

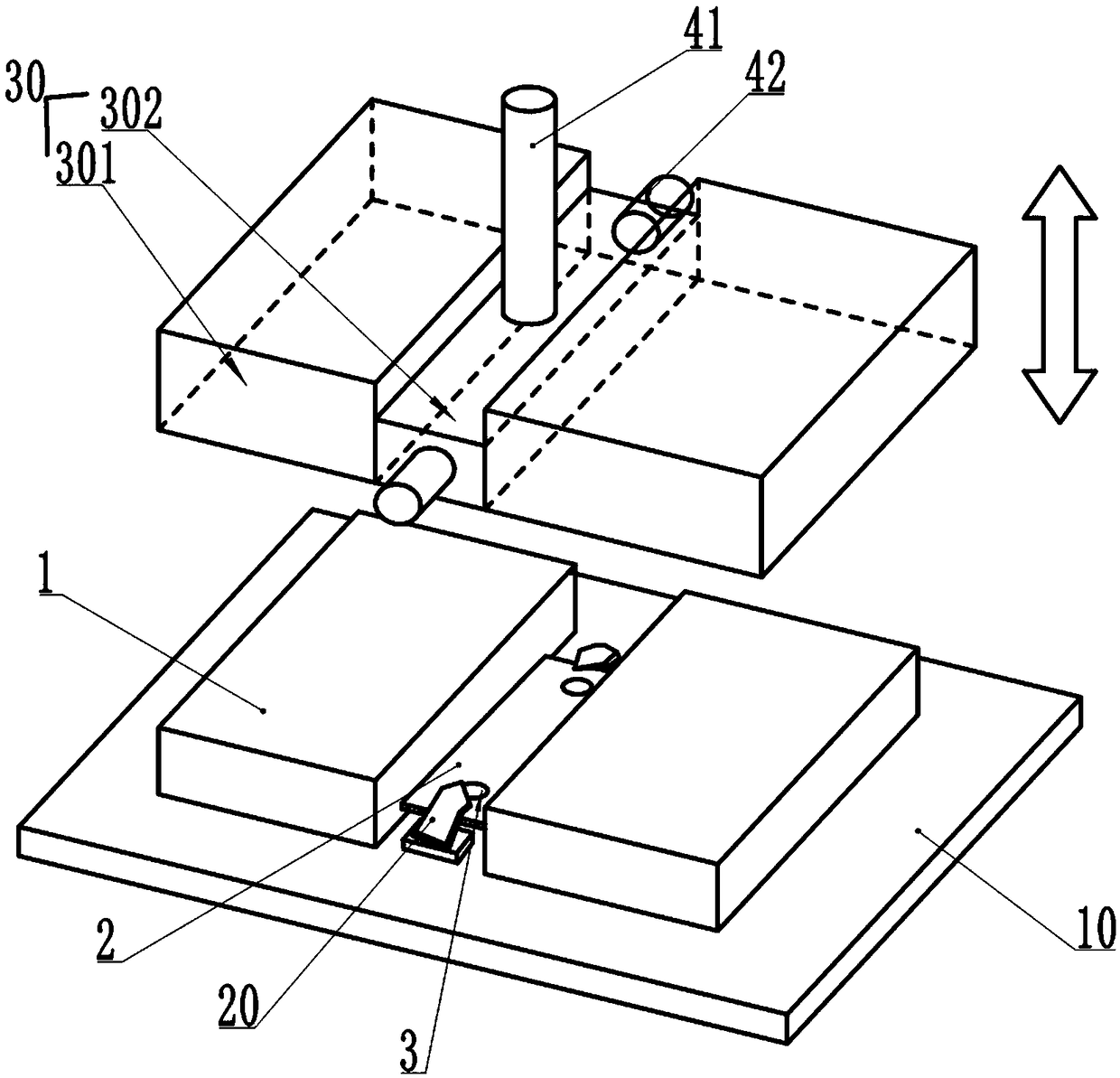

Precise punch

InactiveCN110125223AGuaranteed performance qualityEnsure safetyMetal-working feeding devicesStripping-off devicesPunch pressEngineering

The invention discloses a precise punch which comprises a feeding device, a punching device and a discharging device. The feeding device is connected with a material sending device, and one end of thematerial sending device penetrates the punching device and is connected to the discharging device. One end of the feeding device is connected to a feeding worktable, and a feeding mechanical arm canbe used for transferring a machined workpiece in a workpiece containing disc to the material sending device. The material sending device penetrates a shell and can be used for conveying the machined workpiece to a punching lower die. The end, away from the feeding device, of the material sending device is connected to a discharging worktable, and a discharging mechanical arm can be used for transferring a punched workpiece on the device into the workpiece containing disc. By means of the precise punch, the mechanical arms are used for automatic feeding and discharging, traditional manual workis replaced, the whole process of punching operation of the punching device is automatically executed, manual intervention is not needed, the production efficiency is effectively improved, and the performance quality of the punched workpiece is effectively ensured; and in addition, the punching operation is completed in a relatively independent space, workers can be prevented from making mistakesto stretch hands into the device, and safety during punching is effectively ensured.

Owner:广东虹瑞智能设备股份有限公司

Elongation rate distribution method for high-strength steel straightening and leveling unit

ActiveCN102626717AControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceStructural engineeringUltimate tensile strength

The invention relates to an elongation rate distribution method for a high-strength steel straightening and leveling unit. The method is characterized by comprising the following steps of: controlling the total elongation rate of high-strength steel at a process section of the straightening and leveling unit according to the product deformation characteristic in a hot-rolling processing process and the processing characteristics and control stability of the straightening machine and the leveling machine; proportionally distributing a total elongation rate set value to the straightening machine and the leveling machine for presetting straightening and leveling processes; fully lowering the residual stress level of hot-rolled high-strength steel under the reciprocating bending action of the straightening machine; and effectively controlling the final performance of the high-strength steel by using the real-time dynamic adjusting capability of the leveling machine. According to the method, the internal residual stress level of band steel after hot rolling can be lowered fully, the yield strength of the hot-rolled high-strength steel is controlled effectively, and the performance quality of a product is ensured.

Owner:WISDRI ENG & RES INC LTD

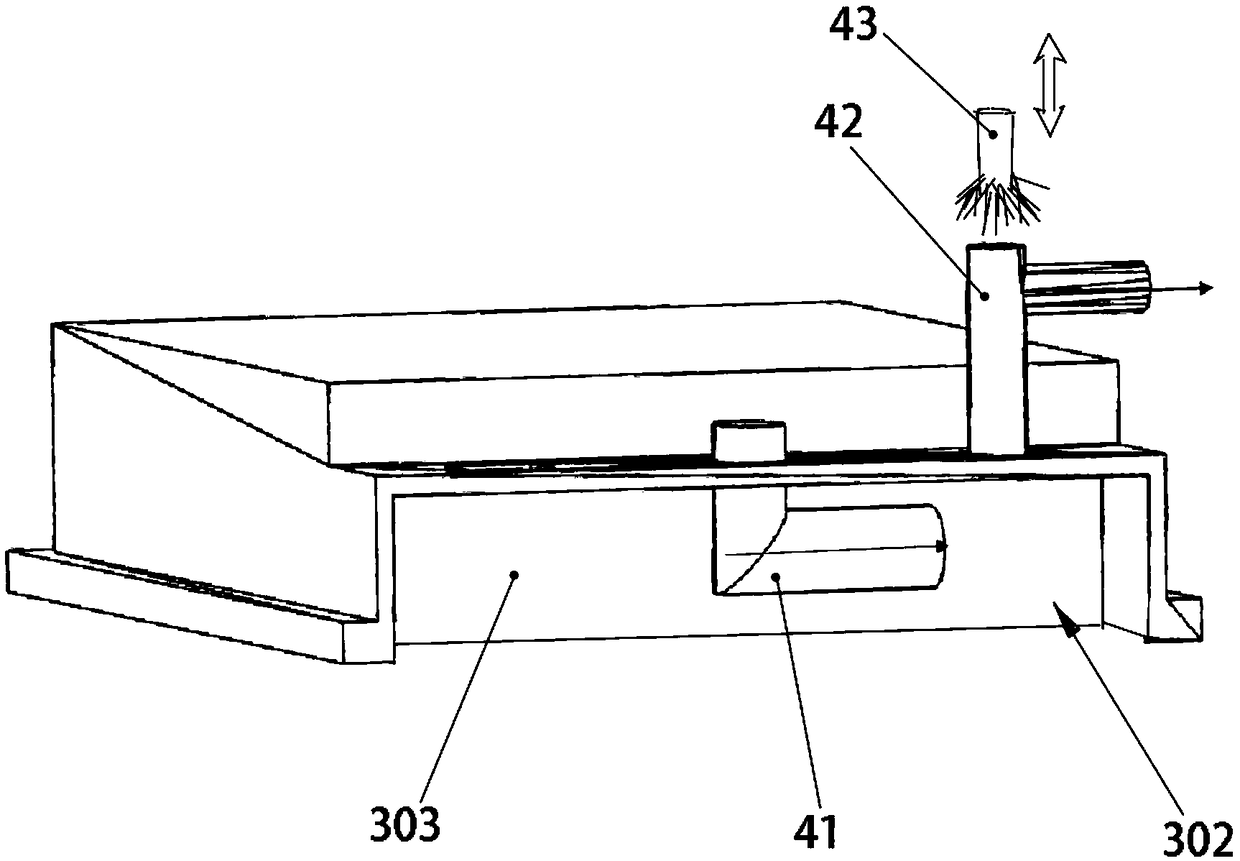

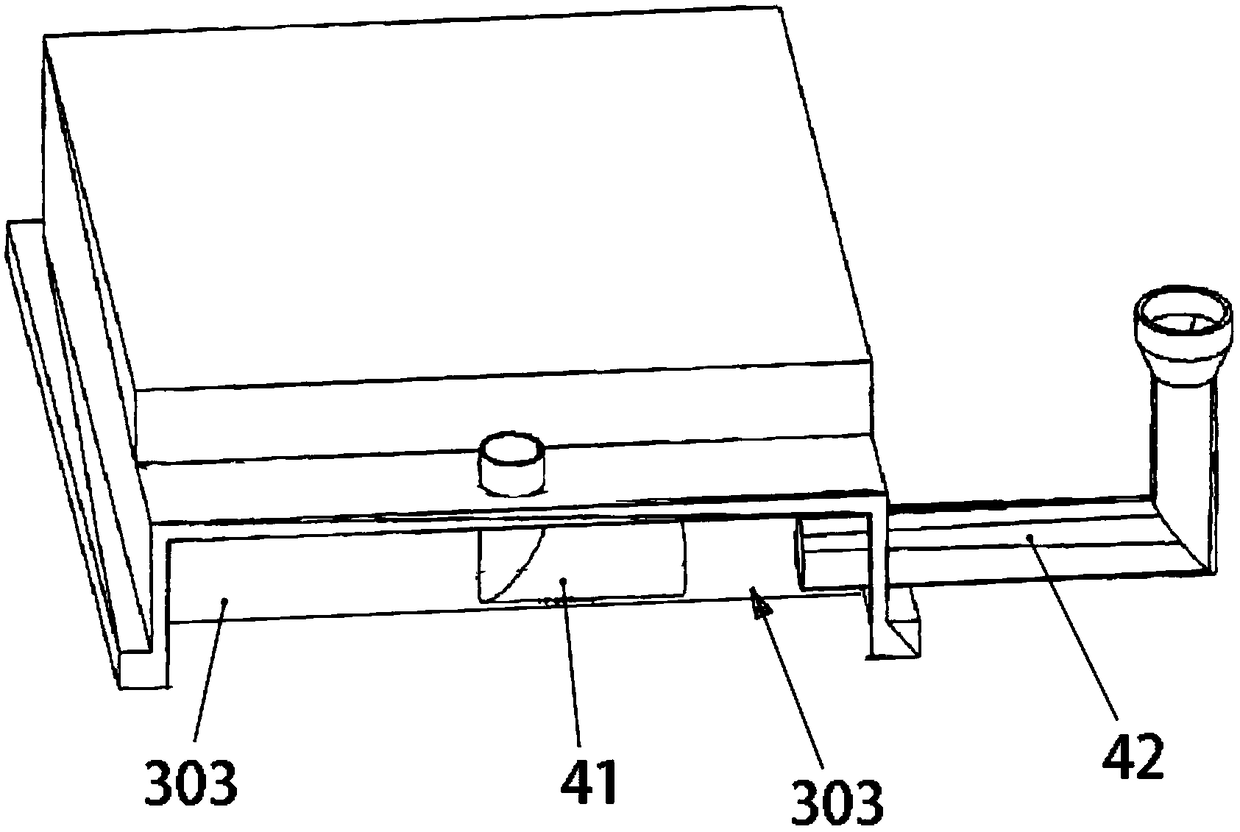

Battery cell connecting piece welding mechanism and welding method thereof

PendingCN109483055AReduce adverse effectsGuaranteed performance qualityLi-accumulatorsCell component detailsVacuum pumpingSlag

The invention discloses a battery cell connecting piece welding mechanism. The welding mechanism comprises a welding table, a laser welding assembly and a dust removal cover; the dust removal cover comprises a battery cell accommodating chamber and a welding chamber; an air inlet hole and an air suction hole are formed in the welding chamber, the air inlet hole is provided with an air blowing pipecommunicating with the welding chamber, and the air suction hole is provided with an air suction pipe communicating with the welding chamber. The mechanism is provided with the dust removal cover, and the welding chamber of the dust removal cover is in communication with a protective gas conveying device and a vacuum generating device through the air blowing pipe and the air suction pipe respectively; when the laser welding assembly is used for carrying out laser welding on a connecting piece of a battery cell and a pole column of a top cover, the protective gas conveying device introduces protective gas into the welding chamber at the same time, the vacuum generating device is used for sucking metal spatters produced by welding and welding slag formed by the metal spatters from the welding chamber in a negative pressure vacuum pumping mode, so that the purpose of eliminating the welding slag is achieved, adverse effects on the battery cell caused by the welding slag are avoided, andtherefore the safety of a battery is improved while the performance quality of the battery is guaranteed.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Control method for high-strength steel straightening and leveling unit

ActiveCN102626718AControl yield strengthReduce residual stress levelsMetal rolling arrangementsElongation control deviceStructural engineeringUltimate tensile strength

The invention relates to a control method for a high-strength steel straightening and leveling unit. The unit mainly comprises a straightening machine and a leveling machine. The method is characterized by comprising the following steps of: dynamically controlling the total elongation rate of high-strength steel at a process section of the straightening and leveling unit; fully lowering the residual stress level of hot-rolled high-strength steel under the reciprocating bending action of the straightening machine; and effectively controlling the yield strength of the hot-rolled high-strength steel by using the real-time dynamic adjusting capability of the leveling machine, and lowering the residual stress level of the high-strength steel by using the straightening machine. According to the method, the performance quality of a high-strength steel product on the tail of the process section is ensured.

Owner:WISDRI ENG & RES INC LTD

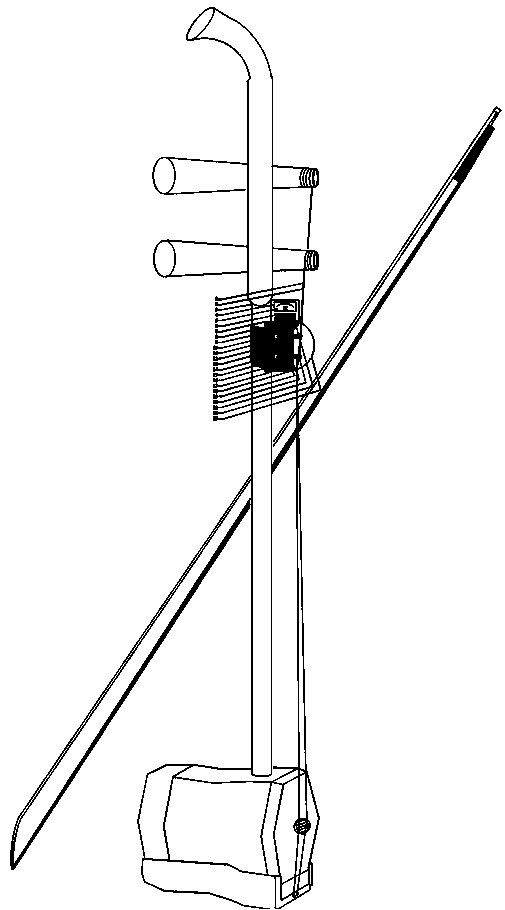

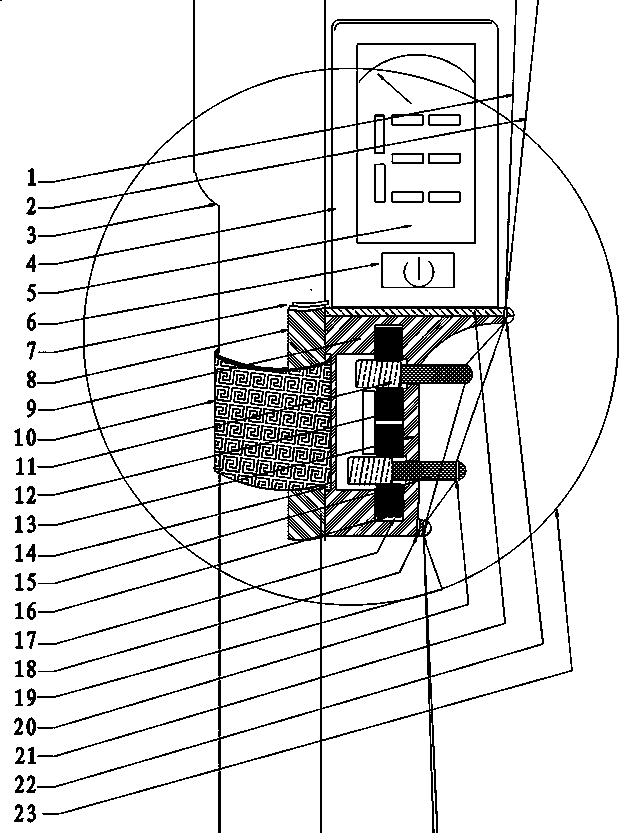

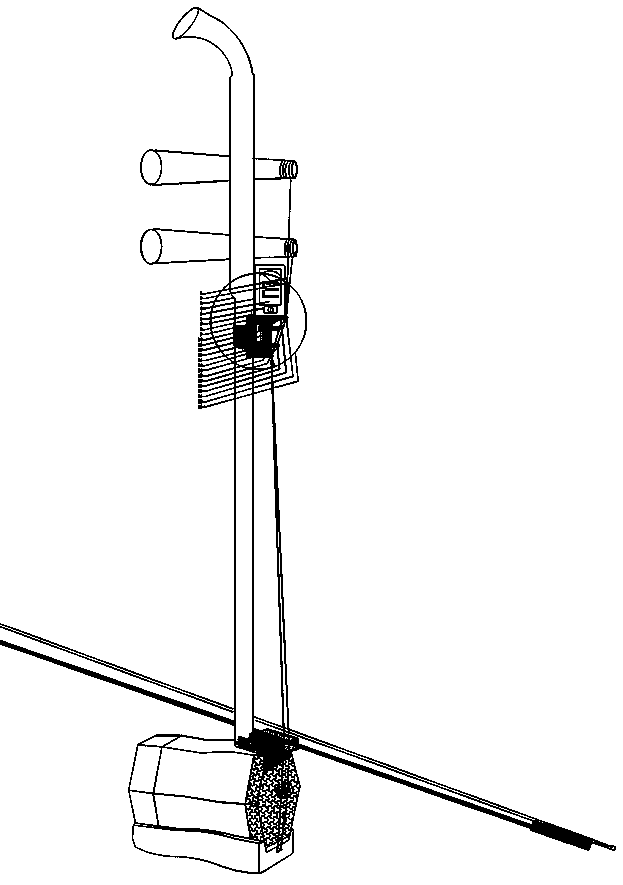

Combined-type erhu tuning nut

The invention belongs to the production field of musical instruments, and particularly relates to a combined-type erhu tuning nut. Erhu is an attractive stringed national instrument and not only can express the deep and miserable scene, but also can paint a state of magnificent momentum, the tone of erhu is close to the human voice and high in emotional rendering force. Since the structure of erhu is simple, and the production method is relatively extensive, inconvenience can be brought to the playing, and a series of problems occur on the aspects such as shifting of the nut, replacement of the tone, intonation calibration, out of tune and the like when a melody of different pitches is played. The intonation calibration of erhu is critical for the playing effect. The combined-type erhu tuning nut integrates a function for limiting the oscillation string length and calibrating the tonality, and the tonality of erhu can be conveniently fixed. By adopting a double-sided adhesive band, the tuning nut is fixed by the double-sided adhesive band in a tying manner, so that the nut is simple and convenient to move; the tuned erhu is deep in low pitch, clear and smooth in medium pitch and clear and cool in high pitch, so that the quality of the erhu - the national treasure can be greatly improved.

Owner:李万红

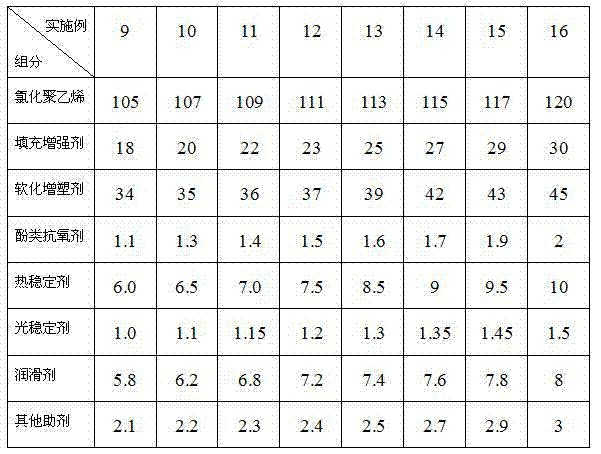

Novel wide-coverage waterproof coiled material substitutable for polyurea waterproof paint

The invention relates to a waterproof material, particularly a novel wide-coverage waterproof coiled material substitutable for polyurea waterproof paint and a preparation method thereof. The invention solves the problems of high construction and formularization cost and the like in the existing spray-coating polyurea waterproof paint. The wide-coverage waterproof coiled material substitutable for polyurea waterproof paint is prepared from chlorinated polyethylene, a filling reinforcer, a softening plasticizer, phenolic antioxidant, a thermal stabilizer, a light stabilizer and a lubricant. The preparation method comprises the following steps: mixing the raw materials, and stirring; granulating by sequentially treating the mixture with a plastic mixing mill, a compounding mill and a dicing machine; putting the granules into a single screw extruder, and forming in a die; and rolling by a tri-roller cooling calender to obtain the waterproof coiled material. The novel wide-coverage waterproof coiled material substitutable for polyurea waterproof paint has high softness, high percentage of elongation and high rebound elasticity in the rubber-type waterproof coiled material on the premise of maintaining high tensile strength in the plastic-type waterproof coiled material, and thus, exceeds the construction standard for spray-coating polyurea waterproof paint; and the novel wide-coverage waterproof coiled material substitutable for polyurea waterproof paint has the advantage of low production cost and has wide application prospects.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

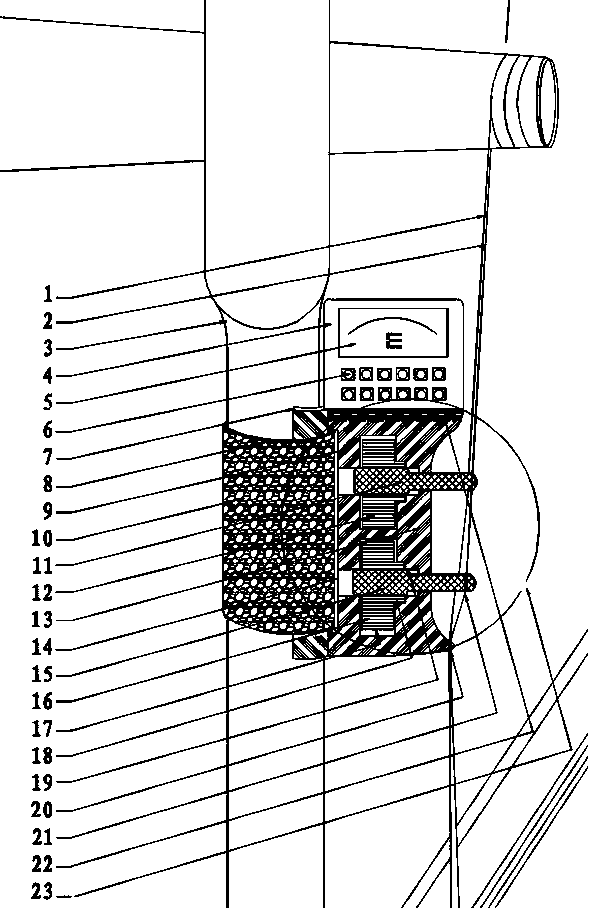

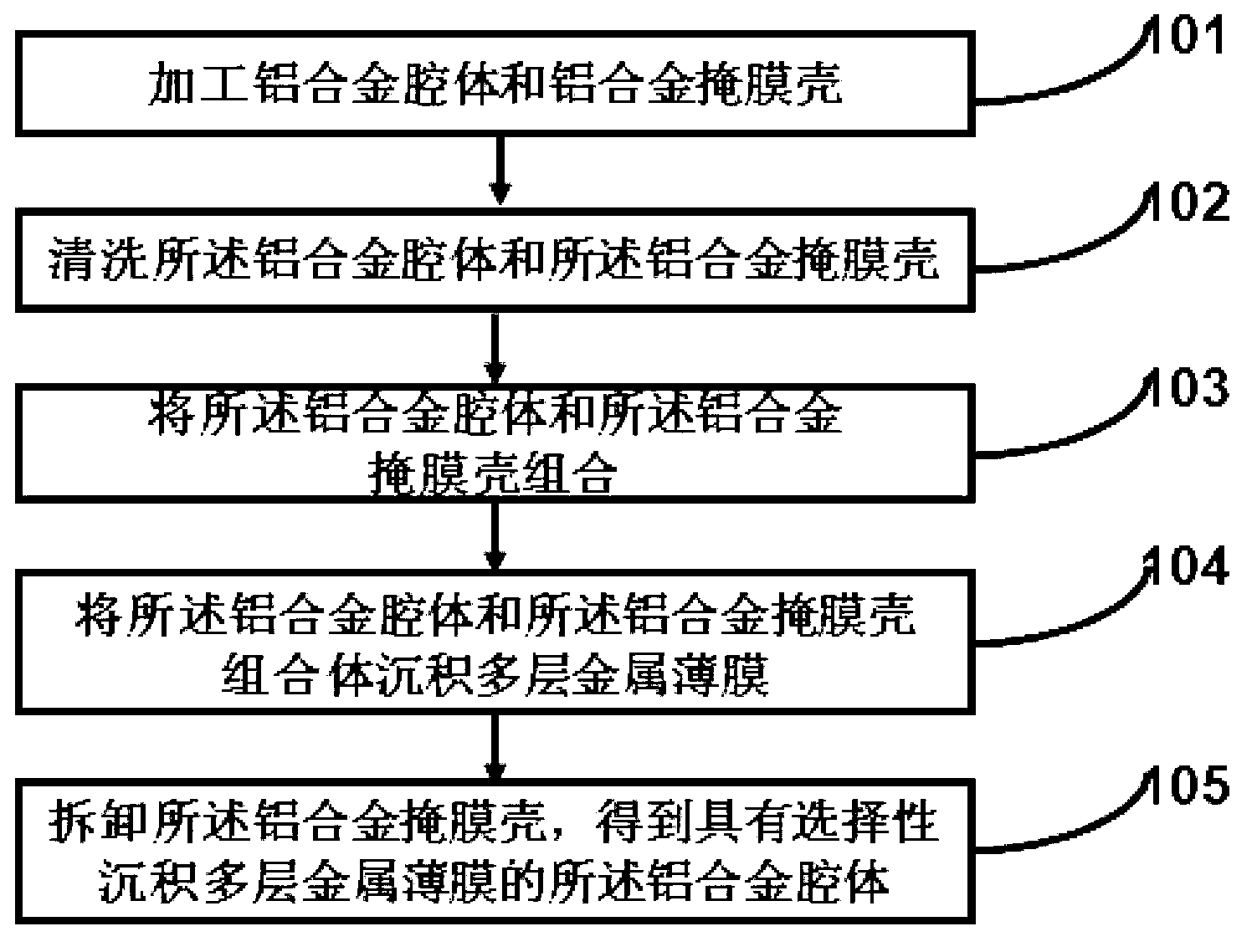

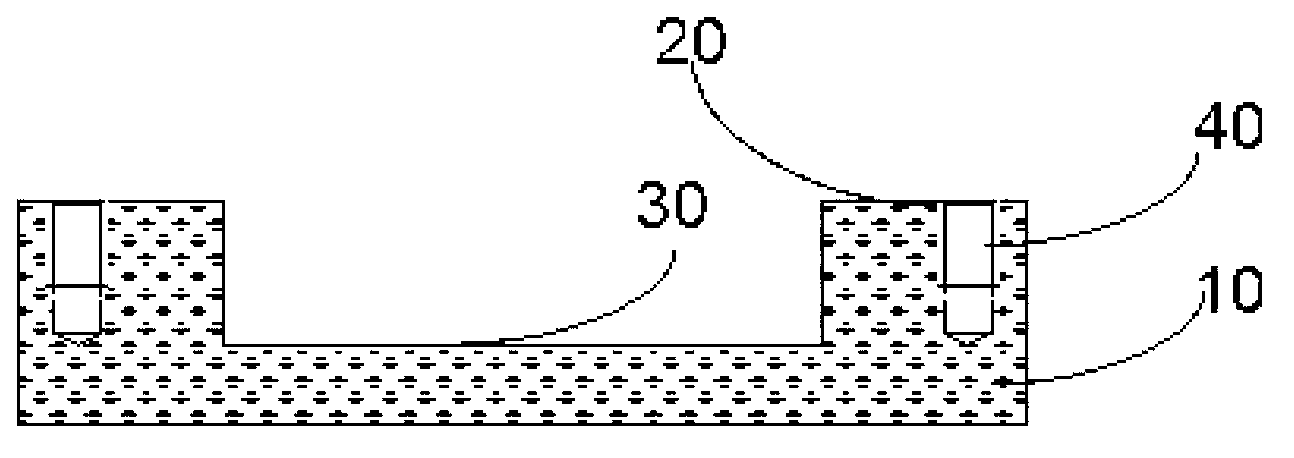

Method for preparing functional coating on surface of aluminum alloy selectively

InactiveCN103243295AGuaranteed performance qualityEnsure consistencyVacuum evaporation coatingSputtering coatingSelective depositionMetal

The invention discloses a method for preparing a functional coating on the surface of an aluminum alloy selectively. The method for preparing the functional coating on the surface of the aluminum alloy selectively comprises the following steps of: S1. machining an aluminum alloy cavity body and an aluminum alloy mask shell; S2. cleaning the aluminum cavity body and the aluminum alloy mask shell; S3. combining the aluminum alloy cavity body and the aluminum alloy mask shell; S4. depositing a plurality of layers of metal films on a combined body of the aluminum cavity body and the aluminum alloy mask shell; and S5. detaching the aluminum alloy mask shell, thereby obtaining the aluminum alloy cavity body for depositing the plurality of layers of metal films selectively. According to the invention, parts of the aluminum alloy cavity body, which are not required to be coated, are subjected to mask protection by adopting the aluminum alloy mask shell so as to achieve the aim of preparing the functional coating accurately and selectively.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

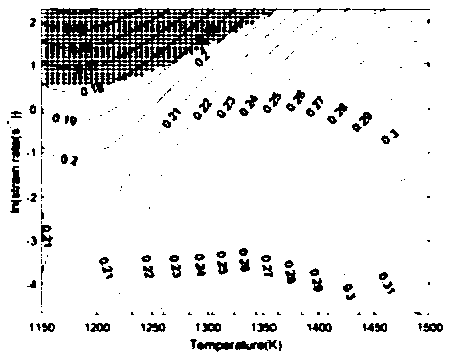

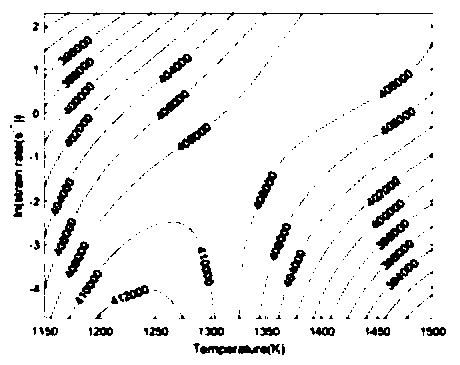

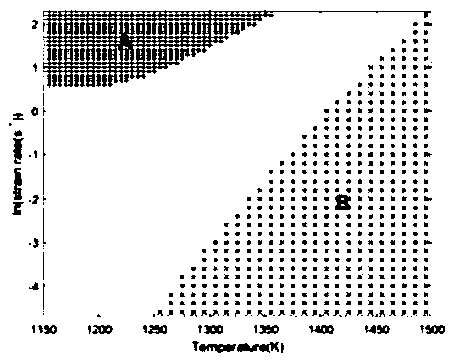

Method for determining thermoforming process parameters of boron-containing microalloyed steel

InactiveCN109856180AUniform dynamic recrystallization structureGuaranteed performance qualityMaterial thermal analysisProcess windowDynamic recrystallization

The invention relates to a method for determining thermoforming process parameters of boron-containing microalloyed steel. According to the method, on the basis of true stress sigma data and true strain epsilon data obtained by a thermal simulation experiment, dynamic recrystallization conditions of the boron-containing microalloyed steel are determined; and thermal processing maps and activationenergy maps of different strains are drawn. An area having the minimum activation energy Q change and fluctuation not exceeding 1% in overlapped regions of safety regions in the thermal processing maps and a dynamic recrystallization region is set as a thermoforming process window of the corresponding strain; and a temperature T and a deformation rate epsilon. that correspond to a maximum power dissipation coefficient eta value in the thermoforming process window are thermoforming process parameters of the corresponding strain. Therefore, defects of coarse grain, crystal mixing, and crack of the boron-containing microalloyed steel can be overcome; and the relatively uniform dynamic recrystallization structure can be obtained. The energy utilization rate is high and the efficient productionand good product quality can be ensured.

Owner:WUHAN UNIV OF SCI & TECH

Combined ehru tuning jack

InactiveCN104036755AFlexible operationFine-tuningStringed musical instrumentsEngineeringNational instrument

The invention belongs to the field of manufacturing of musical instruments, and in particular provides a combined ehru tuning jack. Ehru is a string-pulling type national instrument with unique charm, which can bring a deep and pathetic artistic conception, show a majestic aura and also produce a tone close to human voice and has a high emotional rendering force, however, ehru is simple in structure and extensive in manufacturing method, which are inconvenient to play and also cause a series troubles like offsetting of the jack, change in tone, calibration of intonation and out-of-tune during playing songs of different set tones. In light of that set-tone intonation of ehru plays a decisive role in the playing effect, the combined ehru tuning jack integrates the functions of limiting oscillation string length of the ehru and correcting temperament, thus the intonation of the ehru can be conveniently set; a double-surface hook adhering belt is provided, by which a tying type fixed tuning jack can be simply and quickly moved. The combined ehru tuning jack has the advantages that the low pitch is forceful and deep, the medium pitch is bright and smooth, and the high pitch is clear and bright, and the quality of ehru that is the national treasure is improved.

Owner:慈溪市绿派新能源科技有限公司

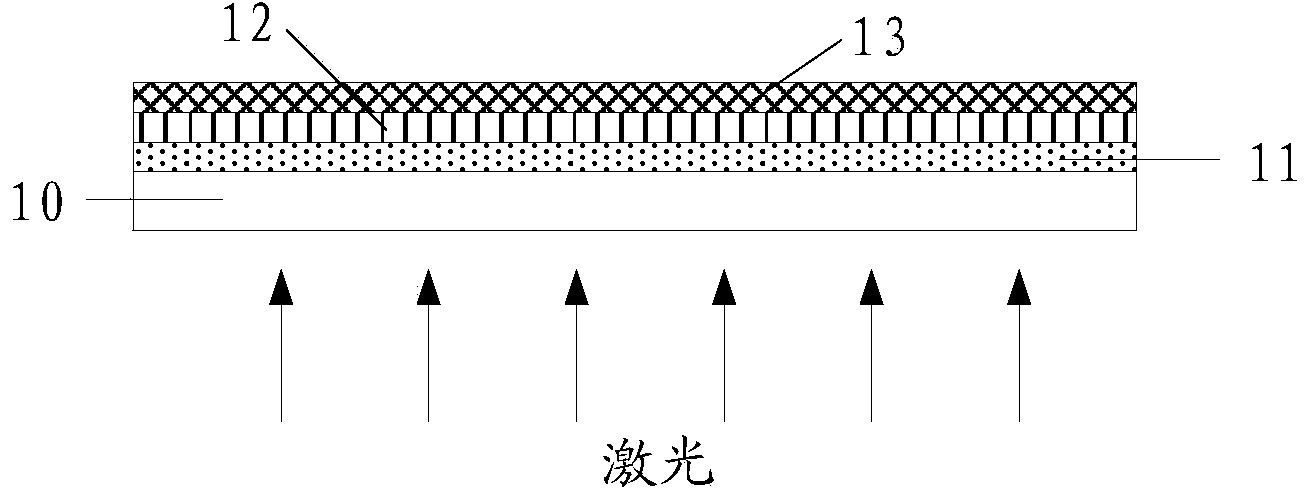

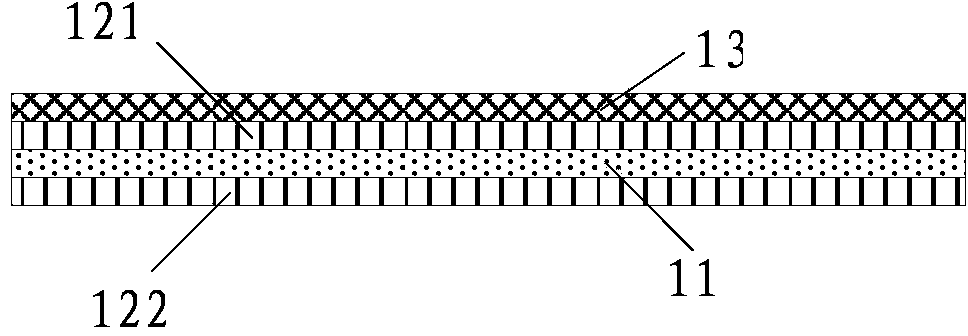

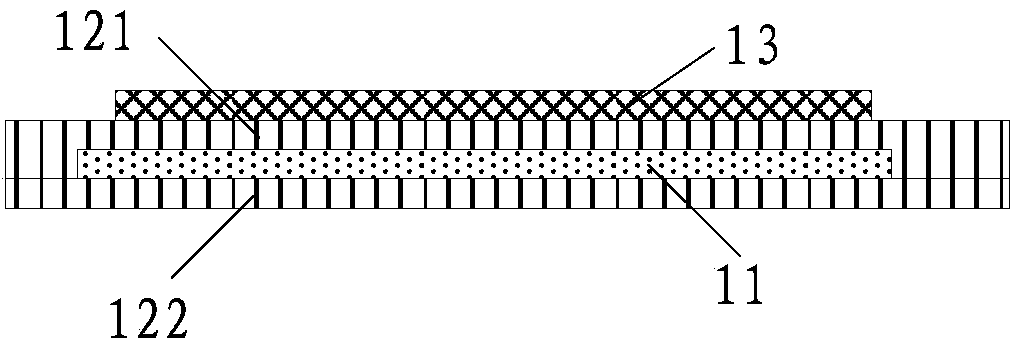

Flexible display panel, manufacturing method thereof, and display device

ActiveCN104022125AGuaranteed performance qualitySimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a flexible display panel, a manufacturing method thereof, and a display device, and relates to the technical field of display, so as to solve the problem that the display panel and a glass substrate are hard to separate during the flexible display panel manufacturing process. The flexible display panel comprises a first protection layer, a second protection layer, a flexible substrate and a display component, wherein the flexible substrate is located between the first protection layer and the second protection layer; and the display component is formed on the second protection layer.

Owner:BOE TECH GRP CO LTD

Compound type chlorinated polyethylene waterproof roll and preparation method thereof

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

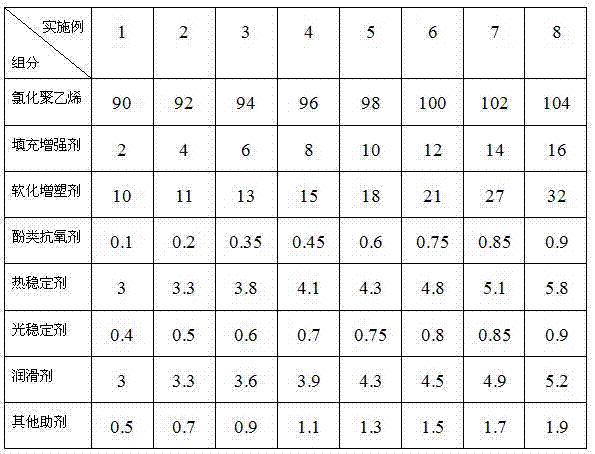

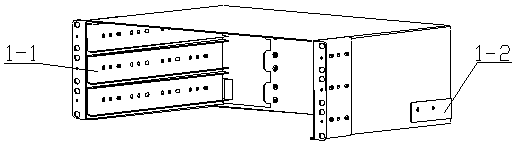

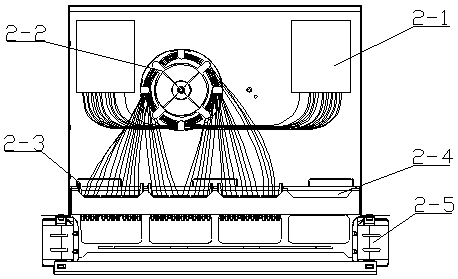

3U modular wiring unit for 19-inch cabinet

ActiveCN108181693AGuaranteed performance qualityReduce construction costsCoupling light guidesFibre mechanical structuresModularityComputer module

The invention relates to a 3U modular wiring unit for a 19-inch cabinet, which comprises a box cover, a light splitting module, a wire arrangement module, a welding and distribution module and an optical fiber jumper, wherein the light splitting module, the wire arrangement module and the welding and distribution module are installed in the box cover through guide rails in the box cover, a movableconnector on the optical fiber jumper is connected with an A switching module on the light splitting module; and certain length of an optical fiber pigtail can be stored in the module, and a pigtailwelding space and a jumper storage space are reserved at the same time. The advantages are that 1) the configuration for an adapter and the jumper is completed before leaving the factory, the performance and the quality are ensured, plug and play can be achieved by only introducing incoming optical cable welding or a pre-terminated optical cable, and the construction cost is saved; 2) light splitting, welding and wiring are integrated, and the jumper storage space is provided, thereby not needing to occupy a cabinet installation space outside the unit body; and 3) the welding and distributionmodule can be compatible with a pre-terminated module inserting box and can be compatible with LC, SC optical fiber adapters.

Owner:NANJING PUTIAN TELEGE INTELLIGENT BUILDING

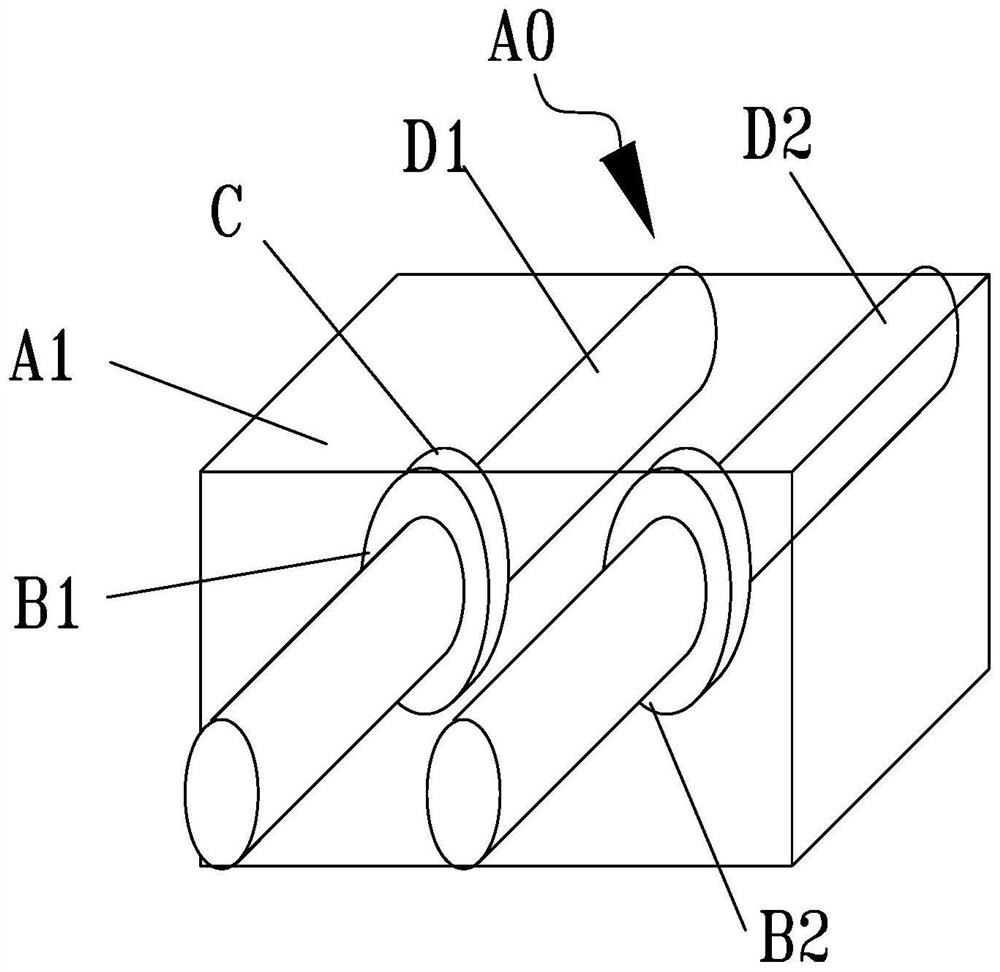

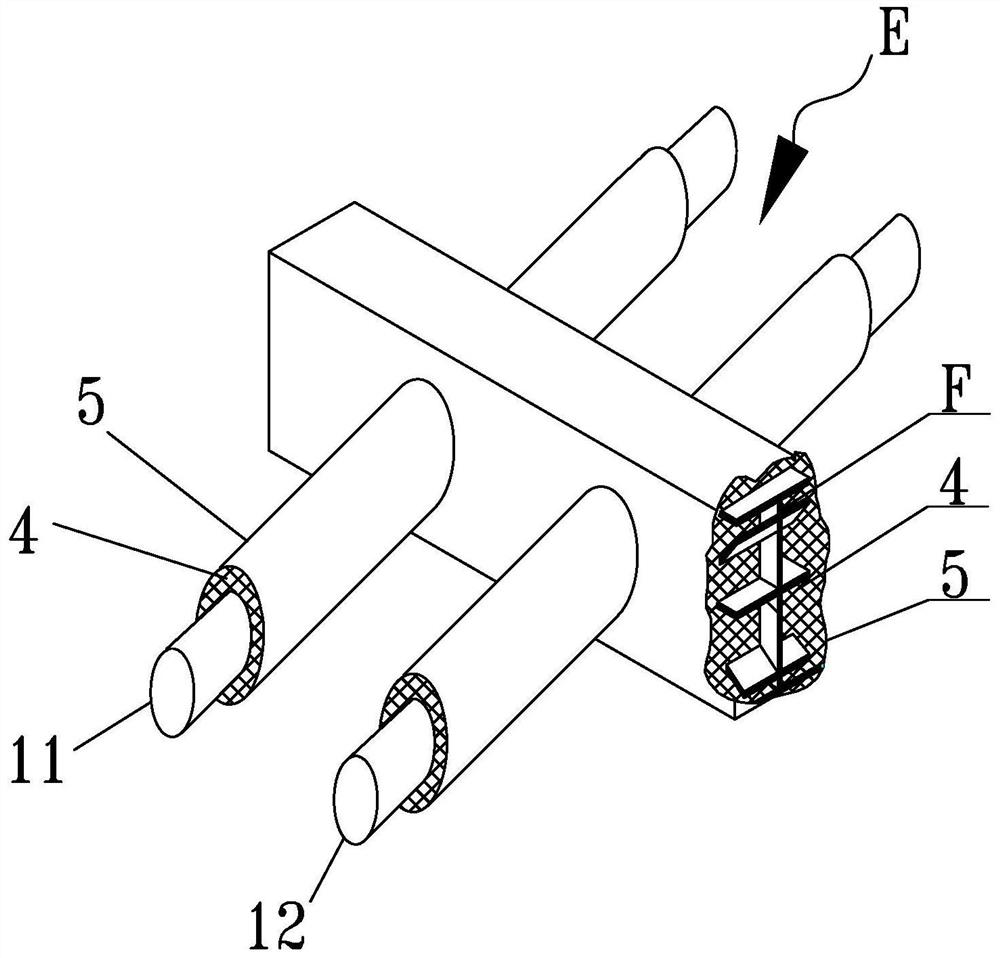

Integrated directly-buried double-pipe fixing joint for directly-buried heat supply pipeline and calculation method of integrated directly-buried double-pipe fixing joint

PendingCN112283455AOvercome limitationsSmall sizePipe supportsDesign optimisation/simulationWater pipeWater supply

The invention relates to an integrated directly-buried double-pipe fixing joint for a directly-buried heat supply pipeline and a calculation method of the integrated directly-buried double-pipe fixingjoint. The double-pipe fixing joint is characterized by comprising a double-pipe fixing joint body composed of an H-shaped component, a water supply pipe section and a water return pipe section, andthe H-shaped component is composed of a web and two wing plates; a water supply pipe section hole and a water return pipe section hole are formed in the web of the H-shaped component, and the water supply pipe section and the water return pipe section penetrate through the water supply pipe section hole and the water return pipe section hole respectively and are symmetrically arranged on the frontside and the back side of the web; a plurality of rib plates are symmetrically arranged on the front side plate surface and the back side plate surface of the web, surround the water supply pipe section and the water return pipe section, are uniformly and symmetrically arranged in the radial direction of the water supply pipe section and the water return pipe section and are connected between thewater supply and return pipe sections and between the water supply and return pipe sections, the wing plates and the side edge of the web; and the outer side of the fixing joint body is coated with aheat preservation layer and a protective layer. The calculation method comprises the steps of calculating thrust torque, calculating the size of the wing plates, determining the size of the web and determining the number of the rib plates. The integrated directly-buried double-pipe fixing joint and the calculation method thereof have the advantages that the one-step formed metal structure fixingjoint replaces a steel and concrete structure fixing pier, and the double-pipe fixing joint is small in size and light in weight, is directly buried underground, and is easy and fast to construct.

Owner:TIANJIN THERMAL POWER DESIGNING INST

Process for producing sioc-bonded polyether siloxanes branched in the siloxane portion

ActiveCN112011056AGuaranteed performance qualityMacromolecular adhesive additivesGrip property fibresAcetic acidPolymer science

Described is a process for producing Si0C-bonded polyether siloxanes branched in the siloxane portion from cyclic branched siloxanes of the D / T type, wherein said process comprises in a first step reacting the mixtures of cyclic branched siloxanes of the D / T type with acetic anhydride optionally in admixture with simple siloxane cycles under acid catalysis to afford acetoxy-bearing branched siloxanes, in a second step performing the equilibration of the acetoxy-modified branched siloxane with superacid, preferably with addition of acetic acid and in a third step reacting the superacid-treatedacetoxysiloxane with polyetherols optionally in the presence of bases and optionally in the presence of an inert solvent.

Owner:EVONIK OPERATIONS GMBH

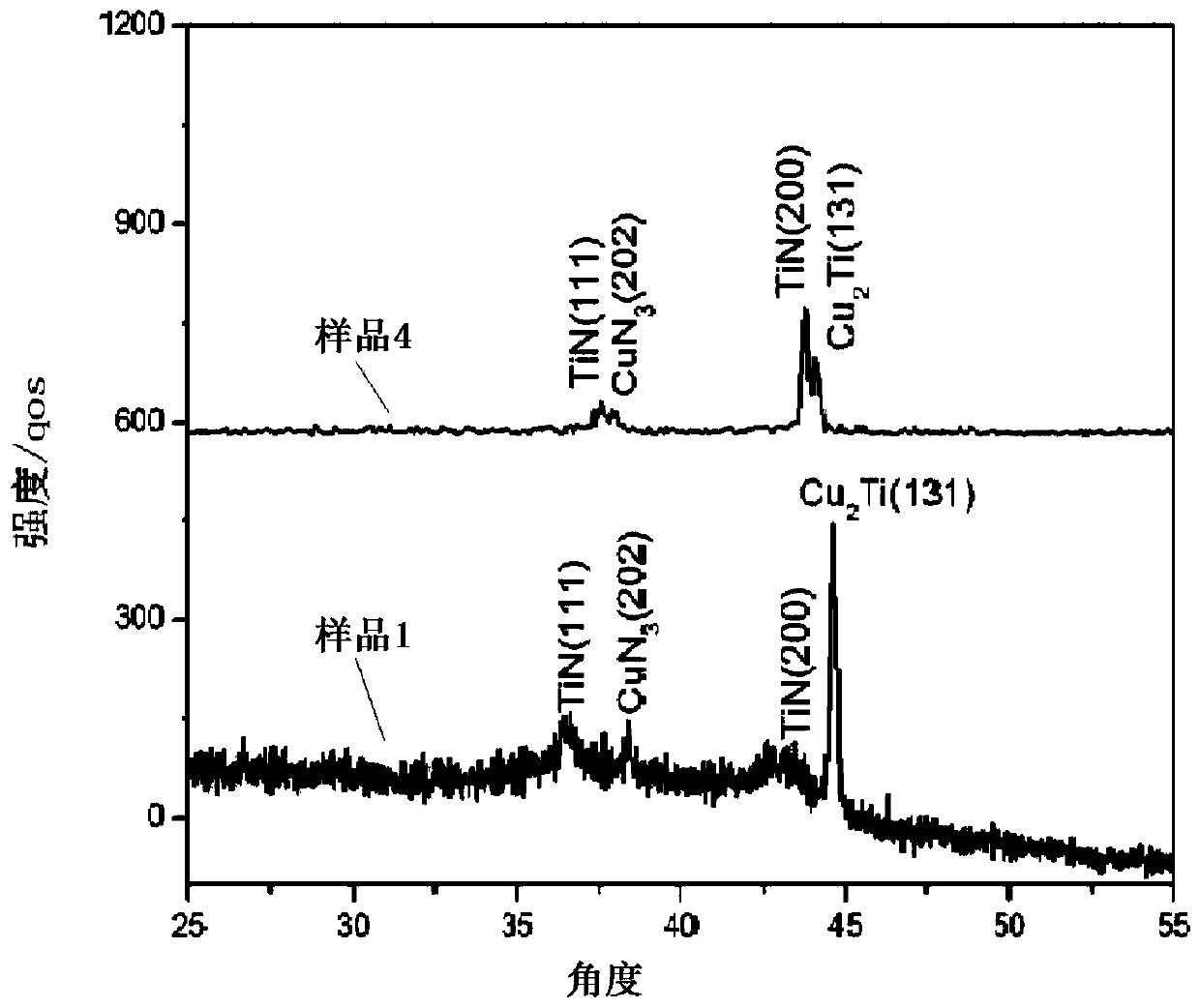

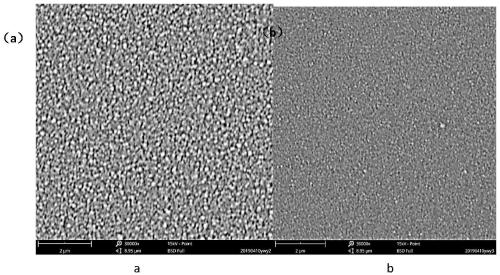

Medical copper-containing composite coating and preparation method thereof

ActiveCN111041433AAvoid destructionDegradableVacuum evaporation coatingSputtering coatingTitaniumMechanical property

The invention relates to a medical copper-containing composite coating and a preparation method thereof, and belongs to the technical field of medical materials. The medical copper-containing composite coating comprises an intermediate phase or a compound formed by three elements of copper, titanium and nitrogen, and the copper content of the coating is larger than 10 wt% and not larger than 60 wt%; an X-ray diffraction pattern of the medical copper-containing composite coating shows characteristic diffraction peaks, namely Cu2Ti, CuN3 and TiN. The medical copper-containing composite coating disclosed by the invention is a new biomedical material which has high blood compatibility and degradability; the coating has certain toughness, so that damage to the coating in the deformation processof the medical instrument is avoided; and the mechanical property and the coating quality of the coating are guaranteed through the preparation method.

Owner:成都迈德克科技有限公司

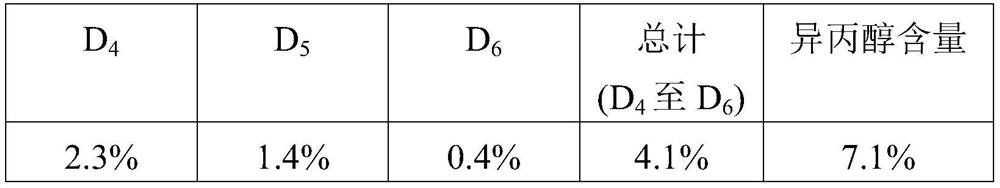

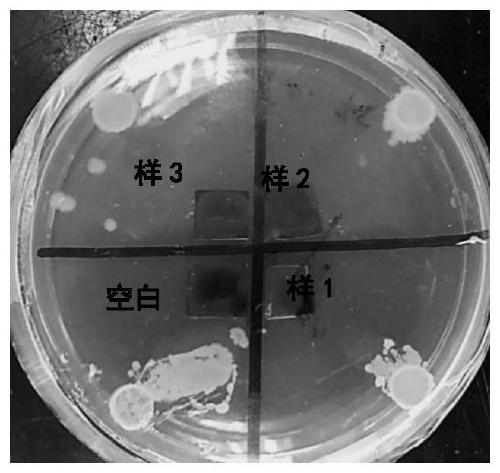

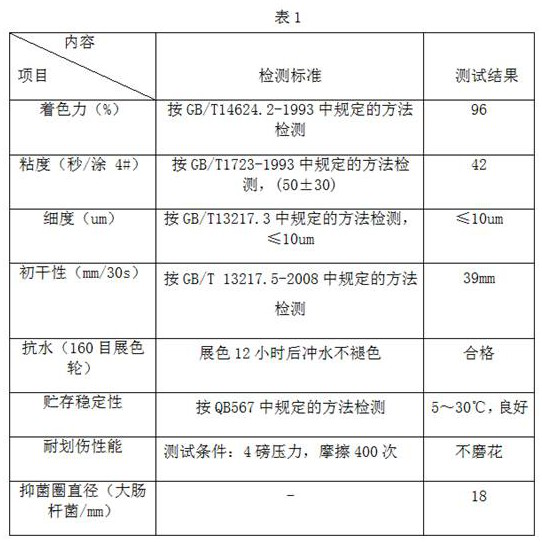

Mildew-proof antibacterial water-based ink for printing packaging carton and production method of mildew-proof antibacterial water-based ink

InactiveCN112300628AGood antibacterial, antibacterial and antimildew effectGood antibacterial and antifungal effectInksAcrylic resinPrinting ink

The invention relates to the technical field of printing ink, in particular to mildew-proof and antibacterial water-based printing ink for printing packaging cartons and a production method of the mildew-proof and antibacterial water-based printing ink. The printing ink comprises, by weight, 60-70 parts of water-soluble acrylic resin, 25-30 parts of a water-based pigment, 2-4 parts of isopropanol,0.1-0.3 part of chitosan, 0.5-1 part of cinnamon oil, 0.5-1 part of an antibacterial agent, 3-5 parts of a pH value stabilizer, 0.2-0.4 part of lauryl sodium sulfate, 0.2-0.4 part of a GPE defoamingagent, 3-5 parts of propylene glycol alginate and 45-55 parts of water. The water-based ink produced by the method has good antibacterial and mildew-proof effects, so that the antibacterial and mildew-proof capability of a packaging carton product printed by the water-based ink is improved, and the water-based ink is safe, environment-friendly, good in wear resistance and water resistance and lowin production cost, and can be widely applied to printing of outer packaging cartons of foods and the like.

Owner:黄展才

Online battery drying equipment

PendingCN108645120AAvoid inaccurate test resultsGuaranteed accuracyDrying solid materials without heatDrying machines with progressive movementsElectrical batteryEngineering

The invention discloses online battery drying equipment. The online battery drying equipment comprises a closed equipment shell, a vacuum drying room mounted in the equipment shell, a circular conveying mechanism penetrating through the vacuum drying room, and a loading mechanism, a first stacking mechanism, a second stacking mechanism, an unloading mechanism and a batter sampling working room assembled around the circular conveying mechanism in sequence. The battery drying equipment is provided with the battery sampling working room; through a separation plate arranged in the working room, the working room is divided into two independent areas; workers can use an operation window for sampling lithium batteries, and take out samples from a sampling box; and under the condition of not needing to contact with external atmospheric environment, the workers can sample the dried lithium batteries in vacuum, so that the problem of inaccurate detecting result caused by traditional incomplete sampling and casual inspection operations of lithium batteries is solved, the detecting accuracy of the lithium batteries is guaranteed, and the performance and the quality of the lithium batteries areeffectively guaranteed.

Owner:DONGGUAN ALI AUTOMATION CO LTD

Production method of universal bone conduction Bluetooth earphone

ActiveCN111866657ASimple structureGuaranteed performance qualityBone conduction transducer hearing devicesShort range communication serviceProduct testingEngineering

The invention provides a production method of a universal bone conduction Bluetooth earphone, which is characterized by comprising the following steps: of S1, dispensing and processing a vibrator, S2,soldering tin of the vibrator, S3, assembling a shell, S4, circuit welding, S5, assembling a horn cover, S6, testing a semi-finished product, S7, conducting wiring, S8, dispensing and packaging, andS9, finished product testing and appearance detection. According to the standardized production method capable of being repeatedly copied, the structure of the product is simplified, the performance quality of the product is guaranteed, meanwhile, the design of the thinner product with the smaller size can be achieved, the production efficiency is improved, the product yield is increased, and theproduction cost is reduced.

Owner:惠州市品能新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com