Battery cell connecting piece welding mechanism and welding method thereof

A welding mechanism and welding method technology, applied in welding equipment, laser welding equipment, circuits, etc., can solve the problems of welding slag generated by the connecting piece of the battery cell and the top cover pole, hidden dangers of battery safety, and affecting the performance and quality of the battery. Guaranteed functionality and strength, less metal spatter, improved performance quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

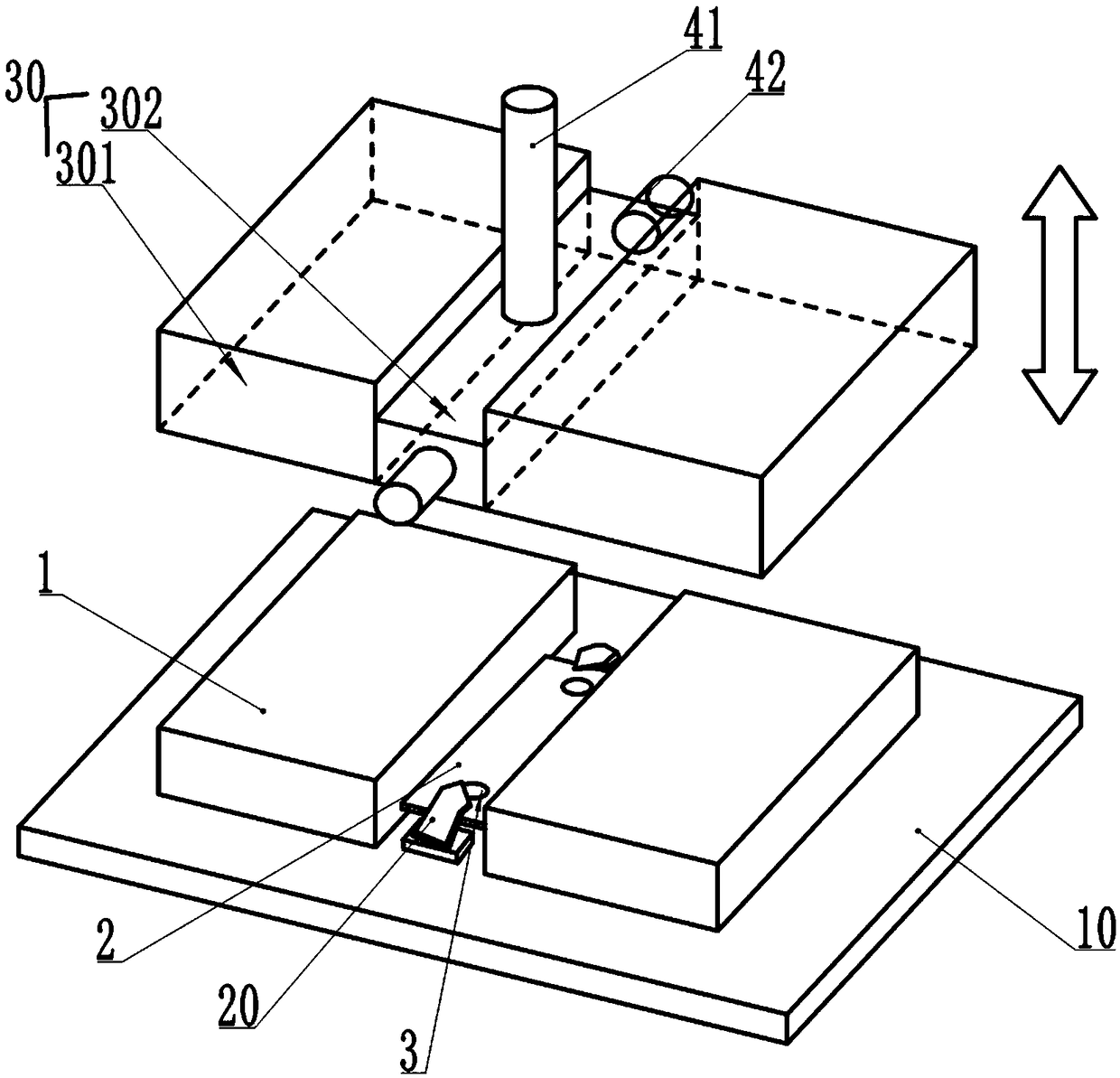

[0040] see figure 1 , which is a structural schematic diagram of a cell connecting piece welding mechanism provided in this embodiment. The cell connecting piece welding mechanism includes:

[0041] A welding station 10, the welding station 10 is used to place the electric core 1 with the connecting piece 2 installed;

[0042] A laser welding assembly 20, the laser welding assembly 20 is installed on the welding table 10;

[0043] A dust removal cover 30, the dust removal cover 30 is movably sealed on the electric core 1 and the laser welding assembly 20;

[0044] Wherein, the dust removal cover 30 includes a cell accommodating chamber 301 for accommodating the electric core 1, and a welding chamber 302 for welding the connecting piece 2; The tuyere is sealed and installed with a blowing pipe 41 communicating with the welding chamber 302, and the air extraction hole is sealed and installed with an exhausting pipe 42 communicating with the welding chamber 302; the end of the ...

Embodiment 2

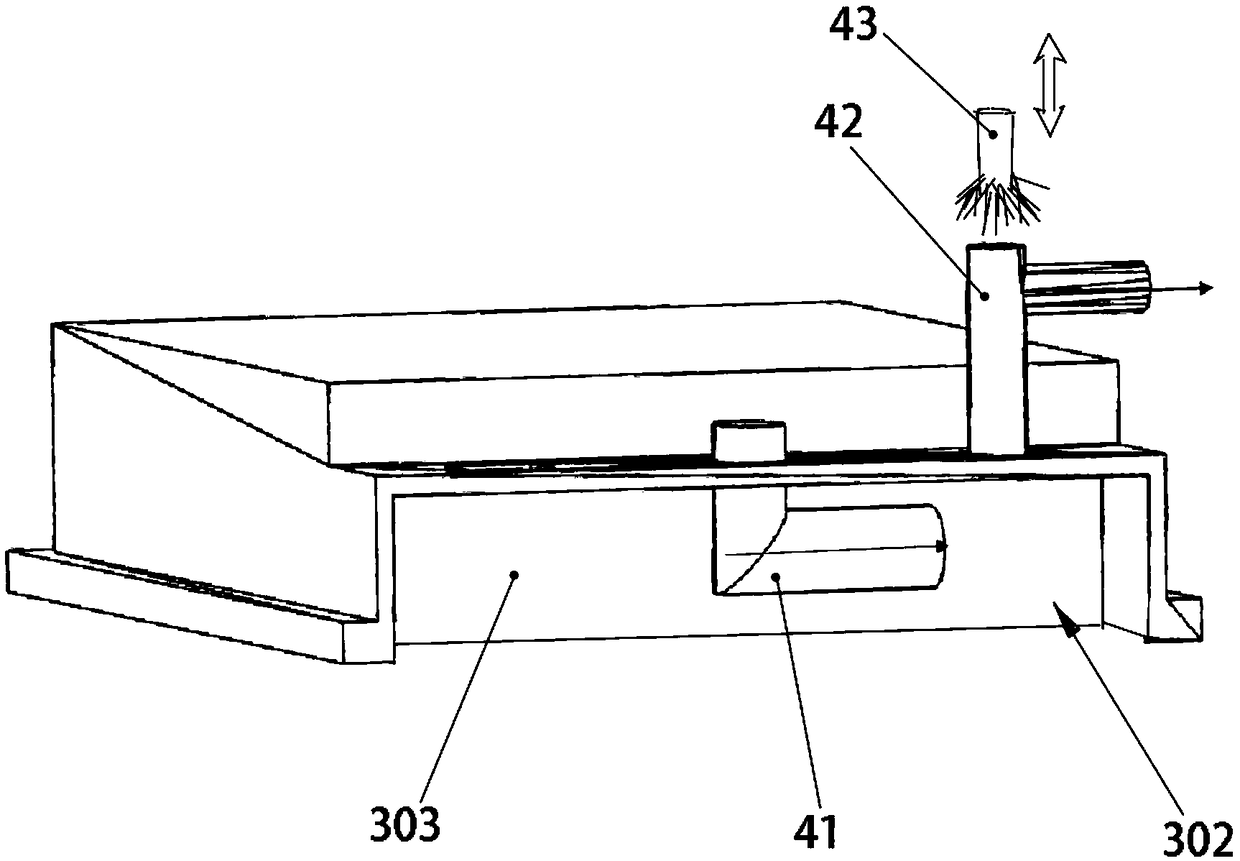

[0050] see figure 2 , which is a cross-sectional view of a dust removal hood in this embodiment;

[0051] In order to further optimize this technical solution, it is preferred on the basis of the above-mentioned embodiment one, such as figure 2 As shown, the air extraction hole is opened on the top of the welding chamber 302 , and the air extraction pipe 42 extends to directly above the welding point 3 of the connecting piece 2 through the air extraction hole. Specifically, through this structural design, the exhaust pipe 42 can adopt a coaxial vacuum suction method to extract welding slag or dust from above the welding point 3, thereby achieving the purpose of eliminating welding slag.

Embodiment 3

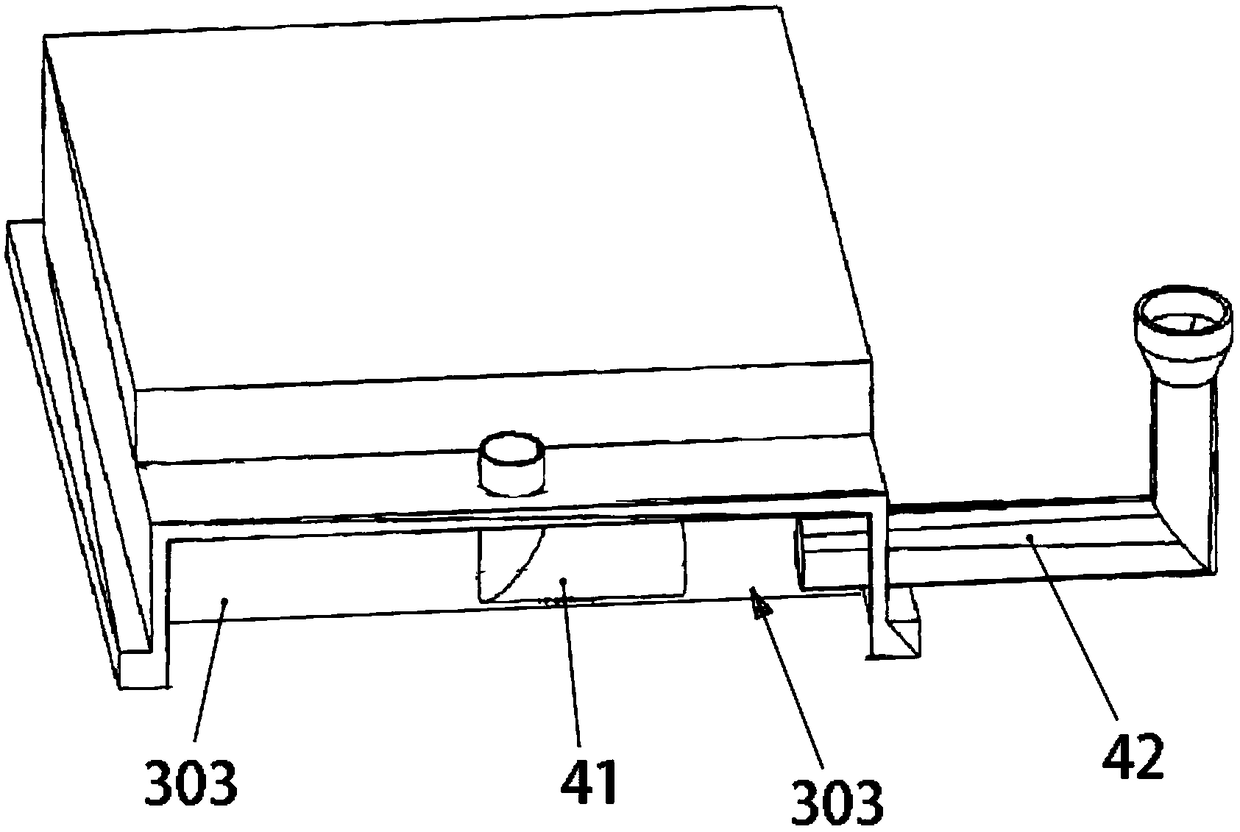

[0053] see image 3 , which is a cross-sectional view of another dust cover in this embodiment;

[0054] In order to further optimize this technical solution, preferably on the basis of the first embodiment above, the air extraction hole is opened on the side of the welding chamber 302, and the air extraction pipe 42 extends to the welding point of the connecting piece 2 through the air extraction hole 3 sideways. Concrete, utilize this structural design, the air extraction port of air extraction pipe 42 can be arranged on the side of welding point 3 as much as possible, because the air blowing port of air blowing pipe 41 is facing the air extraction port of air extraction pipe 42, avoids that the air flow turns and reverses, This avoids slowing down of the airflow speed, thereby improving the performance and efficiency of welding slag removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com