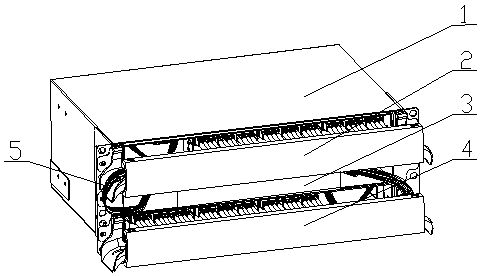

3U modular wiring unit for 19-inch cabinet

A wiring unit and modularization technology, applied in the direction of optical components, optical waveguide coupling, fiber mechanical structure, etc., can solve the problems of difficult construction and limited storage space, and achieve the effect of saving construction costs and ensuring performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

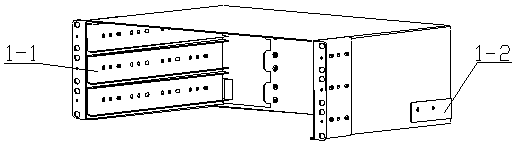

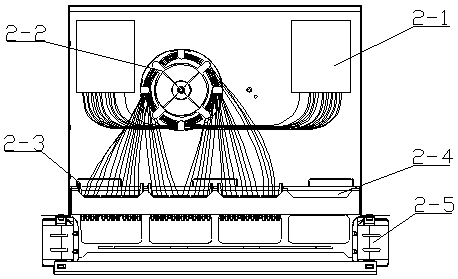

[0041] A 3U modular wiring unit for a 19-inch cabinet, including a box cover (1), an optical splitting module (2), a cable management module (3), a fusion module (4), and an optical fiber jumper (5); The box-type optical splitter (2-1) in the optical splitting module (2) has its own pigtail coiled on the A-reel fiber reel (2-2) in the optical splitting module (2) and then connected to the A-reel in the optical splitting module (2). Connect the module (2-3), connect one end of the pigtail (4-1) in the fusion box (4) to the B transfer module (4-2) in the fusion module (4), and then connect the excess pigtail ( 4-1) Coil on the B-disk fiber tray (4-3) in the fusion box (4), and pass the optical splitting module (2), cable management module (3) and fusion module (4) through the box cover respectively The guide rail (1-1) in (1) is installed in the box cover (1), and the adapter module A ( 2-3), coil the excess optical fiber (5-2) and store it in the A fiber storage area (2-4) in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com