Ultrafine hetero composite elastic fibre and its manufacturing method

A manufacturing method, ultra-fine technology, used in fiber processing, conjugated synthetic polymer rayon, melt spinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

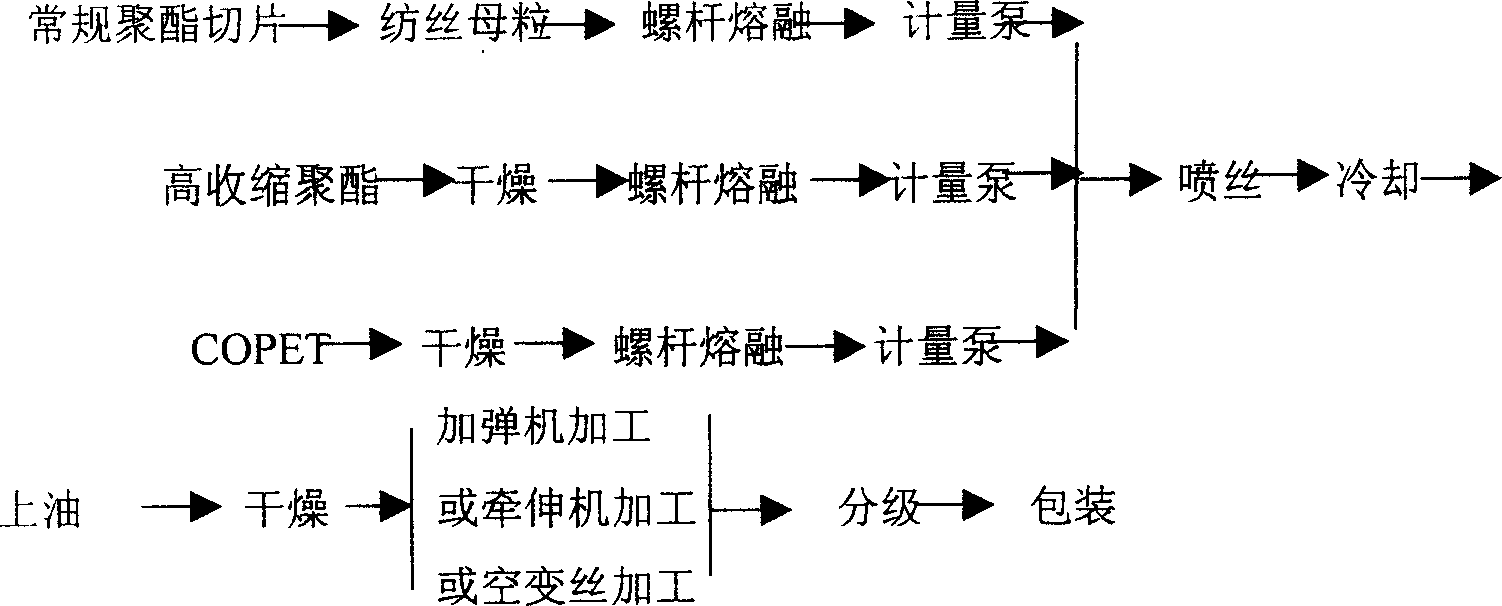

[0031] The manufacture of embodiment 1 ultra-fine anisotropic composite stretching fiber

[0032] After drying conventional polyester chips (amount of 100%) at a temperature of 120°C for 25 hours, add flow stabilizer triphenyl phosphate 0.03%, oxidation stabilizer antioxidant 618, amount 0.04%, Then melt at a temperature of 265°C, inject tape, and pelletize to make spinning masterbatch. Configure high-shrinkage polyester according to the ratio of 40% of conventional polyester chips and dry. According to conventional polyester chips, 20-30% water-soluble polyester (COPET) is dried at a temperature of 100°C for 25 hours, and then 0.1% of dispersant liquid paraffin is added.

[0033] Pass the above-mentioned masterbatch, high-shrinkage polyester, and COPET through different screws, and melt them at temperatures of 270°C, 280°C, and 260°C respectively, adjust the injection volume of each screw according to the ratio, and pass the three molten materials together The special-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com