Compound type chlorinated polyethylene waterproof roll and preparation method thereof

A technology of chlorinated polyethylene and waterproof membrane, which is applied in the field of new waterproof membranes, can solve the problems of polyurea waterproof layer damage, affecting waterproof effect, high engineering cost, etc., and achieves low construction cost, performance quality assurance, and construction quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

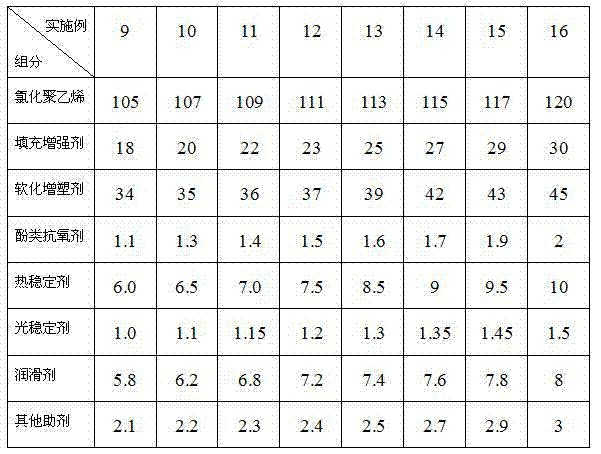

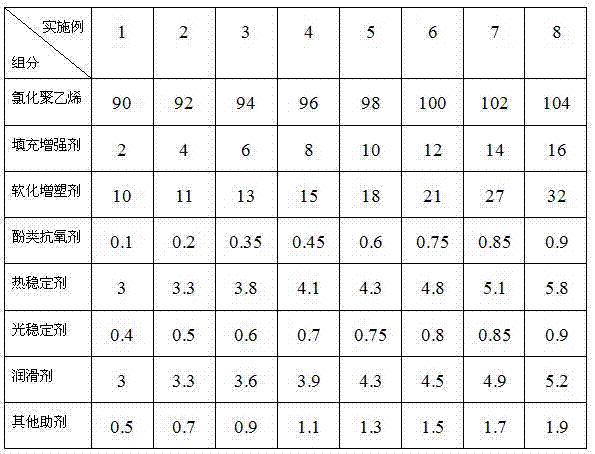

Examples

Embodiment 1

[0031]A new type of wide-width waterproof membrane that can replace sprayed polyurea waterproof coatings is made of the following raw materials in parts by weight: 100 parts of chlorinated polyethylene with a chlorine content of 35%, 10 parts of activated calcium carbonate, o-phthalic acid 20 parts of dioctyl dicarboxylate, 0.6 part of phenolic antioxidant, 4 parts of heat stabilizer, 0.5 part of stearic acid, 0.5 part of ultraviolet absorber (UV-327); It is made of 35% phenolic primary antioxidant 1076 and 65% auxiliary antioxidant DSTDP; the heat stabilizer is made of 60% tribasic lead sulfate and 40% composite heat stabilizer;

[0032] A method for preparing a wide-width new waterproof product that can replace spraying polyurea waterproof coatings includes the following steps: (1) Ingredients: mix various raw materials in proportion, and fully stir them evenly at room temperature; (2) Granulate: put The well-stirred mixture is put into the closed plastic refining machine. T...

Embodiment 2

[0034] A new type of wide-width waterproof membrane that can replace sprayed polyurea waterproof coatings is made of the following raw materials in parts by weight: 100 parts of chlorinated polyethylene with a chlorine content of 35%, 10 parts of kaolin, phthalic acid 20 parts of dioctyl fat, 5 parts of epoxidized soybean oil, 3 parts of polyethylene wax, 0.6 parts of phenolic antioxidant, 4 parts of heat stabilizer, 0.5 part of stearic acid, 0.5 part of ultraviolet absorber (UV-327); Described phenolic antioxidant is made by the secondary antioxidant DSTDP that is 35% phenolic main antioxidant 1076 and 65% by weight; Described thermal stabilizer is made of 60% tribasic lead sulfate and Made of 40% compound heat stabilizer;

[0035] A method for preparing a wide-width new waterproof product that can replace spraying polyurea waterproof coatings includes the following steps: (1) Ingredients: mix various raw materials in proportion, and fully stir them evenly at room temperature...

Embodiment 3

[0037] A new type of wide-width waterproof membrane that can replace sprayed polyurea waterproof coatings is made of the following raw materials in parts by weight: 100 parts of chlorinated polyethylene with a chlorine content of 35%, 10 parts of white carbon black, o-phthalic 15 parts of dioctyl dicarboxylate, 5 parts of epoxidized soybean oil, 4 parts of polyethylene wax, 0.6 parts of phenolic antioxidant, 4 parts of heat stabilizer, 0.5 part of stearic acid, 0.5 part of ultraviolet absorber (UV-327) part; described phenolic antioxidant is made by the auxiliary antioxidant DSTDP that is 35% phenolic main antioxidant 1076 and 65% by weight; Described thermal stabilizer is made of 60% tribasic sulfuric acid Made of lead and 40% composite heat stabilizer;

[0038] A method for preparing a wide-width new waterproof product that can replace spraying polyurea waterproof coatings includes the following steps: (1) Ingredients: mix various raw materials in proportion, and fully stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com