Device for rotary working into coil or piece material

A technology of rotary processing and sheet materials, which is applied in the direction of shearing devices, metal processing, metal processing equipment, etc., can solve the problem of not being able to replace brackets, etc., to avoid waste, reduce manufacturing costs, and reduce preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clarify several terms commonly used in the following description to describe the orientation and position of certain components, it must be noted that the terms "machine direction" and "transverse direction" refer to the direction in which the roll or sheet material travels in the machine , while the terms "upstream" and "downstream" refer to the side closest to the machine inlet and machine outlet, respectively.

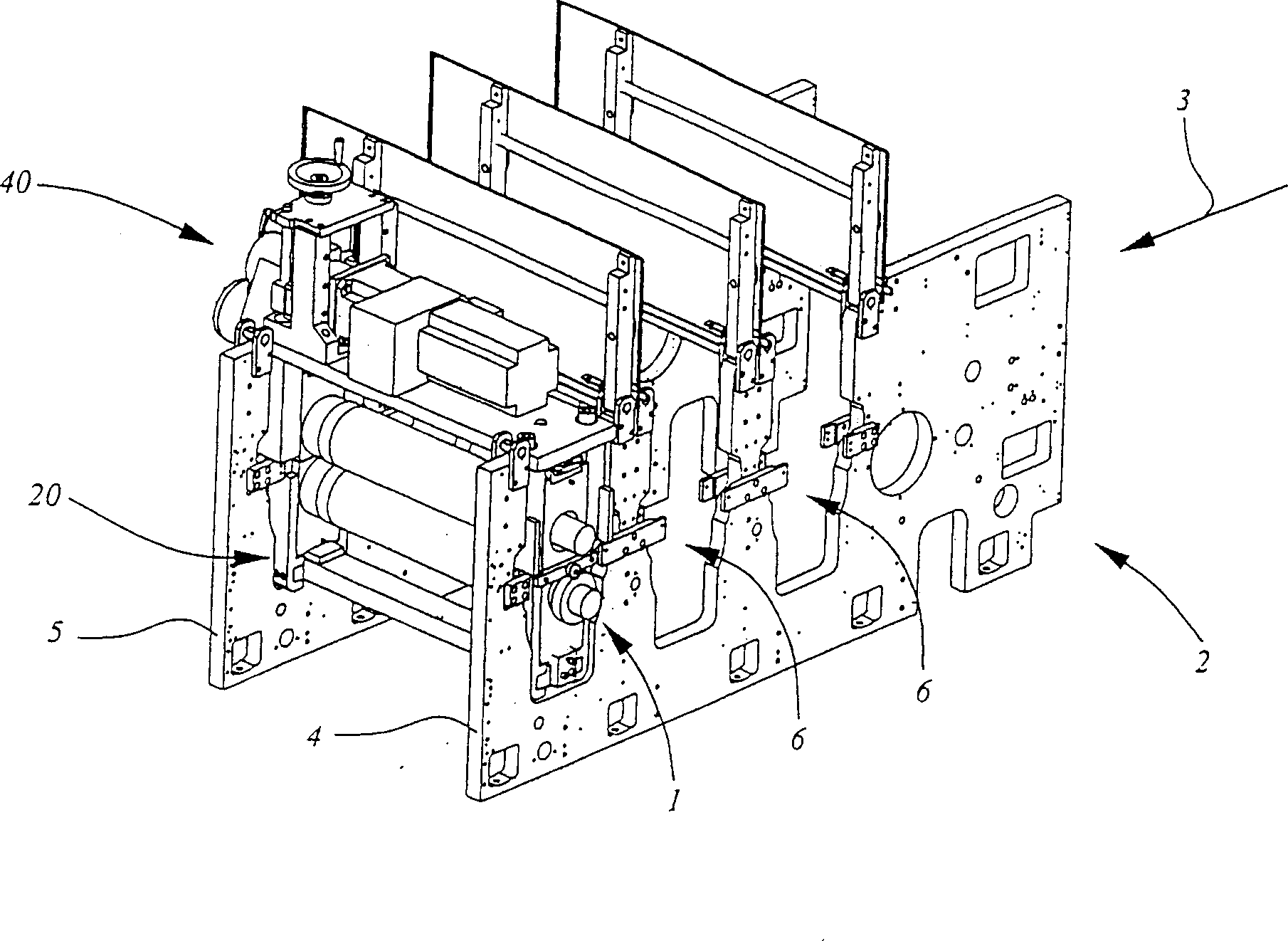

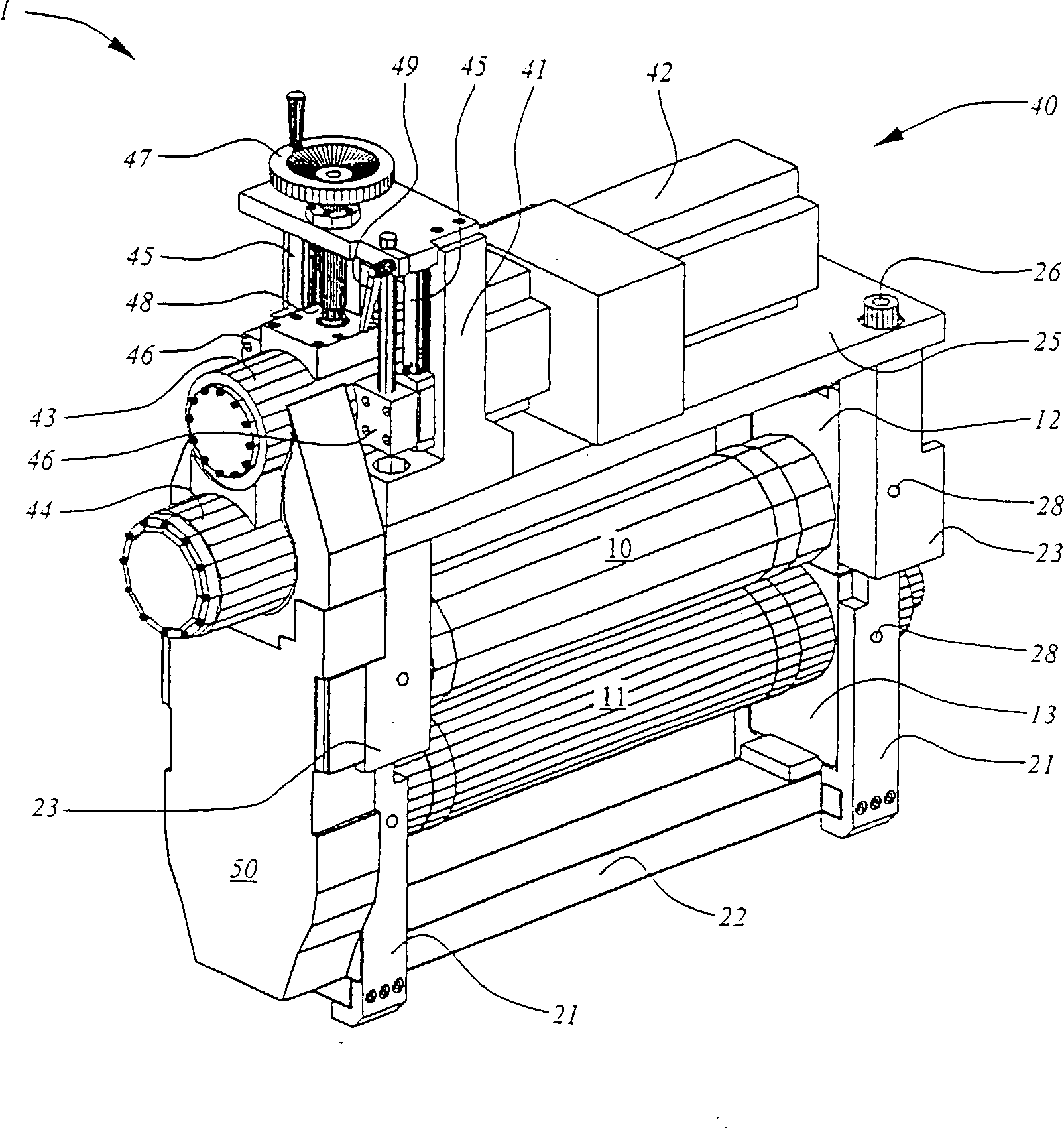

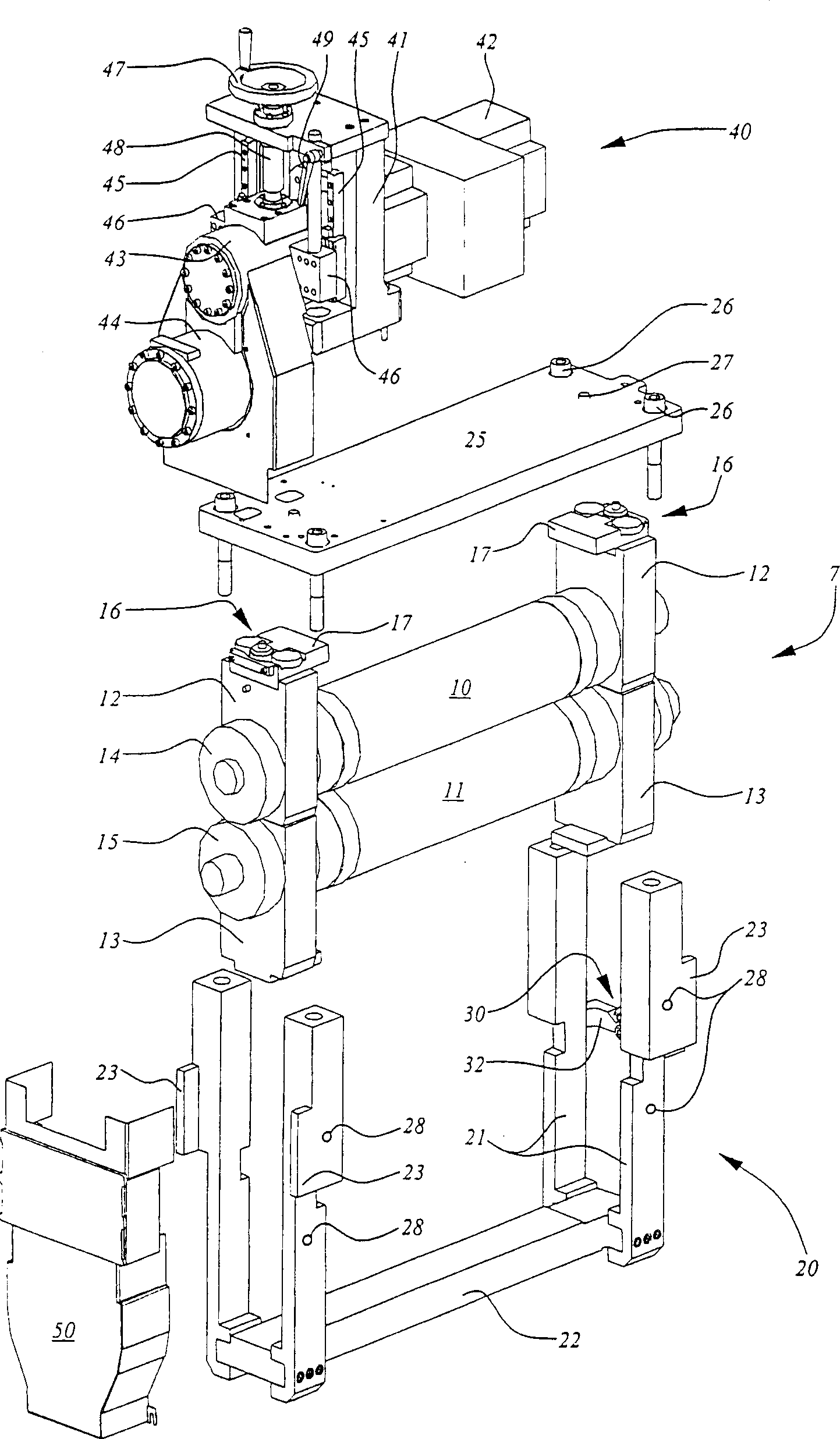

[0018] figure 1 is a perspective view showing the device 1 according to the invention in a conventional machine 2 for processing roll material. The running direction of the material (not shown in the figure) is from upstream to downstream as shown by arrow 3 in the figure. The frame of the machine 2 consists of two side walls 4,5. There is a wide oval or rectangular vertical opening 6 on the side wall, and devices for embossing (forming concave-convex patterns), forming creases, and cutting are respectively housed therein. exist figure 1 , onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com