Double-face chamfering and drilling tool

A drilling tool, double-sided technology, used in drilling tool accessories, drilling/drilling equipment, drilling and other directions, can solve the problems that the surface quality cannot meet high-quality products, affect the quality of the processed surface, and the processing efficiency is not high. Achieve the effect of ensuring cutting performance and processing quality, saving processing time and worker operation time, and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

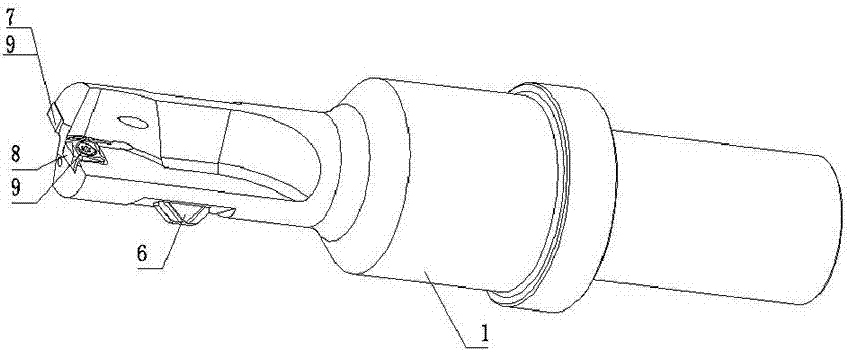

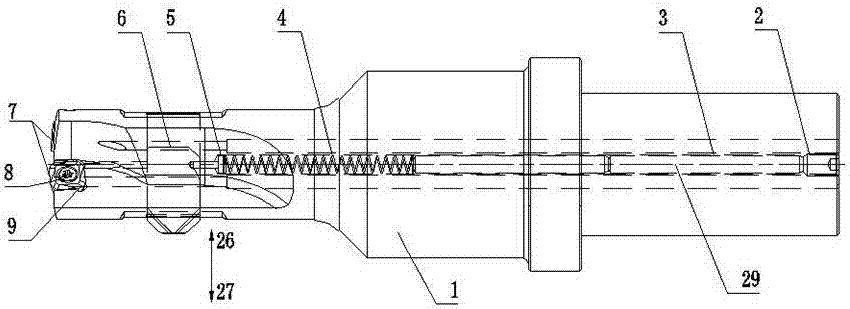

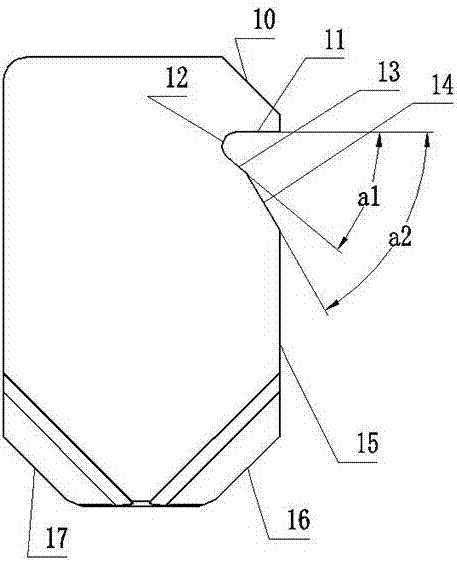

[0019] Such as Figure 1~Figure 5 As shown, a double-sided chamfering drilling tool includes a cutter body 1, a chamfering blade 6 and a drilling blade 7, the end of the cutter body 1 is provided with a blade platform 9, and the end of the cutter body 1 The head is also provided with a longitudinally arranged blade installation transverse hole 19, the right end of the cutter body 1 is provided with a clamping portion 28, the inside of the cutter body 1 is provided with an axial hole 20, and one end of the extension rod 3 is positioned and fixed by the set screw 2. Installed in the axial hole 20, the other end of the extension rod 3 is connected with a spring 4, and the spring 4 is connected with the limit pin 5; the drilling blade 7 is installed on the blade platform 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com