Production technology of non-sewn hot-melt adhesive film

A hot-melt adhesive film and production process technology, which can be applied to other household appliances, household appliances, flat products, etc., can solve the problems of affecting the performance and quality of rubber materials, increasing costs, not being flat, and beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

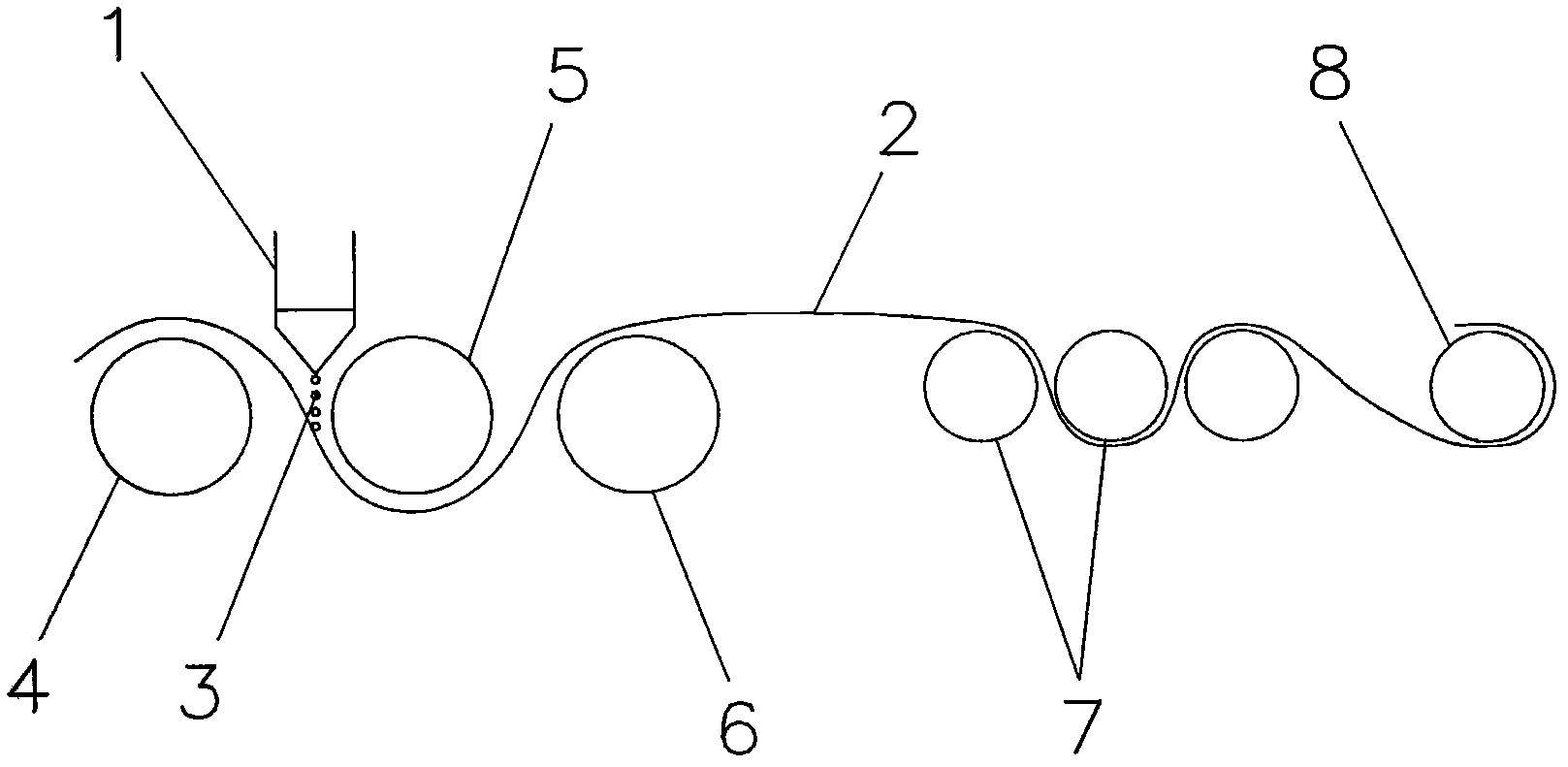

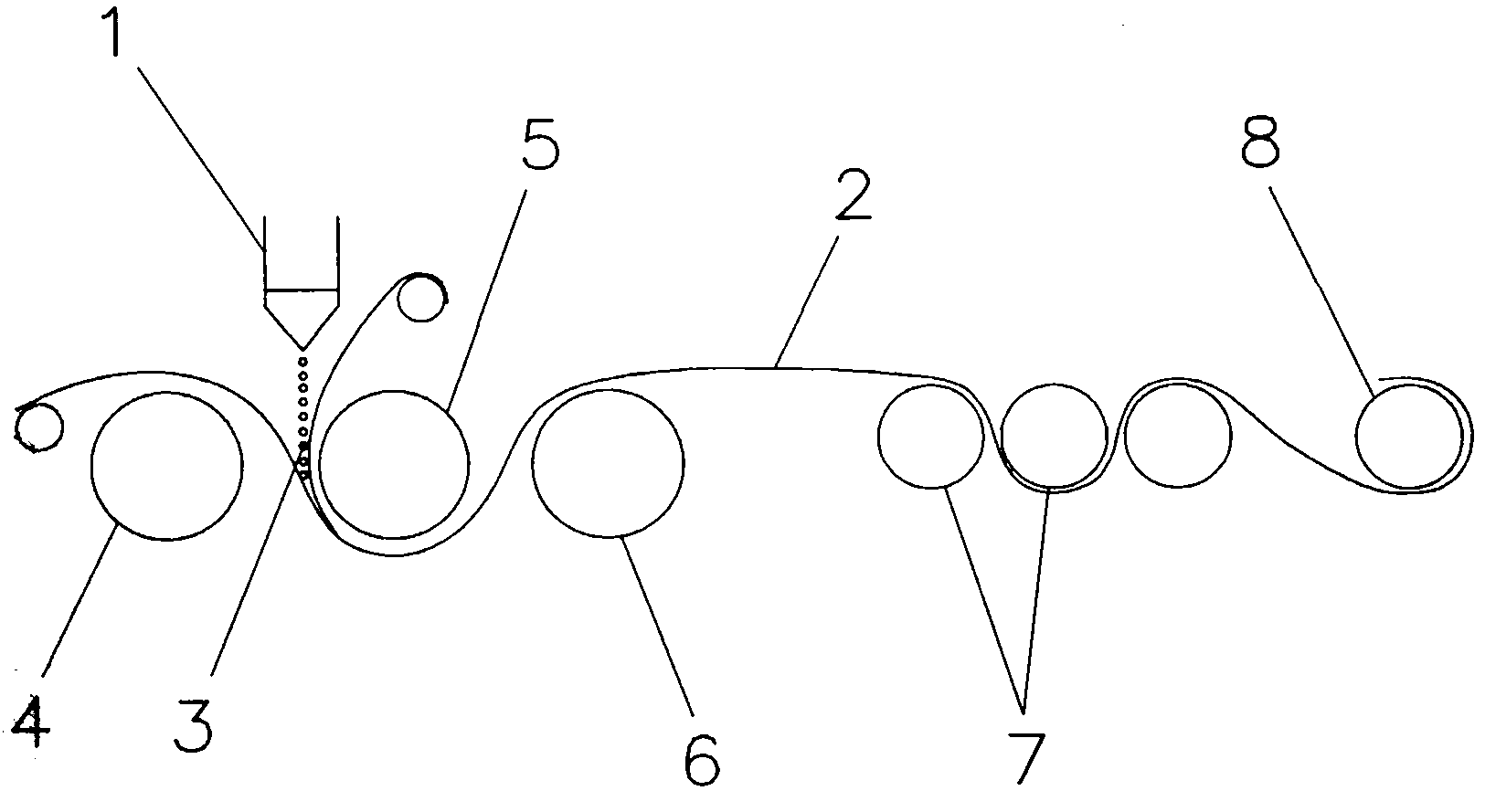

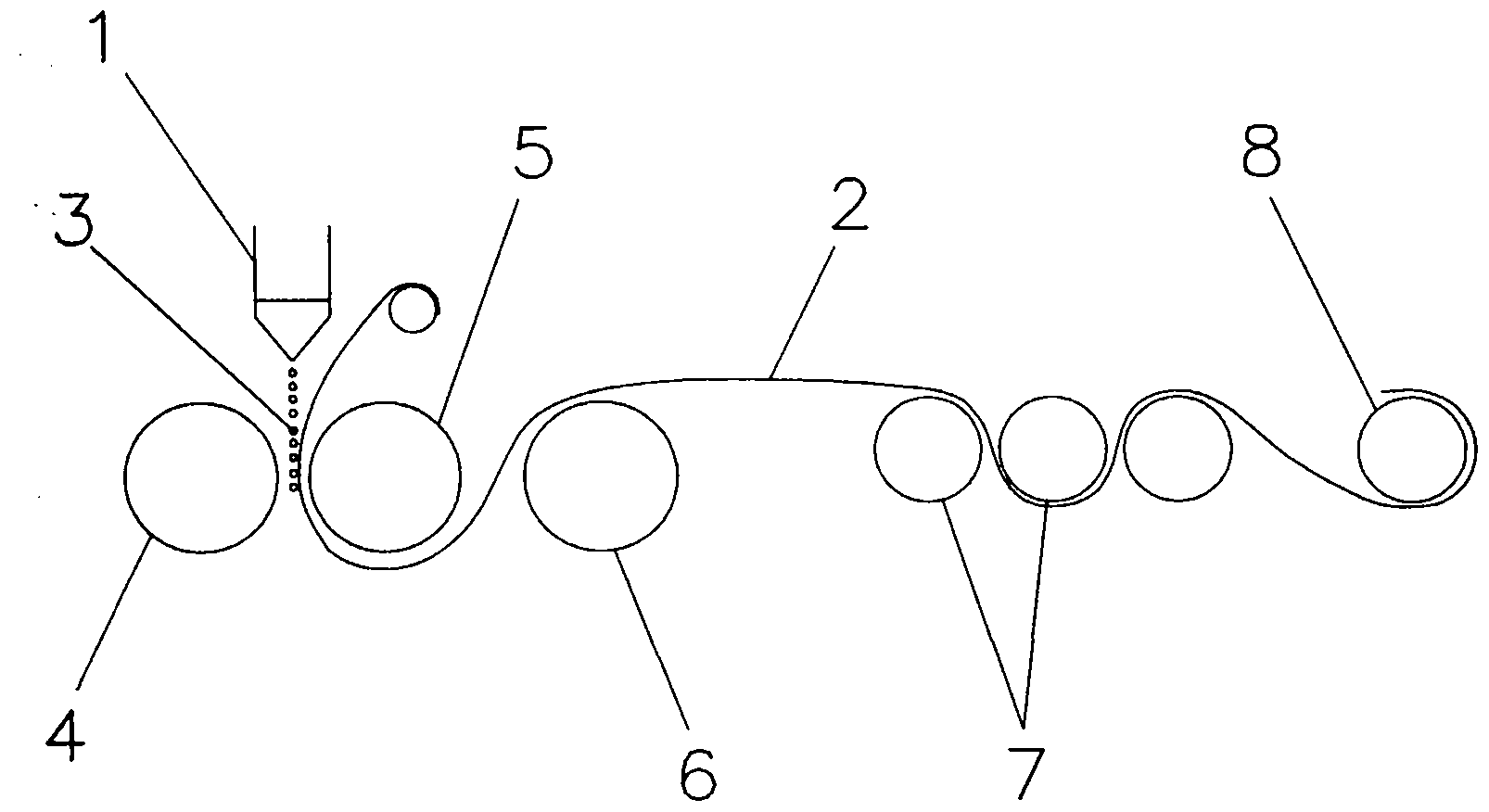

[0024] Such as figure 1 As shown, it is a schematic diagram of the first working process, with figure 1 Illustrate a kind of seamless hot-melt adhesive film production technique of the present invention as an example, it comprises the following steps:

[0025] The first step is to prepare TPU hot-melt collagen material particles, put the TPU hot-melt collagen material particles into the hopper connected to the extruder; pass the adhesive paper 2 with release function around the rubber roller 4 and emboss in turn Wheel 5, forming wheel 6, traction wheel 7 and take-up wheel 8;

[0026] The second step is to turn on the power supply and open the extruder; set the set temperature value when the extruder is produced; The TPU hot-melt collagen material is heated so that the TPU hot-melt collagen material reaches the extrusion temperature requirement after being processed. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com