Method for determining thermoforming process parameters of boron-containing microalloyed steel

A technology of microalloy steel and definite method, which is applied in thermal analysis of materials, measuring devices, instruments, etc., can solve problems such as undetermined process parameters, achieve uniform dynamic recrystallization structure, reduce development cost, and ensure performance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

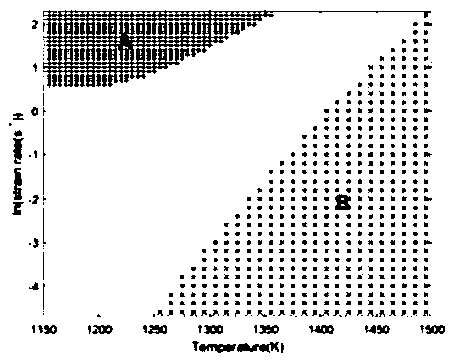

[0042] A method for determining hot forming process parameters of boron-containing microalloy steel. The determination method of the boron-containing microalloy steel hot forming process parameters described in this embodiment is:

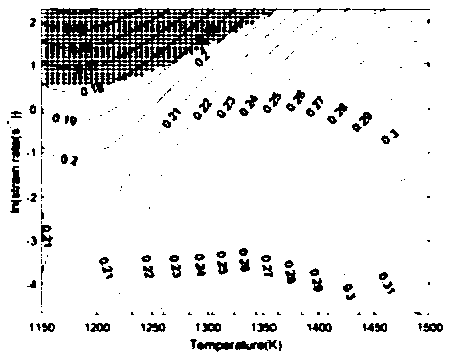

[0043] 1) Heat the boron-containing micro-alloyed steel sample at a rate of 10K / s to 1500K, and keep it for 3-5 minutes; then cool it to 1150-1500K at a rate of 3K / s, and keep it for 2-3 minutes; , at the deformation rate After isothermal compression to true strain ε=0.7, the true stress σ data, true strain ε data and σ-ε curves of the boron-containing microalloy steel during plastic deformation at high temperature were obtained.

[0044] 2) According to the σ-ε curve, set the true stress σ, true strain ε, deformation temperature T and deformation rate The functional relationship between

[0045]

[0046] In formula (1): a 0 、a 1 、a 2 ...a 11 Indicates different regression coefficients; the acquisition of the regression coefficients: th...

Embodiment 2

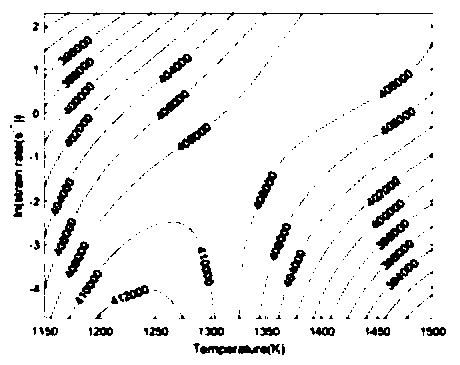

[0070] A method for determining hot forming process parameters of boron-containing microalloy steel. The determination method of the boron-containing microalloy steel hot forming process parameters described in this embodiment is:

[0071] 1) Heat the boron-containing micro-alloyed steel sample at a rate of 10K / s to 1500K, and keep it for 3-5 minutes; then cool it to 1150-1500K at a rate of 3K / s, and keep it for 2-3 minutes; , at the deformation rate After isothermal compression to true strain ε=0.7, the true stress σ data, true strain ε data and σ-ε curves of the boron-containing microalloy steel during plastic deformation at high temperature were obtained.

[0072] 2) According to the σ-ε curve, set the true stress σ, true strain ε, deformation temperature T and deformation rate The functional relationship between

[0073]

[0074] In formula (1): a 0 、a 1 、a 2 ...a 11 Indicates different regression coefficients; the acquisition of the regression coefficients: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com