Determining method of bainite steel hot forming process window

A bainitic steel, determination method technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of microscopic defects in the deformation area, and achieve the goal of improving product quality, reducing development costs and saving development time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for determining the hot forming process window of bainitic steel. The chemical composition (by mass percentage) of the bainitic steel described in this embodiment is:

[0042] 0.053C-0.310Si-1.567Mn-0.014P-0.005S-0.246Mo-0.014Ti-0.236Ni-0.0012.

[0043] The dimensions of the bainitic steel specimens are

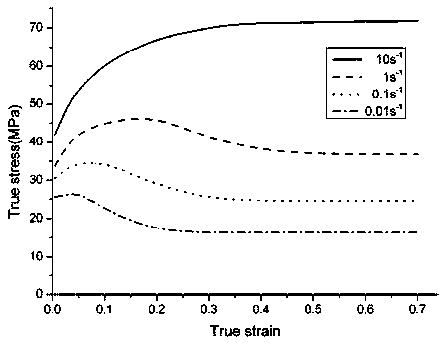

[0044]1) Heat the bainitic steel sample to 1500K at a rate of 10K / s, and keep it for 3-5 minutes; then cool it to 1150-1500K at a rate of 3K / s, and keep it for 2-3 minutes; then at the same temperature, at deformation rate Isothermal compression to the true strain ε = 0.7, to obtain the true stress σ and true strain ε data of the bainite steel during plastic deformation at high temperature, as follows: figure 2 The σ-ε curve shown.

[0045] 2) According to the σ-ε curve, set the true stress σ, true strain ε, deformation temperature T and deformation rate The functional relationship between

[0046]

[0047] In formula (1): a 0 、a 1 、a 2 ...a ...

Embodiment 2

[0065] A method for determining the hot forming process window of bainitic steel. The chemical composition (by mass percentage) of the bainitic steel described in this embodiment is:

[0066] 0.053C-0.310Si-1.567Mn-0.014P-0.005S-0.246Mo-0.014Ti-0.236Ni-0.0012.

[0067] The dimensions of the bainitic steel specimens are

[0068] 1) Heat the bainitic steel sample to 1500K at a rate of 10K / s, and keep it for 3-5 minutes; then cool it to 1150-1500K at a rate of 3K / s, and keep it for 2-3 minutes; then at the same temperature, at deformation rate After isothermal compression to true strain ε=0.7, the true stress σ and true strain ε data of bainite steel during plastic deformation at high temperature are obtained, and the σ-ε curve is obtained.

[0069] 2) According to the σ-ε curve, set the true stress σ, true strain ε, deformation temperature T and deformation rate The functional relationship between

[0070]

[0071] In formula (1): a 0 、a 1 、a 2 ...a 11 Indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com