Integrated directly-buried double-pipe fixing joint for directly-buried heat supply pipeline and calculation method of integrated directly-buried double-pipe fixing joint

A technology for heating pipes and fixing joints, which is applied in calculation, pipe support, computer-aided design, etc., can solve the problems that specifications cannot fully meet the needs, labor-intensive, time-consuming, and H-shaped steel instability, etc., so as to improve construction efficiency and application The effect of expanding the scope and ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

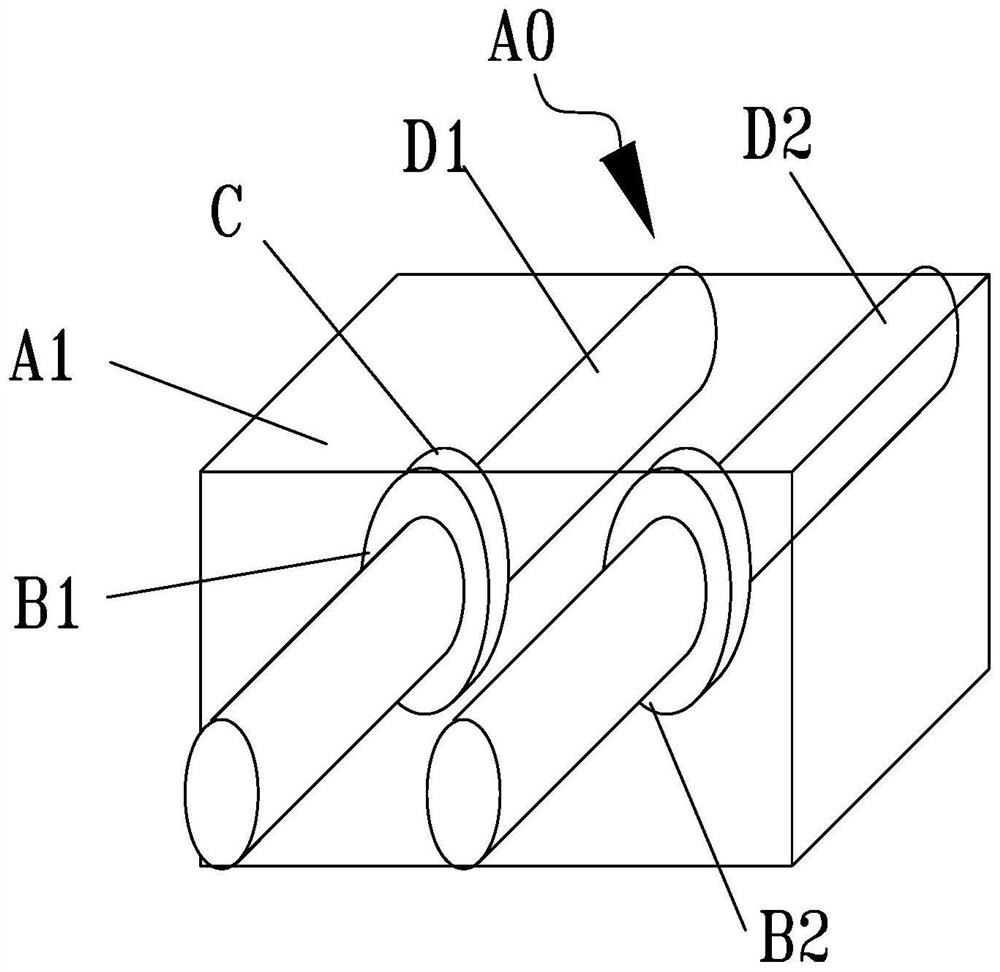

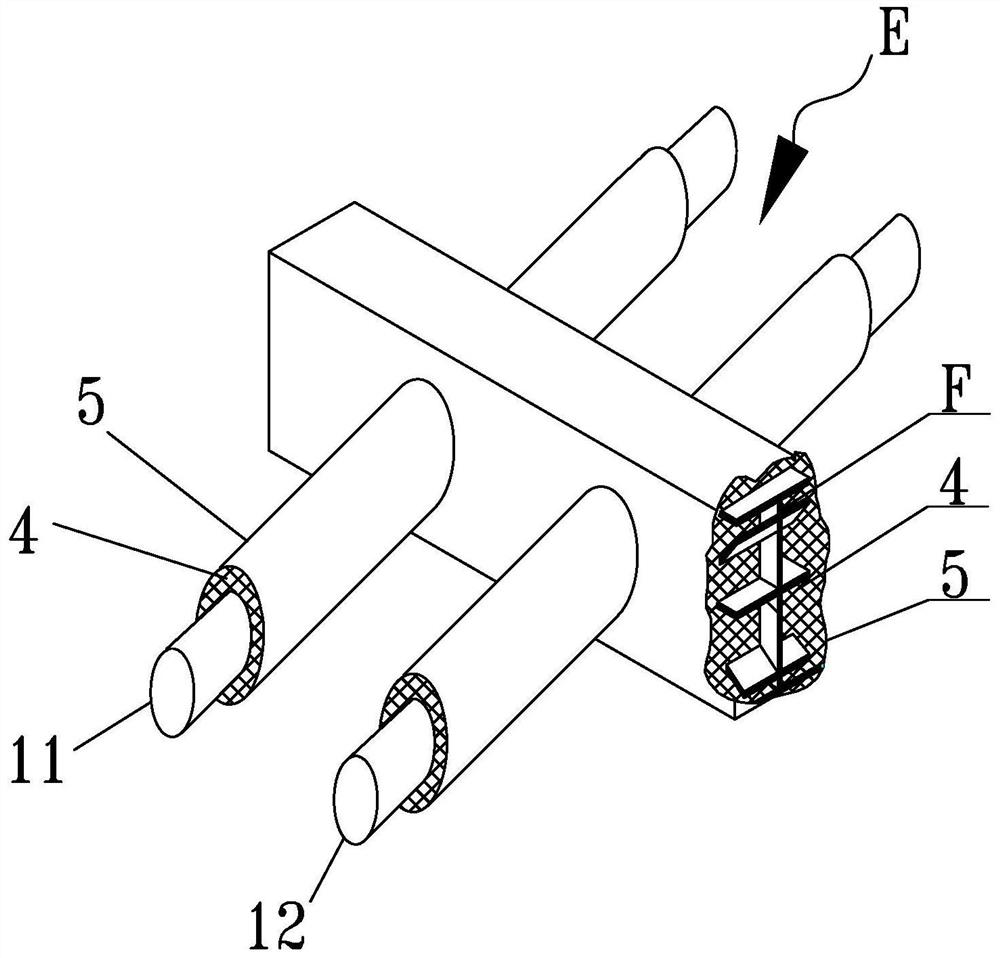

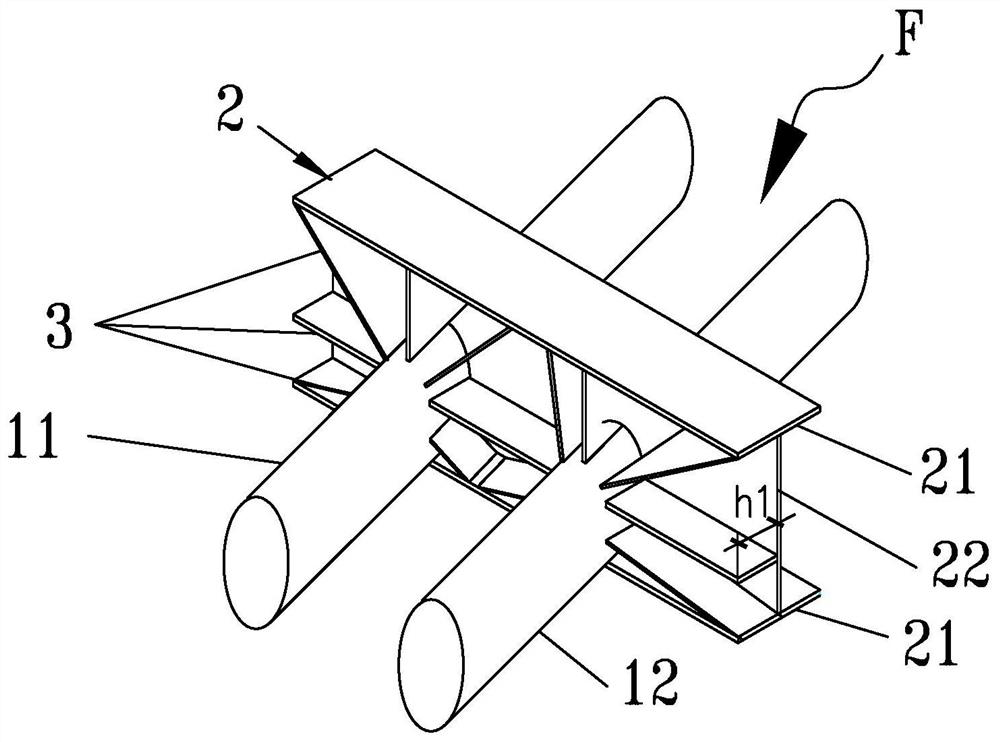

[0078] Figure 2-6 An integrated direct-buried double-pipe fixed joint E for direct-buried heating pipelines is shown, which is characterized in that it includes a double-pipe fixed joint main body F composed of an H-shaped member 2 and water supply and return pipe sections 11 and 12. The H-shaped member is composed of a web 22 and two wings 21 that are symmetrical and vertically connected to the top edge and the bottom edge thereof, and the dimensional values of the web and the two wings are values calculated according to the use requirements; in the web of the H-shaped member On the plate 22, holes for the water supply and return pipe sections are arranged symmetrically along the center of the horizontal center line, and the water supply and return pipe sections 11 and 12 respectively pass through the holes of the water supply and return pipe sections vertically through the web and are arranged symmetrically on both sides of the web. On the side, the water supply and ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com