Steel for glass lining and manufacturing method of steel

A manufacturing method and glass-lined technology, applied in the field of metal materials and their manufacturing, can solve problems such as poor low-temperature toughness and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

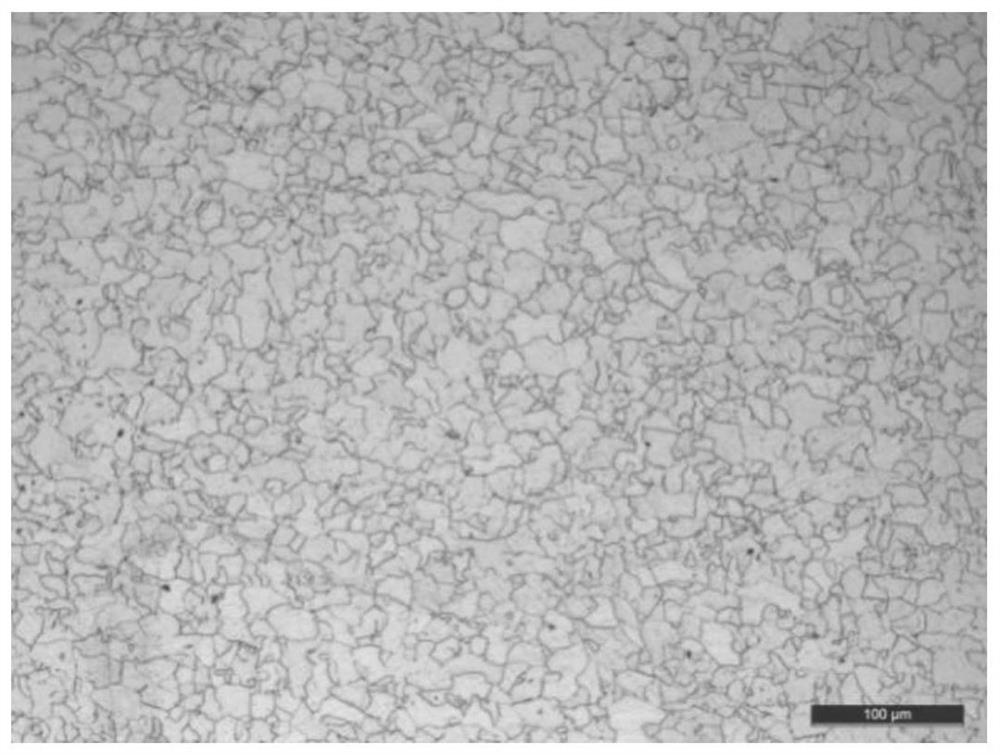

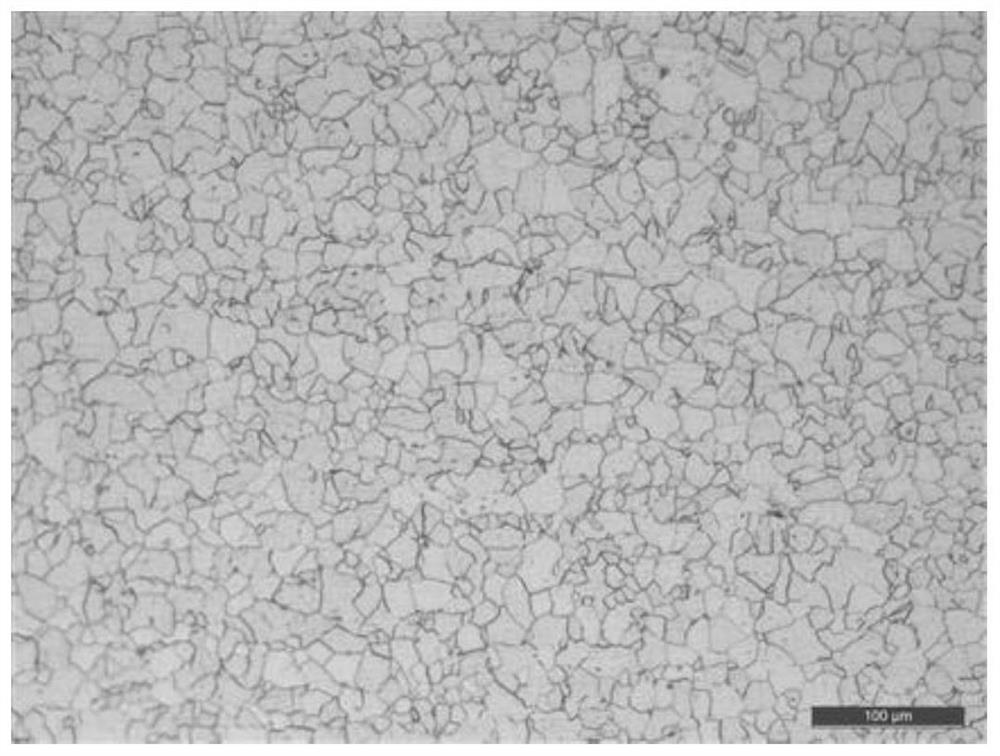

Image

Examples

Embodiment 1-6

[0075] Glass-lined steel of the present invention adopts following steps to make:

[0076] (1) Smelting, refining, and continuous casting to obtain slabs.

[0077] (2) Heating: The heating temperature is 1050-1250°C.

[0078] (3) Hot rolling: Control the temperature at the end of hot rolling to be 800-920°C.

[0079] (4) Cooling: use air cooling or water cooling, when using air cooling, cool to room temperature; when using water cooling, control the final cooling temperature to 650~750°C, and the cooling rate is not more than 50°C / s.

[0080] (5) Heat treatment: The heat treatment temperature is 880-980°C.

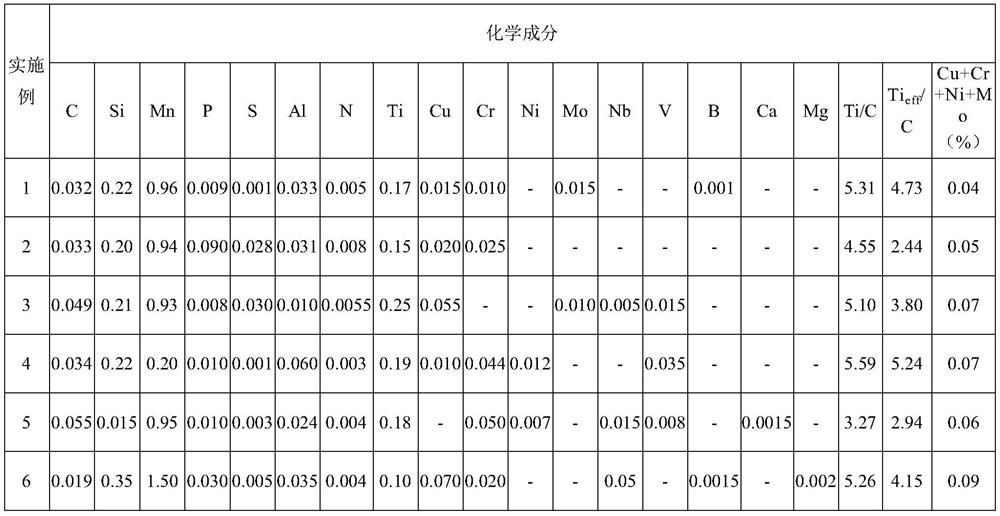

[0081] Table 1 lists the mass percentage distribution ratio of each chemical element in the glass-lined steel of Examples 1-6.

[0082] Table 1. (wt%, the balance is Fe and other unavoidable impurities)

[0083]

[0084] Table 2 lists the specific process parameters of each step of the manufacturing method of Examples 1-6.

[0085] Table 2.

[0086]

[0087] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com