A semi-hard machining process for electromagnetic wire

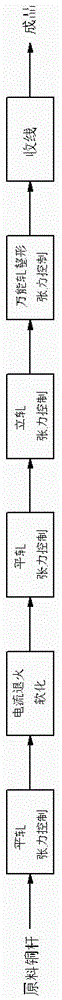

A processing technology and technology of electromagnetic wire, applied in the field of semi-hard processing technology of electromagnetic wire, can solve the problems of unstable semi-hard quality of electromagnetic wire, uneven cross-sectional size of electromagnetic wire conductor, etc., and achieve the effect of ensuring size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

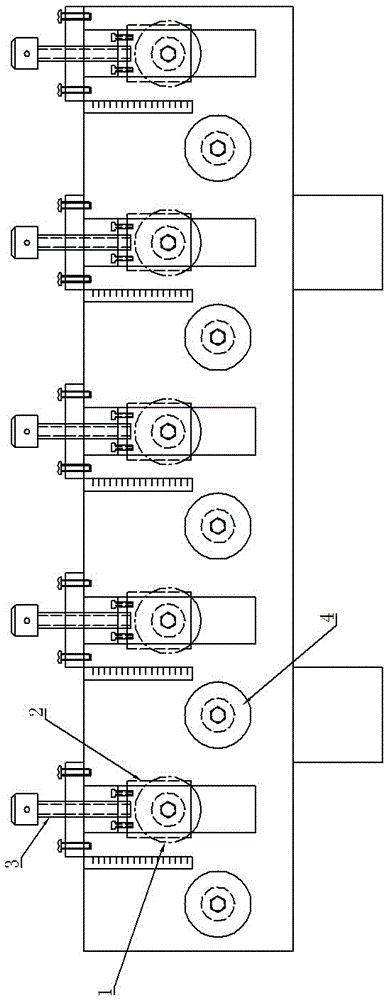

[0022] The raw copper rod is processed by the finishing mill through two flat rolling processes to obtain the billet, and then the billet is softened by means of electric current annealing. , Continuous heating is carried out in the oven, wherein the heating of the annealing furnace adopts a three-stage continuous heating method, the heating temperature T1 of the first section is 550°C, the heating temperature T2 of the second section is 530°C, and the heating temperature T3 of the third section is 480°C, the heating temperature of the oven is 240°C, the speed of the billet passing through the annealing furnace and the oven is 8m / min; The universal rolling machine performs universal rolling and shaping treatment on the electromagnetic wire, and then the wire is taken up by the wire take-up machine and packaged to the finished product. After testing, the yield strength of the magnet wire is 310N / mm 2 ; In each flat rolling process, vertical rolling process and universal rollin...

Embodiment 2

[0024] The raw copper rod is processed by a finishing mill to obtain a billet after a flat rolling process, and then the billet is softened by means of electric current annealing. Continuous heating is carried out in the oven, and the heating of the annealing furnace adopts a three-stage continuous heating method. The heating temperature T1 of the first section is 570°C, the heating temperature T2 of the second section is 520°C, and the heating temperature T3 of the third section is 500°C. ℃, the heating temperature of the oven is 240 ℃, the billet passes through the annealing furnace, and the speed in the oven is 5 m / min; The universal rolling machine performs universal rolling and shaping treatment on the electromagnetic wire, and then the wire is taken up by the wire take-up machine and packaged to the finished product. After testing, the yield strength of the magnet wire is 317N / mm 2 ; In each flat rolling process, vertical rolling process and universal rolling shaping pr...

Embodiment 3

[0026] The raw copper rod is processed by the finishing mill through two flat rolling processes to obtain the billet, and then the billet is softened by means of electric current annealing. , Continuous heating is carried out in the oven, wherein the heating of the annealing furnace adopts a three-stage continuous heating method, the heating temperature T1 of the first section is 580°C, the heating temperature T2 of the second section is 550°C, and the heating temperature T3 of the third section is 470°C, the heating temperature of the oven is 240°C, the billet passes through the annealing furnace and the oven at a speed of 10m / min; The universal rolling machine performs universal rolling and shaping treatment on the electromagnetic wire, and then the wire is taken up by the wire take-up machine and packaged to the finished product. After testing, the yield strength of the magnet wire is 323N / mm 2 ; In each flat rolling process, vertical rolling process and universal rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com