System and method for preparing longitudinal submerged arc welding (LSAW)

A technology of longitudinal submerged arc welding and welded pipes, which is applied in the system field of preparing longitudinal submerged arc welded pipes, can solve the problems of unstable yield strength and tensile properties, achieve the effect of reducing the fluctuation range and improving the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

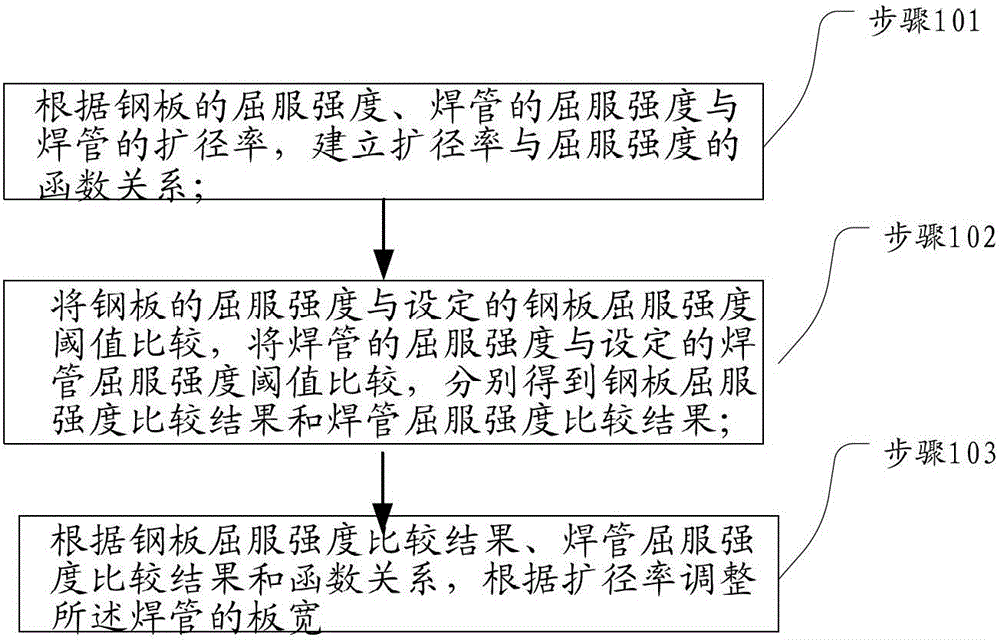

[0019] A system for preparing longitudinal submerged arc welded pipes provided by an embodiment of the present invention includes a diameter expansion rate relationship module, a function judgment module, and a plate width adjustment module;

[0020] The diameter expansion rate relationship module, according to the yield strength of the steel plate, the yield strength of the welded pipe and the diameter expansion rate of the welded pipe, establishes the functional relationship between the diameter expansion rate and the yield strength;

[0021] The function judgment module is used to compare the yield strength of the steel plate with the set steel plate yield strength threshold, compare the welded pipe yield strength with the set welded pipe yield strength threshold, and obtain the steel plate yield strength comparison result and the welded pipe yield strength comparison result respectively;

[0022] The plate width adjustment module adjusts the plate width of the welded pipe a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com