Constant-tension taping machine

A tape wrapping machine, constant tension technology, applied in electrical components, circuits, conductor/cable insulation, etc., can solve the problem of unstable tape tension value of tape unwinding device, difficult manufacturing, processing and maintenance, affecting cable product packaging With quality and other issues, to achieve the effect of improving dynamic balance and stability, high real-time feasibility, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

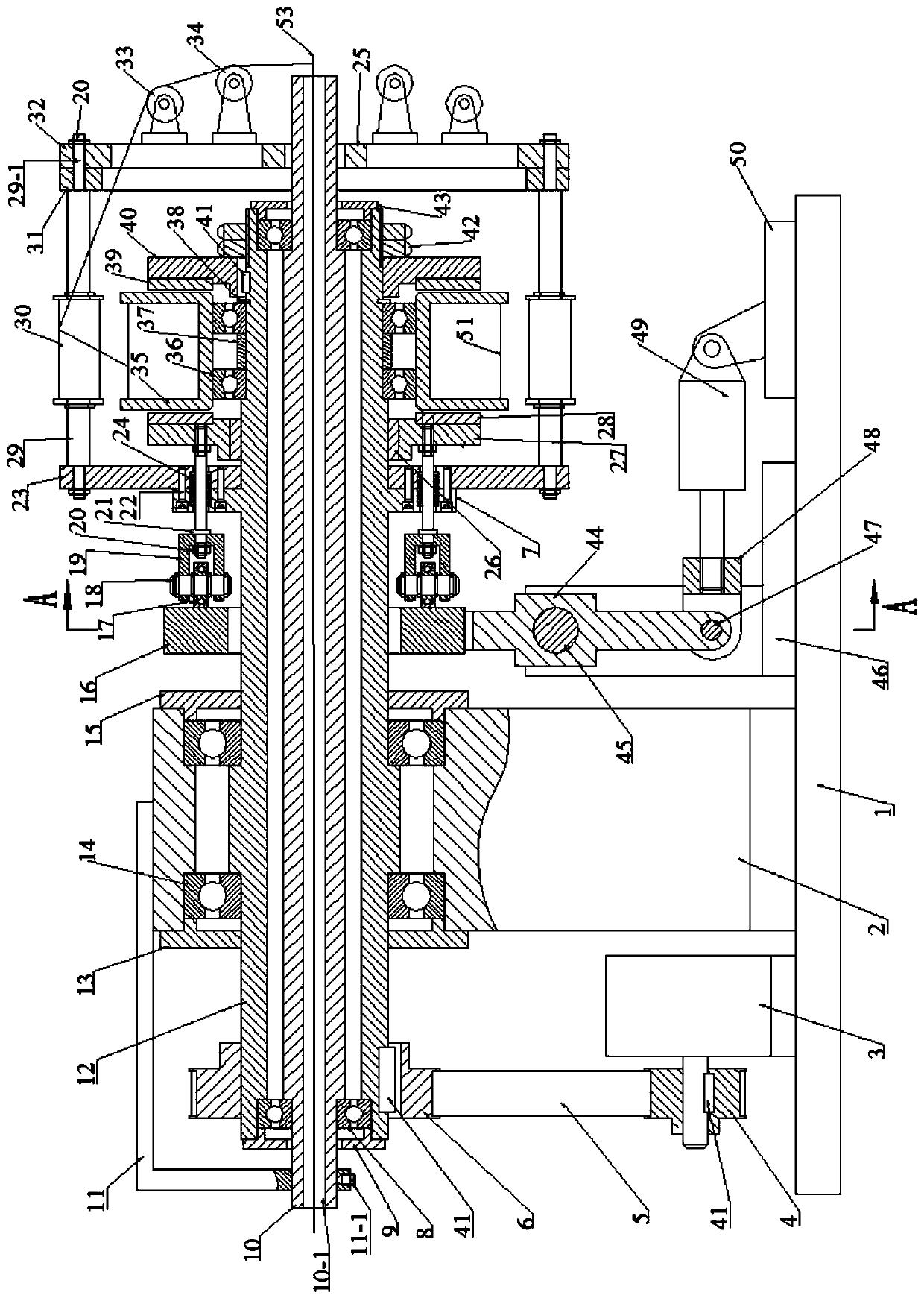

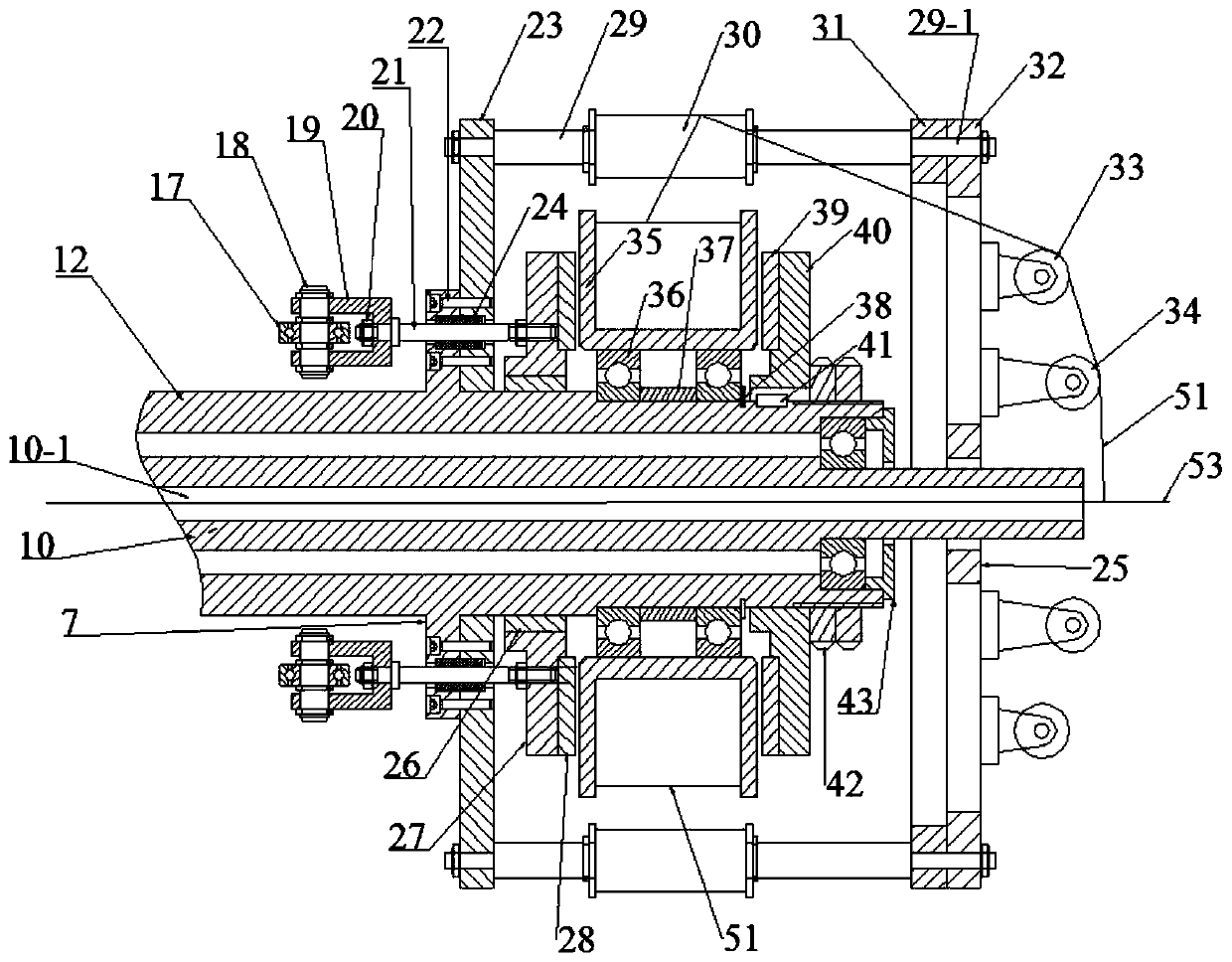

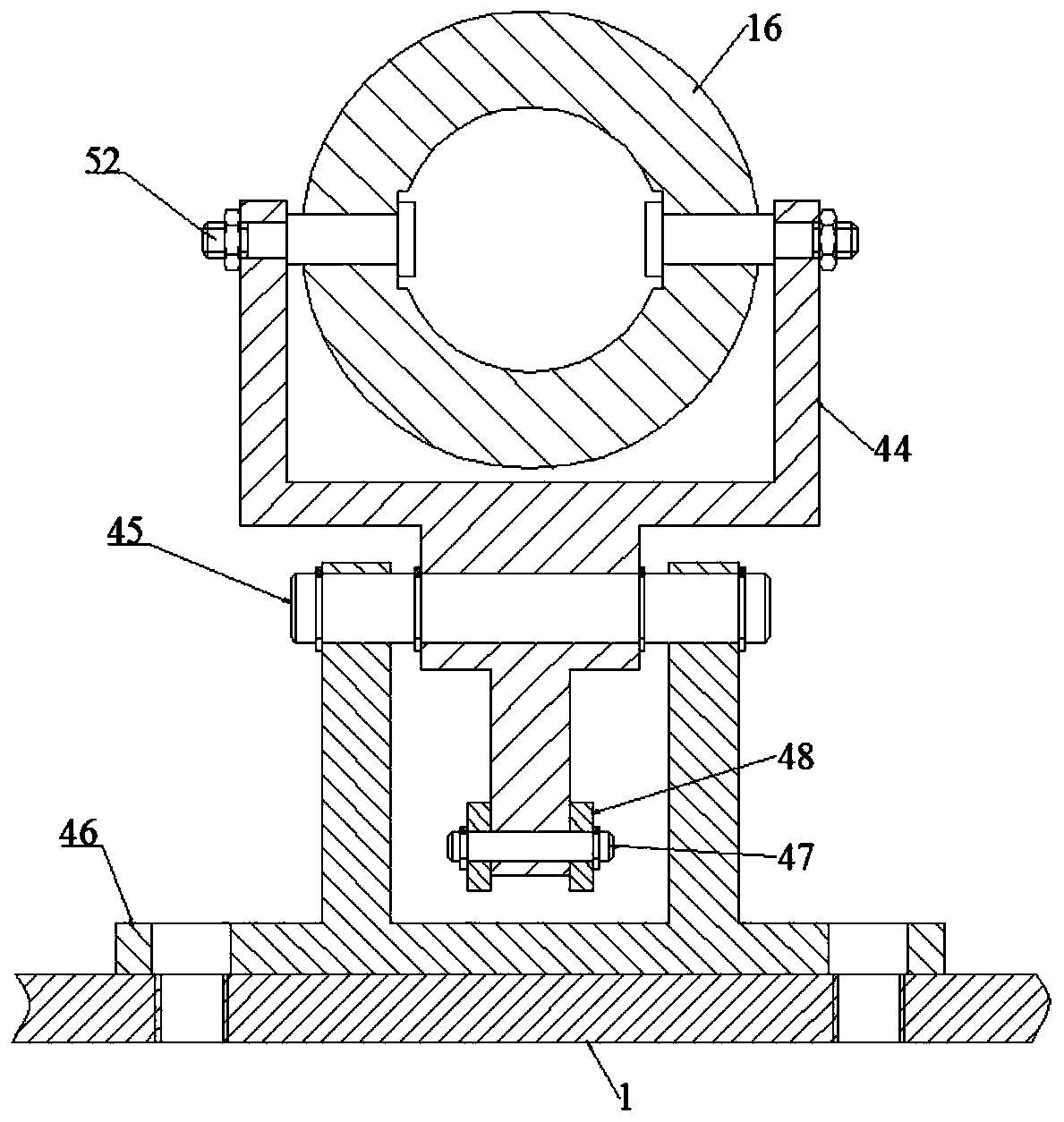

[0029] Such as Figure 1~3 As shown, the present invention is a constant tension taping machine, comprising a base plate 1, a tape unwinding device, a tape wrapping device and a controller. The upper end of the fixed seat 2 is provided with a main shaft 12 for rotation, and the main shaft 12 is connected to the first driving mechanism 3 through transmission. An inner shaft 10, the inner shaft 10 is provided with a wire passing hole 10-1 through the axis, both ends of the inner shaft 10 extend outside the main shaft 12, and one end and / or both ends of the inner shaft 10 are connected to the base plate 1 Fixedly connected, the first driving mechanism 3 is connected with the controller; the tape unwinding device includes a tension adjustment mechanism, a left baffle plate 27, a tape storage drum 35, and a right baffle plate 40, and the tension adjustment mechanism is connected with the controller , the right end of the main shaft 12 is screwed and fixed with a double nut 42, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com