Carbon product roasting furnace

A roasting furnace and roasting technology, applied in the preparation/purification of carbon, etc., can solve problems such as environmental pollution, unsatisfactory, high temperature and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

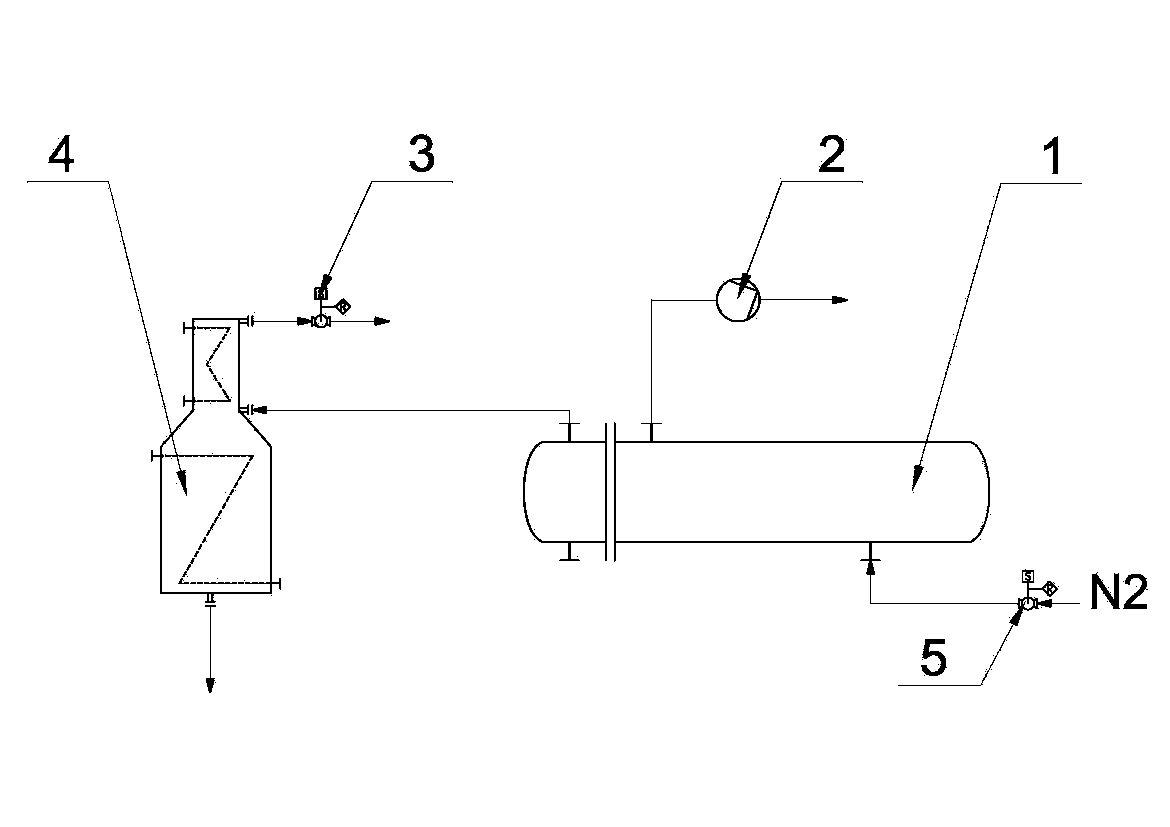

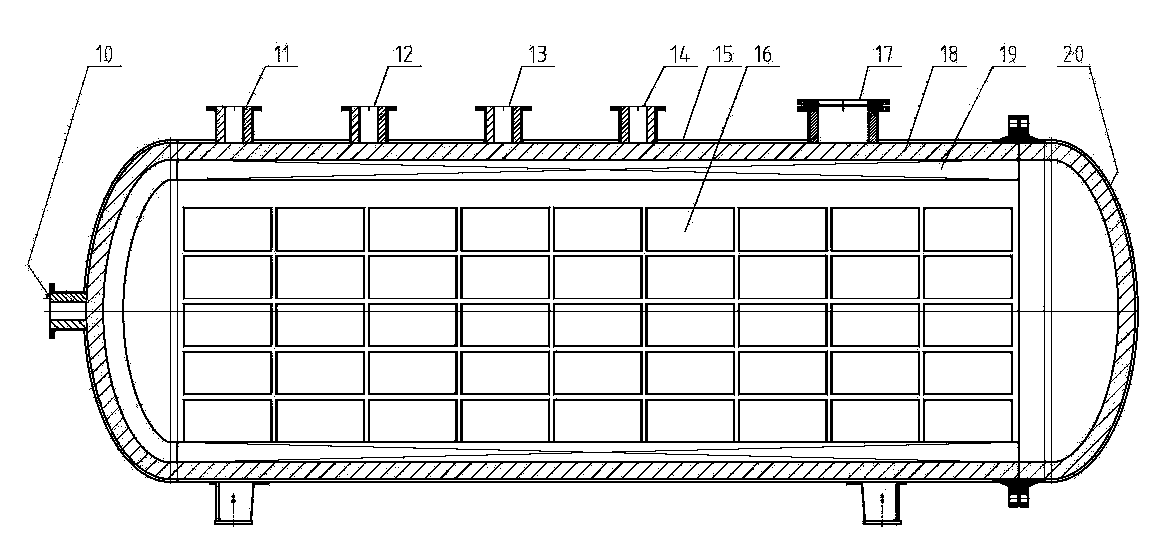

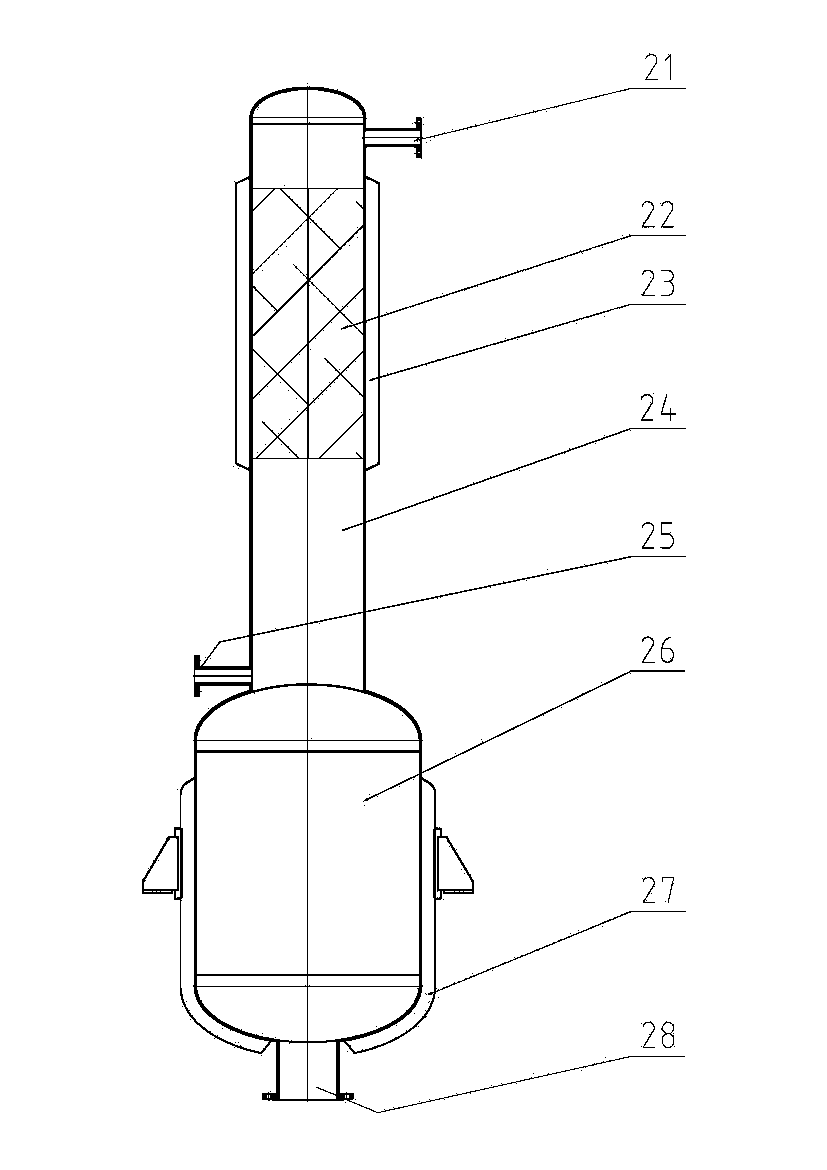

[0024] Illustrate in conjunction with the following examples with the carbon product roasting furnace involved in the present invention:

[0025] Example : Roast and press blanks with the carbon product roasting furnace involved in the present invention, put 20 pieces of carbon product blanks formed by isostatic pressing of φ200×500 into the furnace hearth of the roasting tank 1 in a naked shape, and do not use granular coke as the charging charge when charging the furnace. The technical conditions of the compact are shown in Table 1.

[0026] Table 1 Technical conditions of compact

[0027]

[0028] Start the vacuum pump 2 to evacuate the system. The vacuum degree of the system should reach above -0.09 MPa and maintain for 1 hour. After closing the valve of the vacuum line, nitrogen gas was introduced. Slowly increase the pressure, and the system will increase the pressure in the system to 0.02MPa(G) through the pressure control valve 5, and the pressure will be automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com