Fuel injection system

A fuel injection system, injection system technology, applied to fuel injection pumps, fuel injection devices, charging systems, etc., to achieve small current requirements, improve overall power efficiency, and reduce power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

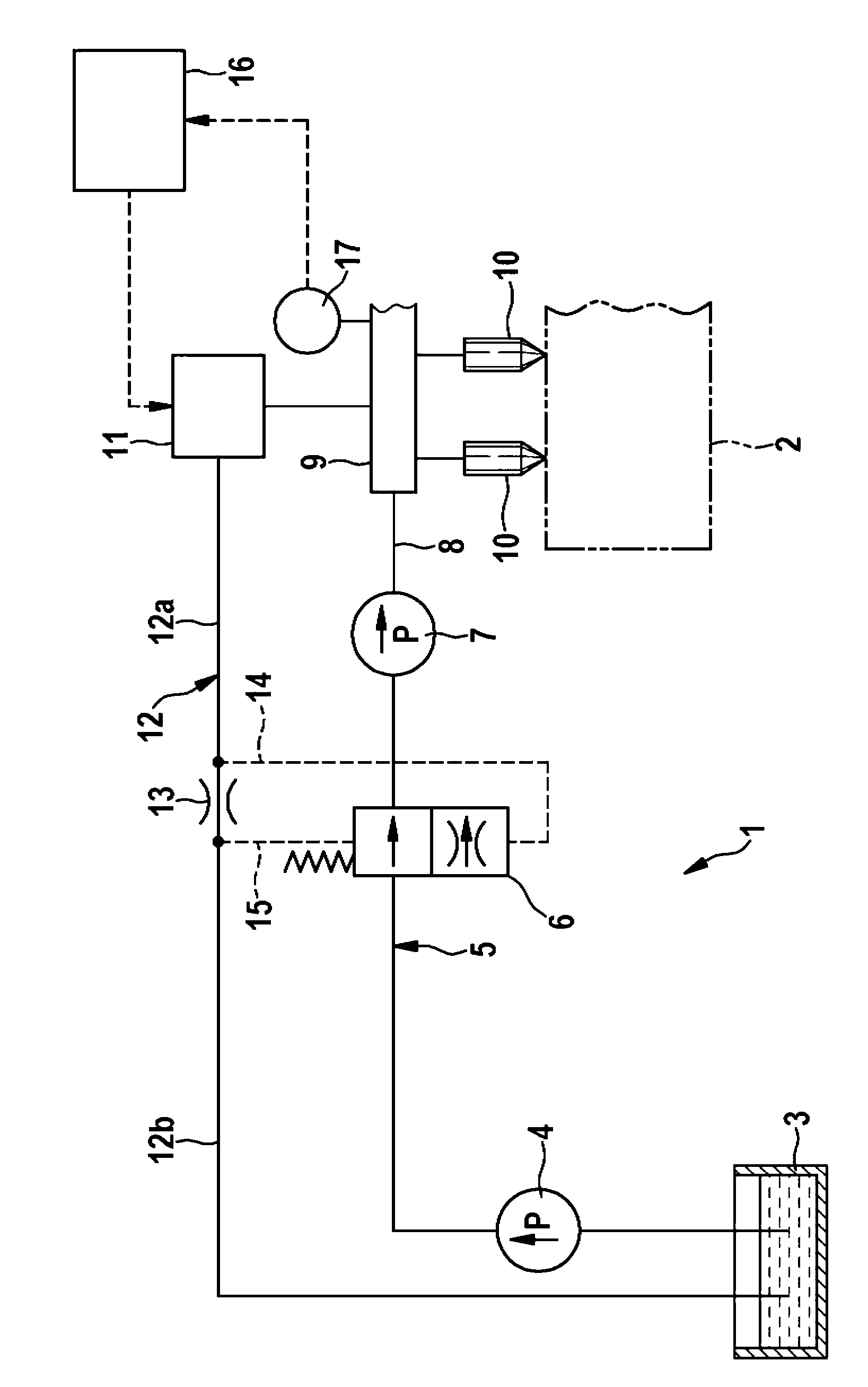

[0024] FIG. 1 shows a prior art fuel injection system 1 for supplying an internal combustion engine 2 , however it is only schematically represented in FIG. 1 by dotted lines. The fuel injection system 1 comprises a fuel container 3 from which an electrically driven fuel delivery pump 4 delivers fuel into a low-pressure line 5 to a measuring unit 6 . Downstream of the measuring unit 6 , the low-pressure line 5 feeds a high-pressure pump 7 mechanically driven by the internal combustion engine 2 . The high-pressure pump 7 compresses the fuel to a very high pressure and delivers them via the high-pressure line 8 into a high-pressure accumulator 9, also called a "rail". A plurality of injectors 10 are connected to said rails, injecting fuel into the combustion chambers of the internal combustion engine 2, not shown.

[0025] The exhaust control valve 11 is connected to the high-pressure accumulator 9 , and the exhaust pipeline 12 is controlled by the exhaust control valve 11 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com