Blocking tool in oil pipe

A tool and oil pipe technology, which is applied in the field of plugging tools in the oil pipe, can solve the problems of unrecoverable, large plugging depth error, seat hanging, etc., and achieve good promotion value, good stability, and adjustable seat hanging depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

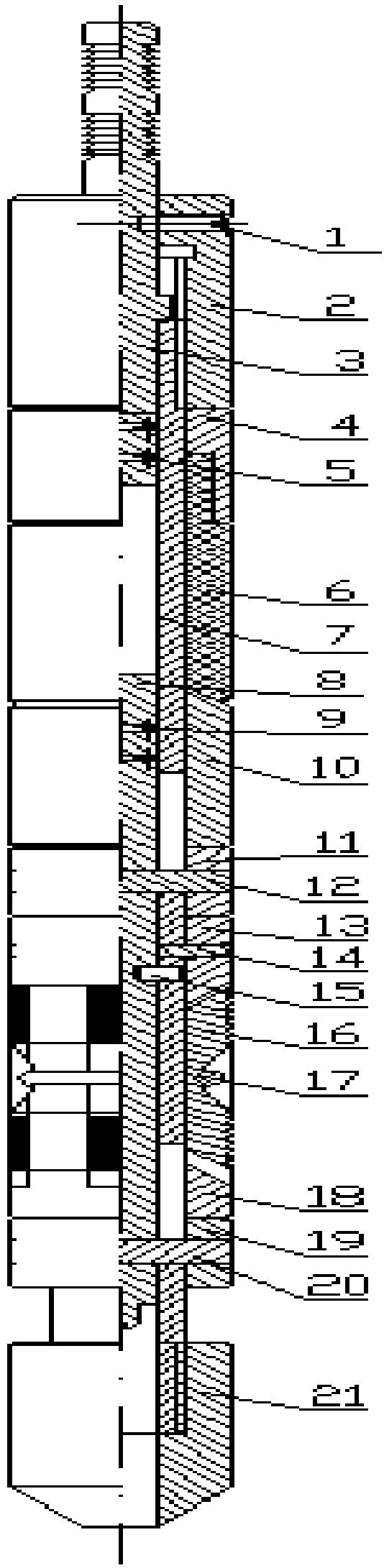

[0024] Such as figure 1 As shown, the embodiment of the present invention provides a plugging tool for oil pipes under pressure, including an unsealing pin 1, an upper end cap 2, an unsealing lance 3, a rubber cylinder gland 4, a first sealing ring 5, Sealing rubber cylinder 6, central tube 7, linkage plunger 8, second sealing ring 9, rubber cylinder expansion sealing cone 10, rubber cylinder expansion sealing push ring 11, first connecting shaft 12, anchor shoe conical base 13, Locking pin 14, seat sealing pin 15, slips 16, cone 18, anchor shoe propulsion ring 19, second connecting shaft 20, variable diameter guide head 21.

[0025] Wherein, the unsealing lance 3 is worn in it from the upper end of the central tube 7, the unsealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com