Combustion device for researching soot characteristics in low-pressure environment

A low-pressure environment and combustion device technology, which is applied in the direction of chemical analysis by means of combustion, can solve problems such as optical path deviation, difficult operation, and impact on results, and achieve the effects of high popularization, easy implementation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

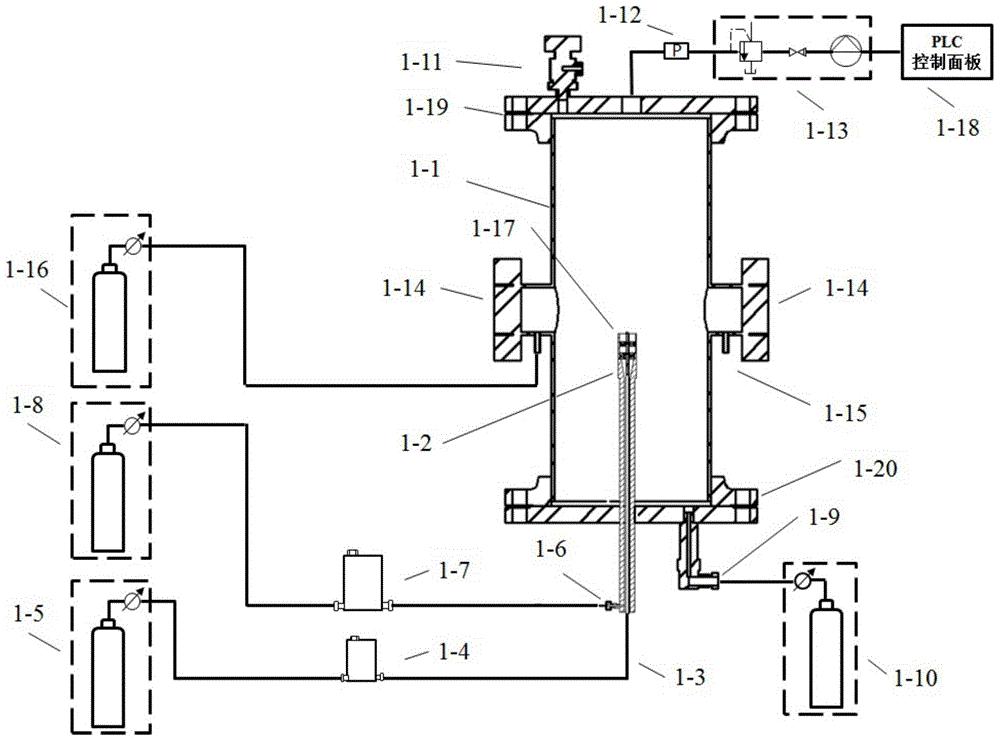

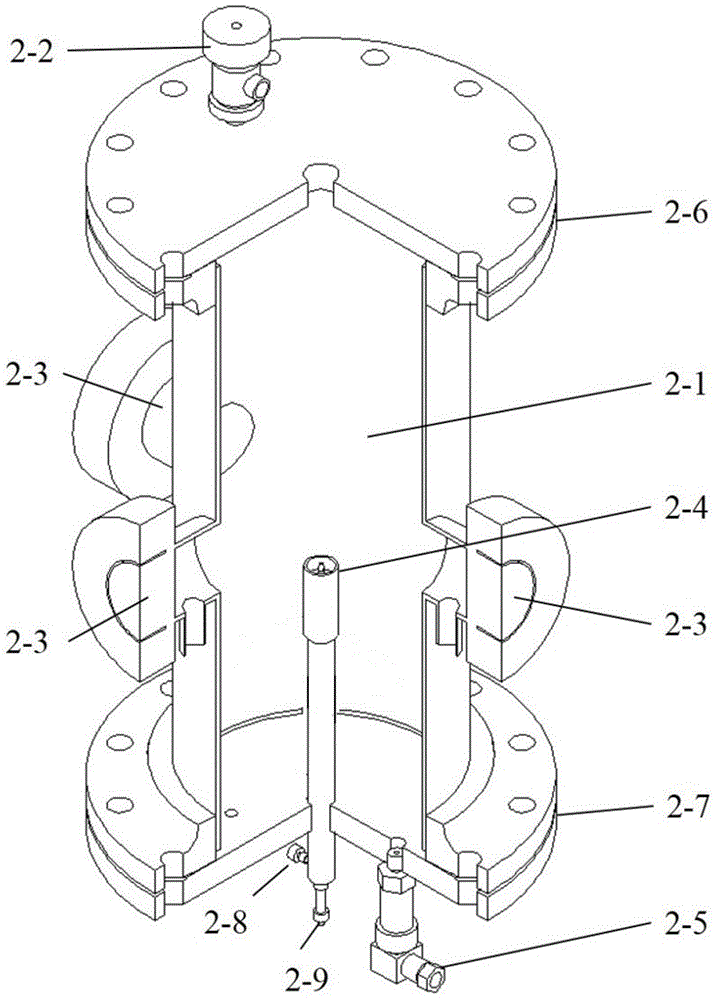

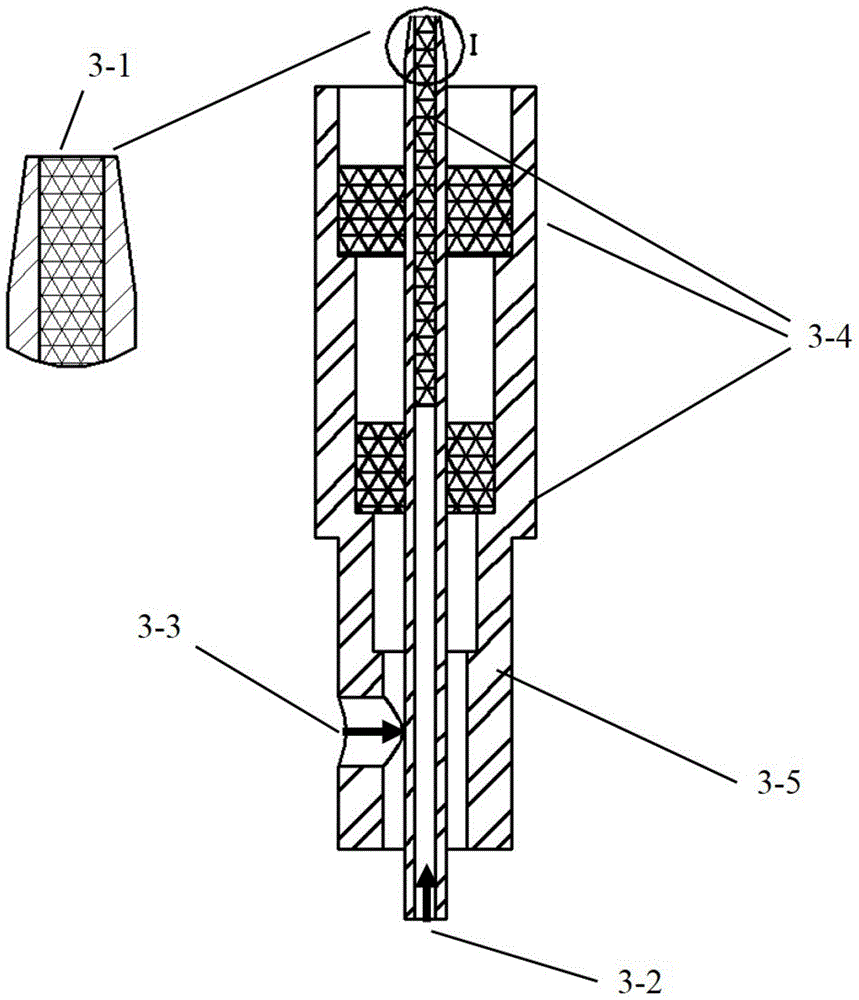

[0021] A kind of combustion device that is used for the soot characteristics research under low-pressure environment, it is characterized in that, this device comprises low-pressure cabin, and cabin body adopts SUS stainless steel to make, and its cabin inner cavity (1-1), the inner diameter of space is 24cm , the height is 60cm, the pressure range of the chamber is 30.0-101.3kPa, which can simulate the low pressure environment; it is sealed by the quick release upper flange (1-19) and the gland type lower flange (1-20). The gas burner (1-2) is welded at the center of the gland type lower flange (1-19) of the cabin body; the burner is composed of two layers of casing and stuffed sintered metal (3-4), and the inner layer is The stainless steel fuel inlet pipe (1-3) has an inner diameter of 3mm, and the outer layer of the burner is a stainless steel follower air inlet pipe (1-7), whose inner diameter is 25mm; Threaded, and connected with the special gas delivery pipe and the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com