Cup body polishing machine and polishing strength control method thereof

A technique for polishing machines and cups, applied in grinding/polishing equipment, grinding automatic control devices, manufacturing tools, etc., which can solve the problems of increasing control difficulty and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

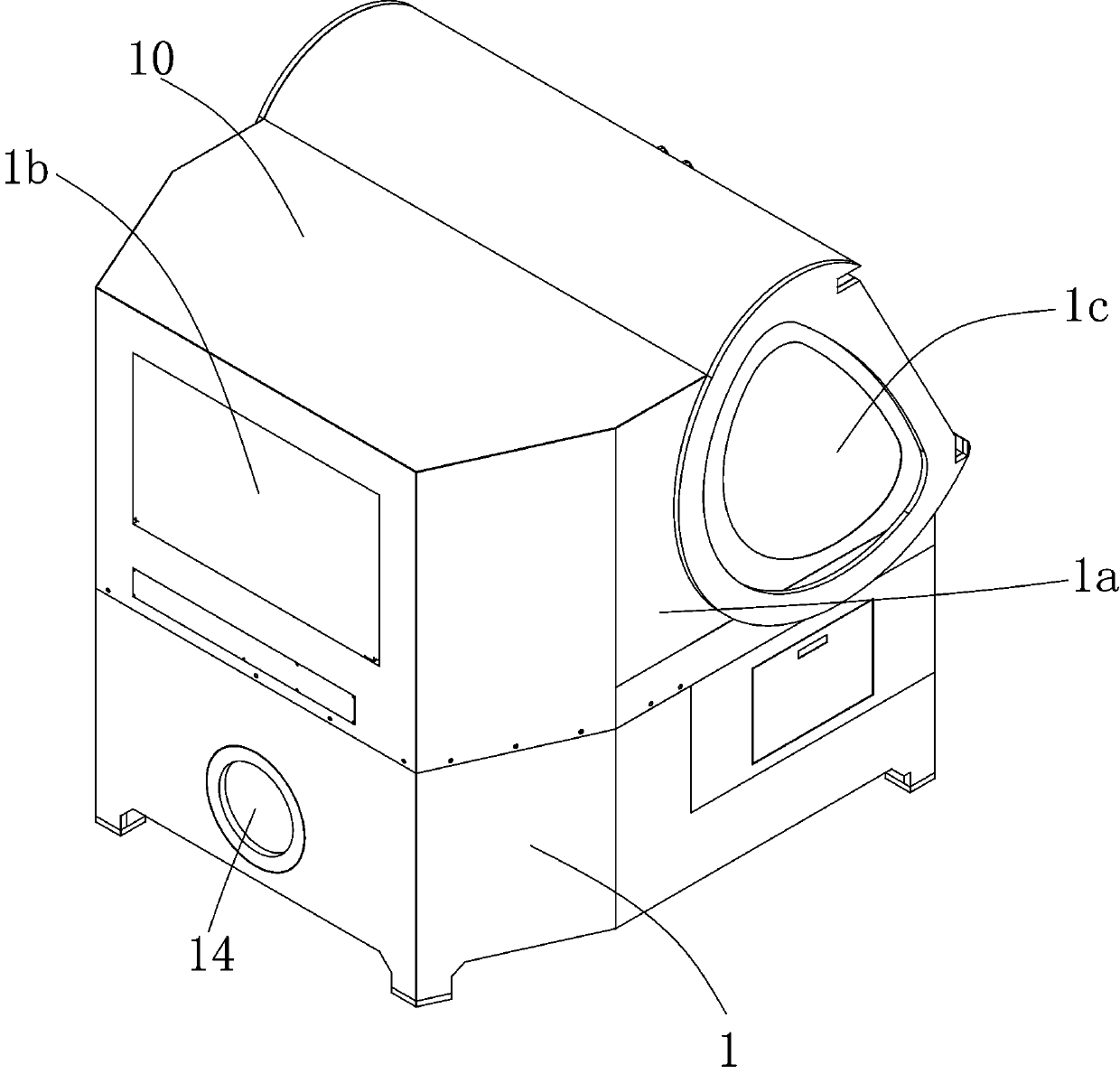

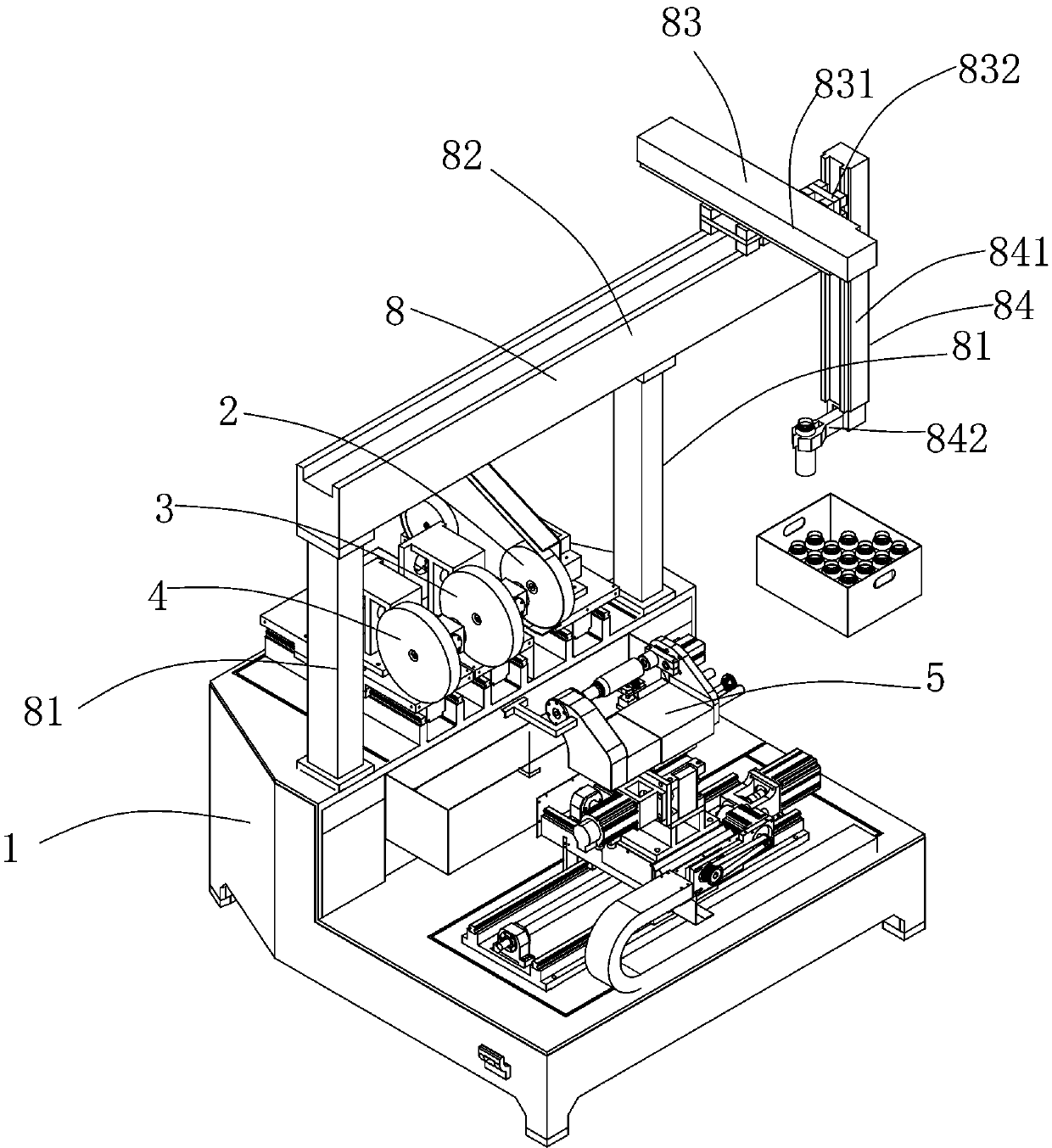

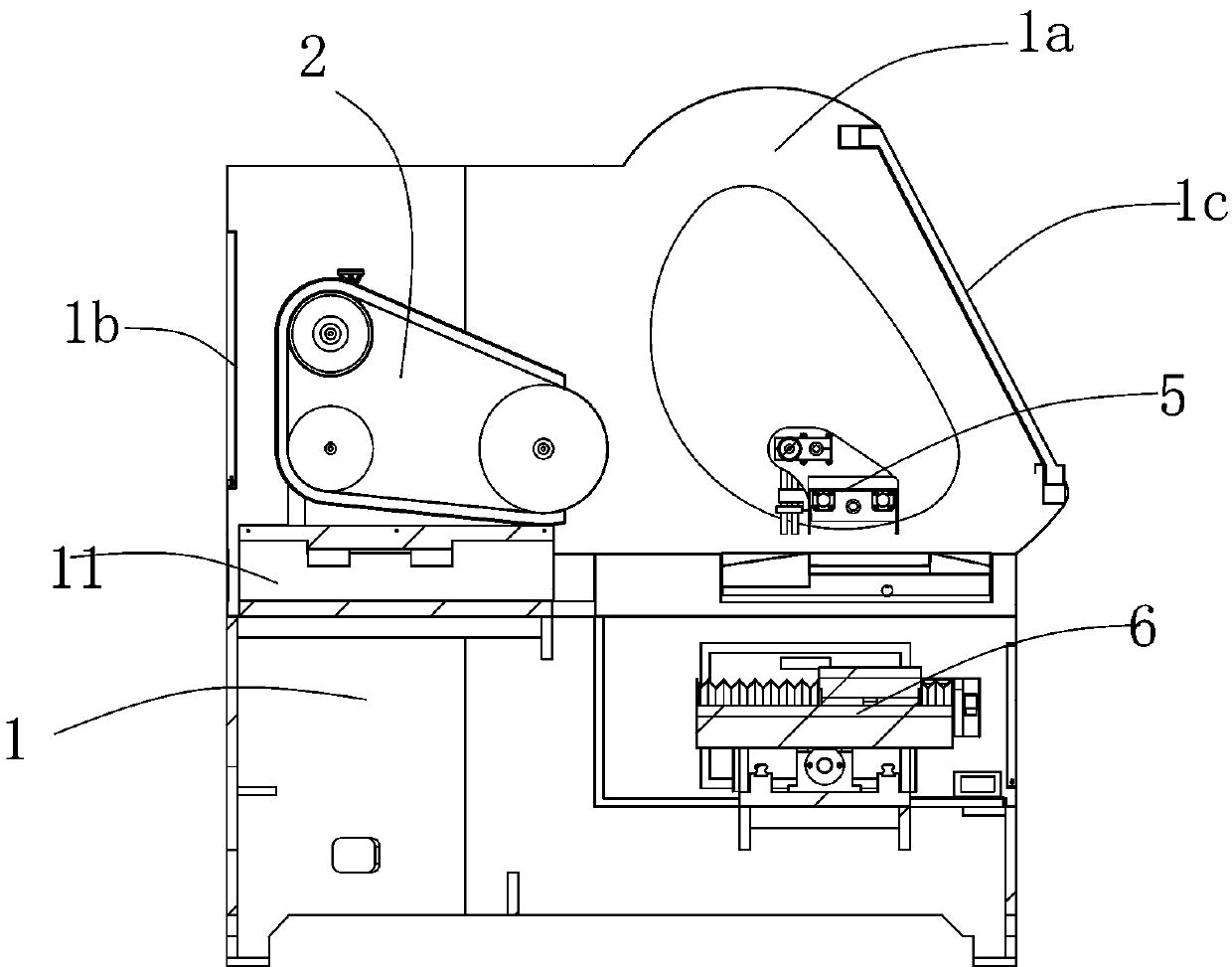

[0026] see Figure 1 to Figure 10 , a kind of cup body polishing machine, comprises base 1, and the top of described base 1 is provided with cover 10, and described cover 10 comprises the surrounding board of outer base circle, and the two sides of each described surrounding board are connected with each other, so The bottom of the enclosure is fixed on the base. And a door 1b that can be opened is provided on one surface of one of the surrounding boards 1a. The cover is also provided with a transparent glass window 1c for easy observation. The metal chips produced during grinding are blocked by the cover and will not spread into the air and the ground, thus avoiding the pollution of the air and the ground and effectively protecting workers. In good health.

[0027] One side of the base 1 near the door 1b is provided with an abrasive belt gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com