Piston automatic quenching device and method based on incomplete solution treatment technology

A technology of solution treatment and quenching device, applied in quenching device, heat treatment furnace, heat treatment equipment and other directions, can solve the problems of manual control and operation difficult to match, the piston is not put in and taken out in time, and the water temperature of the quenching medium is affected. Quenching quality and process consistency, saving energy and man-hours, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

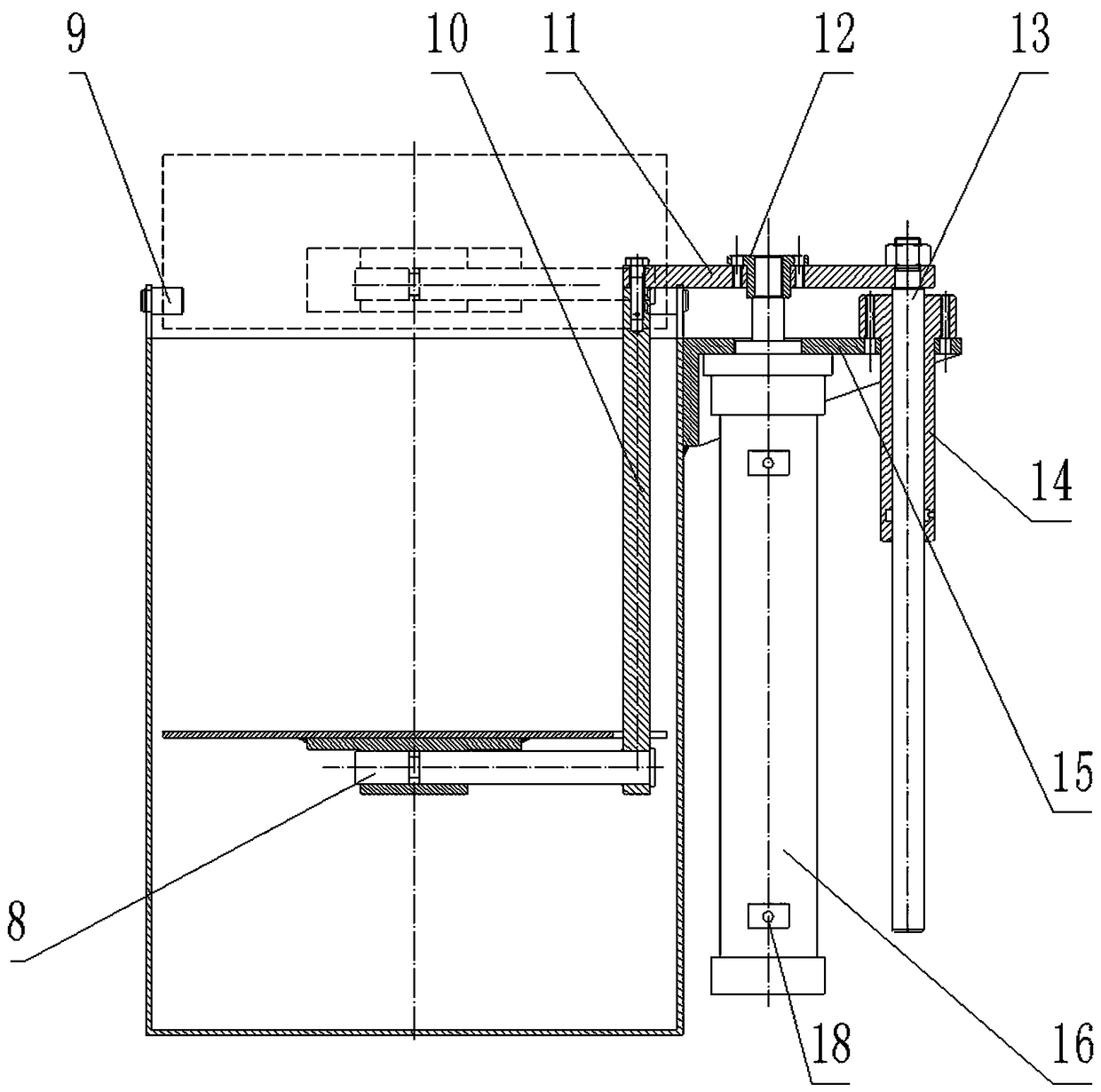

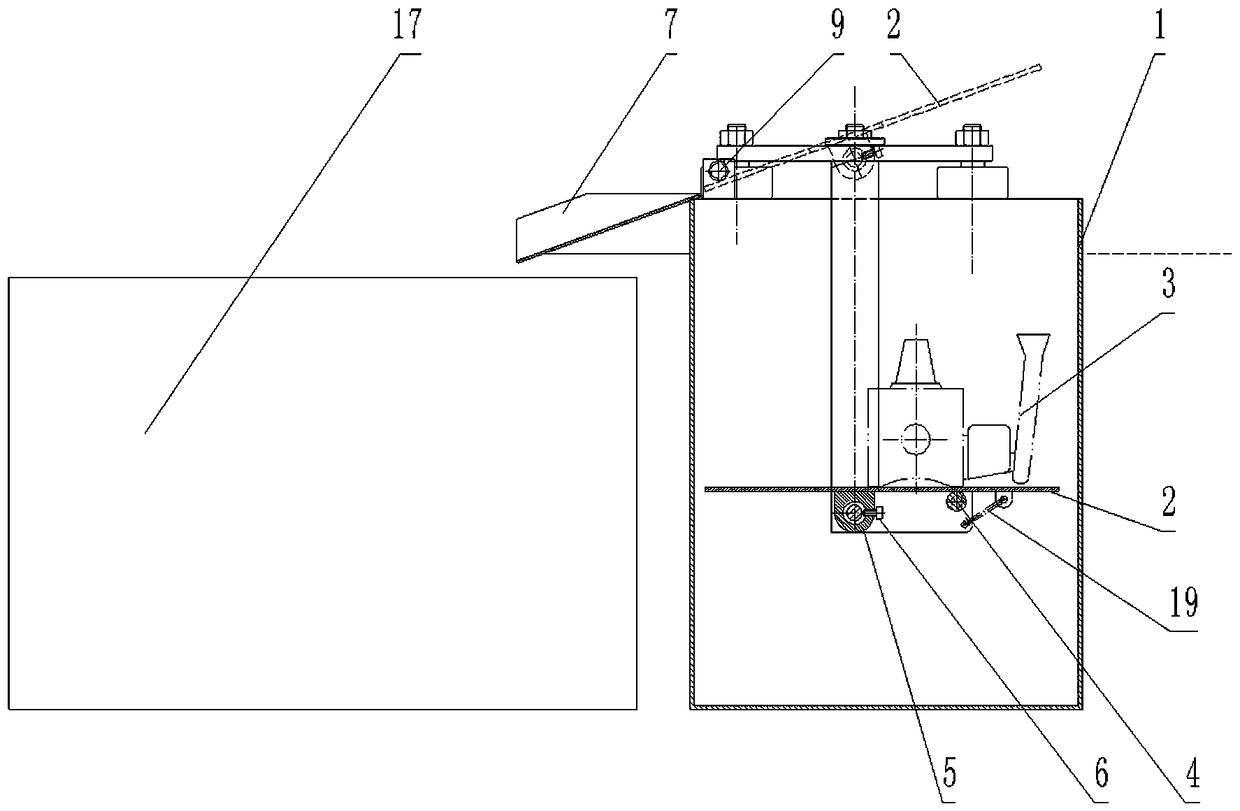

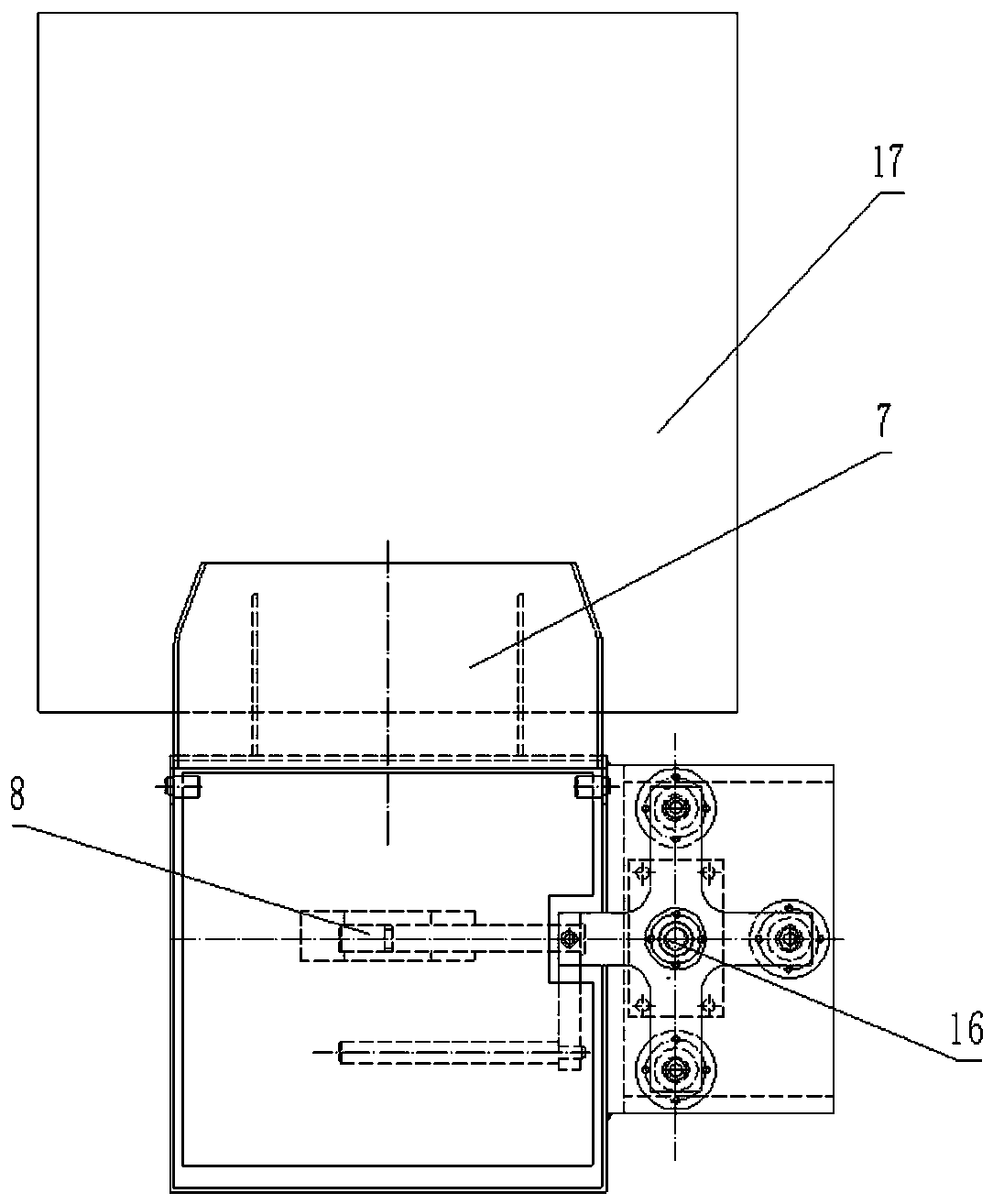

[0026] Such as figure 1 , figure 2 , image 3 It can be seen that the automatic piston quenching device based on the incomplete solution treatment process of the present invention includes a quenching water tank 1, a lifting mechanism is arranged outside the quenching water tank 1, and a receiving plate support 10 is arranged in the quenching water tank 1 along the vertical direction, The lower end of the receiving plate support 10 is provided with a receiving plate support 5 along the horizontal direction, and the receiving plate support 5 is connected with a receiving plate 2, and the lifting mechanism is connected with the described receiving plate support 10; It also includes a material receiving plate tilting device, which is used to drive the material receiving plate 2 to tilt and discharge; it also includes a material receiving device.

[0027] The material receiving plate tilting device includes a material receiving plate rotary support shaft 8 arranged on the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com