Microminiature atomic frequency standard microwave cavity based on microstrip line structure

A technology of atomic frequency standard and microstrip line, which is applied in the field of atomic frequency standard, can solve the problems of limited uniformity, unfavorable high-intensity atomic transition signal, unsuitable for the development of high-performance atomic frequency standard, etc. Concise, guaranteed processing accuracy and consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

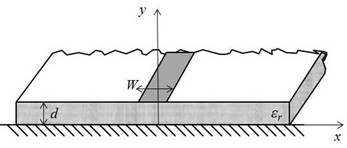

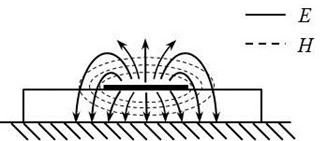

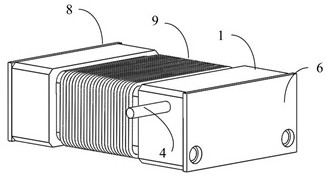

[0039] An ultra-small atomic frequency standard microwave cavity based on a microstrip line structure, including a cavity 1, one end of the cavity 1 is a light outlet 1a, the other end is a light inlet, the inner space of the cavity 1 is a cuboid, and the outer surface of the cavity 1 is circumferentially arranged. There is a wire slot 1b, the C field coil 9 is wound in the wire slot 1b, the light outlet 1a of the cavity 1 is provided with an end cover 6, the inner surface of the end cover 6 is fixed with a photodetector 7, and the light inlet of the cavity 1 is provided with The bottom cover 8 is provided with a light inlet, the cavity 1 is provided with an atomic bubble 3, and the cavity 1 is provided with a microstrip line substrate 2, the microstrip line substrate 2 includes a dielectric substrate 2b and is arranged on The metal conductor 2 a on the dielectric substrate 2 b is bonded to the inner wall of the cavity 1 , and the metal conductor 2 a faces the atomic bubble 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com