Work fixture for processing brake valve body

A tooling fixture and valve body technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the shape and position tolerance of the sealing surface and the dimensional tolerance are difficult to obtain consistent guarantee, the overall operation efficiency is low, and the clamping Cumbersome and difficult problems, to achieve the effect of simple and fast rotation operation, compact structure, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing of description, the present invention will be further described.

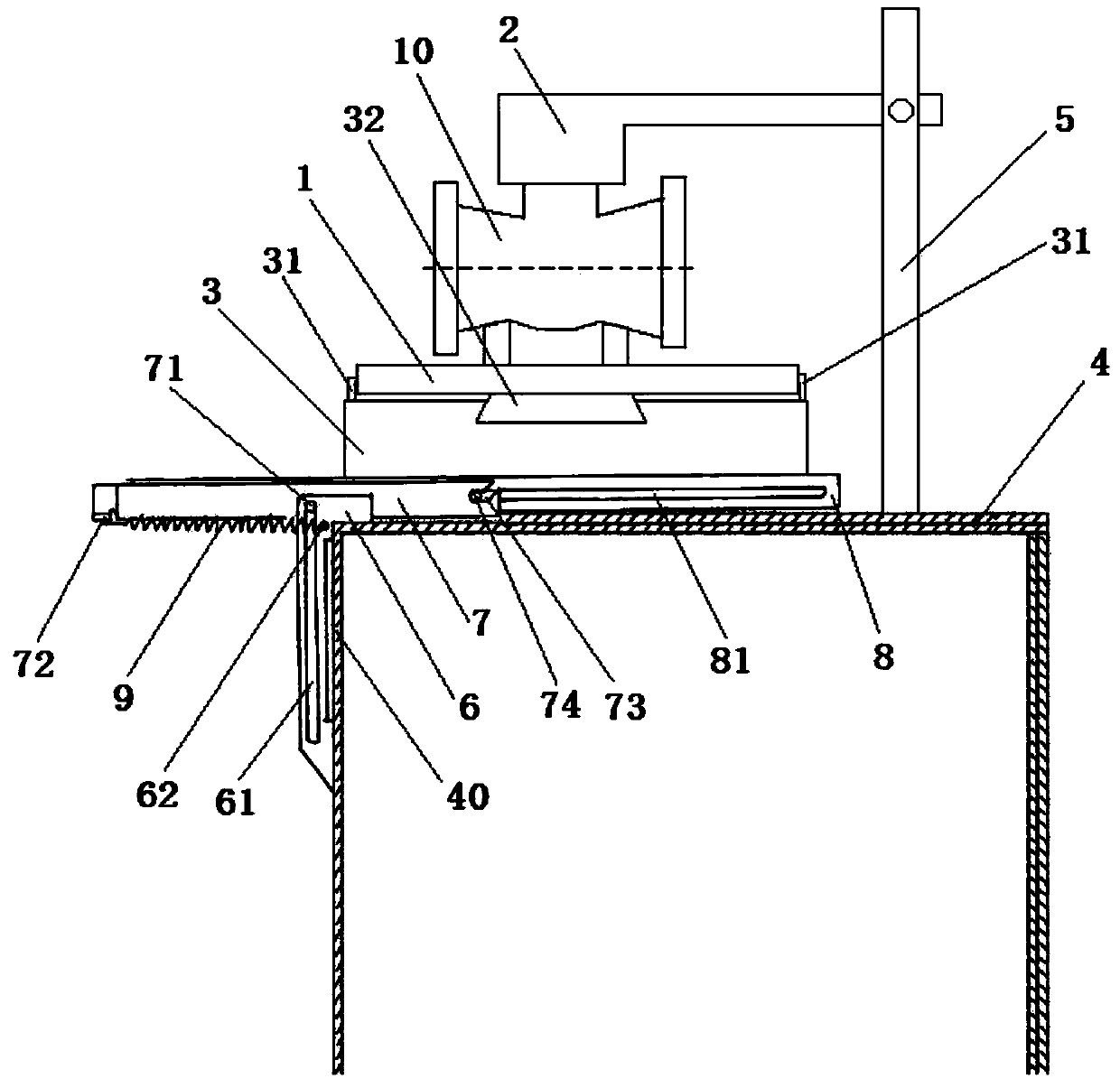

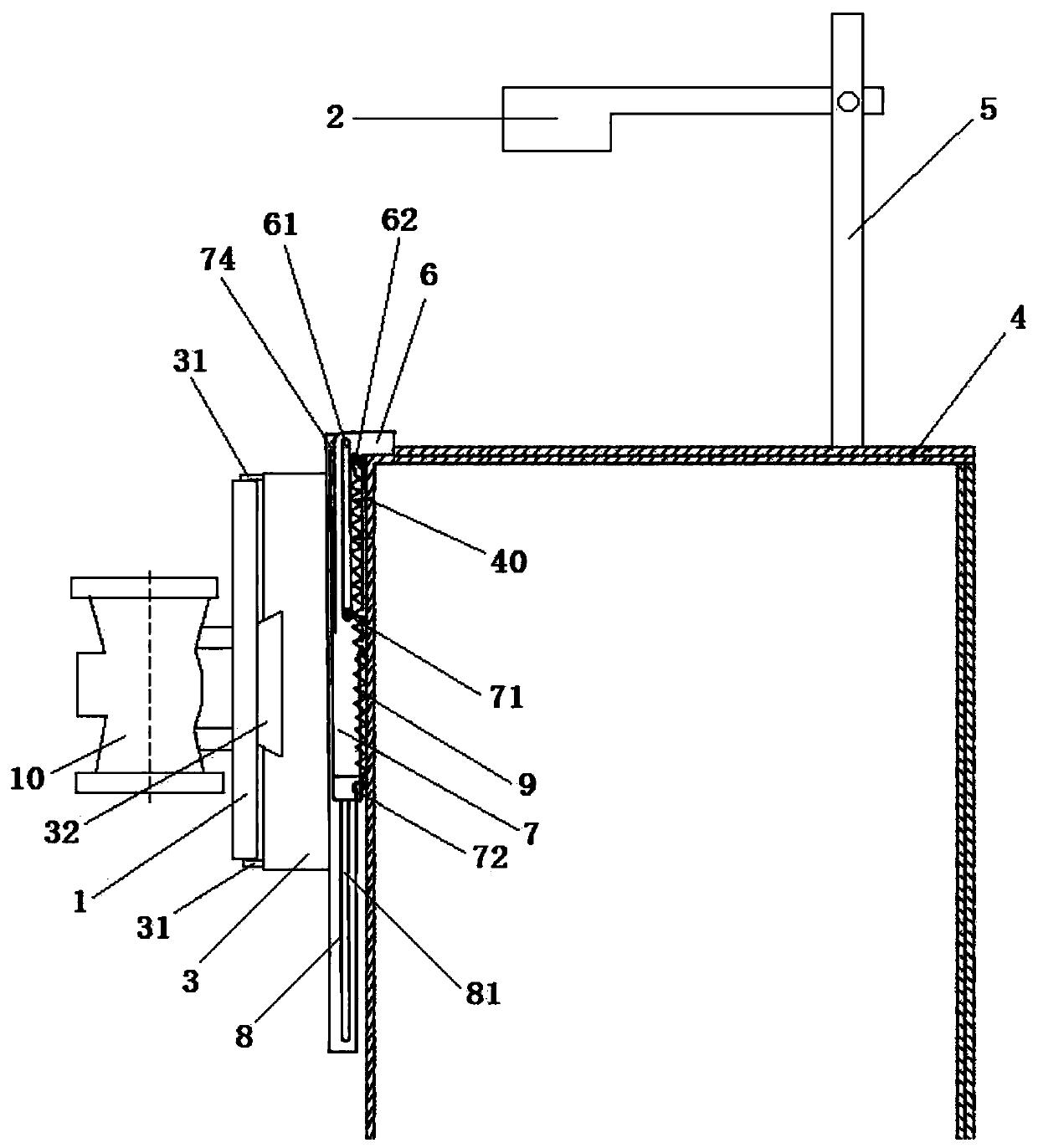

[0024] Such as figure 1 and figure 2 As shown, a tooling fixture for processing the gate valve body includes a rotating tray 1 for fixing the base of the valve body 10 and a cover plate 2 for pressing down and giving the flange clamping force in the valve body 10; the rotating The tray 1 is arranged on a chassis 3, and the chassis 3 is arranged on a fixed platform 4 with a right angle, and the chassis 3 is provided with a locking pin 31 for fixing the rotating tray 1; The column 5 of the cover plate 2, the cover plate 2 is detachably connected with the column 5. The rotary tray 1 is arranged on the chassis 3 through the turntable 32, the upper end surface of the turntable 32 is fixed with the rotary tray 1, and the lower end surface of the turntable 32 falls into the turntable groove on the chassis 3, and the size of the turntable groove is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com