Rotary clamping block caterpillar track for wooden tenon automatic processing machine

A technology for automatic processing and clamping of blocks, used in wood processing appliances, manufacturing tools, mitering working devices, etc., can solve problems such as hidden safety hazards and low efficiency, and achieve simple and compact structure, stable clamping effect, and processing accuracy. Reliable results with consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

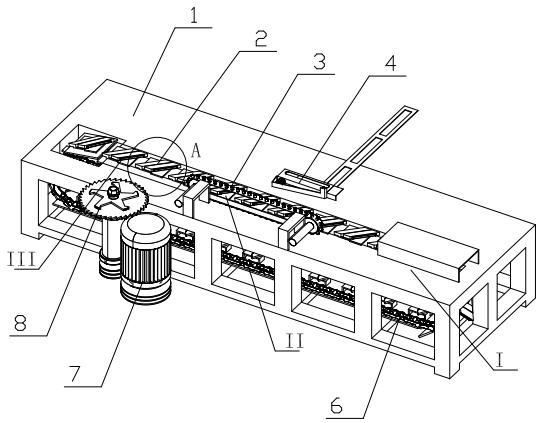

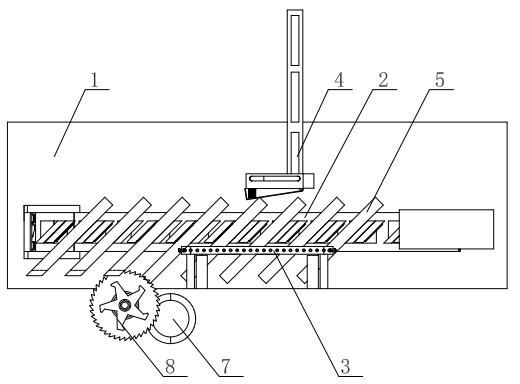

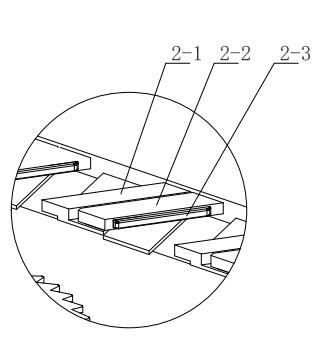

[0016] Such as figure 1 As shown, the frame 1 of the wood tenon automatic processing machine is provided with a motor 7 and a saw blade 8 driven by it, and various saw blades 8 can be flexibly selected and combined according to the type of tenon cut out; There is the rotary clamping block track 2 described in the present invention, and the two sides of the rotary clamping block track 2 are provided with chains 6, which are driven by a drive motor and a reducer to rotate between the inside of the frame 1 and the top hole. In the middle of the top surface of the frame 1, located on both sides of the rotary clamping block track 2, there are respectively provided with a vertical pressing belt 3 and a pushing elastic frame 4, wherein the vertical pressing belt 3 is arranged on a side close to the saw blade 8 side, and the push elastic frame 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com