Steel ball pressing device and crankshaft production equipment

A steel ball pressing and press-fitting technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor process consistency, inconsistent steel ball pressing depth, inconsistent crankshaft micro-deformation, etc., to avoid The effect of low machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

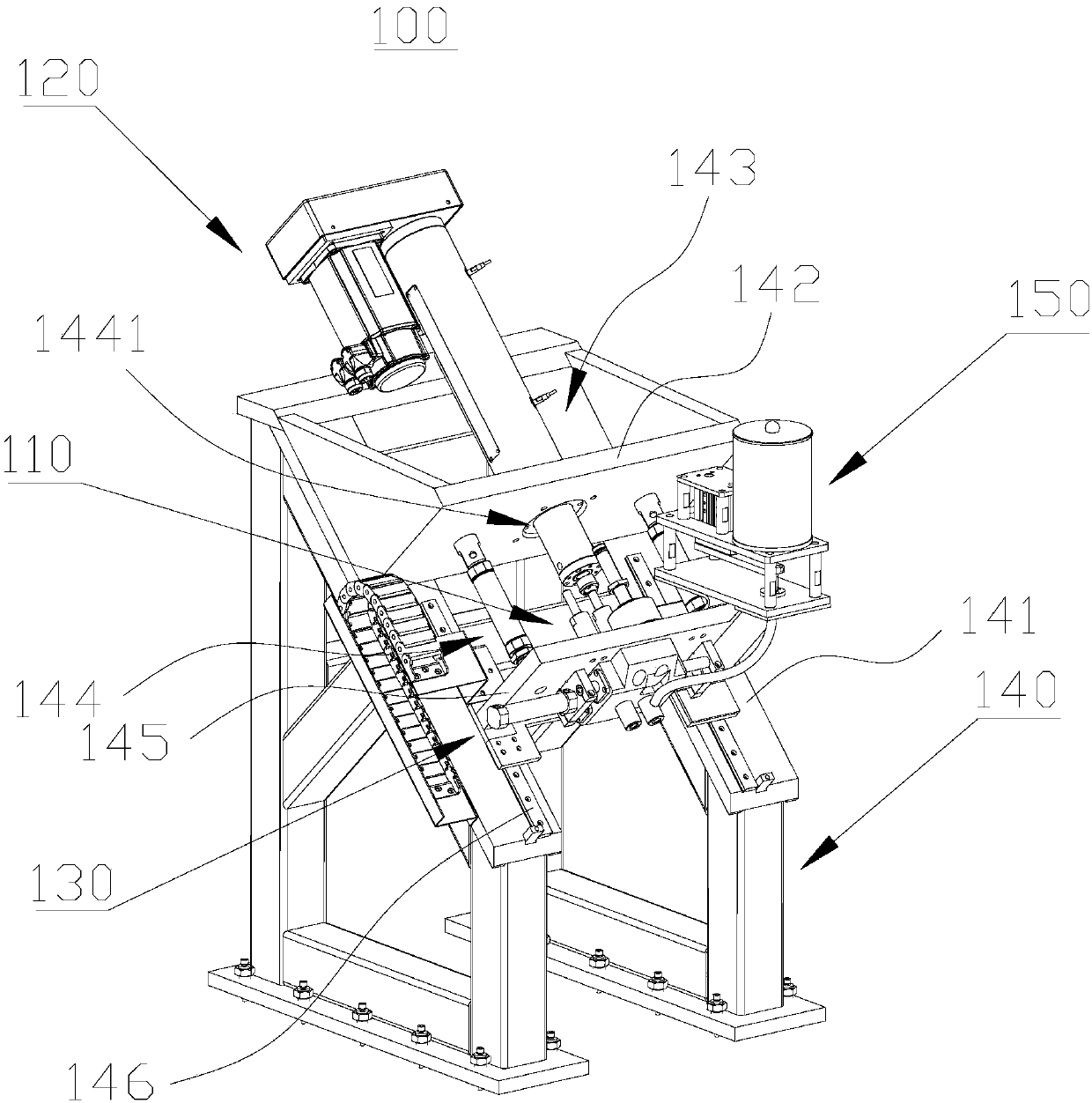

[0037] This embodiment provides a steel ball pressing device 100, refer to figure 1 As shown, it includes a ram assembly 110 , a power unit 120 , a conversion mechanism 130 and a frame 140 .

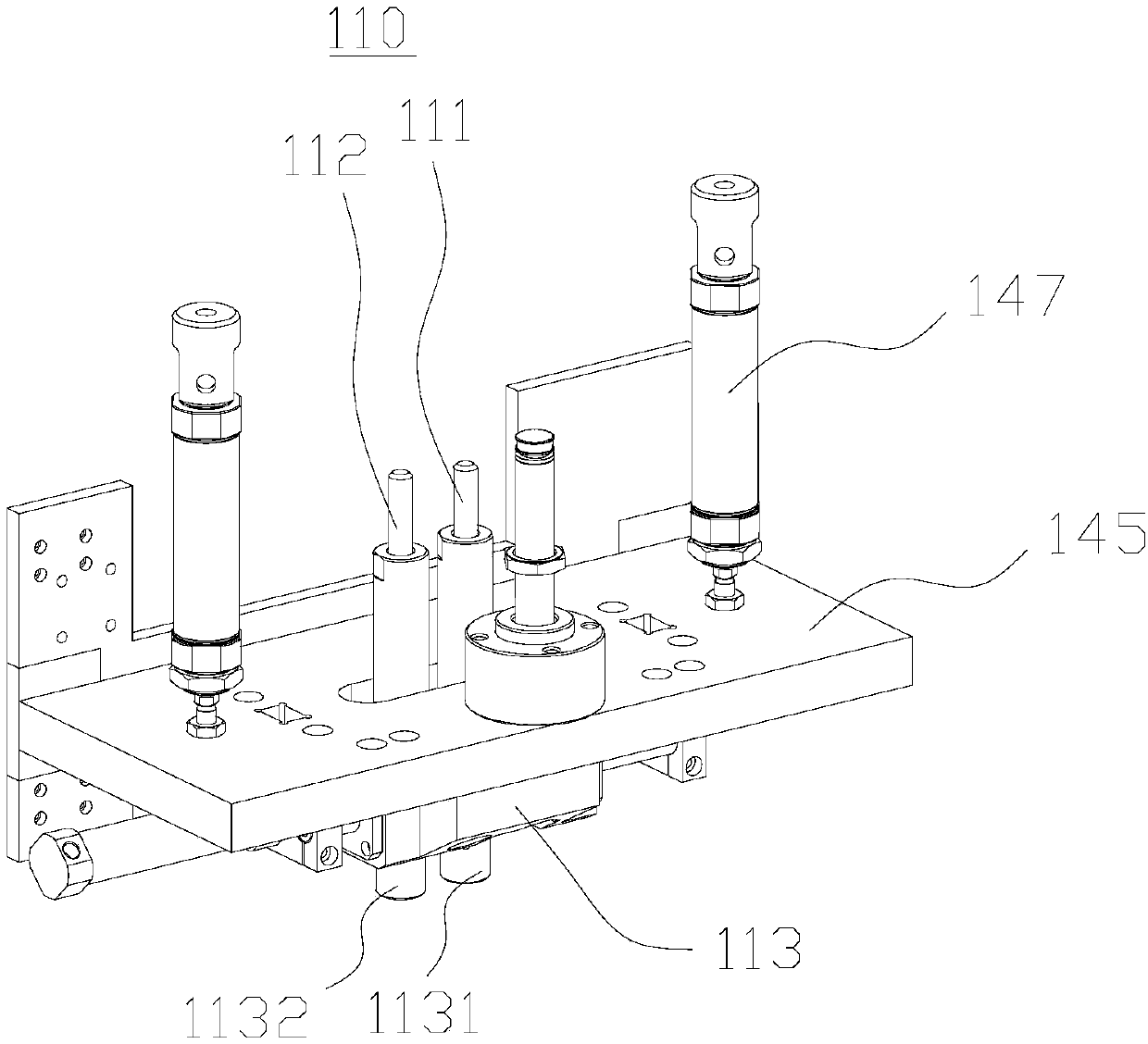

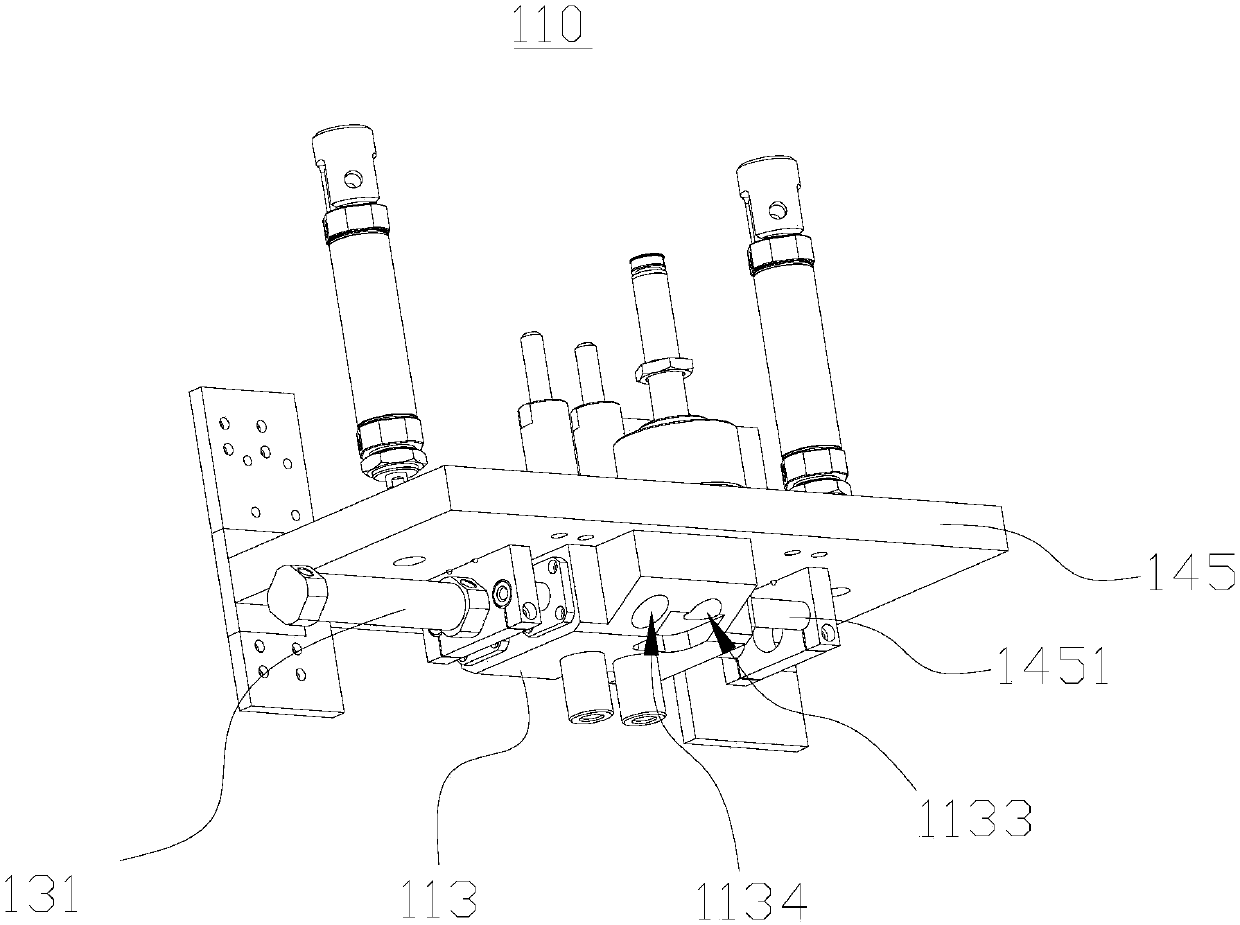

[0038] Among them, such as figure 2 As shown in and 3 , the press head assembly 110 includes a press rod 111 , a riveting rod 112 and a base 113 . The base 113 is provided with a press-fit rod barrel 1131 for accommodating the press-fit rod 111 , the press-fit rod barrel 1131 is fixedly connected with the base 113 and penetrates through the base 113 . The press-fit rod 1131 is formed with a first accommodating cavity 1131a that runs through both ends of the press-fit rod 1131, and the press-fit rod 111 is movably embedded in the first accommodating cavity 1131a, and can move along the axial direction of the press-fit rod 1131. slide. In this embodiment, the press rod 111 has a first force-receiving end 1111 for contacting the power device 120 , and a first force-applying end 1112 for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com